Patents

Literature

108results about How to "Shorten laying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

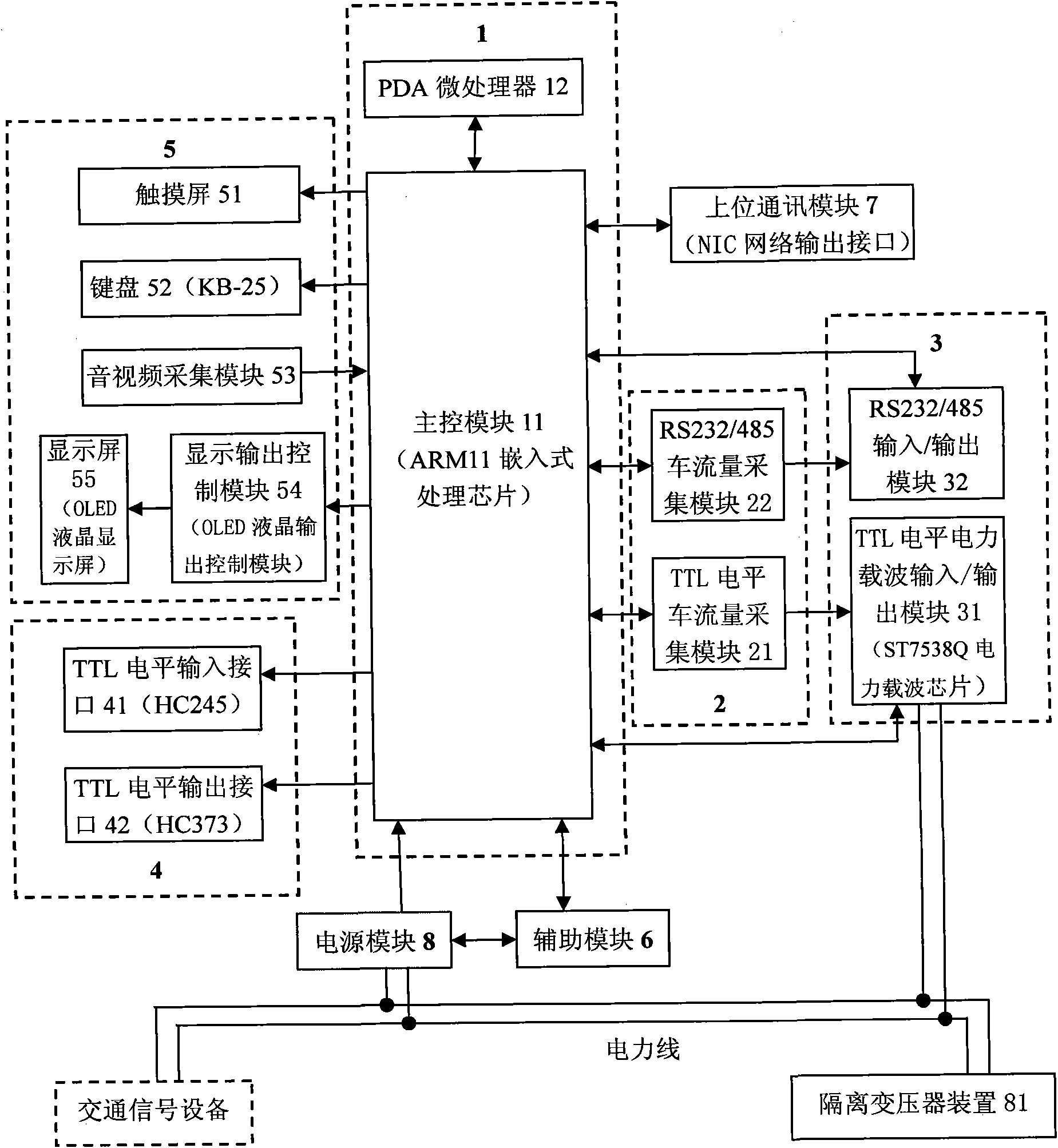

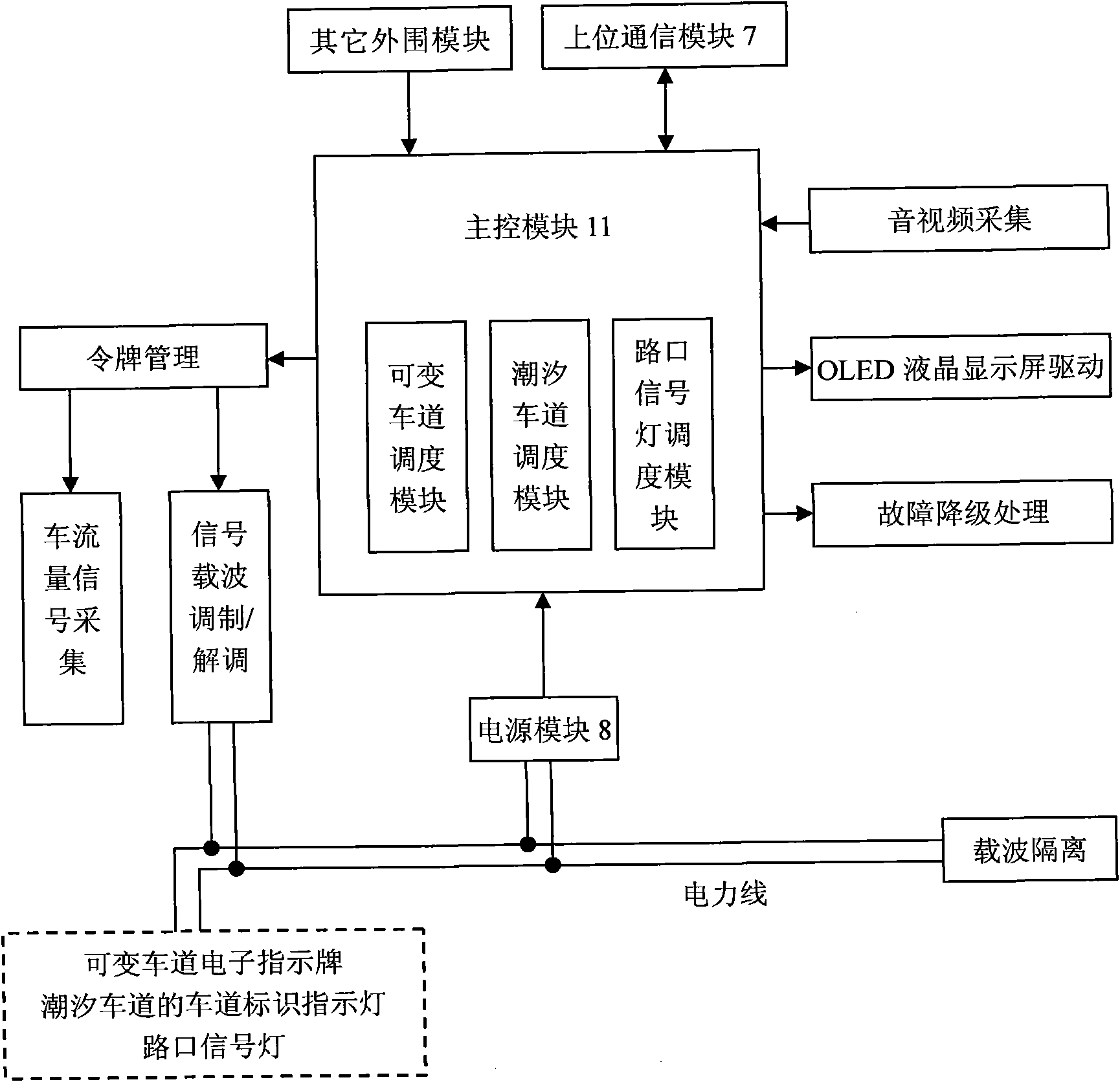

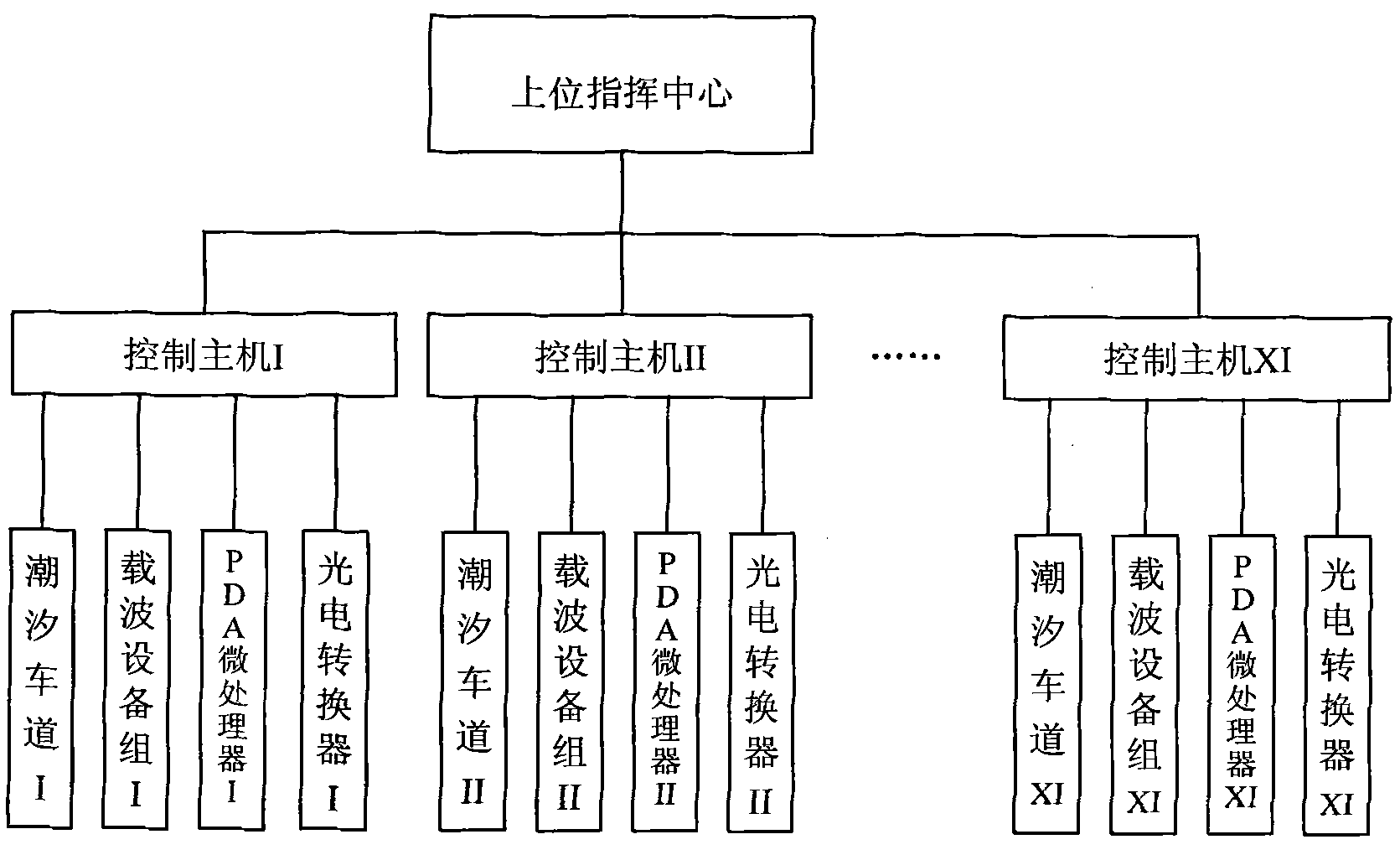

Traffic signal controller and traffic signal control method

ActiveCN101840638AReasonable structureSimple structureControlling traffic signalsTraffic signalCarrier signal

The invention relates to a traffic signal controller and a control method. The traffic signal controller comprises a control main machine, a traffic volume acquisition module, a signal input / output module and an IO output module, wherein the control main machine comprises a main control module adopting an ARM11 embedded processing chip and a PDA microprocessor; the traffic volume acquisition module adopts a TTL electric level and a serial traffic volume acquisition module; and the signal input / output module comprises an electric carrier and a serial signal input / output module. The control method adopts a token communication system, a variable lane, tide lane and traffic signal light scheduling module is arranged in the main control module, and a traffic signal equipment set comprises a variable lane electronic directional signboard, a tide lane identifier indicator light and a traffic signal light and performs variable lane control, tide lane control and traffic signal light control. The controller and the control method overcome the drawbacks of the prior art and have the advantages of realizing variable lane sign automatic scheduling, supporting tide lane control, along with reasonable circuit design, convenient operation and use and the like.

Owner:杭州普乐科技有限公司

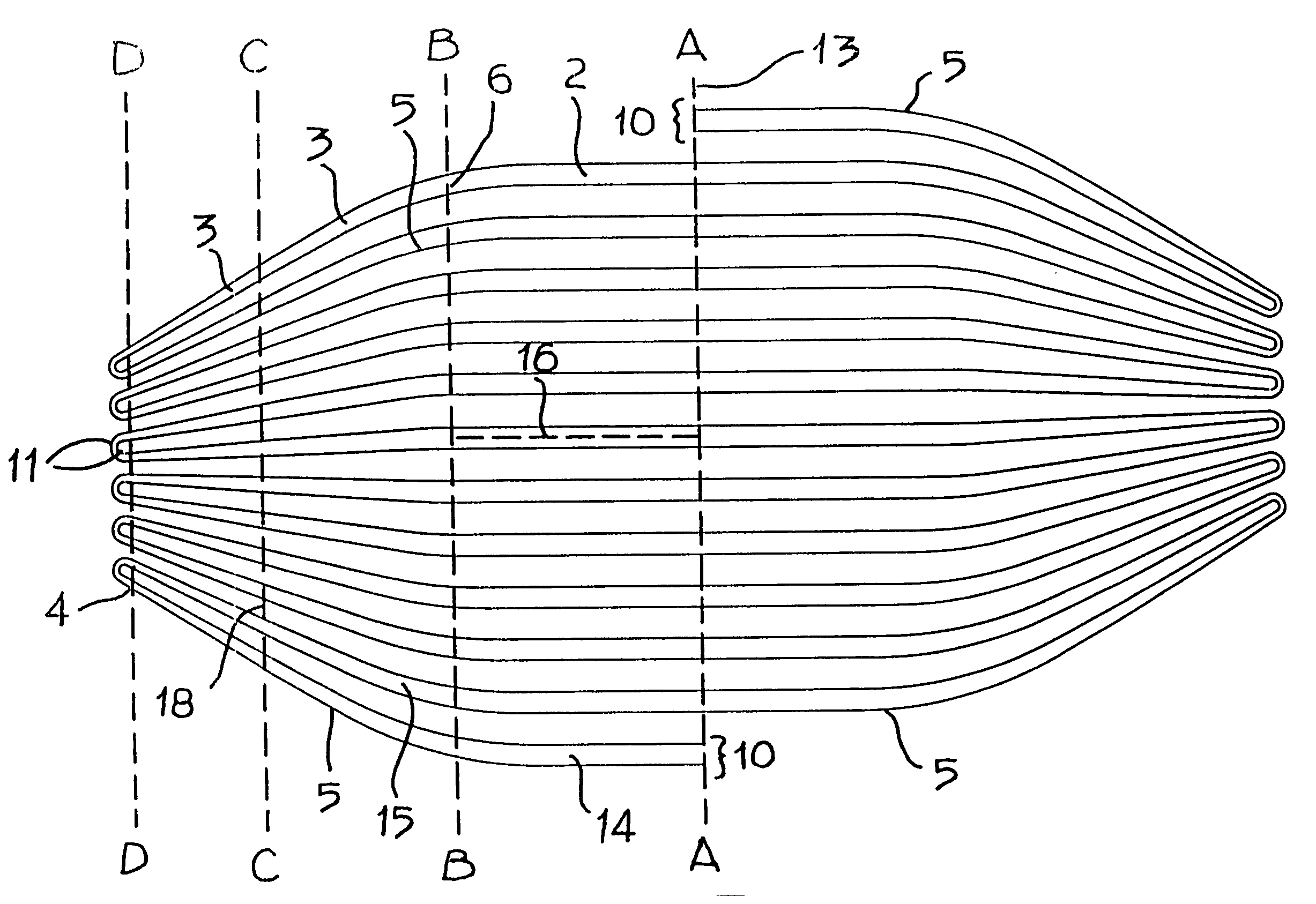

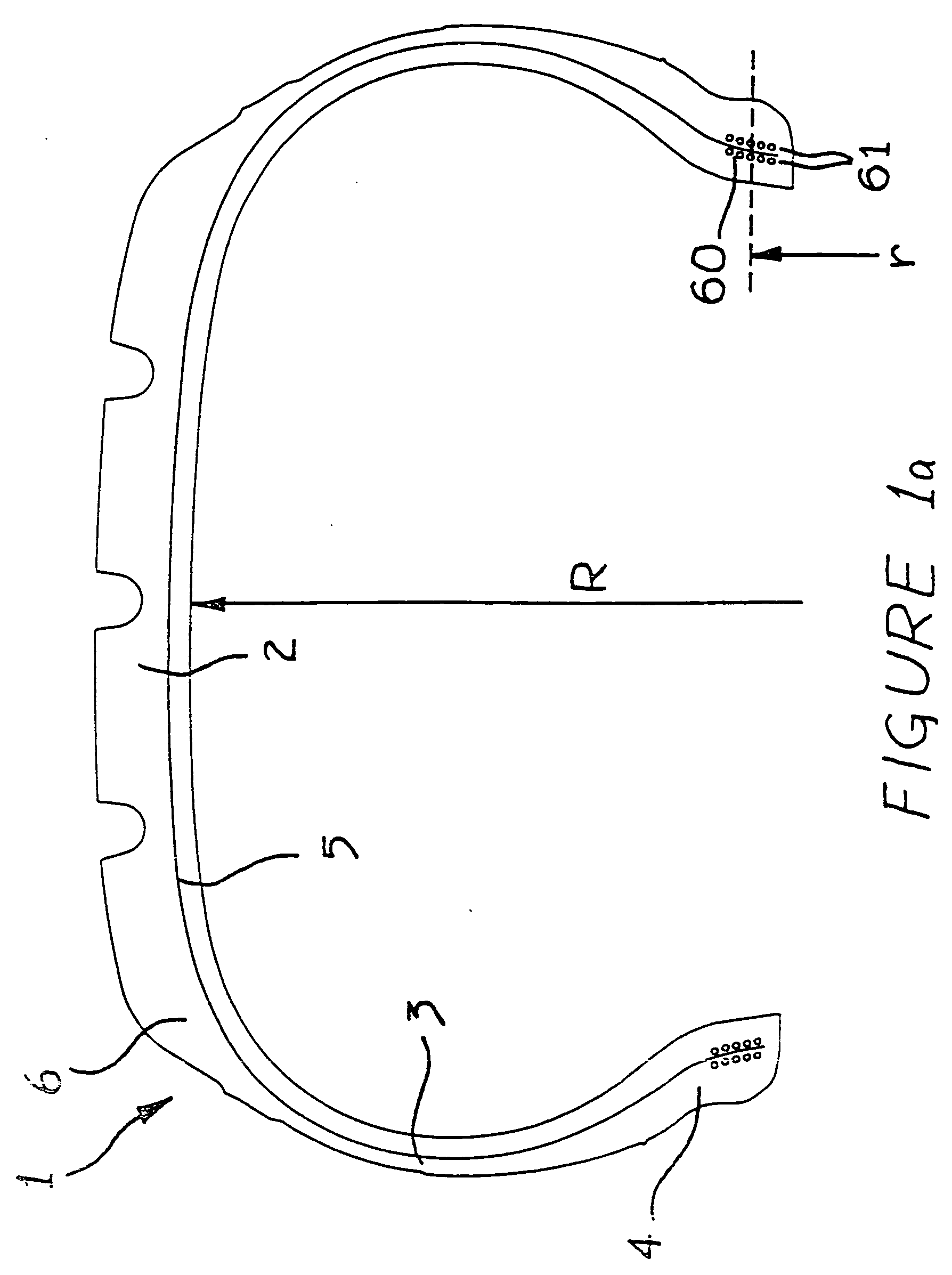

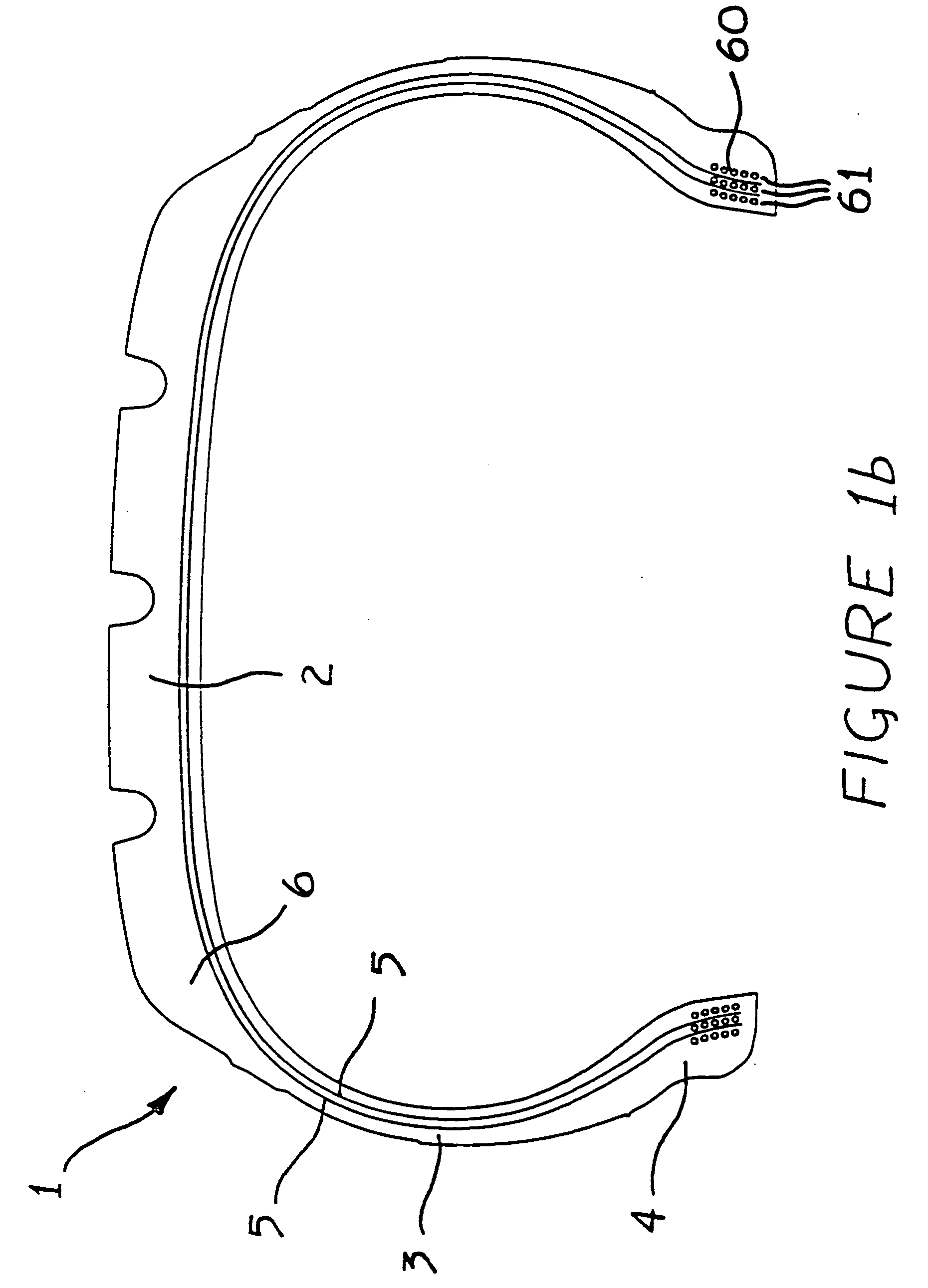

Tire with reinforcement structure forming internal and external loops

InactiveUS20050028915A1Convenient ArrangementShorten laying timeTyresSpecial tyresEngineeringInternal connection

Tire comprising at least one carcass-type reinforcement structure anchored on either side of the tire in a bead, the reinforcement structure comprising: a first and a second filament each forming on one hand a series of transverse portions extending substantially from one bead of the tire to the other, and on the other hand, U-shaped connections joining two successive transverse portions of said first and second filaments, the first and second filaments being arranged so that, for a given circumferential position of the tire, in a first bead, the first filament forms a radially outer connection, radially inside of which an internal connection formed by the second filament is arranged, and, in the second bead, the second filament forms a radially outer connection, radially inside of which an internal connection formed by the first filament is arranged.

