Halogen-free flame retardant conductive elastomer used for electromagnetic shielding of data cable and preparation method of halogen-free flame retardant conductive elastomer

An electromagnetic shielding and data line technology, applied in the fields of halogen-free flame retardant conductive elastomer and its preparation, polymer materials and its preparation, can solve the problem that the polymer conductive electromagnetic shielding layer of the data line cannot be applied, the toughness of the thermoplastic elastomer is lost, and the Elasticity, inability to meet data cable requirements, etc., to achieve the effect of increasing bonding force, improving tensile properties, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

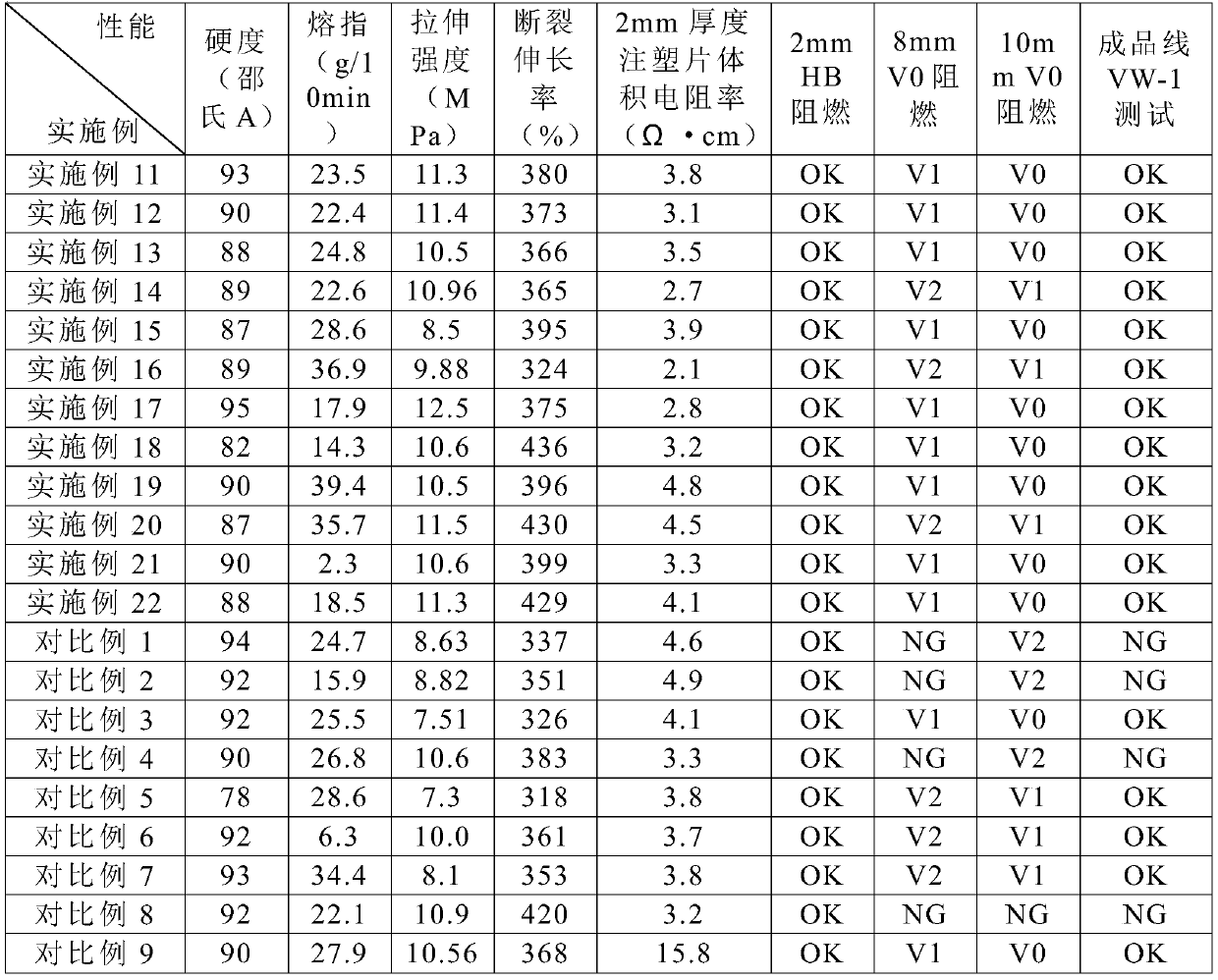

[0053] The components and mass percentages of the halogen-free flame-retardant conductive elastomer used for electromagnetic shielding of data lines in Examples 1-10 are shown in Table 1 below.

[0054] Table 1: Components and mass percentages of halogen-free flame-retardant conductive elastomers in Examples 1-10

[0055]

[0056] In Table 1, the content of acrylate in the ethylene butyl acrylate copolymer is 18%; SEBS is a non-oil-extended SEBS; the melt flow rate of MLLDPE is 33g / 10min, and the flow rate test conditions are 230°C temperature and 2.16kg load; The flow rate of the melt viscosity modifier is 13000g / 10min, and the flow rate test conditions are 190°C temperature and 2.16kg load; the model of the halogen-free flame retardant is Japan Otsuka Chemical SPB100.

Embodiment 11

[0058] The preparation method of the halogen-free flame-retardant conductive elastomer used for electromagnetic shielding of data lines in this embodiment includes the following steps:

[0059] (1) Prepare various raw materials according to the mass percentage of the halogen-free flame-retardant conductive elastomer component in Example 1;

[0060] (2) All raw materials are fed according to the pre-set gravity automatic metering program, ethylene acrylate copolymer, MLLDPE, SEBS, melt viscosity modifier high flow ethylene-octene polymer, halogen-free flame retardant SPB100 and processing aid (lubricant, dispersant, antioxidant) join in the high-speed mixer and mix 4min, join in the twin-screw extruder main feeding hopper after mixing, conductive additive (conductive carbon black, graphene ) mixed uniformly and then added to the side feeding hopper of the twin-screw extruder for extrusion and granulation to obtain the halogen-free flame-retardant conductive elastomer.

[0061]...

Embodiment 12

[0064] The preparation method of the halogen-free flame-retardant conductive elastomer used for electromagnetic shielding of data lines in this embodiment includes the following steps:

[0065] (1) Prepare various raw materials according to the mass percentage of the halogen-free flame-retardant conductive elastomer component in Example 1;

[0066] (2) All raw materials are fed according to the pre-set gravity automatic metering program, ethylene acrylate copolymer, MLLDPE, SEBS, melt viscosity modifier high flow ethylene-octene polymer, halogen-free flame retardant SPB100 and processing aid (lubricant, dispersant, antioxidant) join in the high-speed mixer and mix 3min, join in the twin-screw extruder main feeding hopper after mixing evenly, conductive additive (conductive carbon black, graphene ) mixed uniformly and then added to the side feeding hopper of the twin-screw extruder for extrusion and granulation to obtain the halogen-free flame-retardant conductive elastomer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com