Steel grating mounting technology for offshore booster station

An offshore booster station and installation process technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as weakened bearing capacity, poor welding alignment accuracy, and unbalanced force on angle steel, so as to increase the bearing capacity. Force area, ensure connection stability, reduce deformation and crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

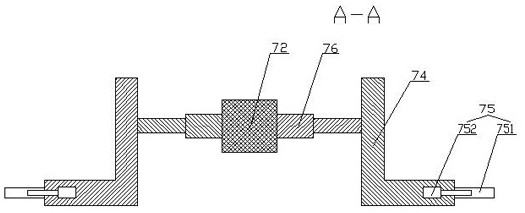

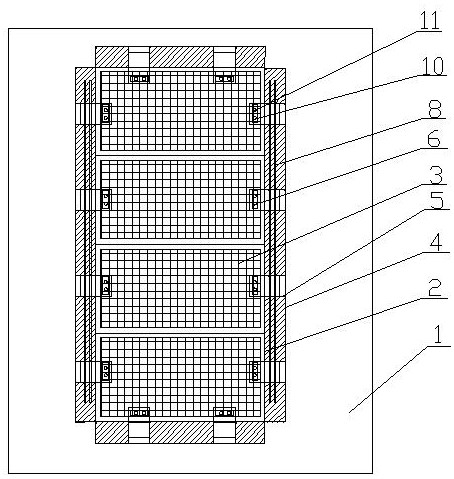

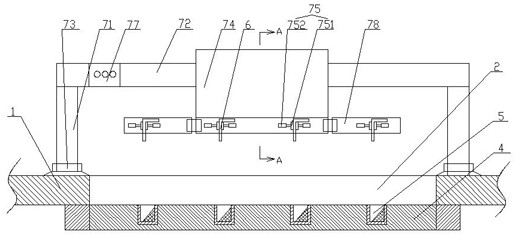

[0037] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0038] This embodiment is a steel grid installation process for offshore booster stations, such as figure 1 As shown, the platform 1 of the offshore step-up station has a rectangular through hole 2, and a plurality of evenly distributed steel grids 3 are arranged in the through hole 2. The specific steps include:

[0039] S1, such as figure 2 As shown, a plurality of rib blocks 4 are spot-welded along the extension direction of the through hole 2 inside the through hole 2, and a plurality of rib blocks 4 are placed around the through hole 2, and the end faces of the rib blocks 4 are in contact with the through hole. The inner wall of 2 is flush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com