Alloy cast steel for high-speed train brake discs and high-speed train brake discs made of the alloy cast steel

An alloy cast steel, high-speed train technology, applied in the field of high-speed train brake discs, can solve the problems of high price, dependence on imports, and the crack resistance can not meet the braking requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of specific embodiments. However, those skilled in the art will appreciate that the detailed description herein with reference to the accompanying drawings is for illustrative purposes only, and the present invention is not limited thereto.

[0069] Table 1 The chemical composition range (weight percent content %) of alloy cast steel of the present invention

[0070]

[0071] The components of the alloy cast steel of the present invention and the weight percentage ranges of each component are shown in Table 1.

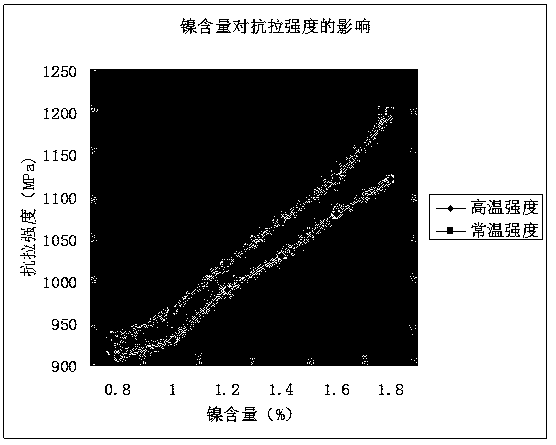

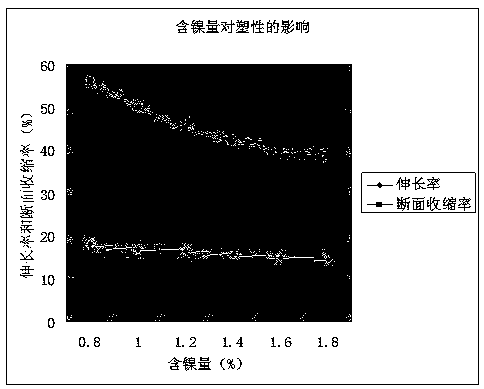

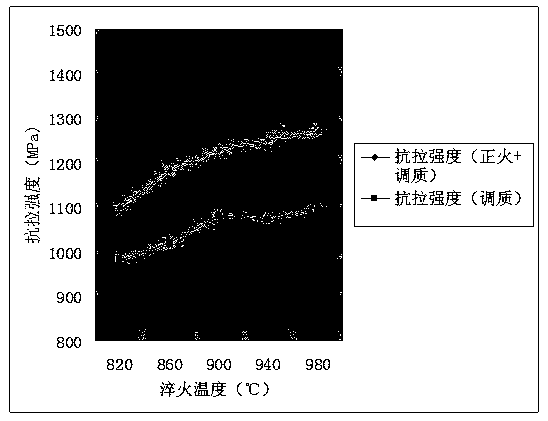

[0072] The specific technical solution is: an alloy cast steel for high-speed train brake discs, its components and the weight percentages of each component are as follows: carbon 0.18-0.26%, silicon 0.16-0.50%; manganese 0.55-1.40% %; phosphorus less than or equal to 0.03%; sulfur less than or equal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com