Owner:MICHELIN RECH & TECH SA

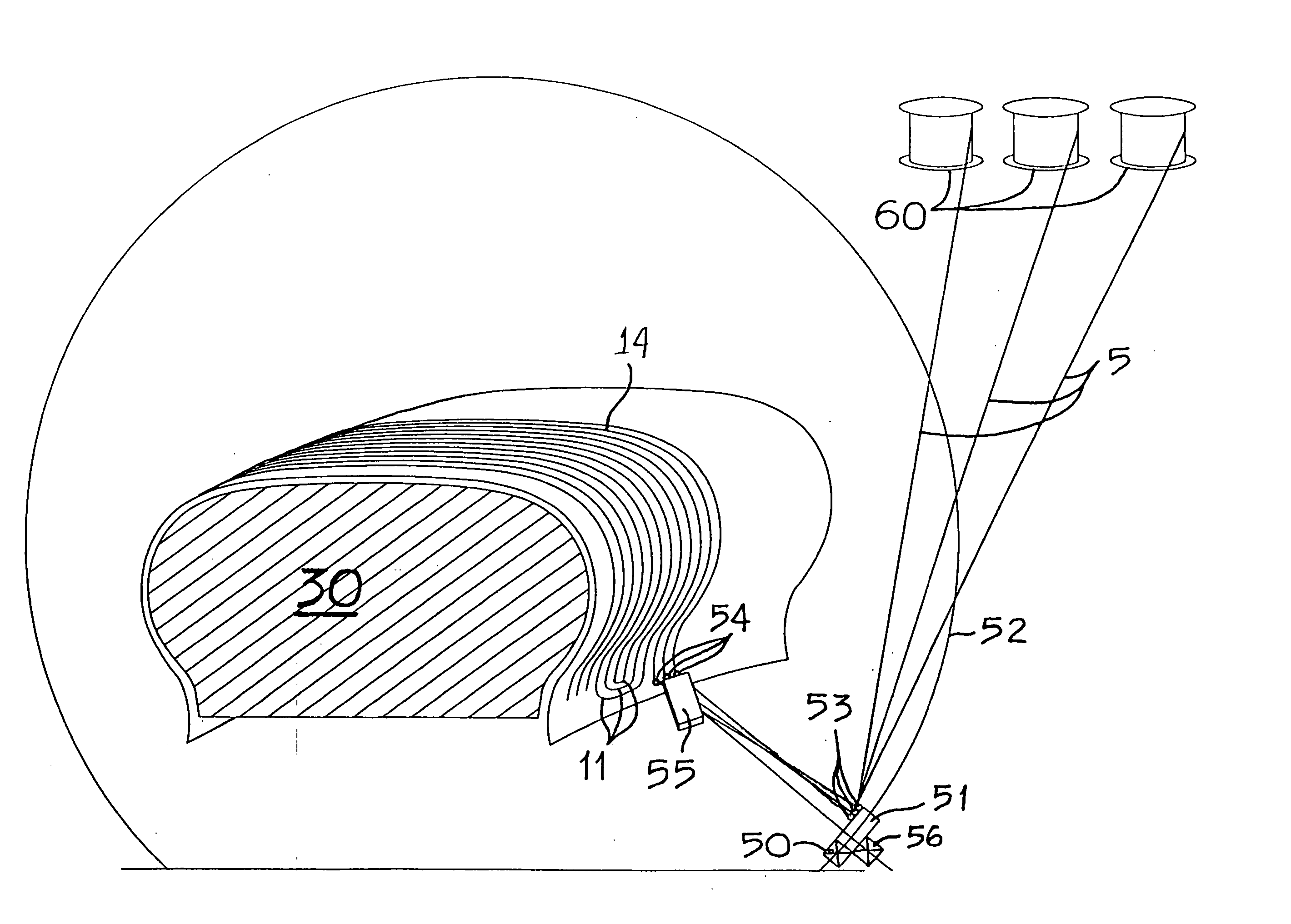

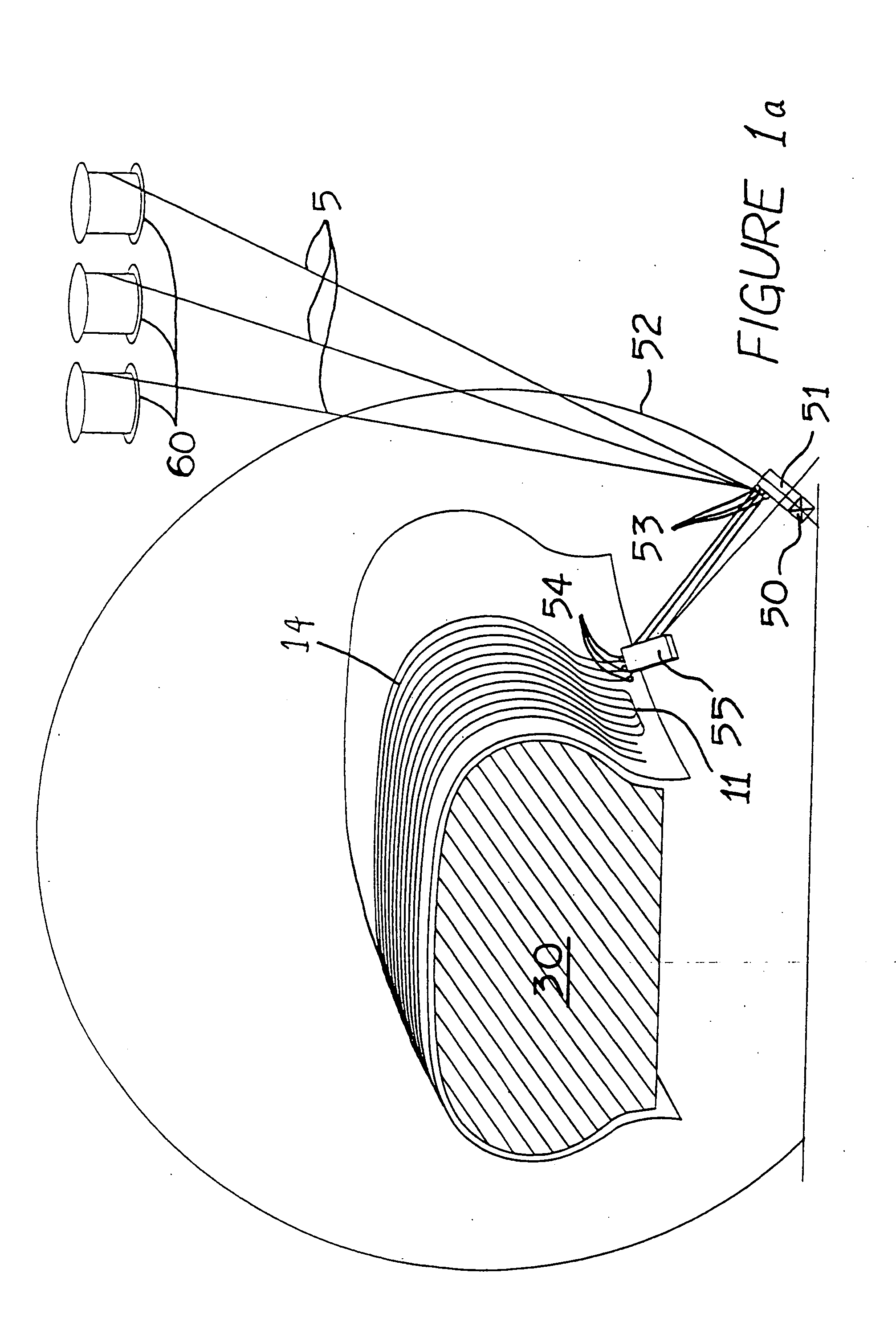

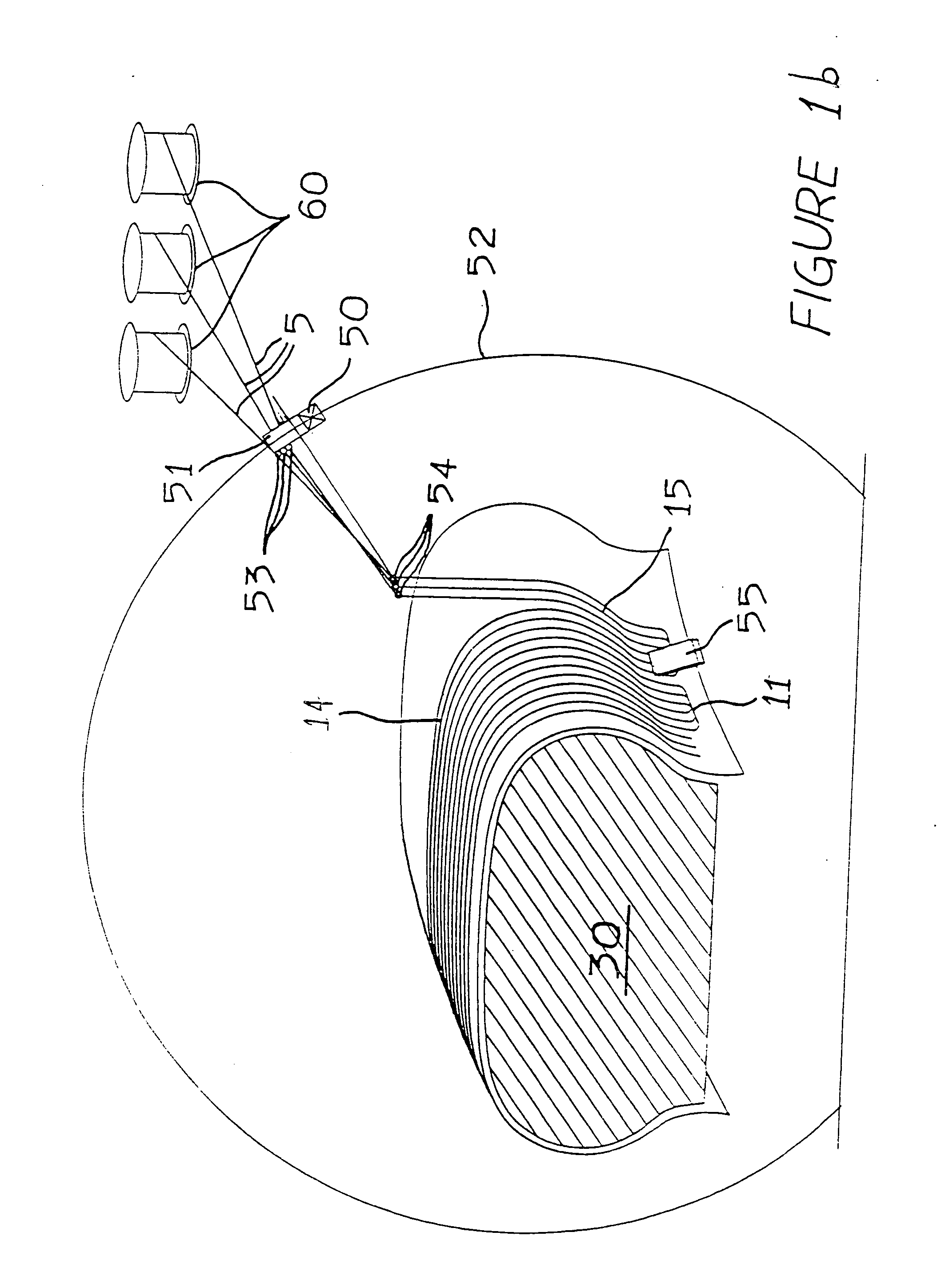

Method of laying cords of a reinforcement structure for tires

InactiveUS20050028919A1Reduce spacingLaying speed is fastTyresPneumatic tyre reinforcementsEngineeringHead parts

Owner:MICHELIN RECH & TECH SA

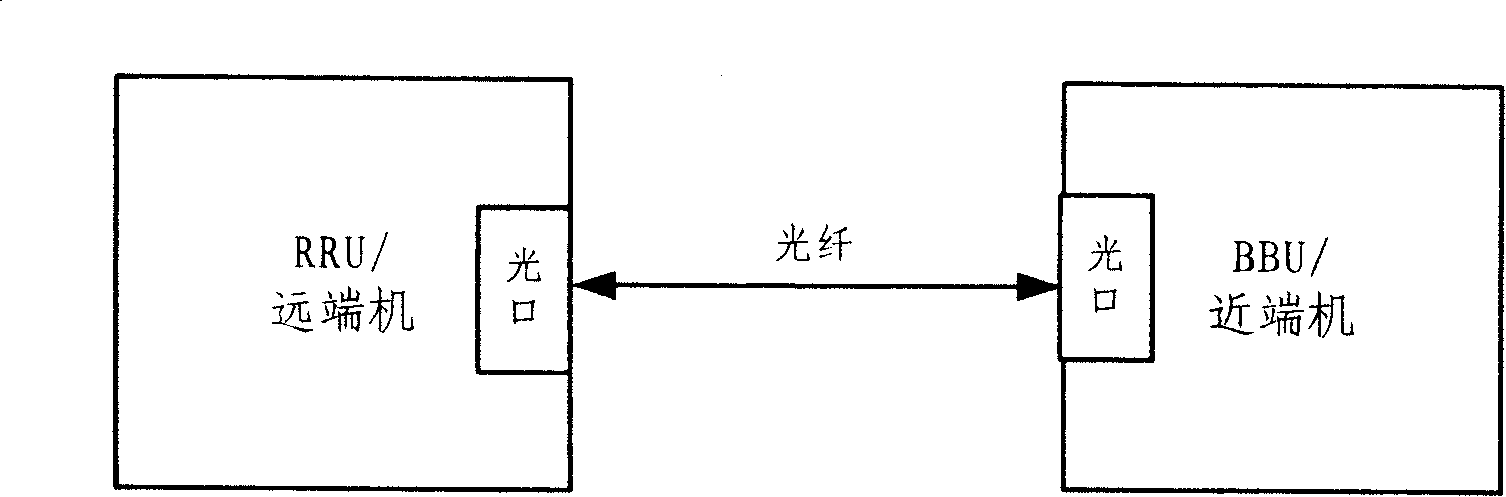

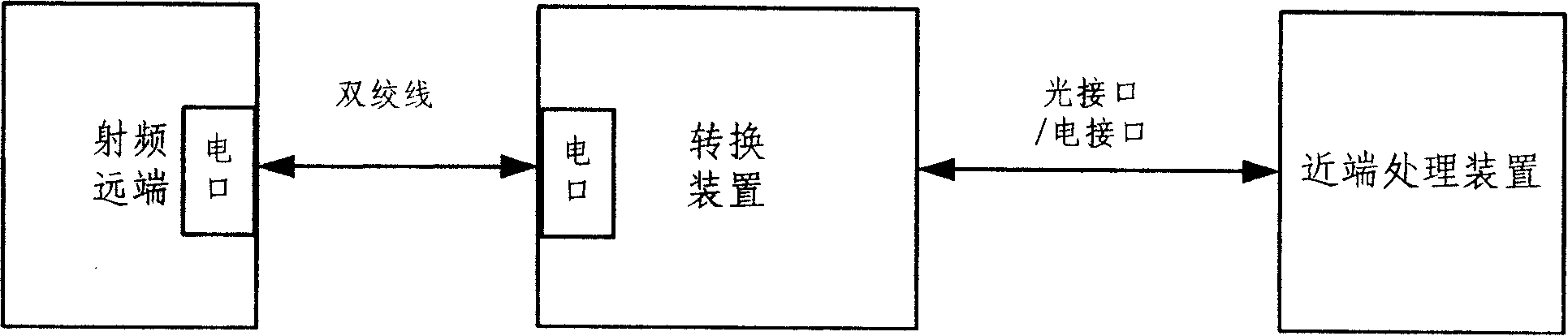

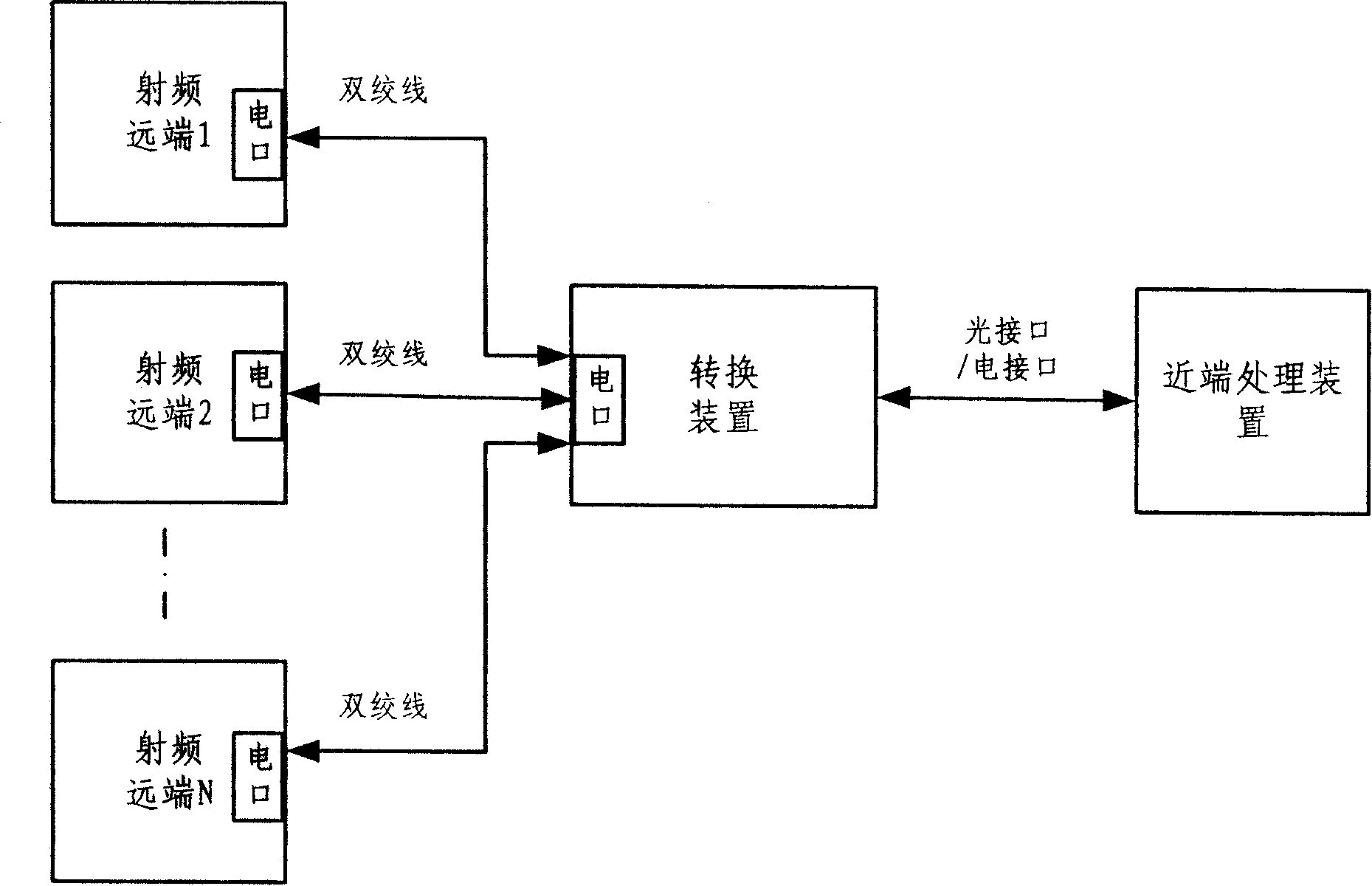

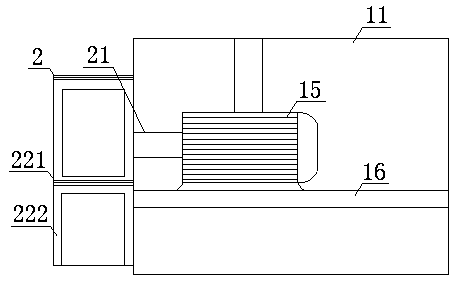

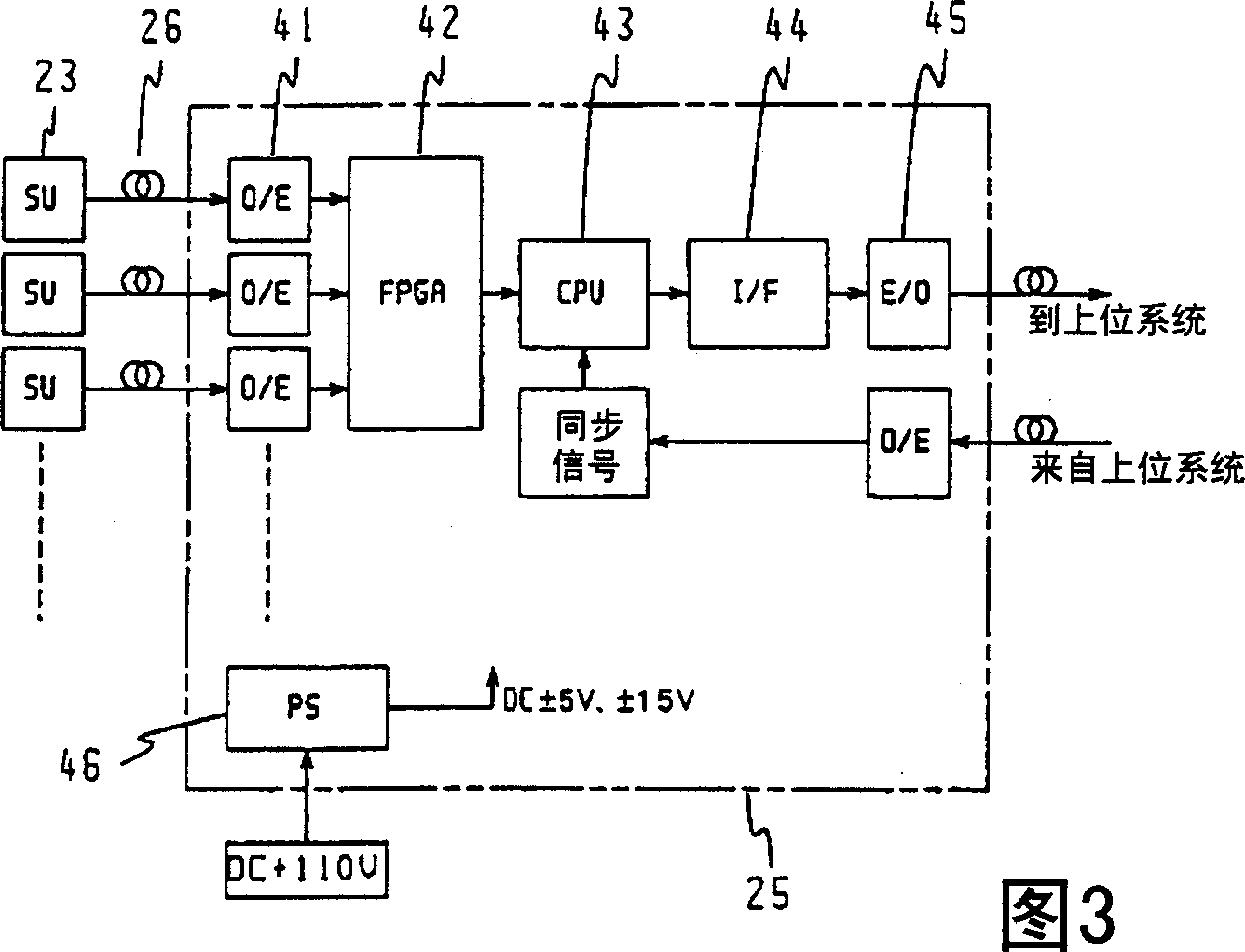

Radio-frequency far end distributed system in radio communication system

InactiveCN101166041AShorten laying timeShorten construction timeTransmission control/equlisationTransmission control/equalisingFiberLow speed

This invention discloses a RF remote distribution system in the radio communication system including: at least one RF remote device connected with a converting device, which is connected with a near end process device, and the RF remote device and the converting device are intercommunicated by ordinary twisted-pair lines at low speed electric signals, and the converting device is used in finishing conversion of RF remote devices and near process devices and placed at a gathered place of five kinds of twisted-pair lines of RF remote devices or a position owning gathered interfaces of fiber and the twisted-pair lines at the same time since large amount of the interfaces are set in a building and the RF remote devices are placed at needed positions by the interfaces.

Owner:ZTE CORP

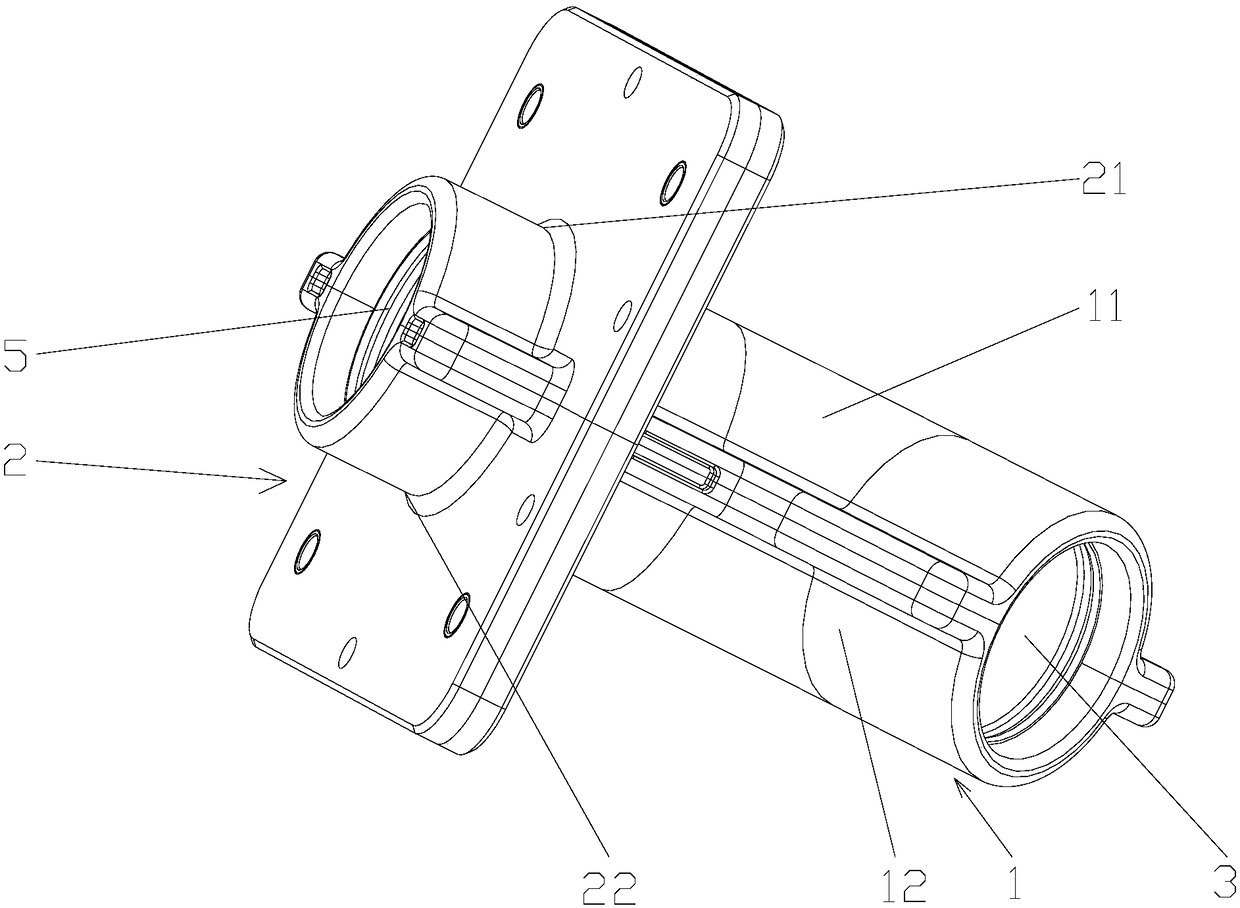

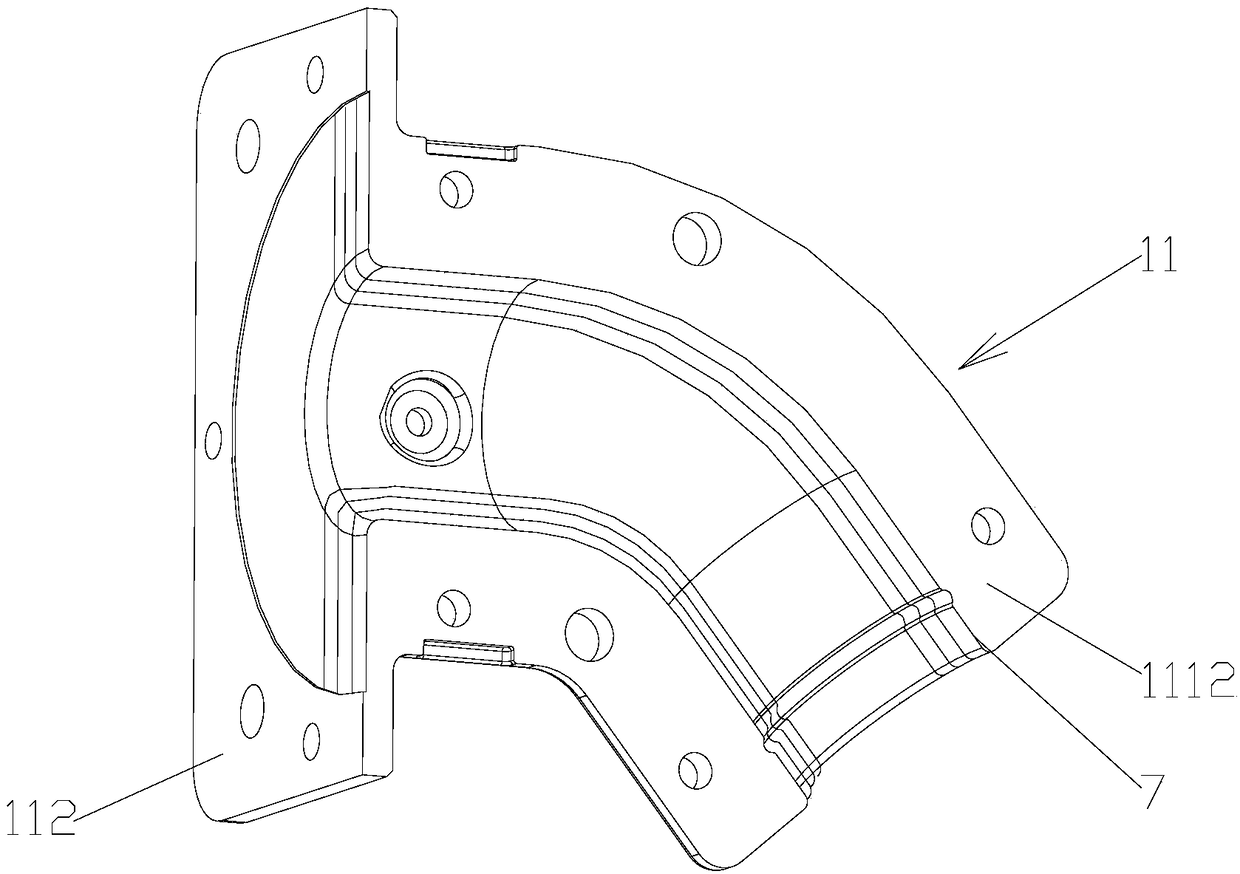

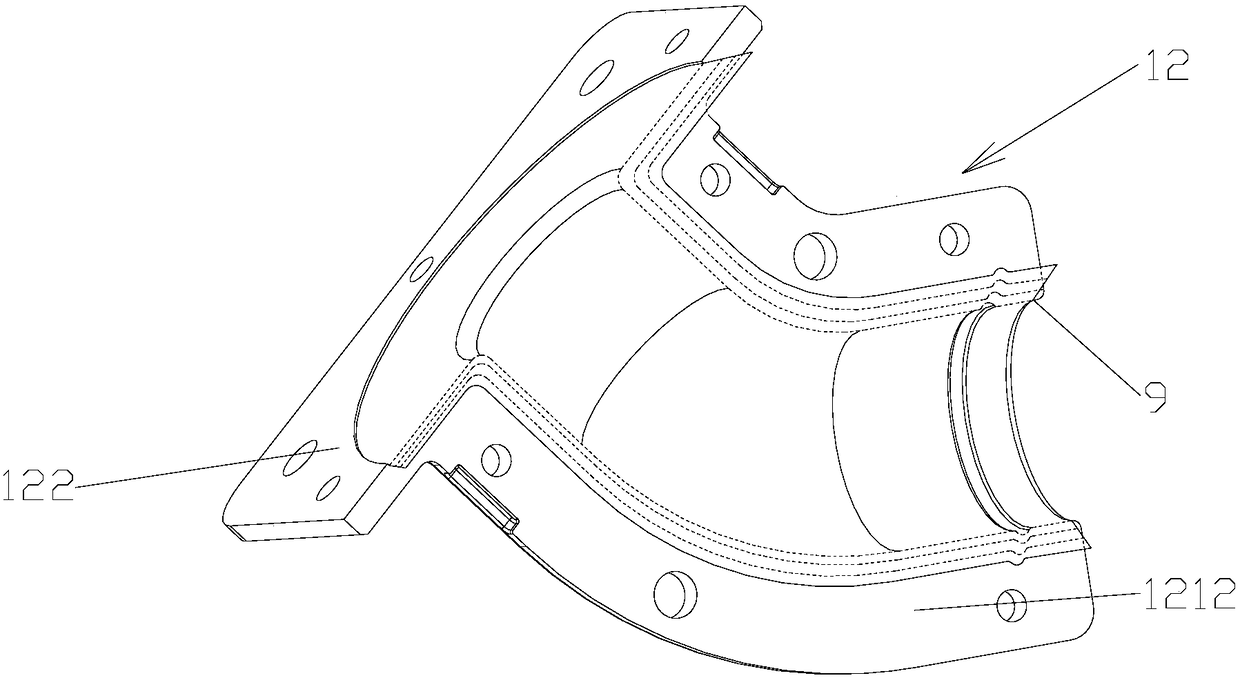

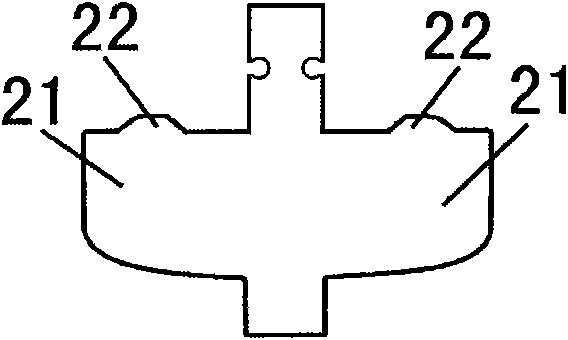

Forming mold and forming method for composite material tubular parts with flanges

InactiveCN108407323AEasy demoulding processLaying is simple and quickDomestic articlesPipeMold removal

The invention discloses a forming mold for composite material tubular parts with flanges. The forming mold for the composite material tubular parts with the flanges comprises a first combined mold anda second combined mold; the first combined mold is provided with a first pipe cavity and a first annular cavity; the first pipe cavity and the first annular cavity communicate with each other at theposition of a pipe port in one end of the first pipe cavity; the second combined mold is provided with a second pipe cavity and a second annular cavity; the second pipe cavity and the second annular cavity communicate with each other at the position of a pipe port in one end of the second pipe cavity; the first combined mold and the second combined mold are subjected to mold closing, and the firstannular cavity is made to communicate with the second annular cavity; and a forming method for using the forming mold to machine the composite material tubular parts with the flanges is disclosed. The forming mold has the beneficial effects that by performing combined design on the forming mold, in the forming process of the composite material tubular parts with the flanges, paving and pasting ofprepreg can be easier and faster, and operation is convenient; after curing molding of the tubular parts, demolding of the forming mold can be achieved easily, and operation is easy and convenient; and the production efficiency is improved, and practicability is high.

