A kind of pultrusion pre-embedded blade root connector for wind power generator blade and preparation method thereof

A wind turbine, blade root connection technology, applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., can solve the problems of blade quality risks, the problem of layup folds becoming more and more prominent, and the impact of blade root strength being greater. , to reduce the pouring and curing time, the quality is continuous, stable and reliable, and the bolt installation time is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

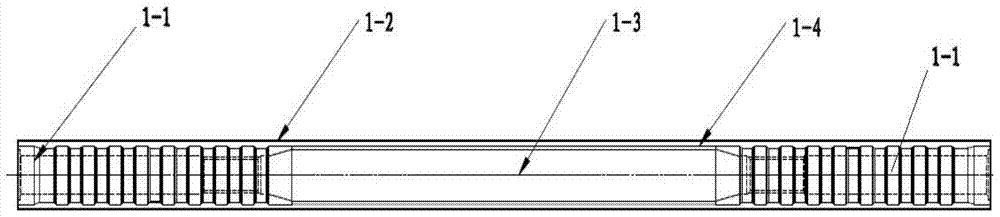

[0040] Such as figure 1 As shown, a pultrusion pre-embedded blade root connector for wind turbine blades, which includes a blade root connector (1-1), a lightweight connector (1-1) connected to the blade root connector (1-1) 4), the lightweight material (1-3) filled in the lightweight connector (1-4), the pultrusion wrapped around the blade root connector (1-1) and the outer periphery of the lightweight connector (1-4) Composites section (1-2).

[0041] The blade root connector (1-1) is an internally threaded casing, an externally threaded bolt, an embedded expansion screw or a wedge-shaped clamp connection structure, and its material can be high-strength metal, composite material, engineering plastic or inorganic non-woven fabric. One or more of the metals.

[0042] The pultruded pre-embedded blade root connector for the blade of the wind power generator, the shape of the blade root connector (1-1) is circular, rectangular, square, elliptical, trapezoidal or triangular.

...

Embodiment 2

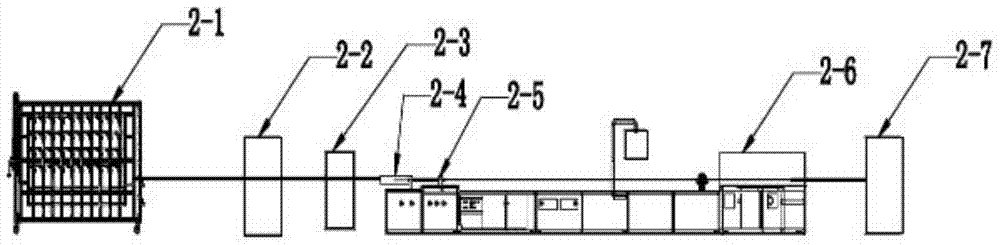

[0047] Such as figure 2 Shown, a kind of preparation method of pultrusion pre-embedded blade root connector for wind power generator blade comprises the following steps:

[0048] Step 1: Assembly of accessories

[0049] e. Treat the surface of the blade root connector (1-1);

[0050]f. Fill the lightweight material (1-3) into the lightweight connector (1-4)

[0051] g. Assemble and connect the blade root connector (1-1) with the lightweight connector (1-4);

[0052] h. Seal the end joints of the assembled blade root connector (1-1) and the lightweight connector (1-4), preferably straightening;

[0053] Step 2: Embedded composite pultrusion

[0054] a. First measure the tension of each fiber on the creel (2-1) to ensure that the tension of each fiber is respectively the same, and then dehumidify the fiber through dehumidification equipment to obtain dry fiber;

[0055] b. Adjust the position between the curing mold (2-5) and the preforming tooling (2-4) to ensure the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com