Owner:JIANGSU MEILONG AVIATION COMPONENTS

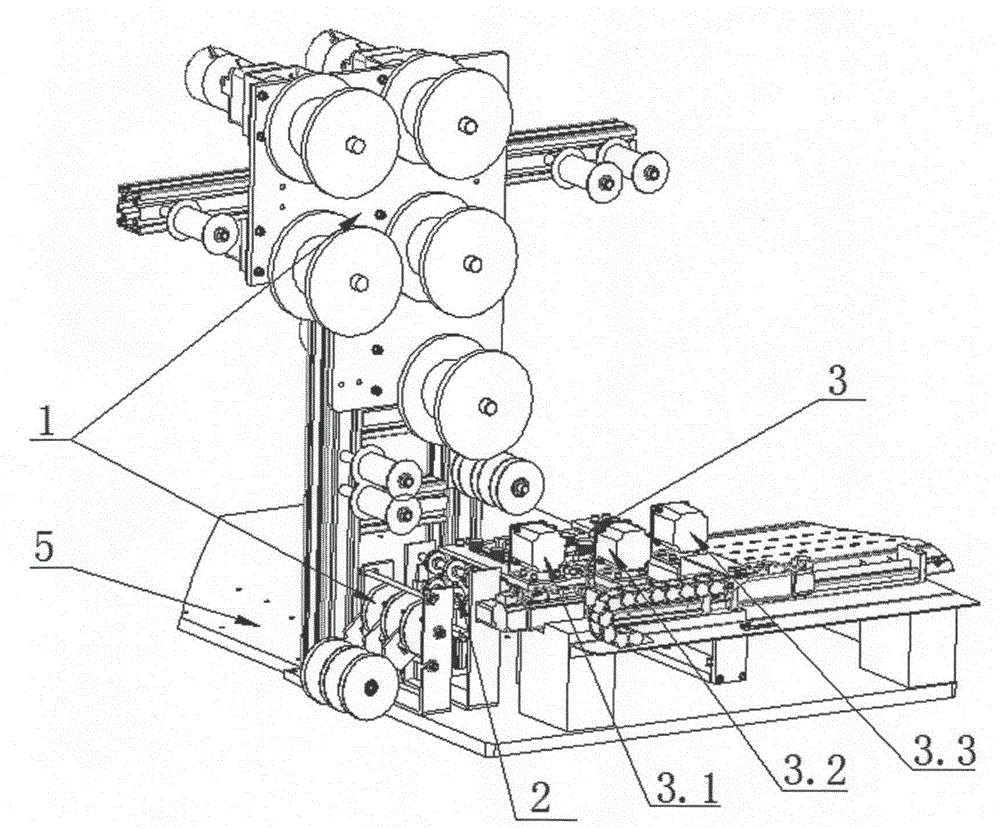

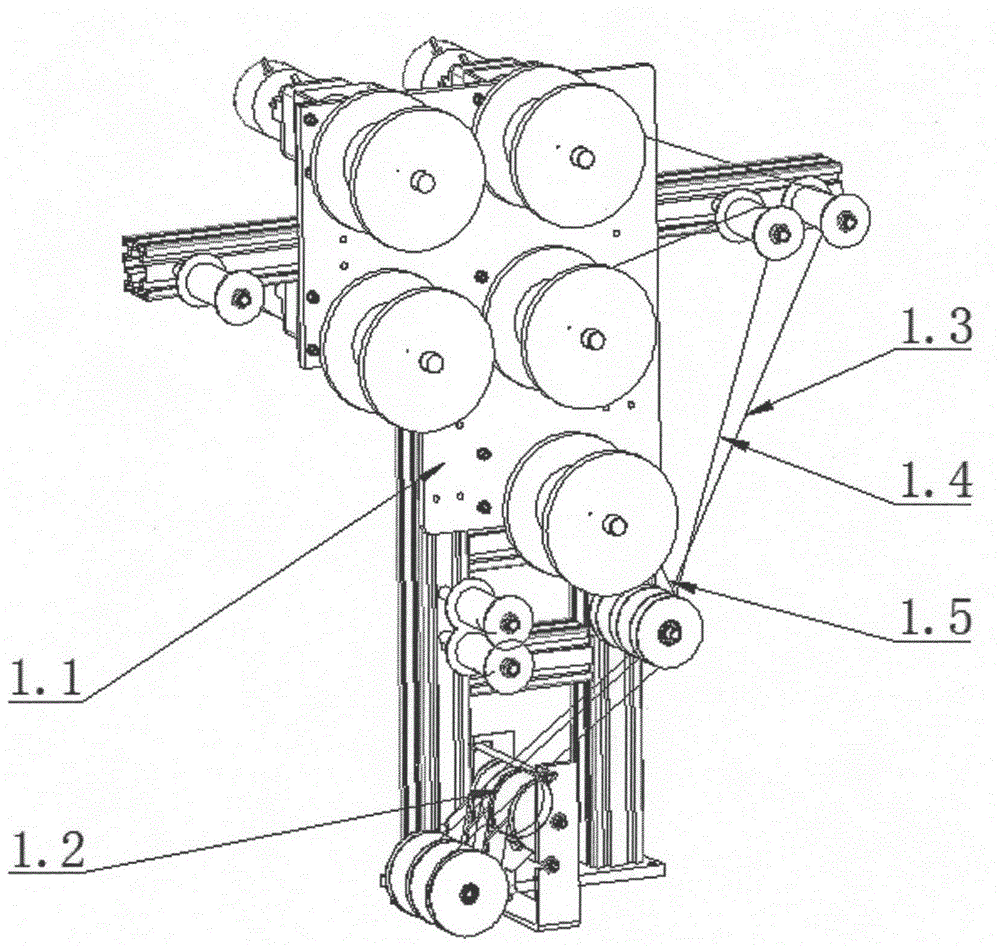

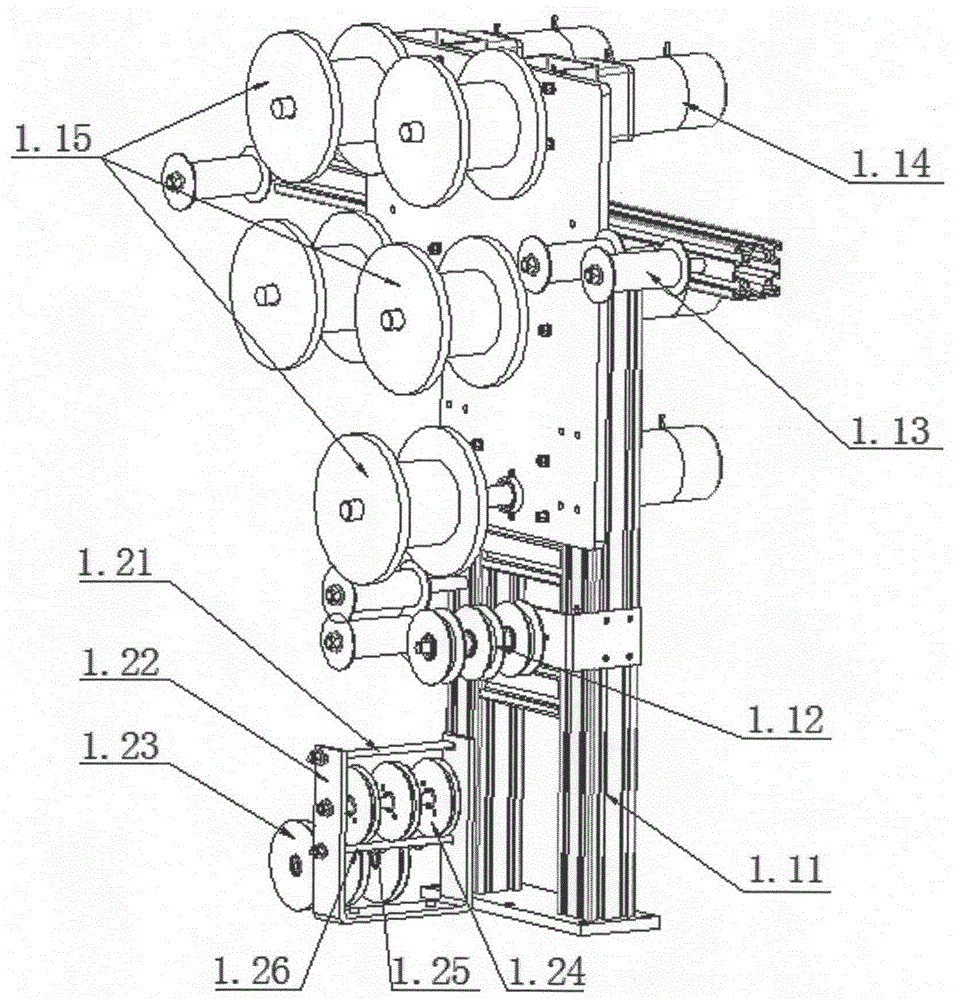

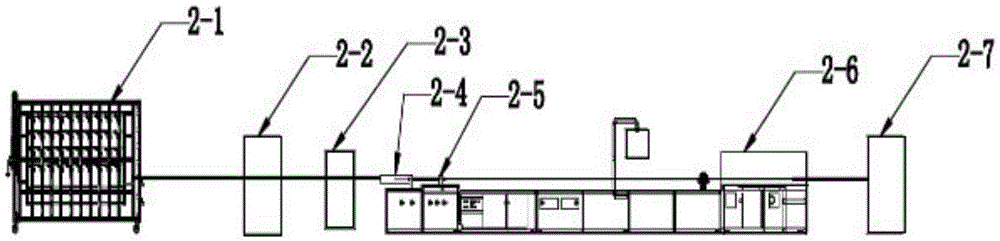

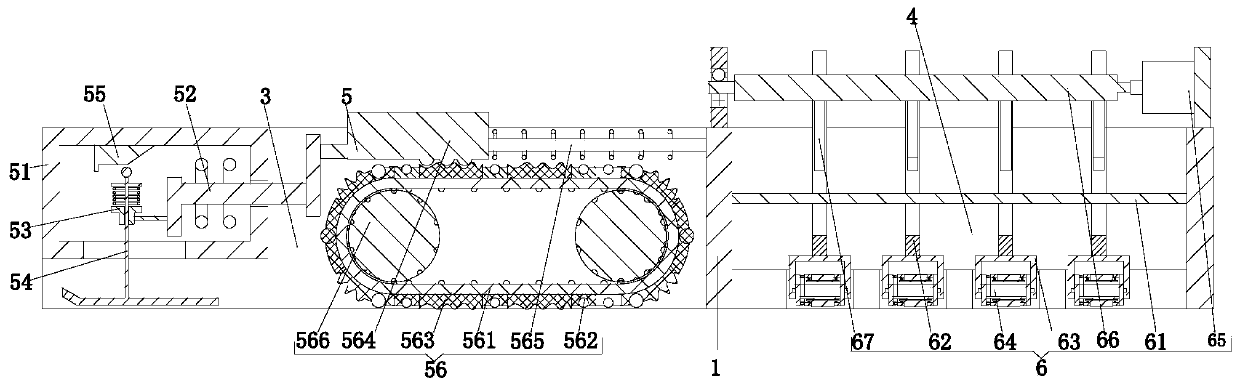

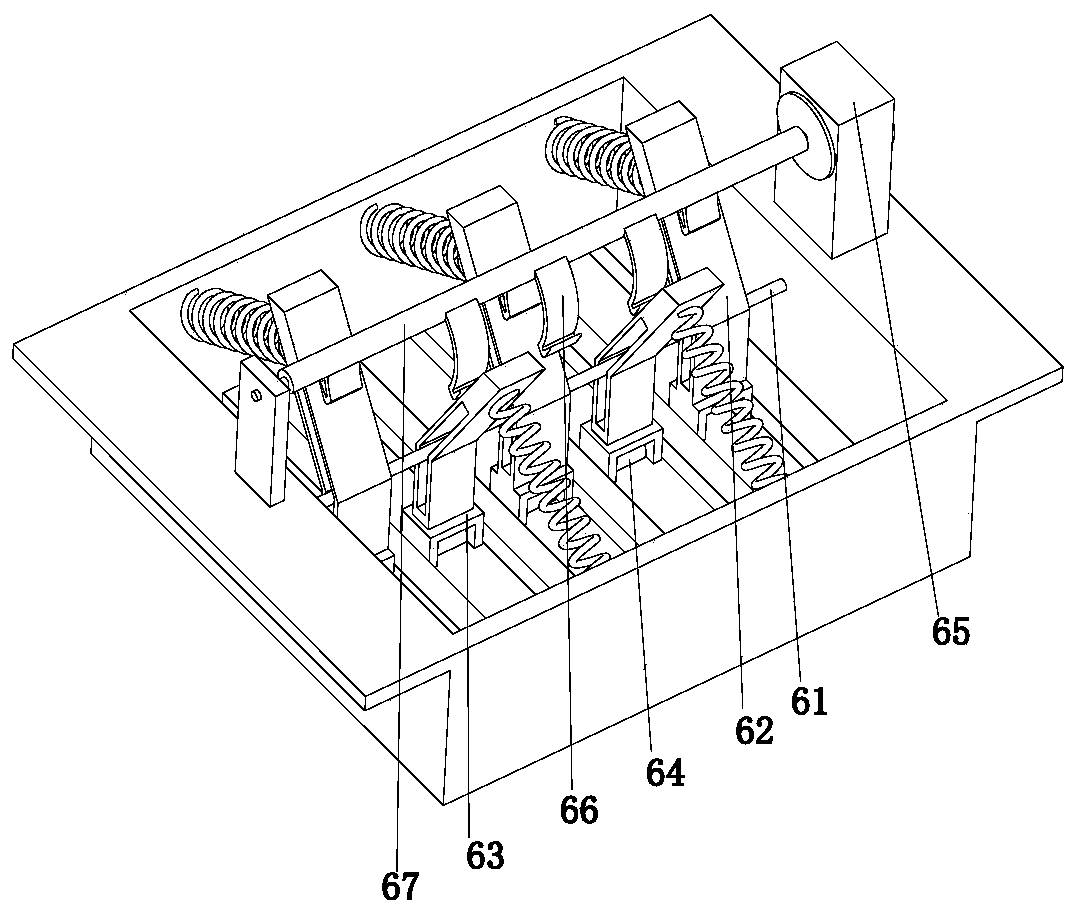

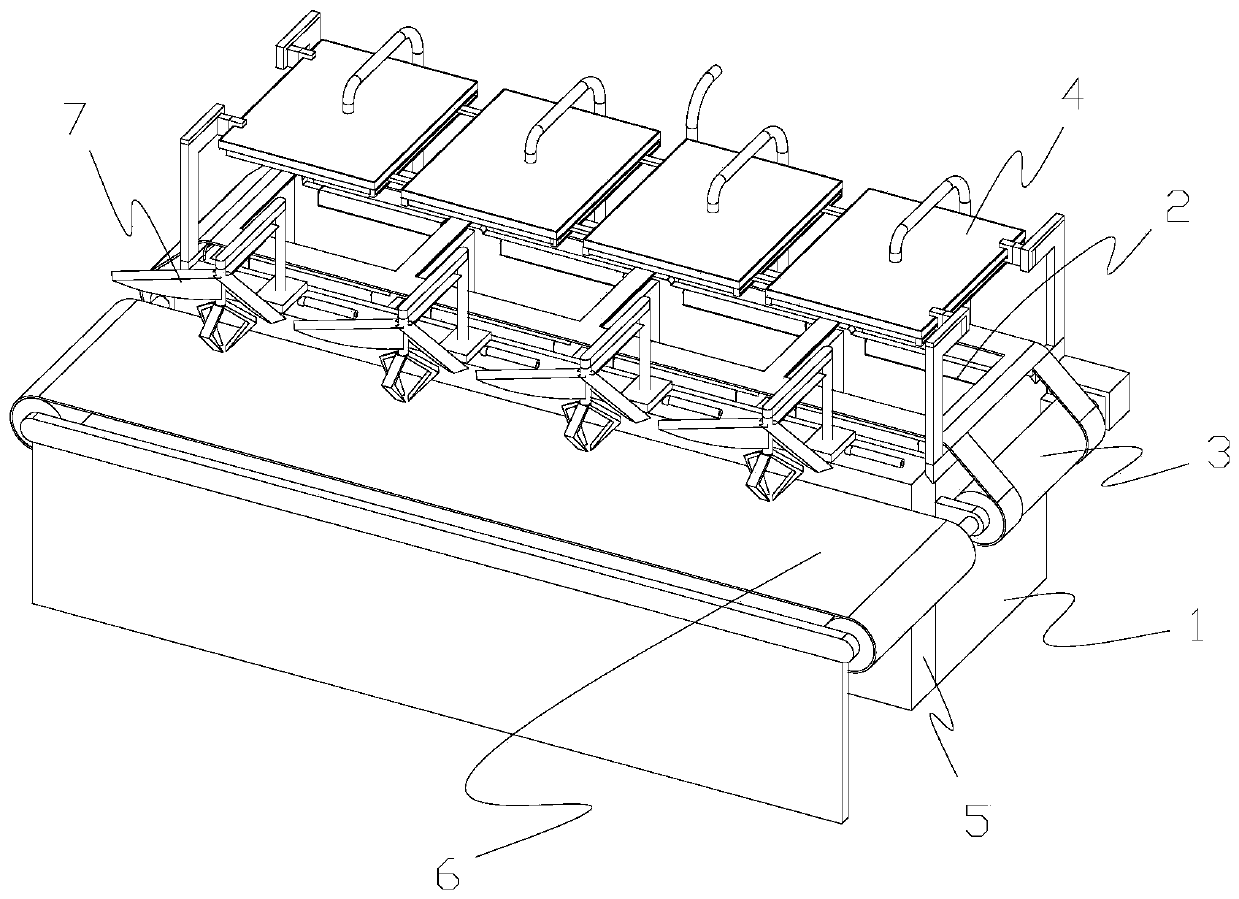

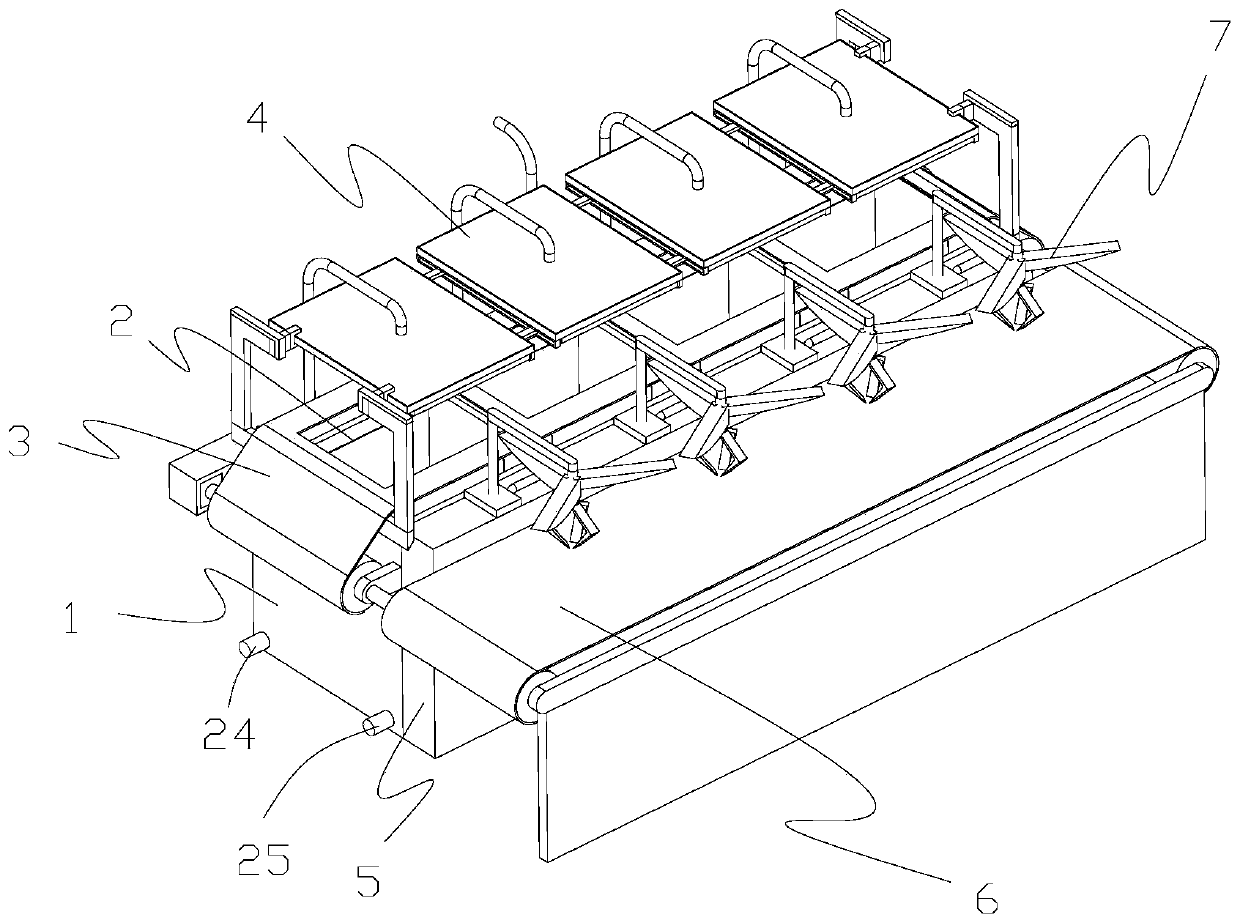

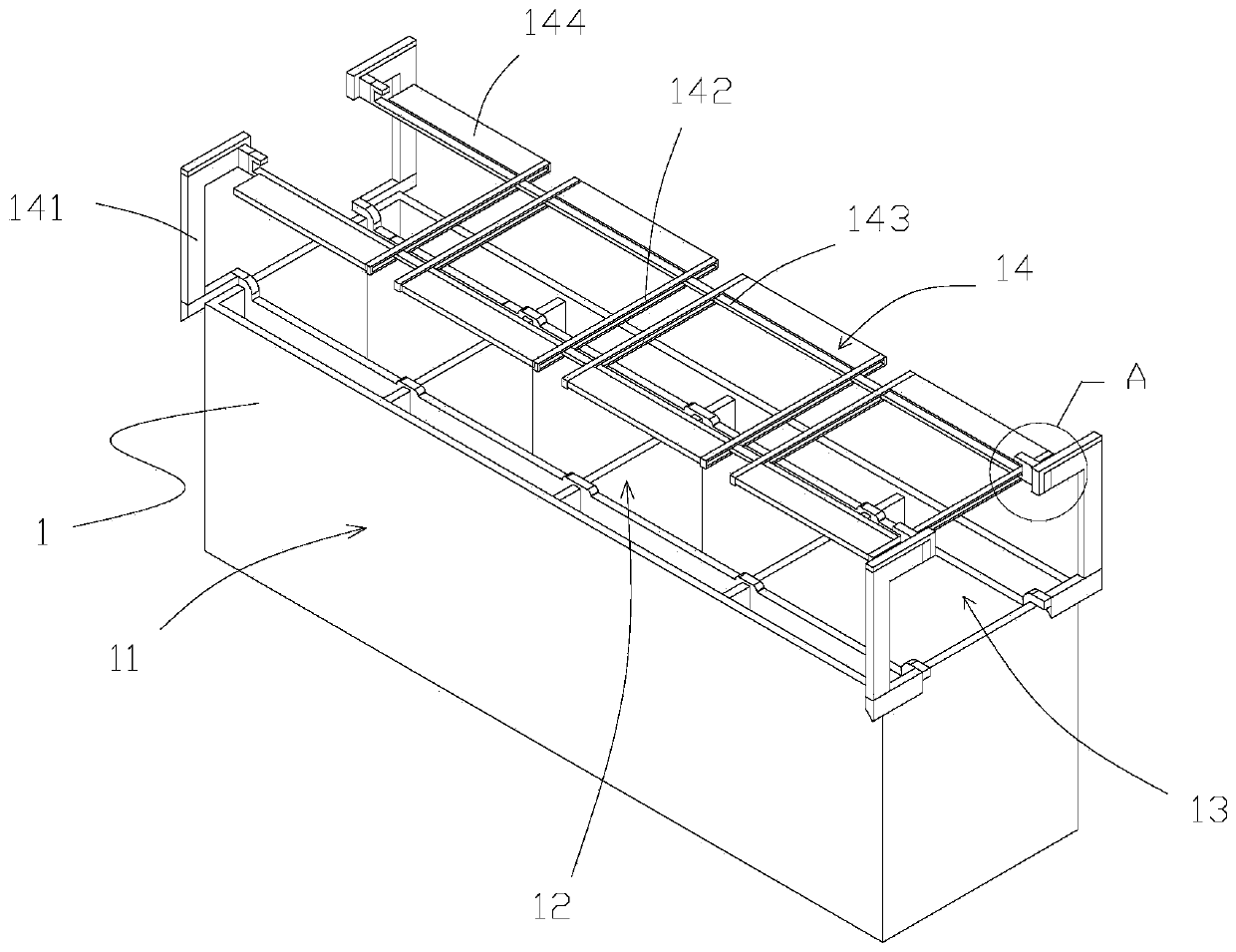

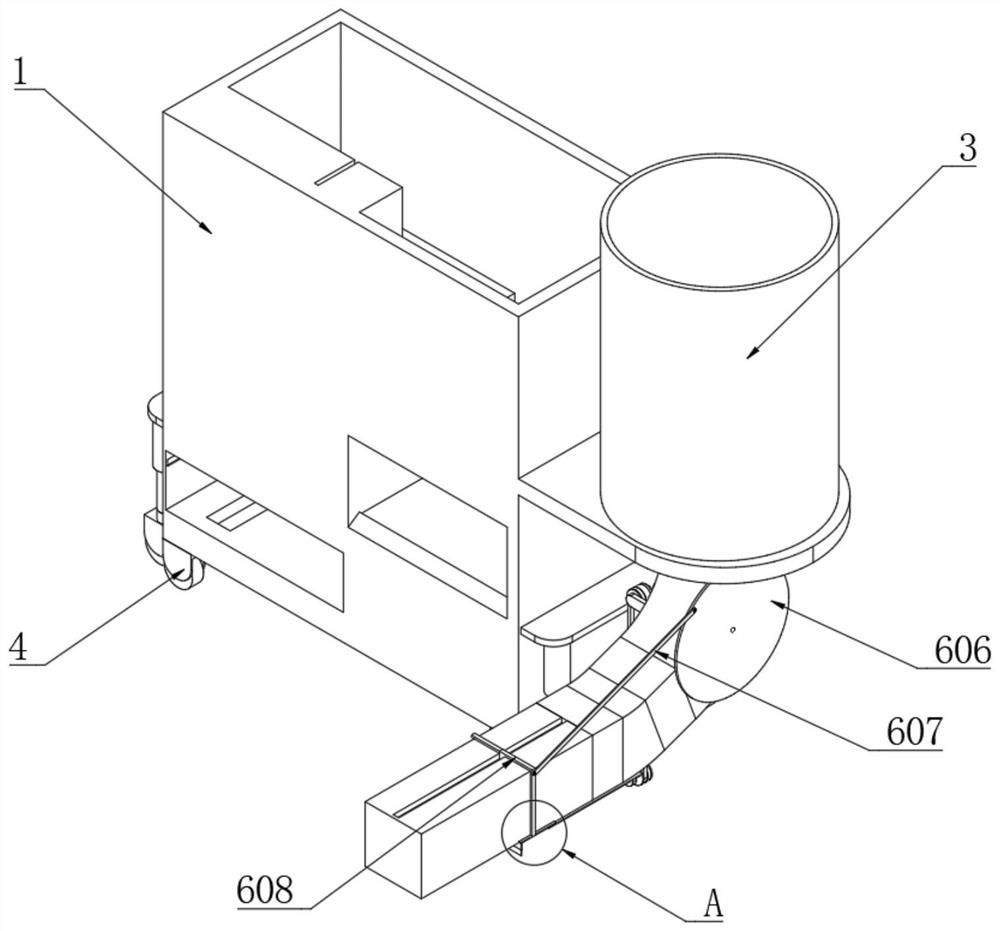

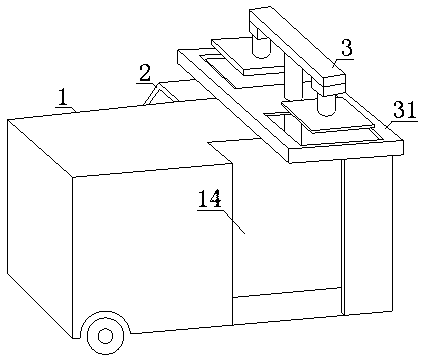

Adjustable welding strip feeding device

InactiveCN104668835APrevent the ribbon from being pulled offShorten laying timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an adjustable welding strip feeding device which is characterized by comprising a welding strip cushioning supplying device, a welding strip feeding device and a welding strip laying device. The welding strip cushioning supplying device, the welding strip feeding device and the welding strip laying device are arranged on a mounting platform, the welding strip feeding device is arranged between the welding strip cushioning supplying device and the welding strip laying device, the welding strip cushioning supplying device comprises a winding unit and a cushioning unit, the front surface of the cushioning unit is connected with the winding unit, the welding strip laying device comprises a welding strip straightening and shaping unit, a welding strip cut-off unit and a welding strip stretching unit, and the welding strip cut-off unit is arranged between the welding strip straightening and shaping unit and the welding strip stretching unit. The adjustable welding strip feeding device has the advantages that welding strips can be quickly and effectively stretched and fed under the matching effects of the winding unit and the cushioning unit, and problems of loose winding of existing welding strips and breakage of the existing welding strips in stretching procedures can be solved; the multiple welding strips can be conveniently and quickly automatically initially fed by the welding strip feeding device instead of labor and can be simultaneously laid, and accordingly the flexibility of the adjustable welding strip feeding device can be improved.

Owner:DONGHUA UNIV

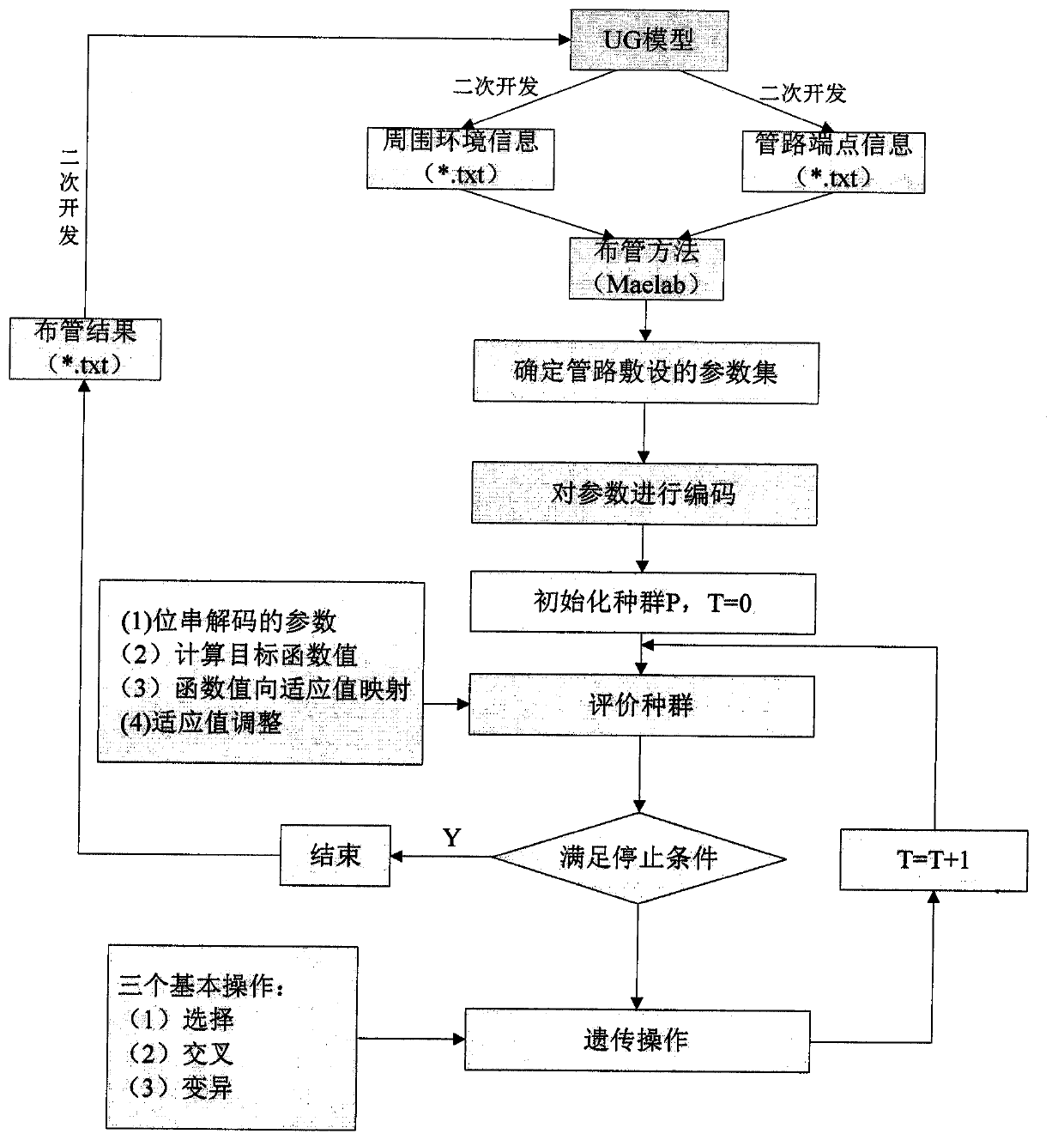

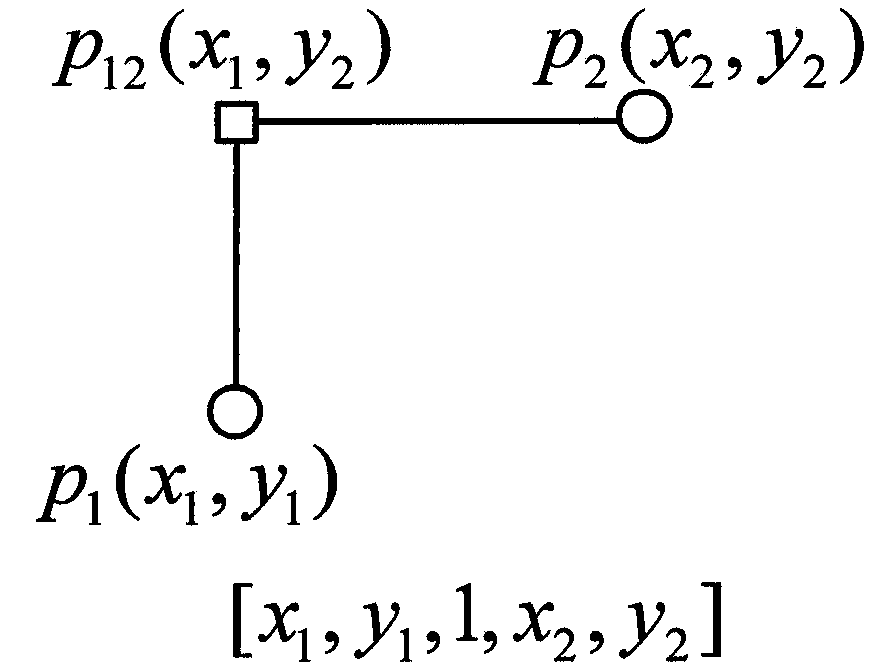

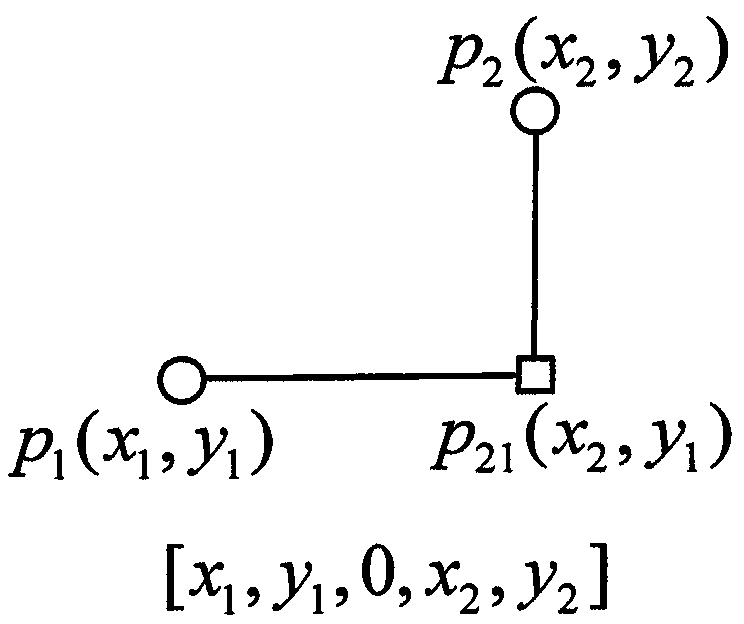

Engine right-angle pipeline genetic algorithm planning method oriented to Manhattan space

InactiveCN104809307AImprove laying efficiencySearch speed is fastGenetic modelsSpecial data processing applicationsAviationAlgorithm

The invention discloses an engine right-angle pipeline genetic algorithm planning method oriented to the Manhattan space. The method comprises the following specific steps: the geometrical information of an aero-engine model is extracted through the secondary development technology in a UG model; a .txt file of the extracted information is then imported into the Matlab software, and a pipeline path is automatically calculated through the technology; a .txt file of the calculation result is finally returned to the UG model through the secondary development technology, so as to achieve visualization of an aero-engine right-angle pipeline curved-surface layout plan. The method provided by the invention has the advantages that regarding the model trend of the right-angle pipeline layout, a fixed-length individual coding method is designed to solve the pipeline layout problem; appropriate evaluation functions are established for targets such as the minimum pipeline length, the minimum number of pipeline elbows, and the minimum energy value; an engine pipe layout space obstacle model is described through a curved-surface polygon; obstacle avoidance handling adopts the approximate geodesic line intersection method. The method provided by the invention achieves the automatic and optimum engine right-angle pipeline design.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

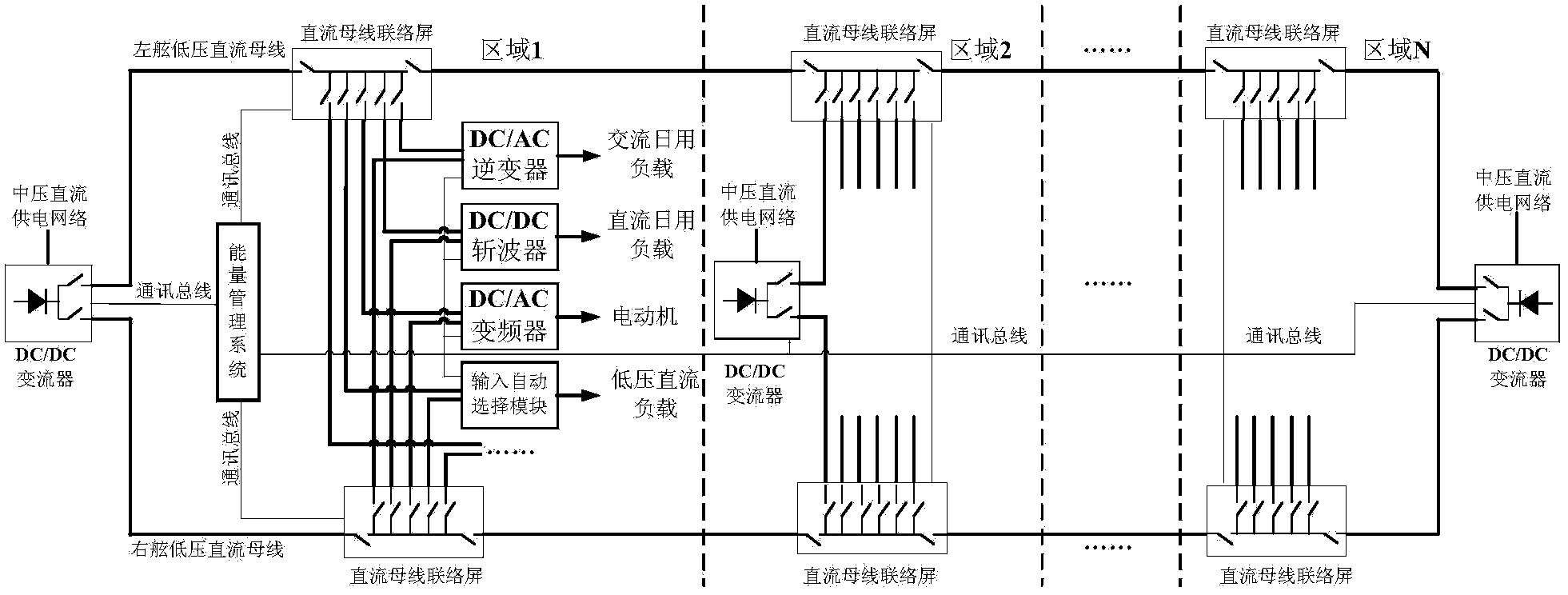

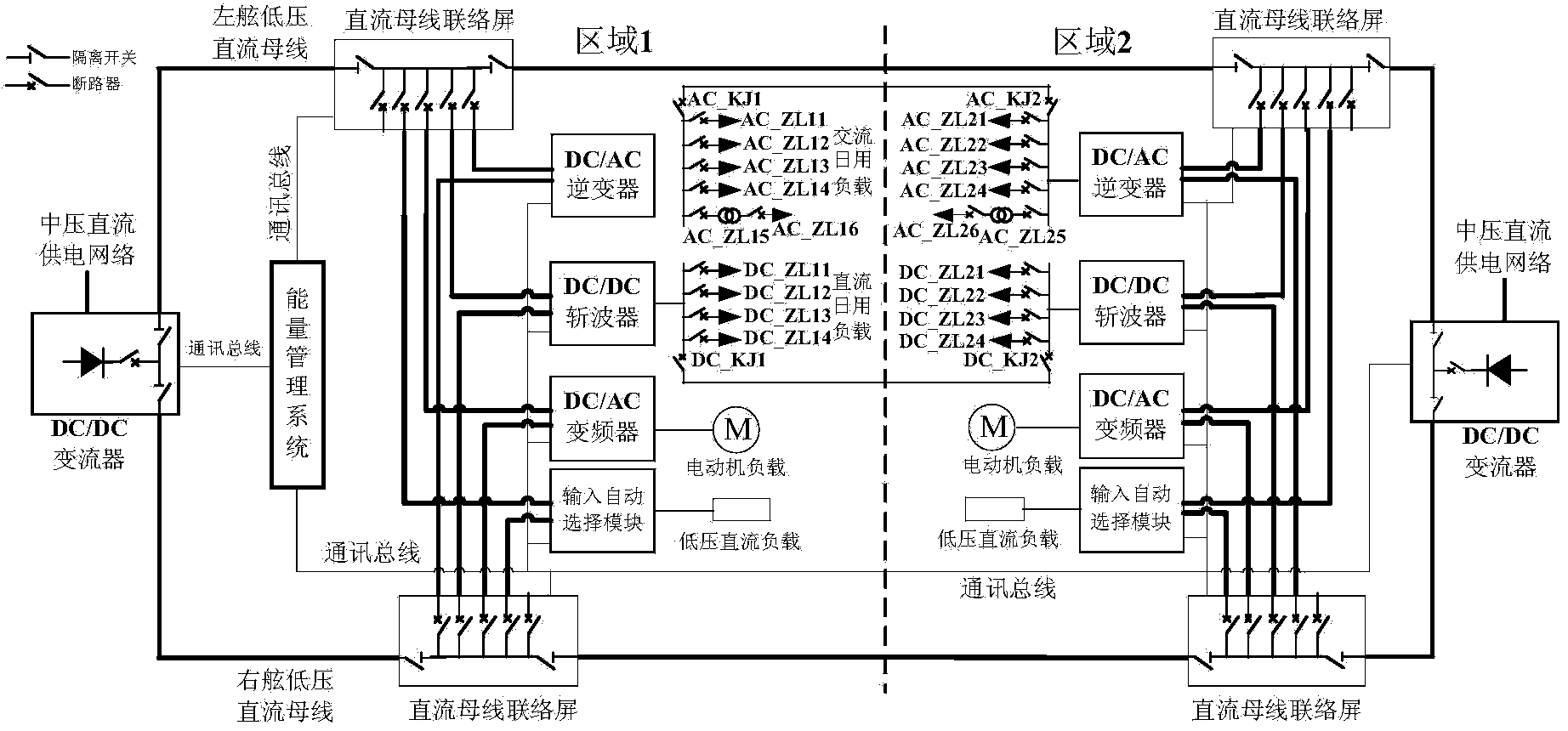

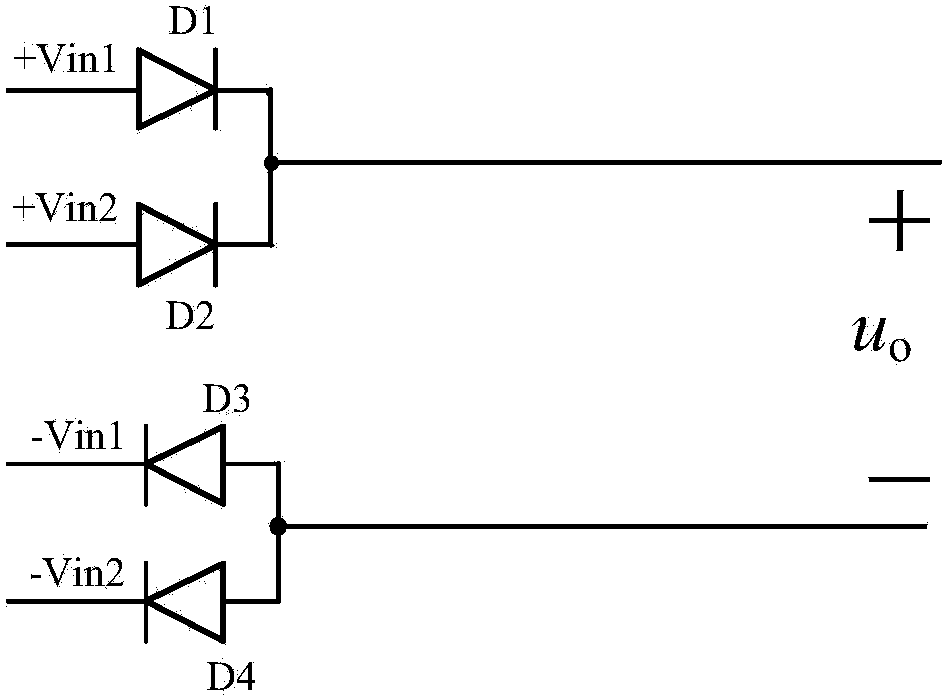

Medium-voltage direct zone distribution system

ActiveCN103457259AReduce dosageReduce the number of hatchesDc network circuit arrangementsTransformerLow voltage

The invention belongs to the field of marine electric power systems, and particularly relates to a medium-voltage direct zone distribution system suitable for a marine comprehensive electric power system in the medium voltage direct current mode. The medium-voltage direct zone distribution system comprises a plurality of distribution zones and an energy managing system, a DC / DC current transformer is arranged inside each distribution zone, the output end of each DC / DC current transformer is respectively connected with a left-ship-board low-voltage direct-current bus and a right-ship-board low-voltage direct-current bus through isolation interlock switches, left-ship-board direct-current bus contact screens and right-ship-board direct-current bus contact screens are connected with the left-ship-board low-voltage direct-current bus and the right-ship-board low-voltage direct-current bus respectively, the output end of each left-ship-board direct-current bus contact screen and the output end of each right-ship-board direct-current bus contact screen are respectively connected with the input ends of power electronic devices, and the energy managing system is connected with the power electronic devices in the distribution zones through a communication bus. According to the medium-voltage direct zone distribution system, the use amount of electric cables is effectively reduced, the number and the area of cable cabin-penetrating holes are reduced, the cable laying time is shortened, the size and the weight of the medium-voltage direct zone distribution system are reduced, and the overall cost such as the economy cost, the size cost and the weight cost of the medium-voltage direct zone distribution system is reduced.

Owner:NAVAL UNIV OF ENG PLA

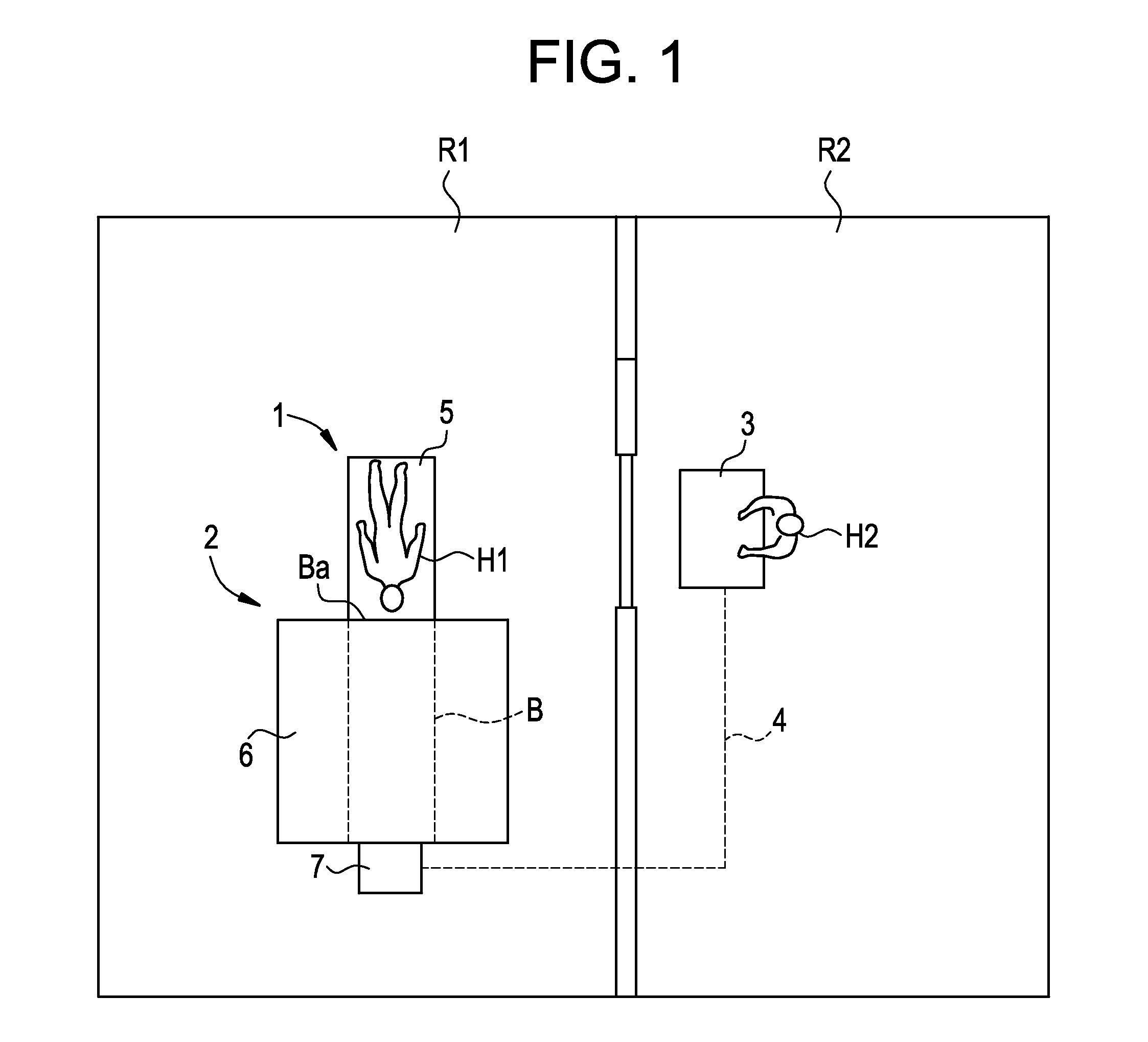

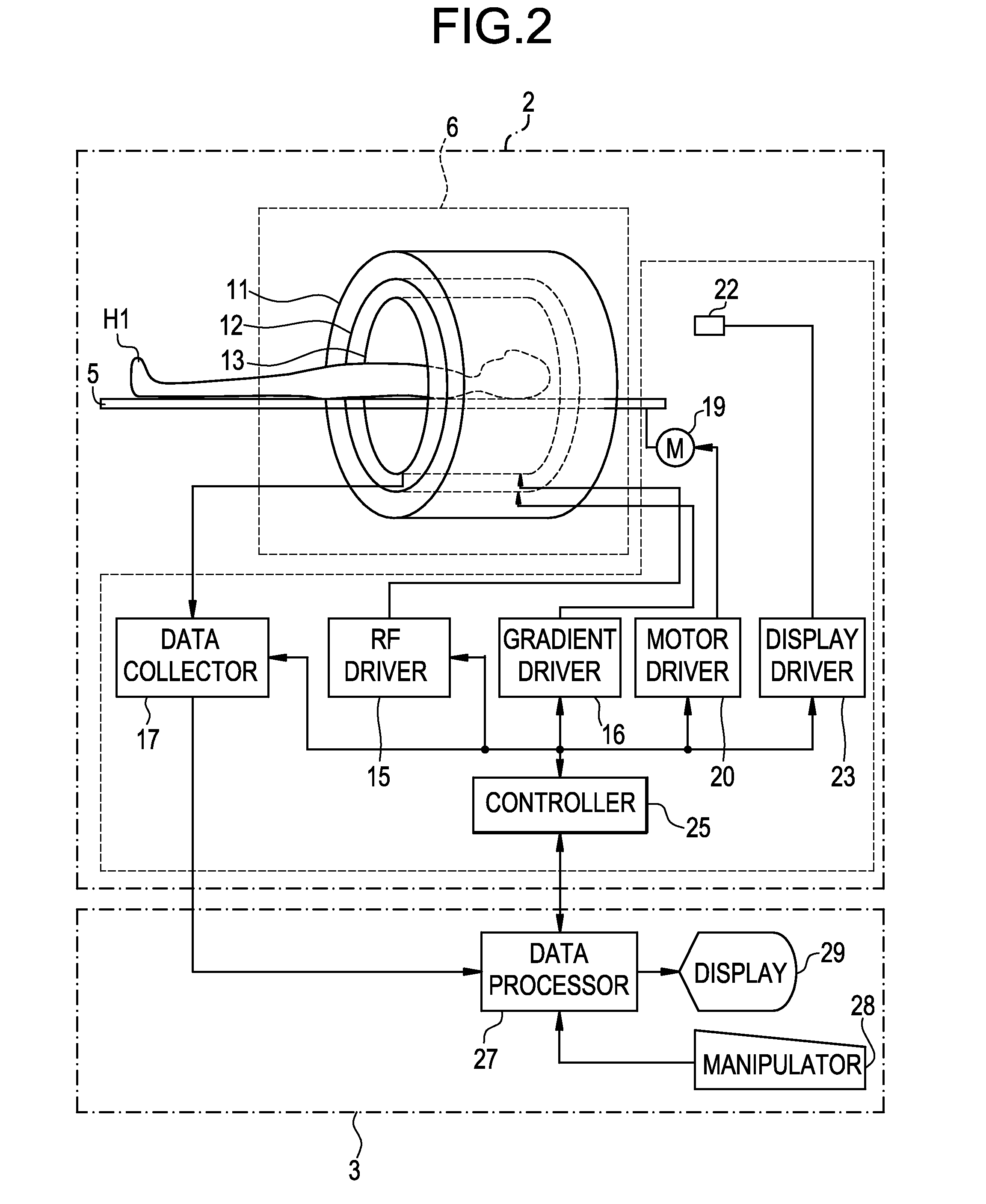

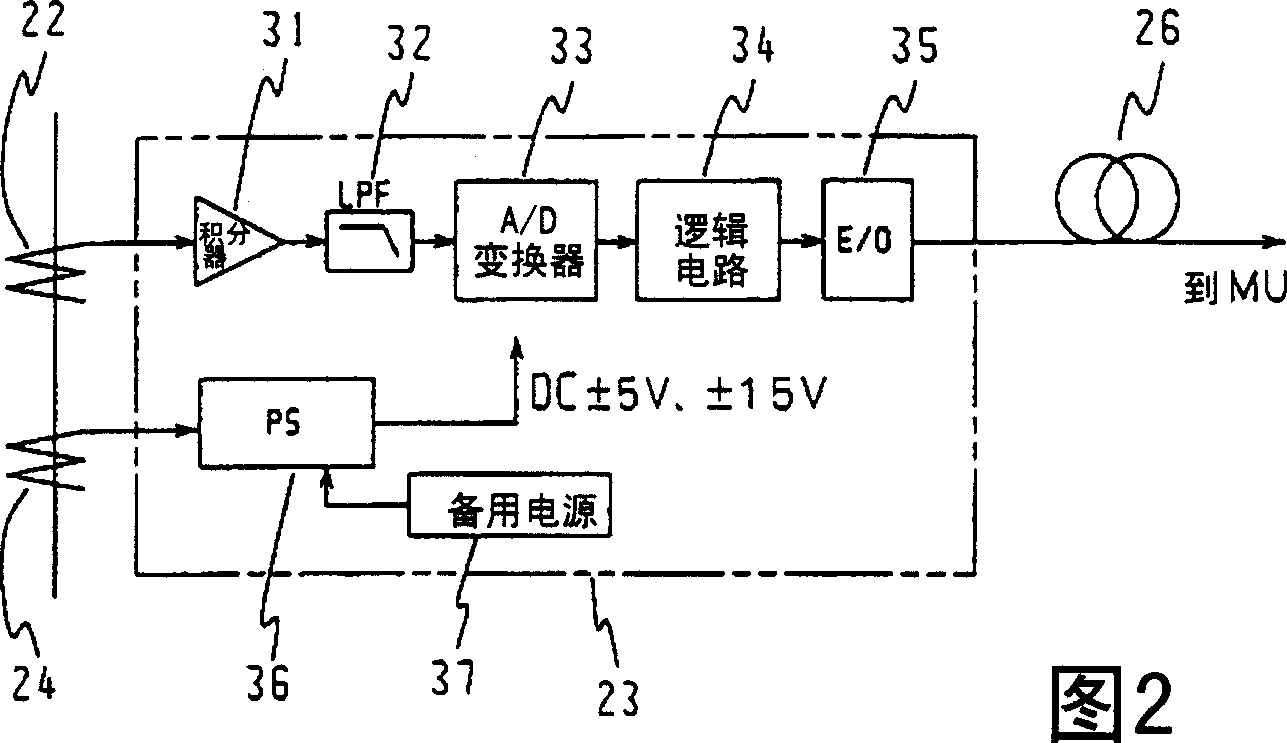

Magnetic resonance imaging apparatus and method of conveying the magnetic resonance imaging apparatus

InactiveUS7501824B2Shorten laying timeRadiating elements structural formsRadiating element housingsData collectorMagnetic field

With a view to shortening the cable laying time there is provided a magnetic resonance imaging apparatus for generating an image of a subject in accordance with a magnetic resonance signal received after application of a high-frequency magnetic field to the subject under a static magnetic field and a gradient magnetic field, the magnetic resonance imaging apparatus comprising a base, operating portions provided in the base and performing predetermined operations, such as a data collector and a controller, two pipes projecting from the base, and plural cables wound in the figure of 8 onto projecting portions of the two pipes projecting from the base, one end of the cables being connected electrically to the operating portions.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

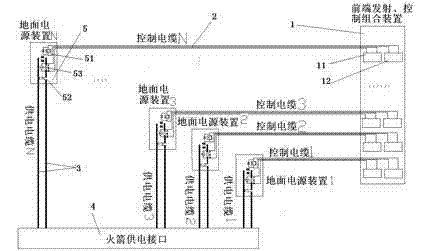

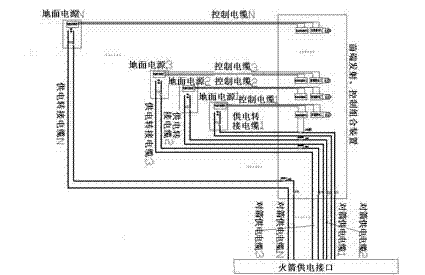

Ground power supply distribution system for carrier rocket

InactiveCN102818484AReduce intermediate transfer linksImprove reliabilityDc network circuit arrangementsSelf-propelled projectilesDistribution power systemElectric power distribution

The invention relates to the technical field of ground power supply and distribution of a carrier rocket, in particular to a ground power supply distribution system for a carrier rocket. The ground power supply distribution system for the carrier rocket, which is disclosed by the invention, comprises a front-end transmitter, a control combination device, a control cable, a power supply cable, a rocket power supply interface and a ground power supply device; the front-end transmitter and the control combination device are used for controlling the ground power supply device by the control cable to ensure the ground power supply device to directly supply power to the carrier rocket by the power supply cable; and the power supply cable is connected onto the carrier rocket by the rocket power supply interface. Compared with the prior art, the ground power supply distribution system for the carrier rocket, which is disclosed by the invention, has the advantages that the intermediate adapter link of the power supply is greatly reduced, so that the cable connection relation between the rocket and the ground and among pieces of equipment is simplified, the equipment expansion recovery and cable laying time is shortened and the reliability of the power supply is further improved; and meanwhile, resources can be greatly saved after the ground power supply distribution system for the carrier rocket, which is disclosed by the invention, is adopted.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

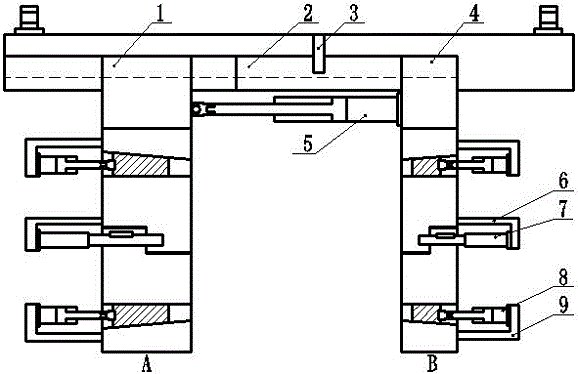

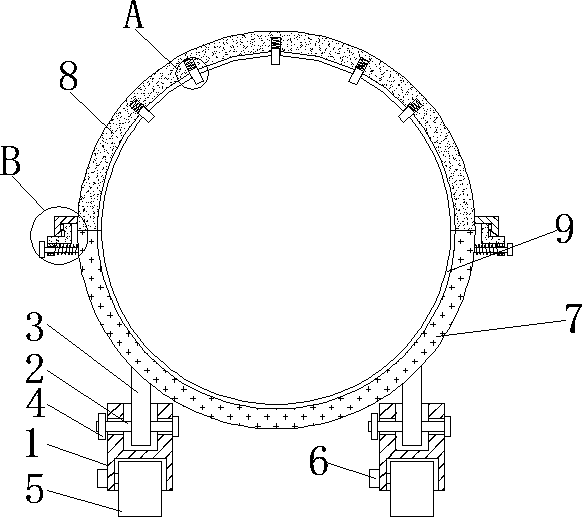

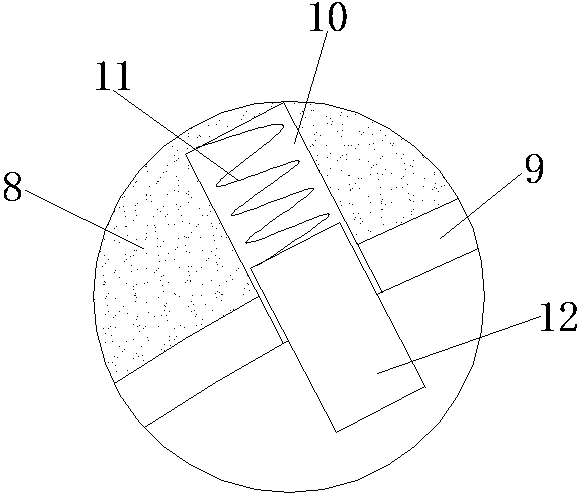

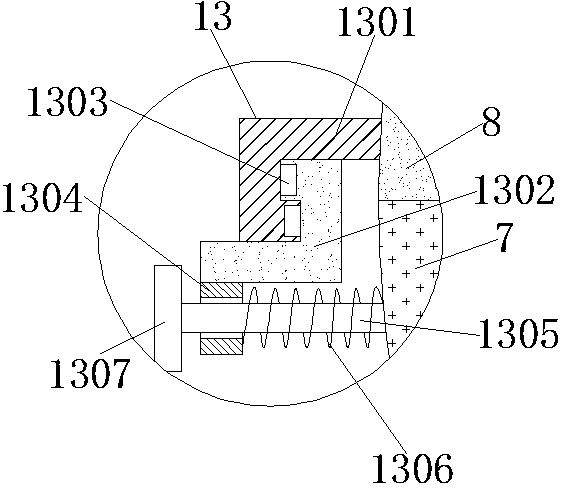

Hydraulic docking device used outside large-caliber gathering and transportation pipeline

InactiveCN105598630AShorten laying timeQuick lockWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderHydraulic motor

The invention relates to a hydraulic docking device used outside a large-caliber gathering and transportation pipeline. The hydraulic docking device achieves the purpose of rapidly achieving pipeline docking and repairing on the premise of guaranteeing welding quality. According to the technical scheme, a fixed holding ring, a right rotating holding ring and a left rotating holding ring are each provided with an arc T-shaped groove of certain gradient; the hanging ring end of the right rotating holding ring and the hanging ring end of the left rotating holding ring are connected with two hanging ring ends of the fixed holding ring through rotating hinge pins; hydraulic cylinder ends of horizontal push hydraulic cylinders are connected with horizontal push hydraulic cylinder bases through flanges, and a push rod end acts on the positions of a circular groove of a wedge-shaped locking ring; hydraulic cylinder ends of swing hydraulic motors are connected with swing hydraulic motor bases through flanges, and rotating shaft ends are connected with the rotating hinge pins through couplings. According to the hydraulic docking device, a hoisting form and hydraulic drive are adopted, the hydraulic docking device can adapt to pipe repair under complex working conditions, and meanwhile centring and weld seam gap adjustment between the pipeline to be welded and a new pipeline can be achieved rapidly.

Owner:SOUTHWEST PETROLEUM UNIV

Novel hydraulic engineering pipe support

The invention discloses a novel water conservancy pipeline bracket, which includes a sleeve, a first bolt, a connecting block, a nut, a support rod, a second bolt, a first pipe sleeve, a second pipe sleeve, a rubber pad, a through hole, and a first spring , rubber block, locking device, first block, second block, magnet block, collar, guide rod, second spring and stopper. The invention has reasonable structure and novel design, can quickly install and disassemble the first pipe sleeve and the second pipe sleeve, can save the time for laying water conservancy pipelines, and facilitates the repair and maintenance of water conservancy pipelines; The first sleeve and the second sleeve are locked, and the first clamping block and the second clamping block are closely fitted by the compressed second spring, and the first clamping block and the second clamping block hook each other through their own J-shaped structure Hold, so that the first sleeve and the second sleeve are locked firmly, and the first block can be separated from the second block by pushing the ring, and the locking of the first sleeve and the second sleeve can be released quickly.

Owner:祝敏

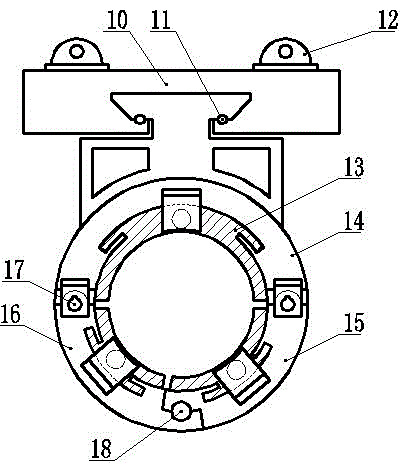

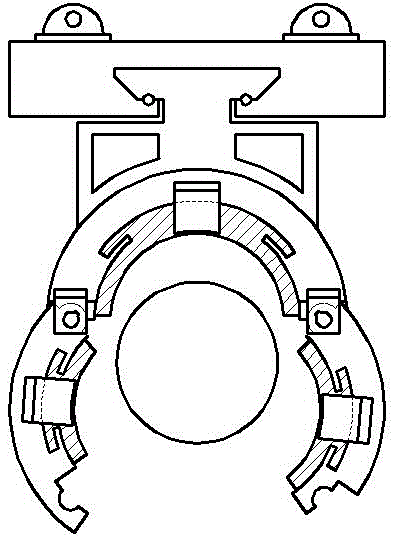

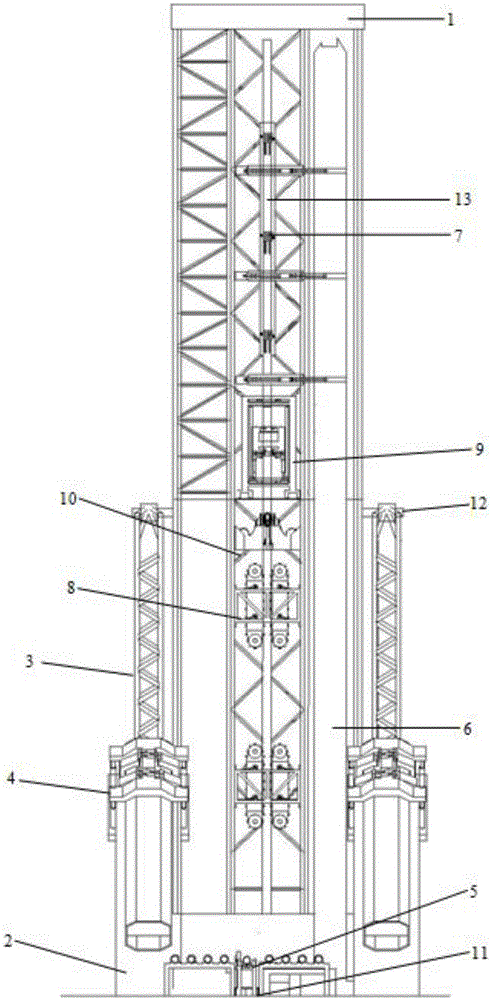

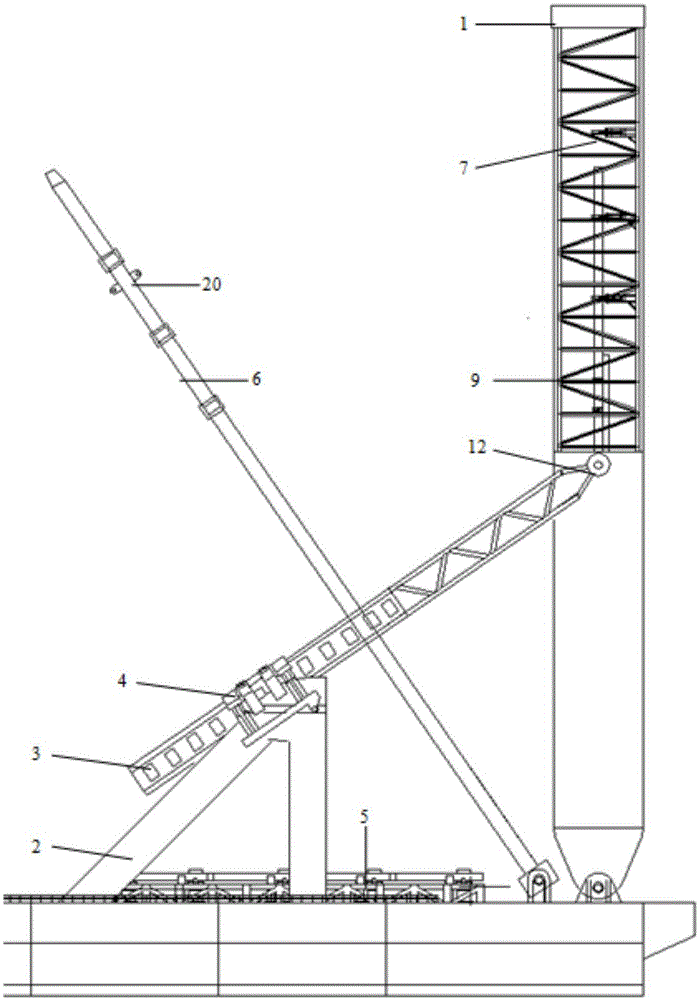

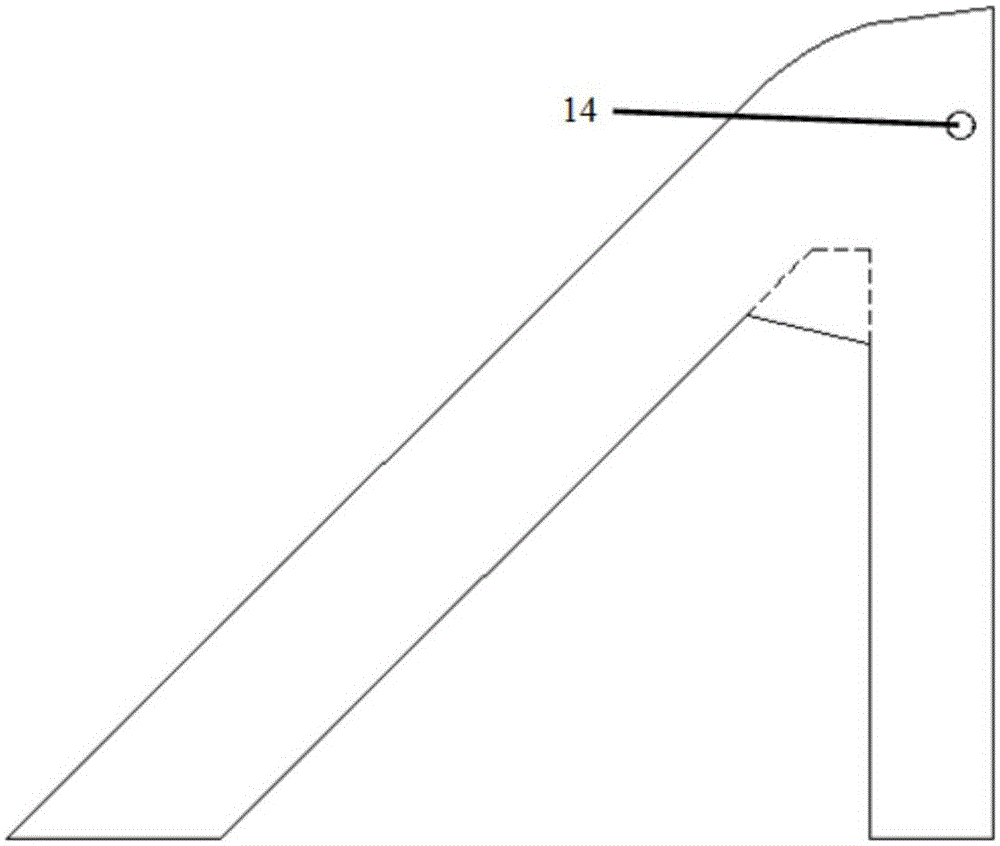

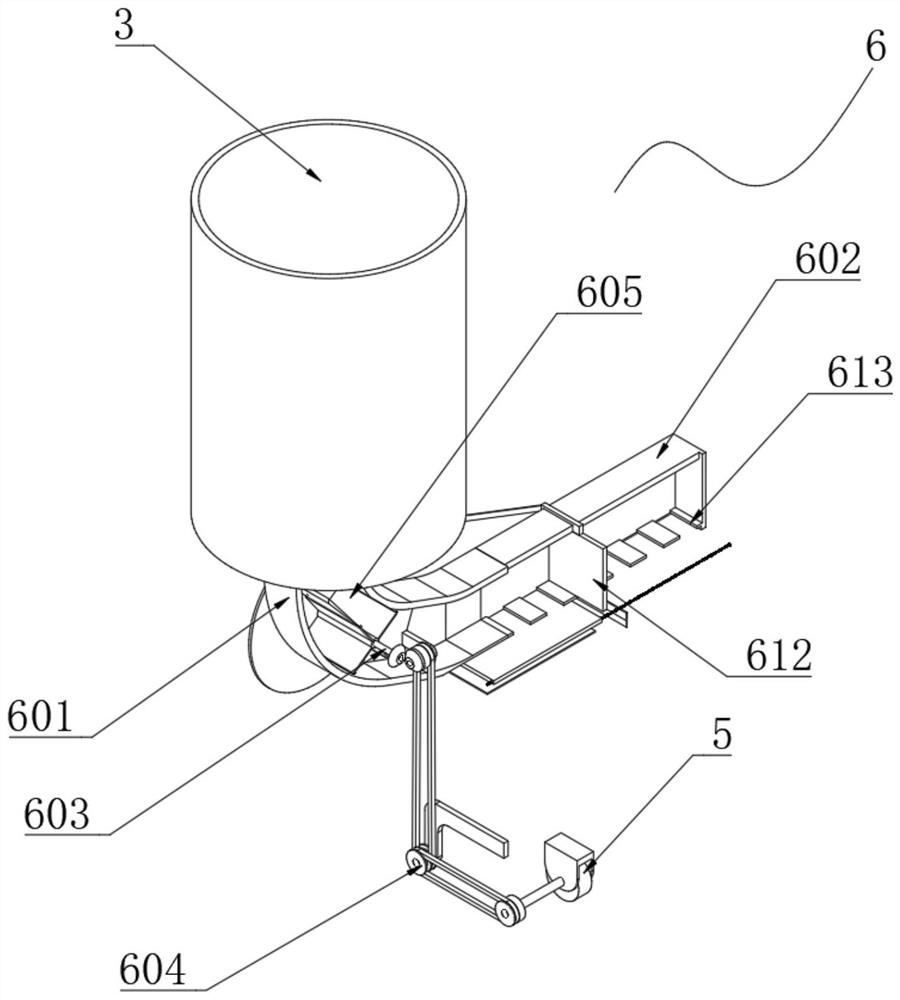

Light double-node pipeline J-shaped laying system

ActiveCN105042184AShorten laying timeAchieve installationPipe laying and repairHydraulic cylinderEngineering

The invention provides a light double-node pipeline J-shaped laying system comprising a J-shaped tower, a J-shaped tower angle adjusting portion, a pipeline conveying portion and a pipeline laying portion. The J-shaped tower is used for supporting, fixing and connecting other structures and key devices of the J-shaped laying system. The J-shaped tower angle adjusting system comprises an angle adjuster, an A-shaped frame and a hydraulic cylinder and can achieve free adjustment of the J-shaped tower within a certain angle range. The pipeline conveying portion comprises a horizontal conveying system, a loading arm, a rotating arm and a vertical idler wheel. The pipeline laying portion comprises an outer centralizer, a tensioning device, a welding station and a coating station which have the conveying function, the centering function and the fixing functions in the laying process. The J-shaped laying system can achieve a 2*2 node laying manner. Some key devices are installed by selecting, arranging and optimizing relevant devices. In this way, the laying cost is reduced, and laying efficiency is improved.

Owner:哈尔滨航沣科技开发有限公司

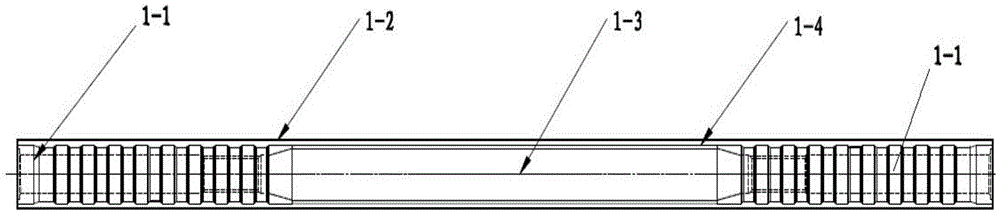

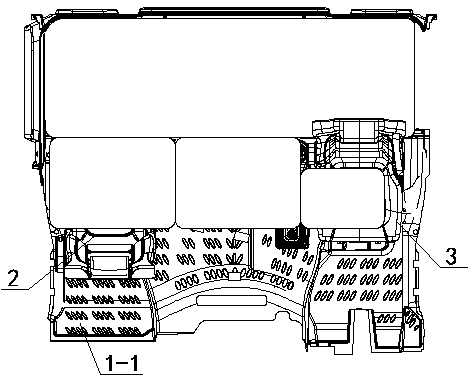

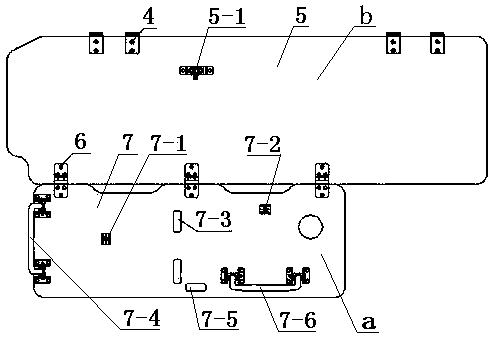

Pultrusion type embedded blade root connector for wind-driven generator blades and preparation method thereof

ActiveCN105465141AUnique strengthUnique Design FreedomFinal product manufactureNutsWind drivenEmbedded system

The invention discloses a pultrusion type embedded blade root connector for wind-driven generator blades and a preparation method thereof. The pultrusion type embedded blade root connector comprises blade root connector bodies (1-1), a light connector body (1-4) connected to the blade root connector bodies (1-1), light material (1-3) filling the light connector body (1-4), and a pultrusion type composite material part (1-2) wrapping the peripheries of the blade root connector bodies (1-1) and the periphery of the light connector body (1-4). The pultrusion type preparation method comprises the steps of part assembly, embedded type composite material pultrusion and finishing. The embedded blade root connector has the advantages that the appearance size is stable, the defect rate of products is low, the quality is continuously stable and reliable, locating is accurate, interfaces between different kinds of material are firmly bonded, and the mechanization level is high. The preparation method has the advantages that the time of occupying molds by the products can be shortened, the time of laying material can be shortened, the time of installing bolts can be shortened, the time of pouring and curing can be shortened, the production efficiency is high, and the labor cost is low.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

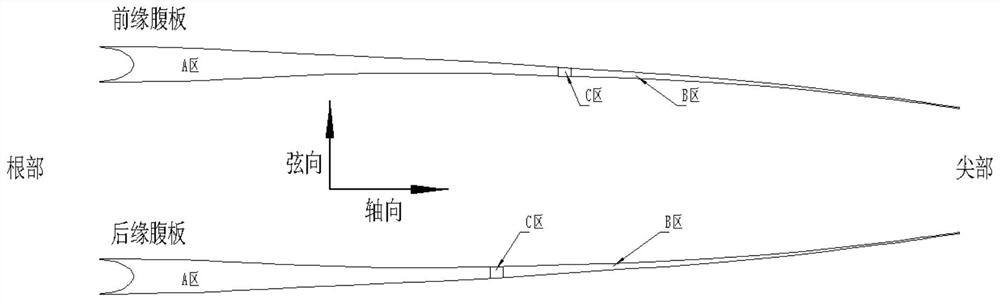

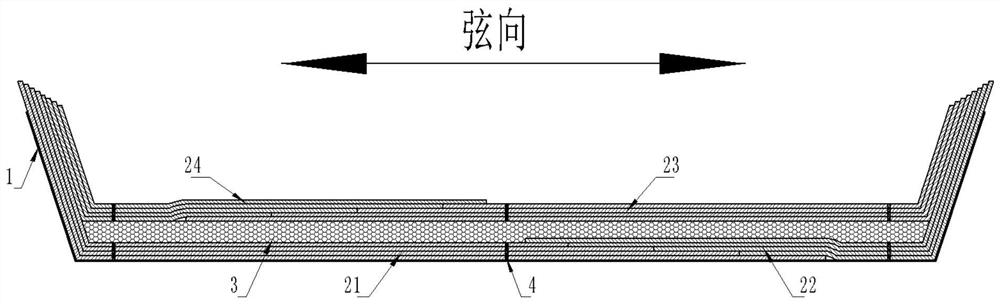

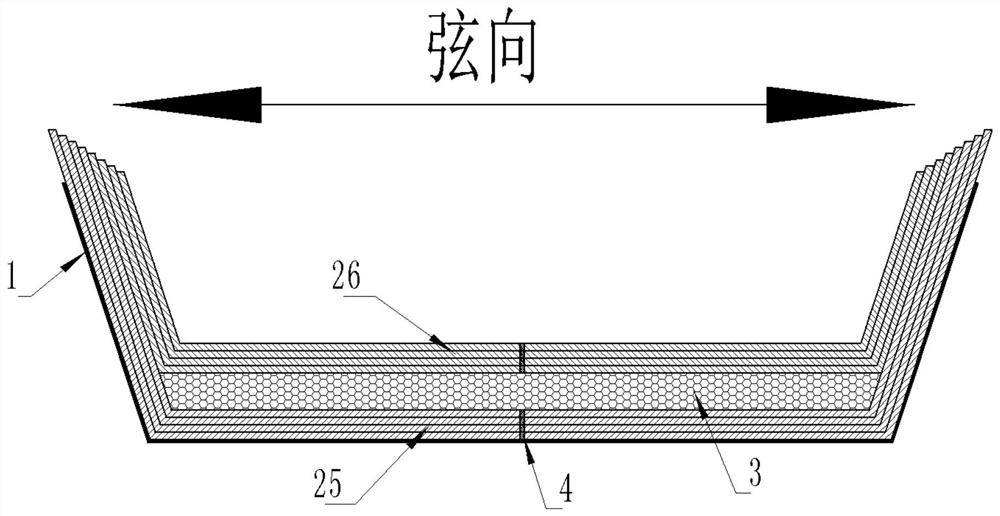

Wind power blade web layering structure and layering method thereof

PendingCN111927701AShorten laying timeSimple and fast operationMachines/enginesWind energy generationGlass fiberStructural engineering

The invention discloses a wind power blade web layering structure and a layering method thereof. The wind power blade web plate layering structure comprises a blade root layering area, a transition layering area and a blade tip layering area, wherein the blade root layering area, the transition layering area and the blade tip layering area are sequentially divided by a leading edge web and a trailing edge web from a blade root to a blade tip; multi-layer glass fiber cloths respectively laid on the lower left layer of the blade root and the lower right layer of the blade root overlap with eachother chordwise; multi-layer glass fiber cloths respectively laid on the upper left layer of the blade root and the upper right layer of the blade root overlap with each other chordwise; multi-layer glass fiber cloths on the lower left layer of the blade root and glass fiber cloths on the lower layer of the blade tip overlap with each other axially; and multi-layer glass fiber cloths on the upperright layer of the blade root and the glass fiber cloths on the upper layer of the blade tip axially overlap with each other. According to the wind power blade web layering structure and the layeringmethod thereof, the web glass fiber cloths are divided into a plurality of pieces by sewing in advance, and the multi-layer glass fiber cloths are laid at one time; zoning of the web layering is carried out, and synchronous and bidirectional operation is carried out without mutual interference; and the operation is simple and convenient, the web laying time is shortened, and the laying speed and quality are improved.

Owner:国能联合动力技术(保定)有限公司

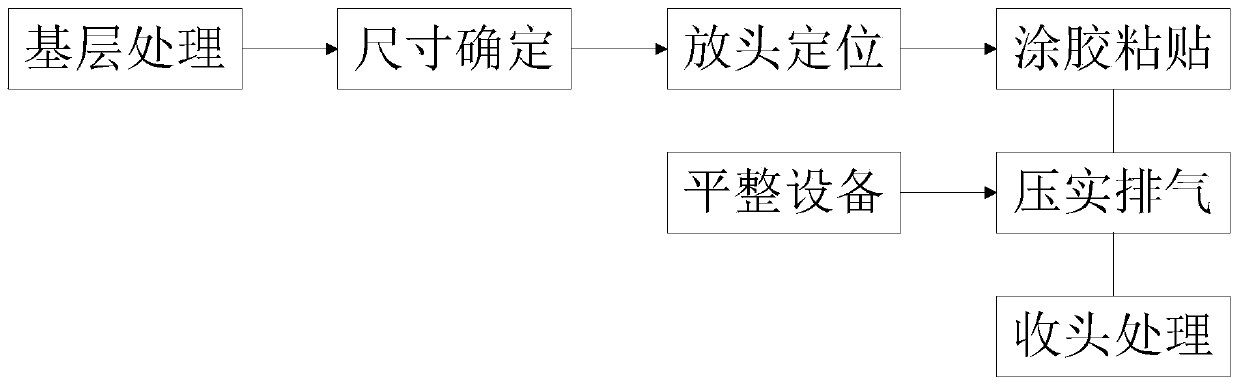

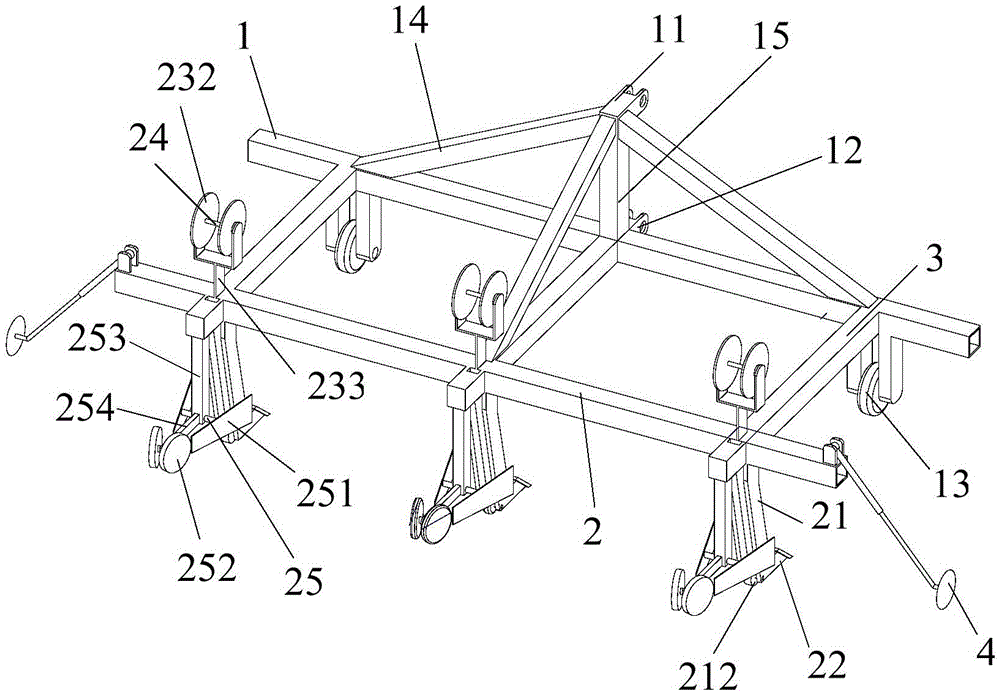

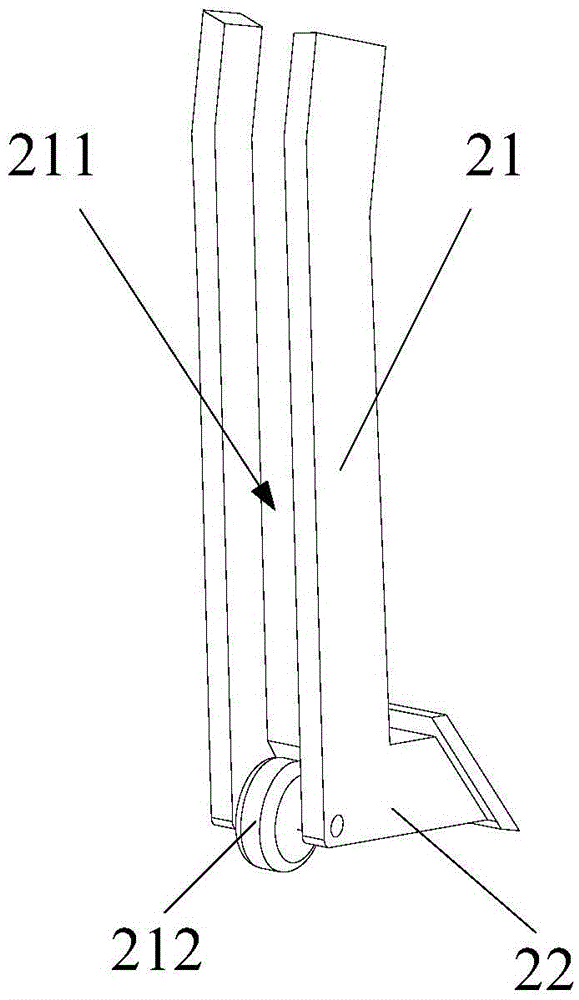

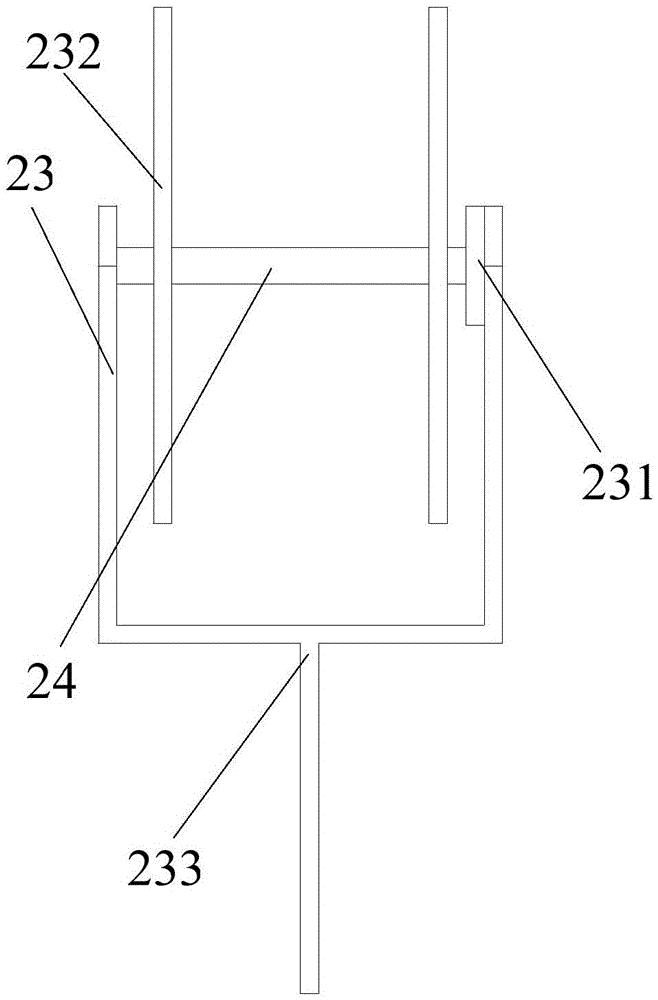

Rubber and plastic co-mixed waterproof roll construction method

ActiveCN110485728ANo artificial exhaust requiredShorten laying timeRoof covering using flexible materialsBuilding material handlingSize determinationEngineering

The invention relates to a rubber and plastic co-mixed waterproof roll construction method. The rubber and plastic co-mixed waterproof roll construction method mainly comprises such steps as base layer treatment, size determination, end placement and positioning, gluing and bonding, compaction exhausting and end collecting treatment; leveling equipment comprises a mounting chassis; the mounting chassis consists of a longitudinal exhaust bracket and a transverse exhaust bracket; a longitudinal exhaust branched chain is arranged on the longitudinal exhaust bracket; and a transverse exhaust branched chain is arranged on the transverse exhaust bracket. The rubber and plastic co-mixed waterproof roll construction method can solve the following difficulties in the construction process of traditional rubber and plastic co-mixed waterproof rolls: (a) paved waterproof rolls need to be manually compacted; and during paving of the rolls, air between the paved rolls and base layers is expelled; and (b) the manual exhaust efficiency of the waterproof rolls during paving is low; the viscosity between the rolls and the base layers after bonding is higher; the air between the rolls and the base layers cannot be totally removed through simple expelling; and the construction quality of the rubber and plastic co-mixed waterproof rolls is influenced.

Owner:广东昊粤建设有限公司

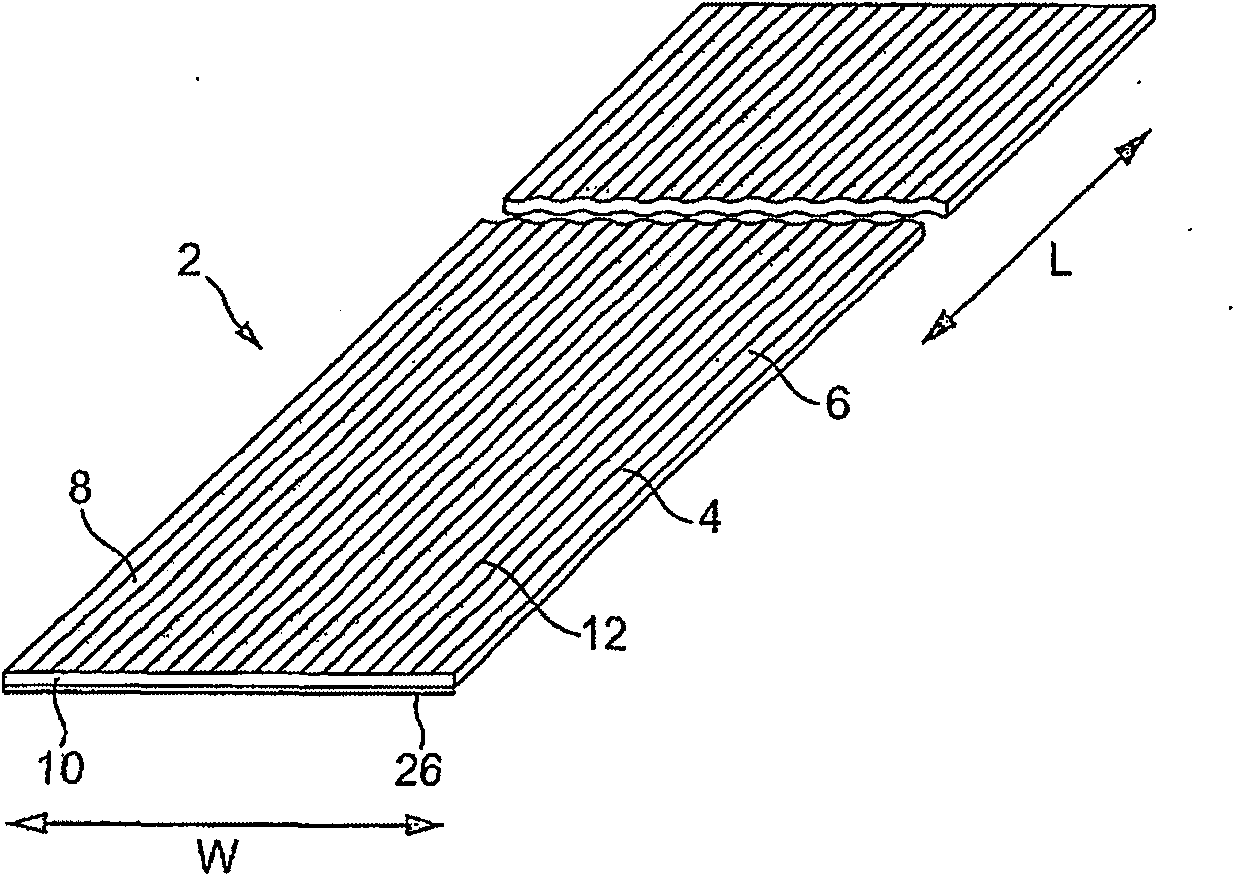

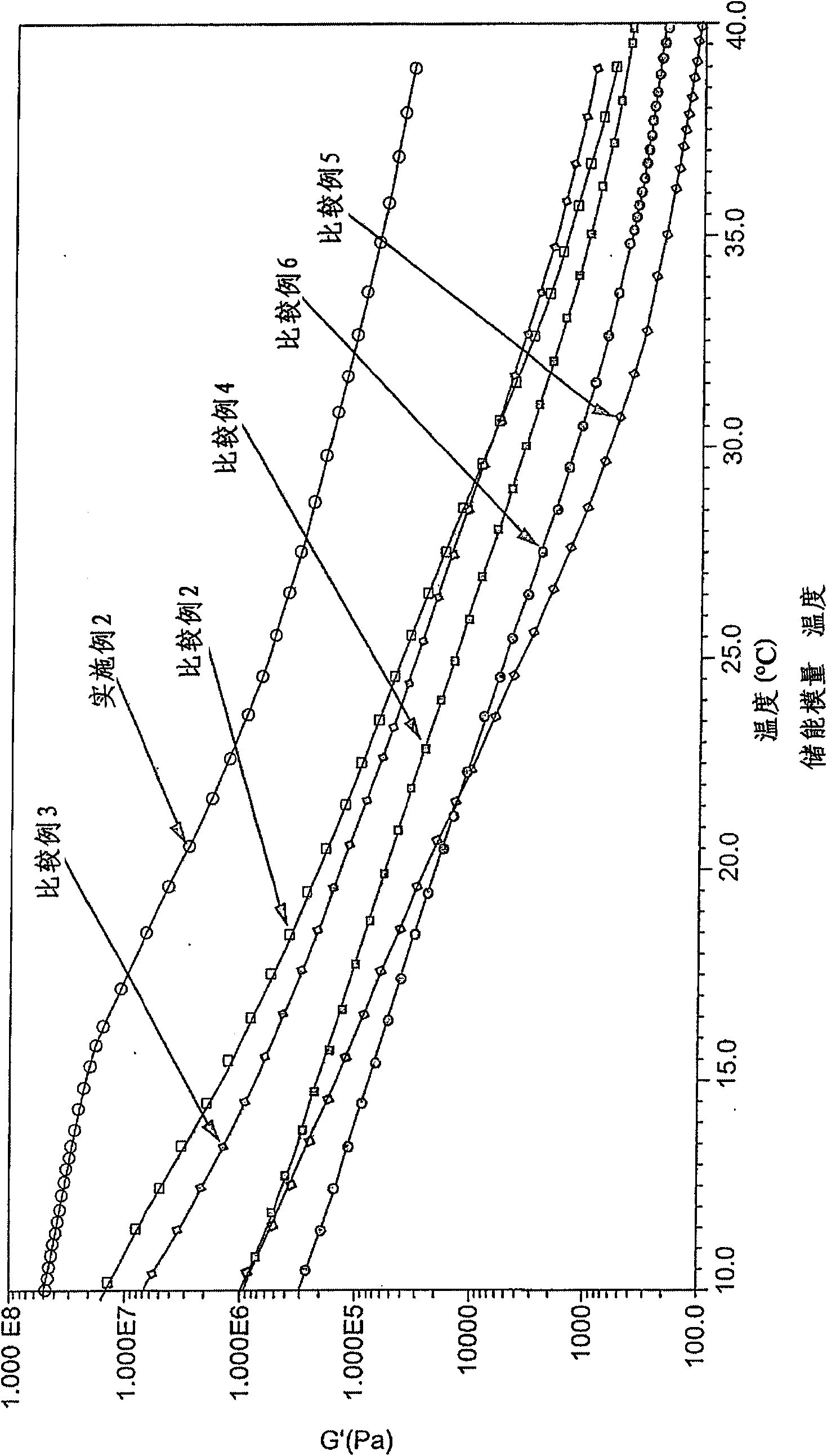

Composite materials

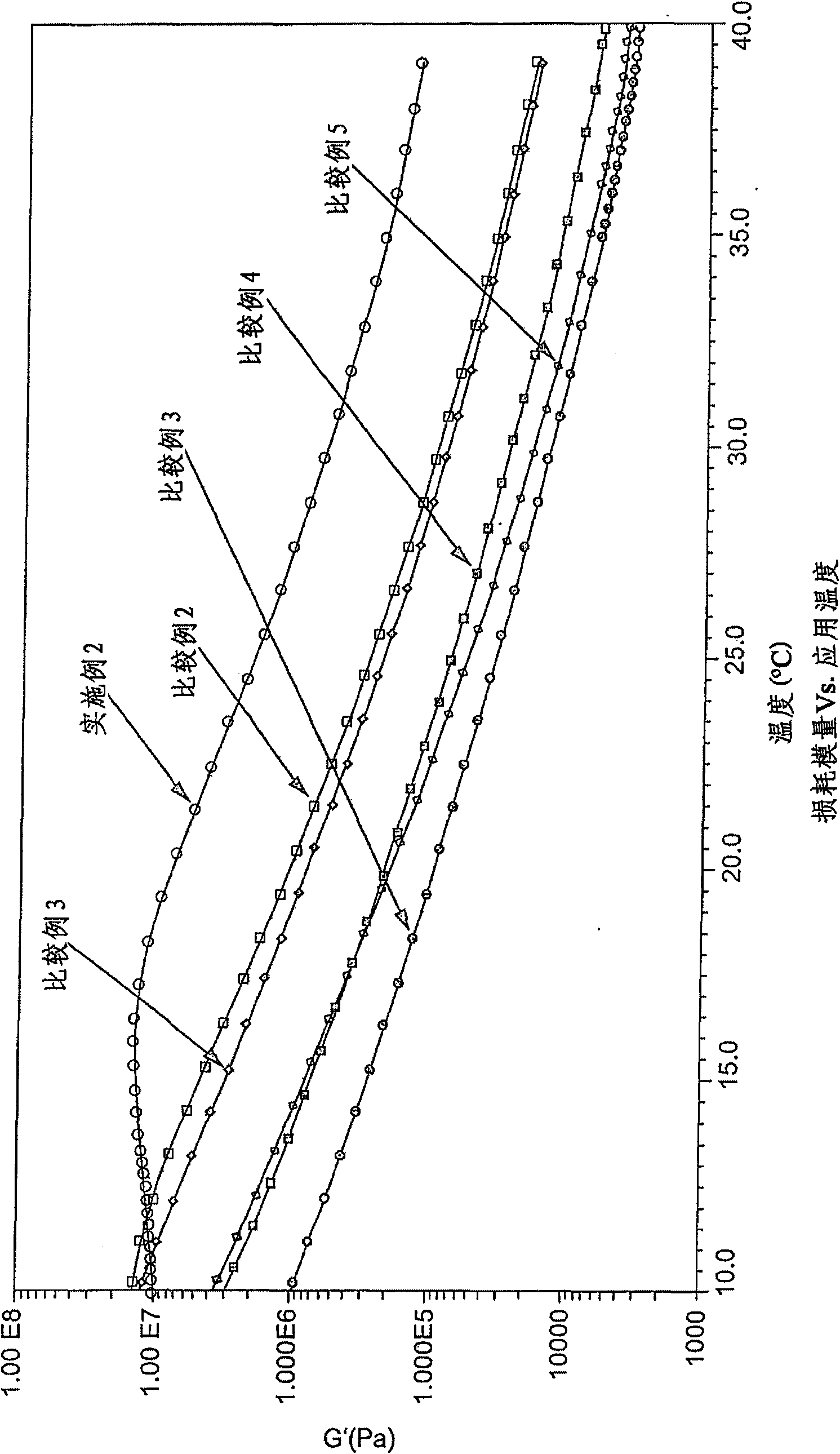

InactiveCN102066469AHigh stiffnessReduce stickinessCoatingsRoom temperatureFiber-reinforced composite

A prepreg for manufacturing a fibre-reinforced composite material, the prepreg comprising a layer of a layer of fibrous reinforcement fully impregnated by a matrix resin material, wherein at least the surface of the resin material has a viscosity and a tack at room temperature, and each prepreg has a stiffness at room temperature, such that when two of the prepregs are disposed as a vertical stack thereof at room temperature with adjacent resin material surfaces, the adjacent resin material surfaces are unadhered and form continuous air paths therebetween.

Owner:GURIT (UK) LTD

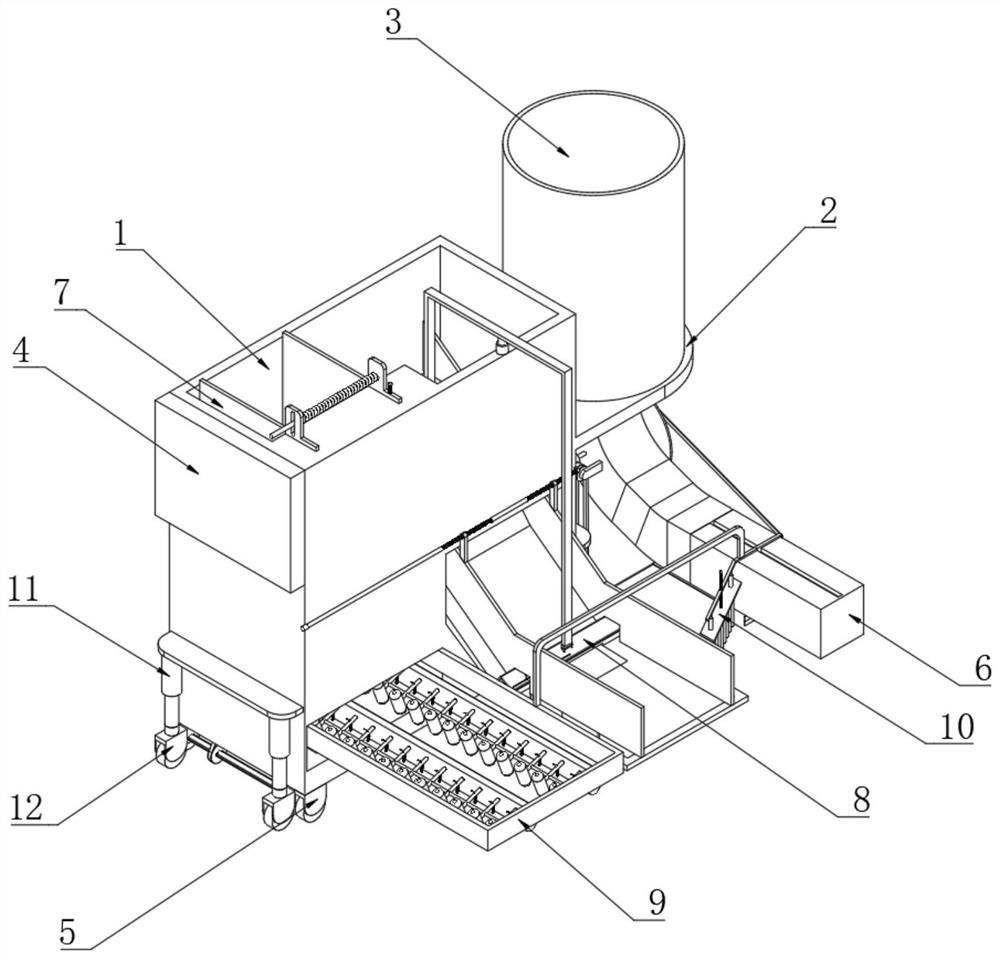

Ditching and pipe distributing device for burying subsurface drip irrigation pipes

InactiveCN105464161AShorten laying timeReduce cost inputSoil-shifting machines/dredgersSubsurface irrigationIntegrated operations

The invention relates to the technical field of agricultural machines, in particular to a ditching and pipe distributing device for burying subsurface drip irrigation pipes. The ditching and pipe distributing device for burying the subsurface drip irrigation pipes comprises a rack, ditching plow assemblies, soil covering and pressing assemblies and pipe distributing assemblies, wherein the ditching plow assemblies, the soil covering and pressing assemblies and the pipe distributing assemblies are arranged on the rack. The pipe distributing assemblies are used for laying the drip irrigation pipes in ditches formed through the ditching plow assemblies, and the soil covering and pressing assemblies are located behind the ditching plow assemblies and used for burying the drip irrigation pipes in the ditches formed through the ditching plow assemblies. According to the ditching and pipe distributing device for burying the subsurface drip irrigation pipes, ditching, pipe distributing, burying, soil covering, pressing and other operation for the subsurface drip irrigation pipes are integrated, integrated operation is achieved, pipe distributing operation is carried out without manual operation, the mechanization degree and the automation degree are higher, the labor intensity for subsurface drip irrigation pipe laying can be lowered, and therefore laying time for the subsurface drip irrigation pipes is substantially shortened, laying efficiency of the subsurface drip irrigation pipes is improved, and engineering cost input for a subsurface drip irrigation system is reduced.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

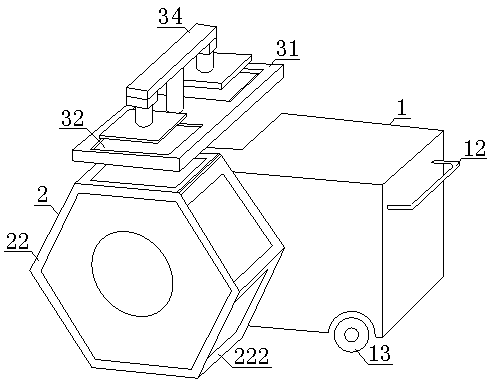

Automatic control device for water transfer printing process

ActiveCN111483216AAvoid wastingGuaranteed to be correctTransfer printingAutomatic controlProcess engineering

The invention discloses an automatic control device for a water transfer printing process. The automatic control device for the water transfer printing process comprises a water tank, multiple membrane slag treatment devices arranged in the water tank, a membrane laying device arranged above the water tank, a sprinkler arranged above the membrane laying device, a fluid supplementation device arranged on the side part of the water tank, a conveying device arranged on the side part of the fluid supplementation device, and multiple water transfer printing devices arranged above the conveying device. Each water transfer printing device comprises a rotating mechanism and a water entry mechanism; each water entry mechanism comprises a telescopic piece, a fixed rod arranged under the telescopic piece, multiple fan blades equidistantly distributed on the side wall of the fixed rod along the circumferential direction of the fixed rod, and a fixture arranged under the fixed rod; each fan blade is provided with five faces; the upper bottom faces, the rear side faces and the right side faces are planes and are perpendicular in pairs; the left side faces are inclined faces; and the front side faces are curved faces. According to the automatic control device for the water transfer printing process provided by the invention, through arranging the water transfer printing devices, the automation of the water transfer printing process is realized, so that the production efficiency is improved.

Owner:明德新材料科技(浙江)股份有限公司

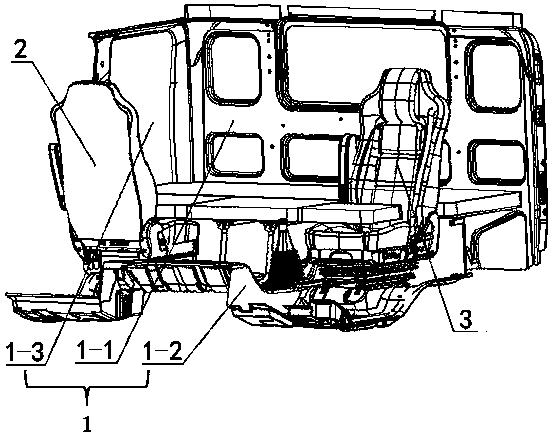

Commercial vehicle sleeper

PendingCN110182116AShorten laying timeImprove liveabilityVehicle arrangementsLoading-carrying vehicle superstructuresEngineeringCommercial vehicle

The invention discloses a commercial vehicle bed, and relates to the technical field of commercial vehicle manufacturing. The sleeper comprises a seat and a main sleeping berth plate, wherein the seatis a rotary seat, the rotary seat is provided with a seat body and a rotating unit arranged under the seat body, the rotating unit is connected with a mobile unit, the main sleeping berth plate is hinged to the rear wall of a cab, an auxiliary sleeping berth plate is hinged to the bottom surface of the main sleeping berth board, and a plurality of movable supports are hinged to the auxiliary sleeping berth plate; and a supporting frame which penetrates through the auxiliary sleeping berth plate to abut against the main sleeping berth plate is arranged on the cab floor, and an air supporting hydraulic rod which is used for assisting in supporting of the main sleeping berth plate is arranged on the supporting frame. Compared with the prior art, the sleeper can solve the problem that an existing commercial vehicle sleeper is narrow in effective width and difficult in article storing and taking.

Owner:DONGFENG LIUZHOU MOTOR

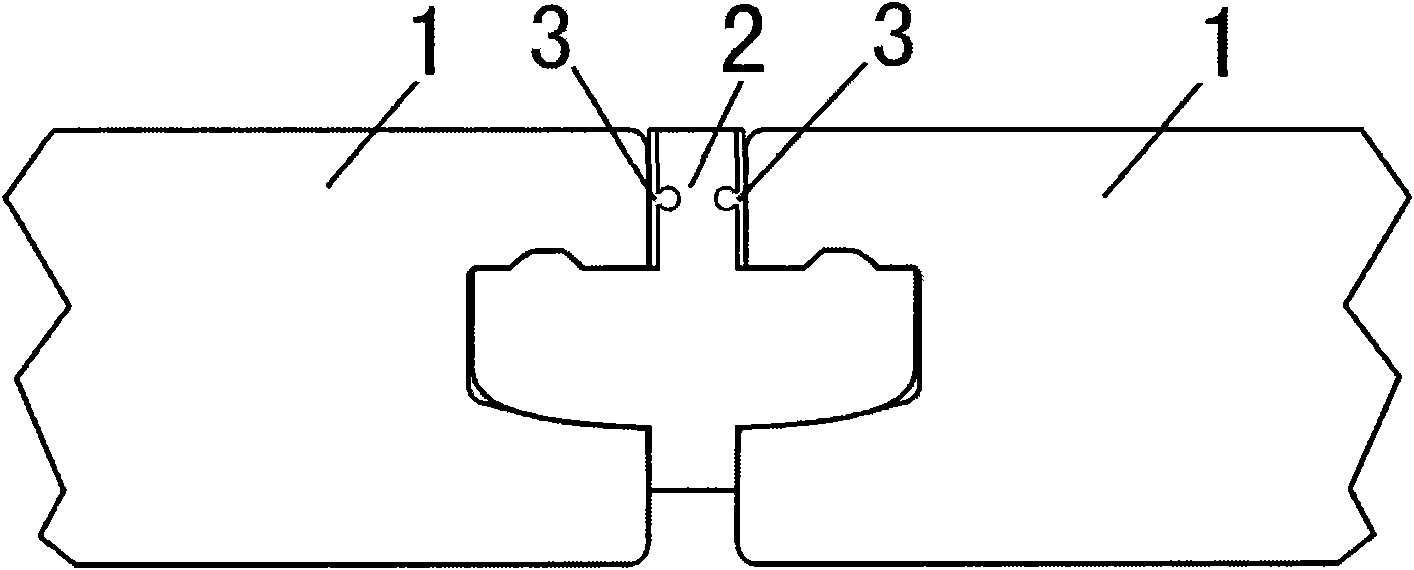

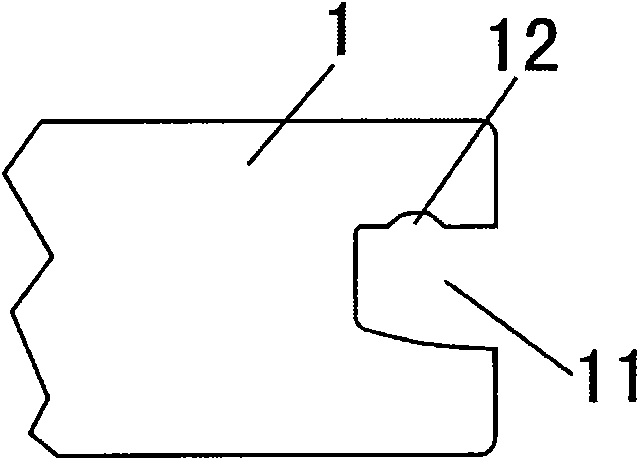

Waterproof composite floor connected by decoration strips

InactiveCN101781924AGood waterproof effectEasy to installBuilding insulationsFlooring insulationsEngineeringMechanical engineering

The invention discloses a waterproof composite floor connected by decoration strips, comprising a floor (1), the decoration strips (2) and waterproof strips (3). The side face of the floor (1) is provided with a groove (11), the side face of each decoration strip (2) is provided with a tenon strip (21) matched with the groove (11), the end face at the top of the decoration strip (2) exposes the surface of the composite floor, an installation slot for installing each waterproof strip (3) is arranged on each decoration strip (2), a convex strip (31) for being clipped into the installation slot is arranged on the side face of each waterproof strip (3) and the cross section of the convex strip (31) is round; and each waterproof strip (3) is located between the floor (1) and each decoration strip (2) and is made of soft waterproof material such as a soft silicon rubber strip and a soft rubber strip. The invention has favorable waterproof effect, long service life, convenient flooring, wood saving and favorable decorative effect and is particularly suitable for laminate flooring products.

Owner:MAC DOUGLAS WOOD FLOORING SUZHOU

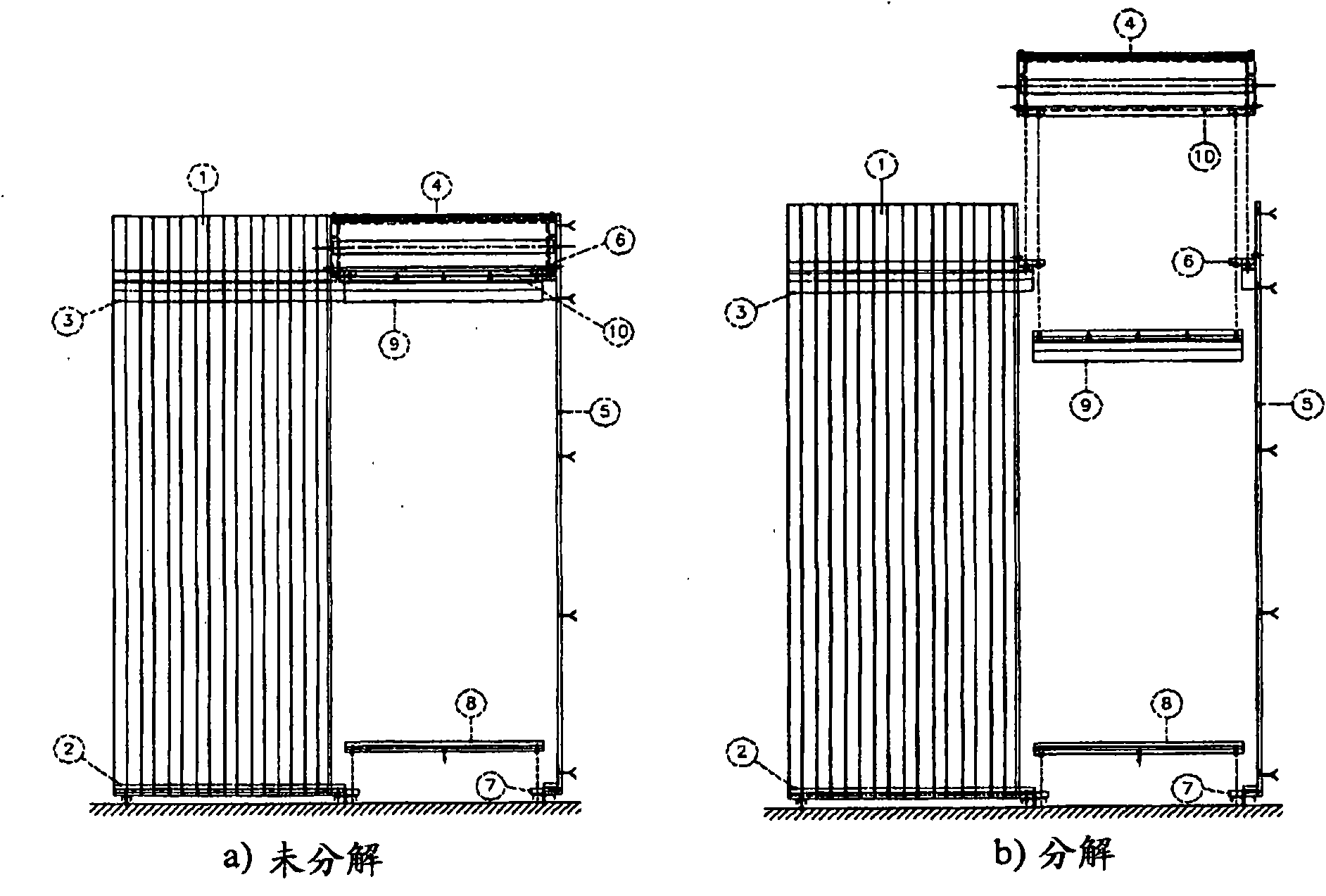

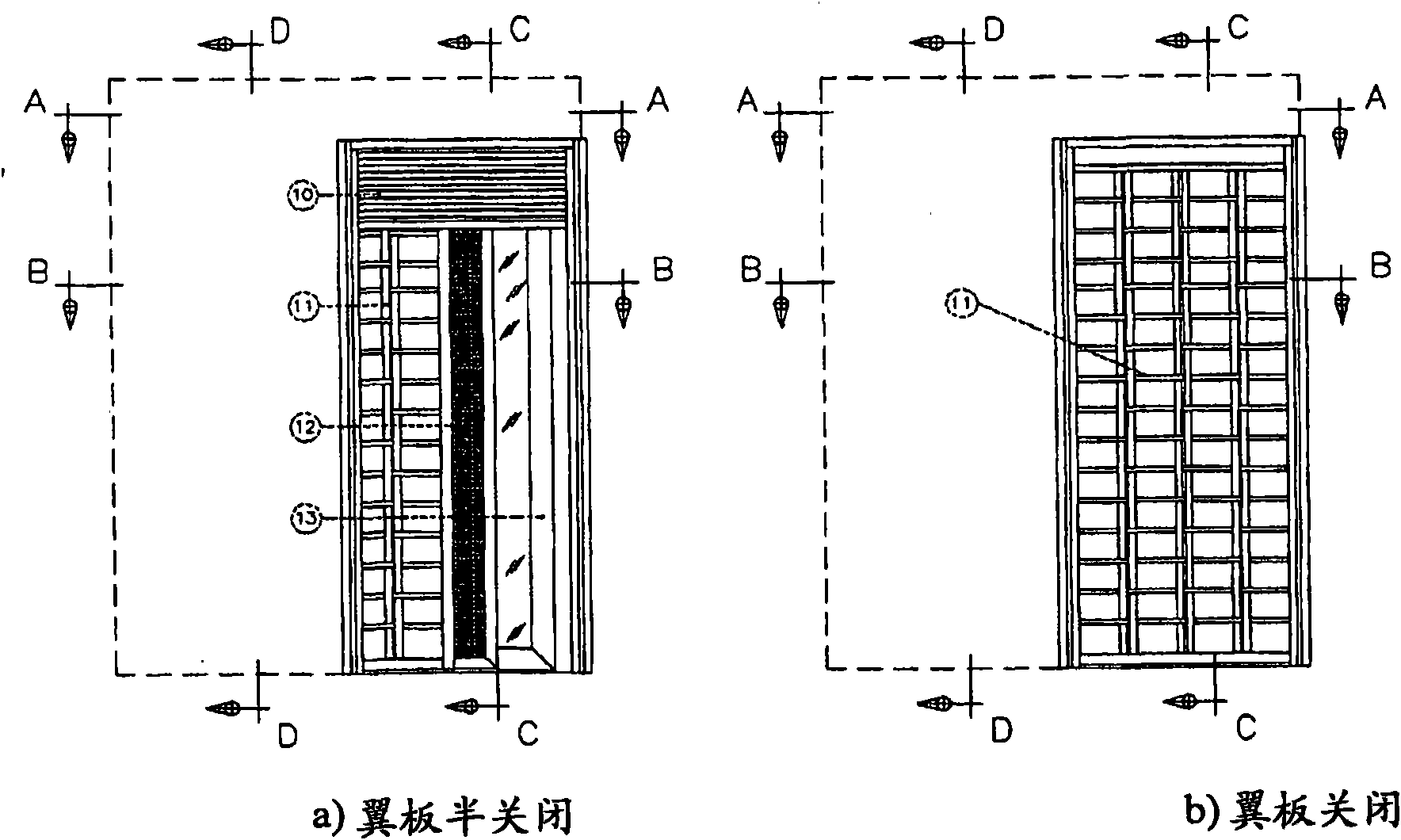

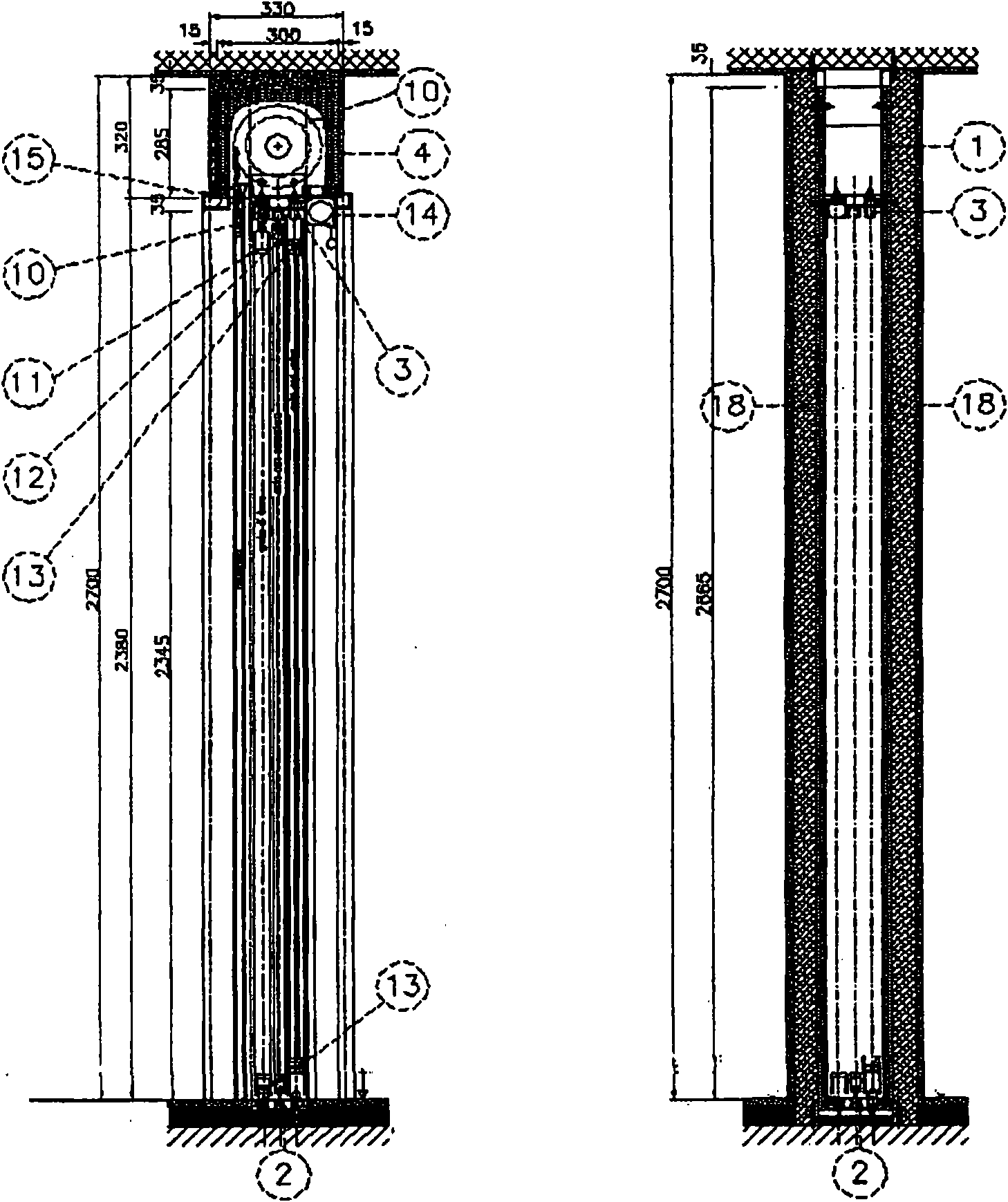

Housing integrated in a wall for receiving sliding doors or windows

InactiveCN101680263AConsistent installationPrevent infiltrationShutters/ movable grillesInsect protectionTotal thicknessRolling shutter

The invention provides a housing integrated in a wall for receiving sliding doors or windows, which comprises a non-conducting box. The housing is mounted in line with the conventional external perimeter masonry. The top of the non-conducting box is attached to the soffit of a floor and is connected with the bottom of a self-bearing wall through a sill in metallic profile. The top of the self-bearing wall is connected with the housing through a guide track. One end of the metallic profile sill is provided with a U-bolt for the connection of the self-propelled sill profile. The top guide track is connected with the self-propelled profile in the passage space. A shutter box (4) contains the winding of the external screen on a roller, which is also formed from two insulating walls and has a minimum total thickness of 30 cm. The housing also comprises a single upright, opposite the non-conducting box, for defining the passage space is made with metallic profile, suitably shaped, a minimum of 30 cm deep and equipped at the ends with a top U-bolt and with a bottom U-bolt. The top U-bolt is used for connection to the non-conducting rolling shutter box and to the tail U-bolt of the top guide track, whereas the bottom U-bolt is used for the fixed connection of the self-propelled sill profile of the passage space.

Owner:马里奥·科莱拉

Construction method of black film biogas slurry pool

InactiveCN110306650AExtended service lifeImprove crack resistanceCesspoolsGeneral water supply conservationPipeflowButt joint

The invention relates to a construction method of a black film biogas slurry pool. The construction conditions of a construction site are firstly surveyed, the construction manner is confirmed, and construction machines are selected; a dam base is excavated, backfilling of a dam is carried out, an anchoring trench is dug, and the biogas slurry pool is formed; pipelines are laid in the biogas slurry pool and are subjected to hot-melting butt joint; geogrids are laid on the wall and the bottom of the biogas slurry pool, and grey cakes are arranged on the lower portions of the geogrids; after concrete at the bottom of the biogas slurry pool is poured, concrete on the wall of the biogas slurry pool is poured; polyethylene films are selected as films, film layout design is reasonably planned through the CAD technology, and the anti-seepage films are cut; the films are laid in the biogas slurry pool, and dual-rail hot-melting welding equipment is selected for carrying out hot-melting weldingon the films; and finally the hot-melting performance of the films is checked. By means of the method, the construction period can be shortened, the construction quality and the anti-seepage effect of the black film biogas slurry pool can be improved, and the service life of the black film biogas slurry pool is prolonged. The method is suitable for sewage storage project construction of large andmedium-sized sewage treatment works, farms and the like.

Owner:SHANXI WUJIAN GRP CO LTD

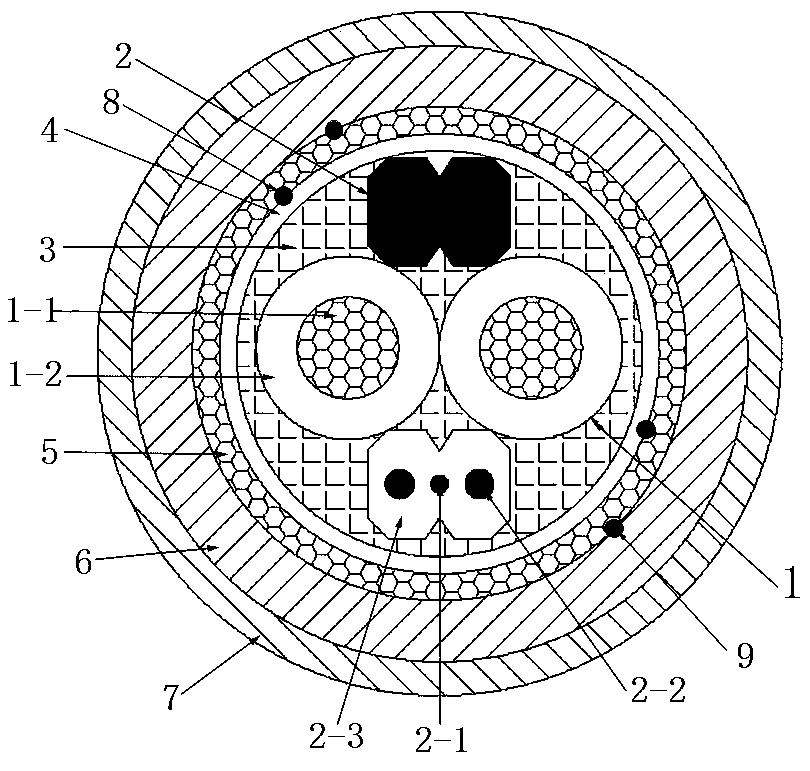

Rat-proof and termite-proof photoelectric hybrid cable for reinforced 5G wireless communication small base station

PendingCN110853807AStable structureReduce volumePlastic/resin/waxes insulatorsPower cables with screens/conductive layersLow smoke zero halogenYarn

The invention discloses a rat-proof and termite-proof photoelectric hybrid cable for a reinforced 5G wireless communication small base station. Two electric cables are arranged in parallel on the leftand right. Two optical cables are symmetrically arranged on the upper and lower sides of the middle parts of the two electric cables. A wrapping tape wraps the outer sides of the electric cables andthe optical cables. A filler, which is a filling rope, fills the gap between the inner side of the wrapping tape and the outer sides of the electric cables and the optical cables. A shielding layer, asheath and an outer coating layer sequentially wrap the outer side of the wrapping tape. Binding yarns are embedded between the wrapping tape and the filler or between the wrapping tape and the shielding layer. Tearing ropes are embedded between the shielding layer and the sheath or between the wrapping tape and the shielding layer. According to the invention, the optical cables and the electriccables are distributed crosswise. The cable core structure of the hybrid cable is stable. The optical cables are butterfly-shaped optical cables which can be connected into a house easily. The outer protective layer, the insulating layer and the sheath are all made of low-smoke halogen-free polyolefin and have good flame-retardant and anti-electromagnetic interference performances. The roundness of the hybrid cable is effectively guaranteed through the binding yarns and the filler. The sheath can be effectively torn through the symmetrical tearing ropes. The nylon outer coating layer can improve the pressure resistance and the abrasion resistance and prevent damage by mice and ants.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

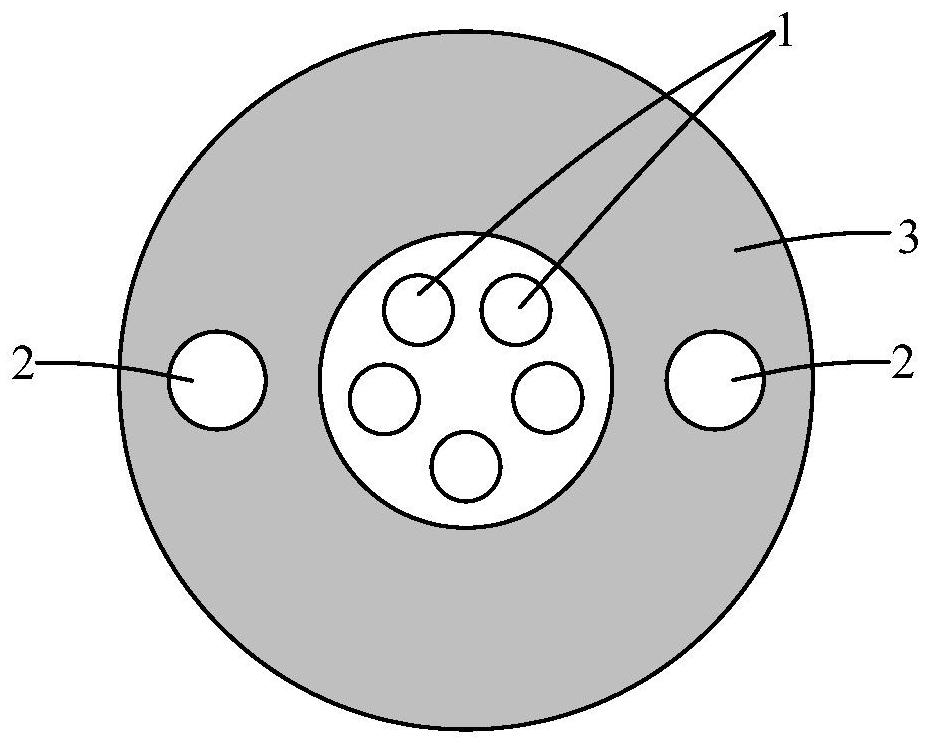

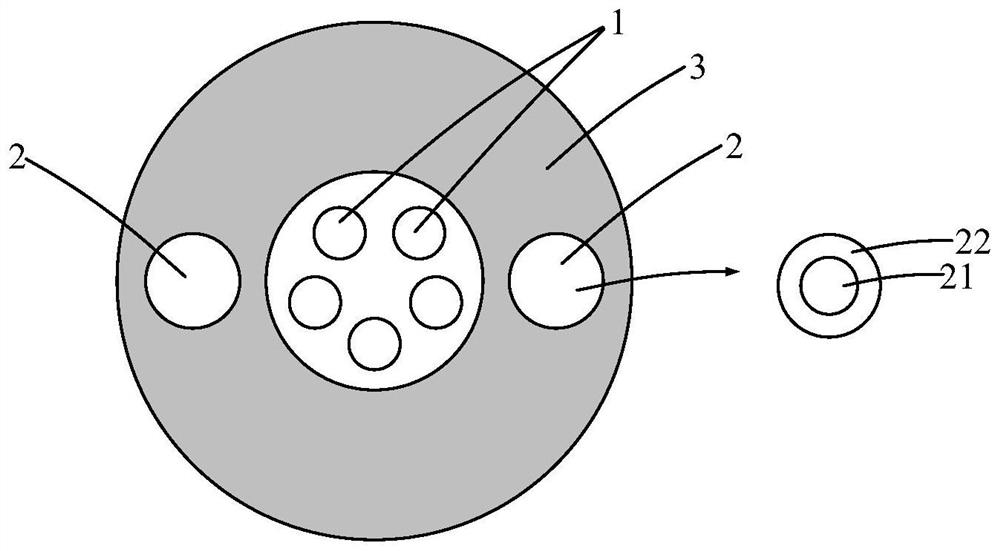

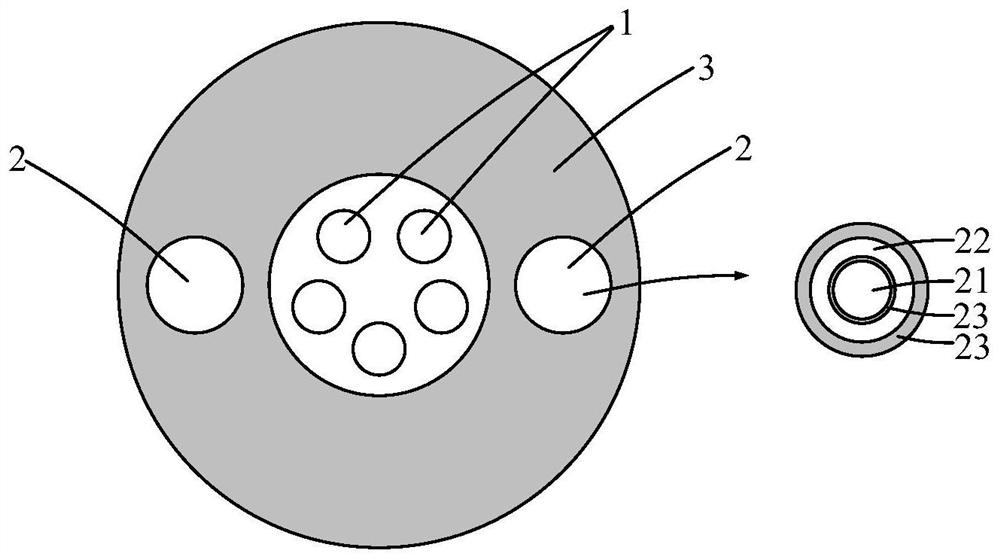

Optical cable

ActiveCN112731603AIncrease elasticityGood bending resilienceFibre mechanical structuresYoung's modulusBend radius

The invention discloses an optical cable, and belongs to the technical field of optical cable laying. The optical cable comprises an optical fiber, at least one reinforcing rod and an outer sheath, wherein the optical fiber and the at least one reinforcing rod are located in the outer sheath; the Young modulus of the reinforcing rod is greater than 53 GPa, the bending radius of the reinforcing rod is less than 26 D, the straightness returning degree of the reinforcing rod is greater than 80%, the straightness returning degree is the degree that the reinforcing rod returns to a straight rod after being bent, and D is the diameter of the reinforcing rod. With the adoption of the application, the reinforcing rod with the mechanical property is used as a reinforcing piece of the optical cable, so that the optical cable has good tensile elasticity and good bending resilience, so that the optical cable can be applied to overhead laying and can also be applied to pipeline laying. Therefore, in optical cable laying, especially in an alternating laying mode of overhead laying and pipeline laying, the optical cable does not need to be replaced, the optical cable laying time can be saved, and the optical cable laying efficiency is improved.

Owner:HUAWEI TECH CO LTD

Floor tile laying device for building construction

PendingCN113585684AScientific and reasonable structureSafe to useBuilding constructionsCement MaterialArchitectural engineering

The invention discloses a floor tile laying device for building construction. The floor tile laying device comprises a loading box, a rectangular plate is installed at one end of the loading box through screws, a feeding cylinder is fixedly installed at the top end of the rectangular plate, a storage battery is fixedly installed at one end of the loading box, and directional wheels are evenly installed at the bottom end of the loading box; a continuous synchronous type discharging and paving assembly is installed at the bottom end of the feeding cylinder and is formed by combining a leveling plate, a sealing plate, a first belt transmission mechanism used for driving the leveling plate, a driving rod, a rectangular rod, a rotating blade with a discharging blocking function, a driving plate and a blocking plate. According to the floor tile laying device for building construction, cement can be guided and conveyed in the walking process, the problems that a large amount of cement falls off and too much cement is accumulated are solved, discharging is conducted through movement of the floor tile laying device for building construction, cement discharging continuity is achieved, floor tiles can be better attached, and the purpose that cement laying is stopped immediately is achieved; the cement laying effect is guaranteed, and meanwhile cement waste can be avoided.

Owner:田静

Indoor ceramic tile laying device for building

InactiveCN111305526AHigh degree of mechanizationAvoid damageBuilding constructionsRotational axisMaterials science

The invention discloses an indoor ceramic tile laying device for a building. The indoor ceramic tile laying device comprises a moving box, a laying mechanism and a tile taking mechanism. A pushing handle is pushed by people to enable the whole device to generate displacement, and ceramic tiles which are not laid are placed in a ceramic tile placing groove. Lifting rods descend to absorb the ceramic tiles through suction cups, and then the lifting rods are retracted and ascend to the initial position. A supporting column drives a cross beam to rotate, and at the moment, the positions of the twosets of lifting rods are exchanged. The lifting rods without the ceramic tiles repeat the actions, and the lifting rods with the ceramic tiles descend again to lower the ceramic tiles into a ceramictile placing frame. The ceramic tiles are adsorbed for a short time through ceramic tile adsorption strips, and a rotating shaft drives an automatic laying device to rotate. When the ceramic tile placing frame absorbed with the ceramic tiles rotates to the bottommost layer, the ceramic tiles fall due to gravity. The above operation is repeated to complete the whole laying process. The mechanization degree is high, damage possibly caused in the manual carrying and ceramic tile laying process is avoided, the laying time is saved, the cost is saved, and the laying efficiency is improved.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Construction method for strengthening track crane

InactiveCN104912003ASimple structureShorten laying timeTemporary pavingsBridge erection/assemblySUSPENDING VEHICLEIndustrial engineering

The invention provides a construction method for strengthening a track crane. The construction method comprises the following steps: firstly fitting up welding roadbed boxes in a workshop by using hot rolled section steel, then paving the roadbed boxes in place at a construction site through a vehicle crane, and finally assembling the track crane by using the vehicle crane; the step of paving the roadbed boxes comprises the following steps: firstly mounting a main engine of the track crane, then mounting tracks on two sides, mounting a balance weight block, mounting a rod, finally threading a steel rope and mounting a lifting hook. After the track crane is completed, the lifting operation can be officially started after an acceptance check is qualified, the track crane runs on the roadbed boxes during the lifting operation of the track crane, and the track crane can lift a roadbed box at the rear part of the track crane to the front part of the track crane, so that long-distance forward running operation is completed; according to the construction method for strengthening the track crane, the length of a roadbed box is at least larger than a distance between supports of a girder through paving the roadbed boxes, so that weight of the roadbed boxes and the weight of the track crane are applied to the supports of the girder; besides according to the track crane, the roadbed boxes can be paved on a running route of the track crane, so that the paving time is shortened, and the construction progress is accelerated.

Owner:ZHEJIANG BADA CONSTR GRP

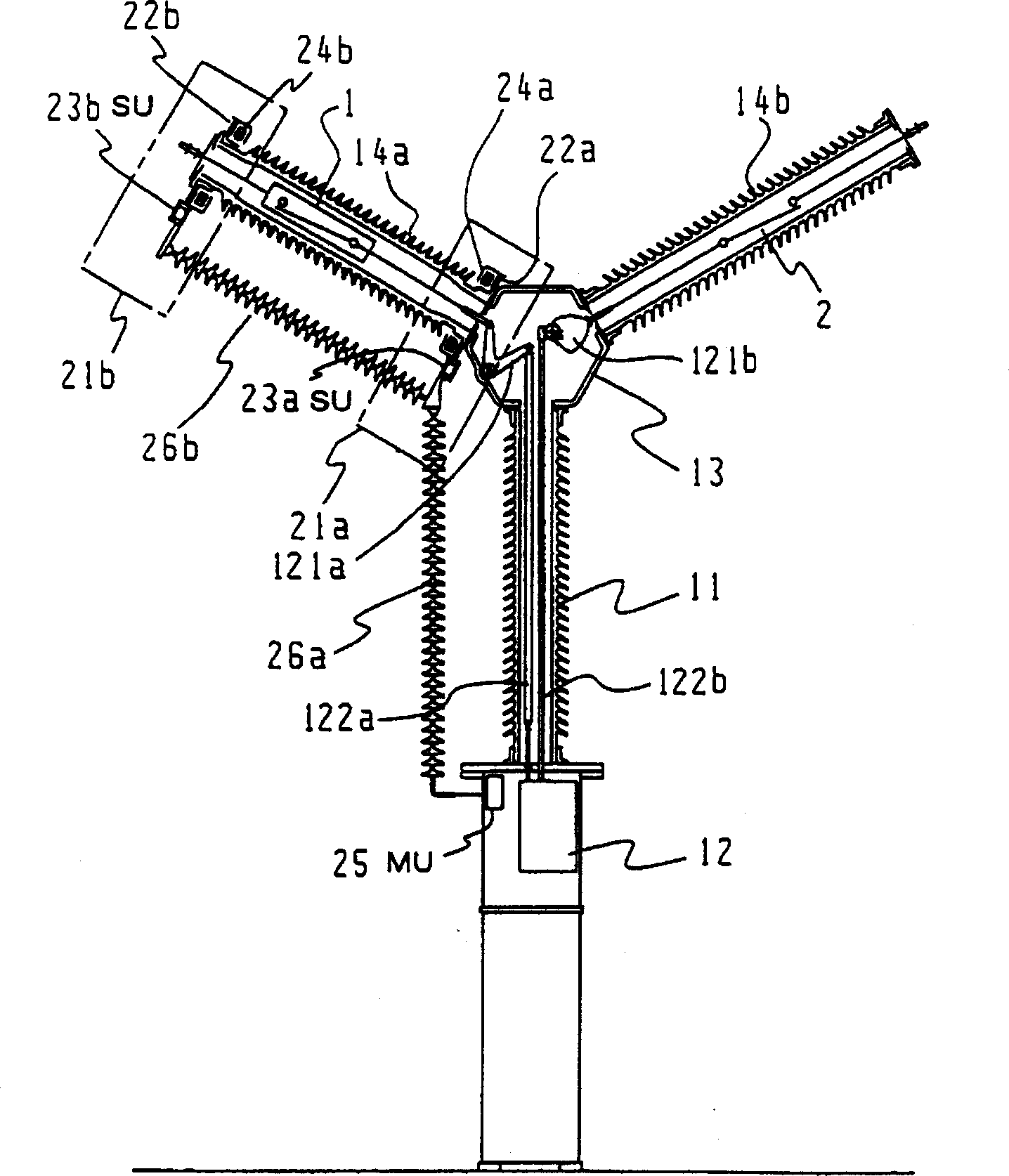

Current transformer used on composite type gas insulation switch

InactiveCN1353487AIncreased Design FreedomSmall output powerElectric signal transmission systemsVoltage/current isolationEngineeringSwitchgear

The present invention provides a current transformer for a compound-type gas-insulated switchgear which can be arranged on either side of a circuit-breaker. To the lower end of an insulating support structure 11, an operating apparatus 12 is connected, and to the upper end a metal container 13 is connected. To the upper part of the metal container 13, a first ceramic bushing 14a, in which a circuit-breaker 1 is housed and a second porcelain bushing 14b in which a disconnector 2 is housed, are connected. The circuit- breaker 1 and the disconnector 2 are opening / closing-operated by the operating apparatus 12. Current transformers 21a, 21b are set at both ends of the ceramic bushing 14a. The current transformers 21a, 21b are composed of current detect means 22a, 22b, sensor units 23a, 23b, power-feeding current transformers 25a, 24b and an integrating unit 25. The integrating unit is set in a housing part for the operating apparatus, and the sensor units 23a, 23b and integrating unit are connected to each other with insulators 26a, 26b which house optical fibers.

Owner:KK TOSHIBA

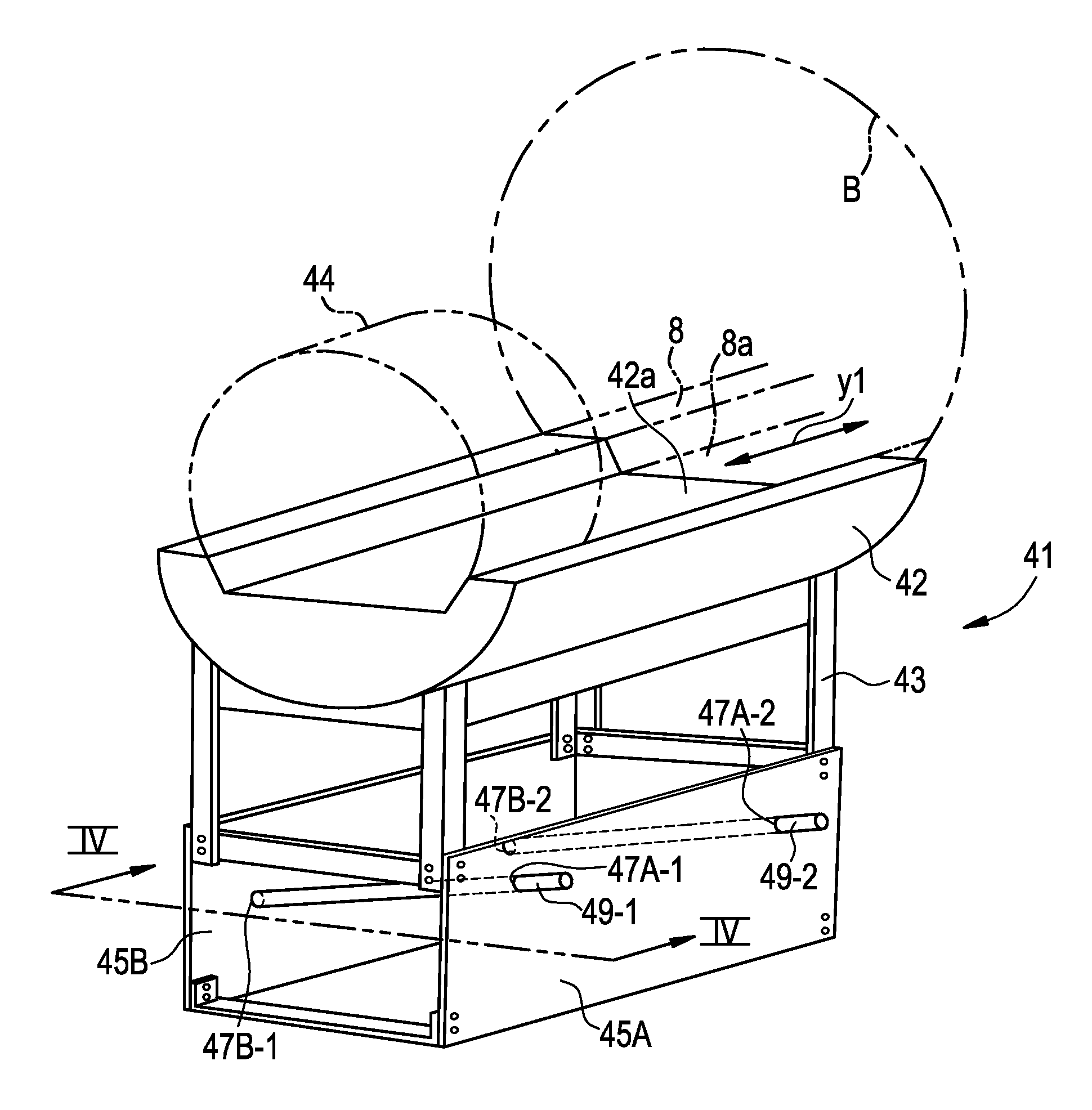

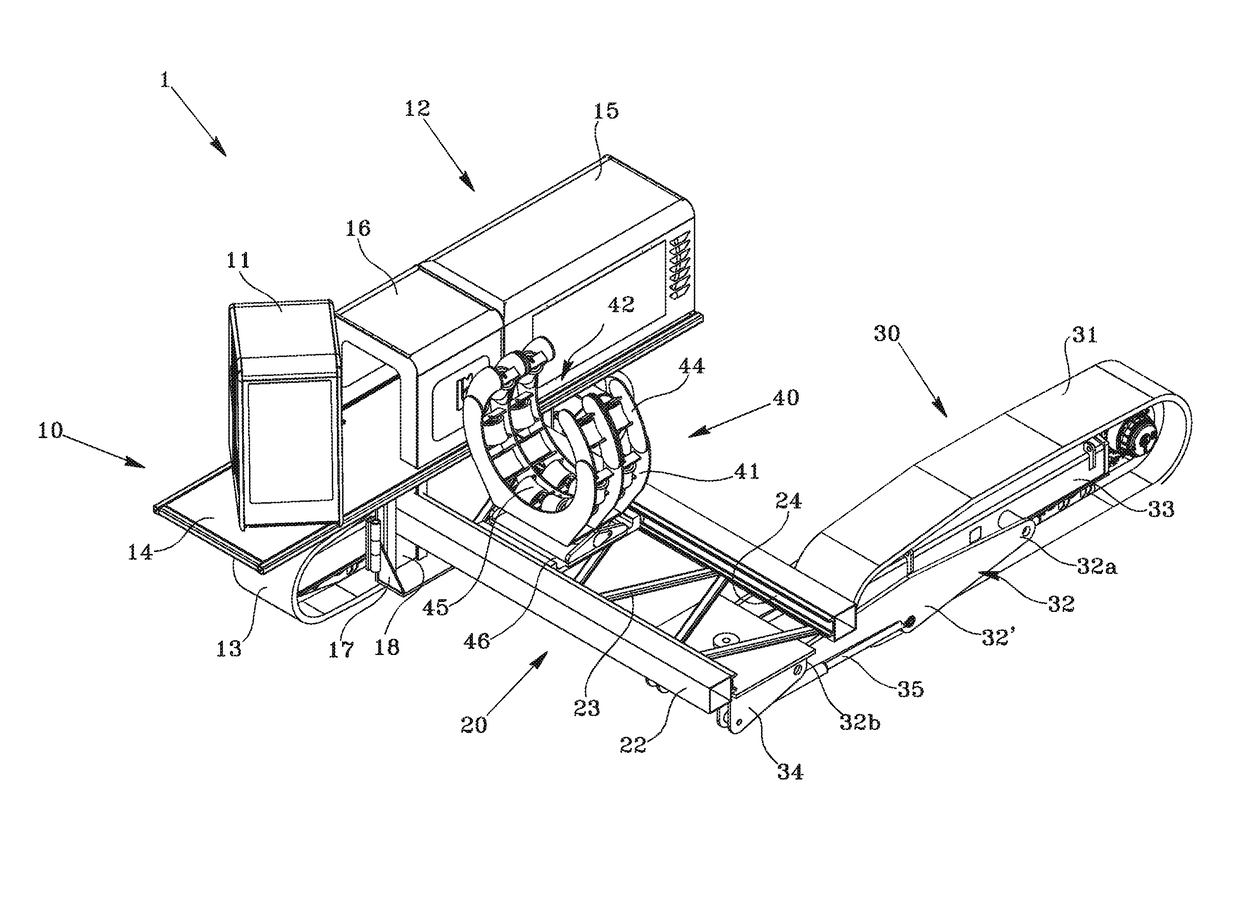

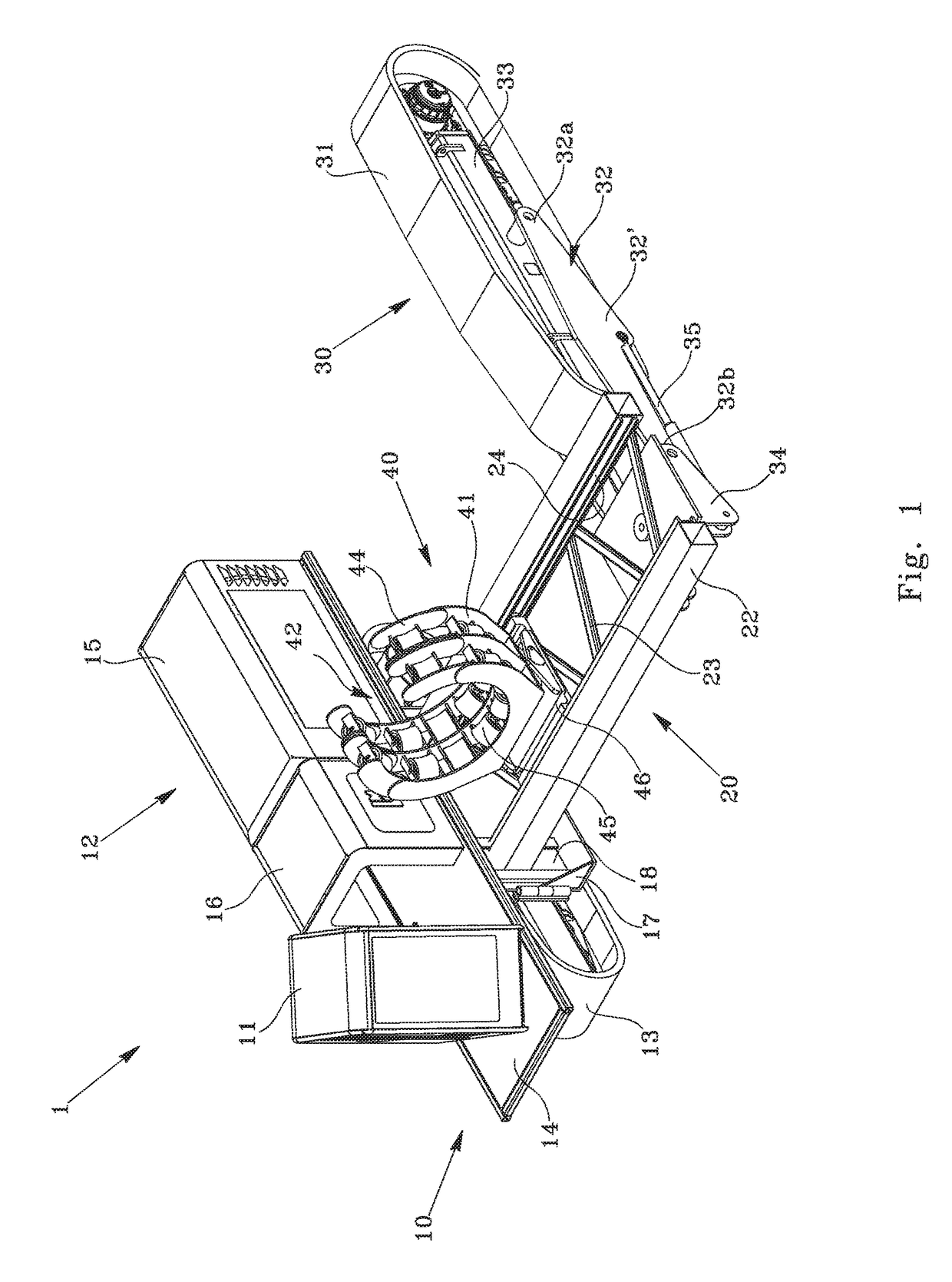

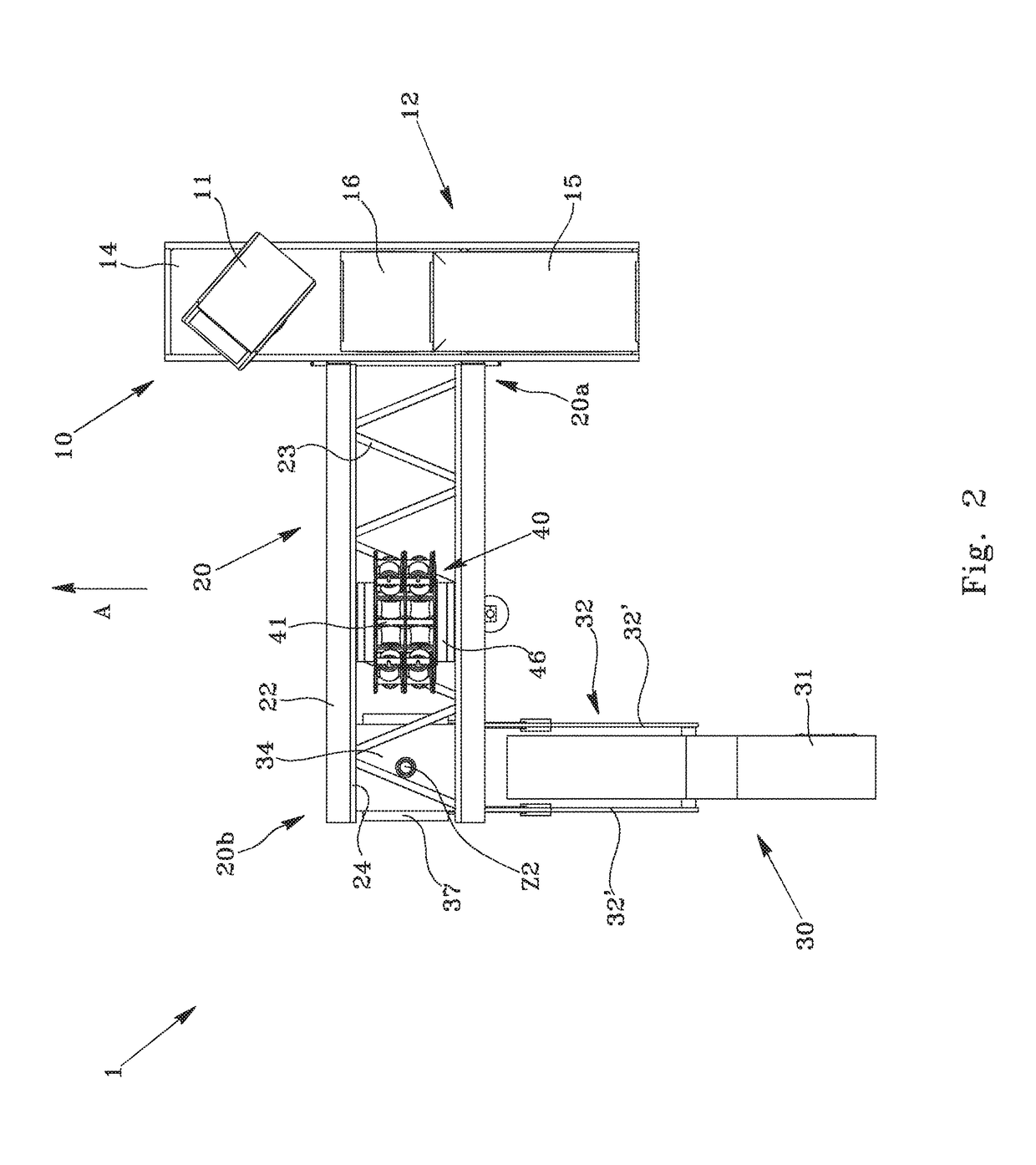

Pipe laying machine and pipe laying method

InactiveUS9746103B2Simplified managementEasy to controlPipe laying and repairSoil-shifting machines/dredgersPowertrainChassis

A pipe laying machine for laying a pipe in a trench, includes a first self-propelled chassis (10) on which a driver's cab (11) and powertrain (12) are located, a beam (20) connected at a first end (20a) to the chassis and which extends laterally therefrom, a second moving chassis (30) connected at a second end (20b) of the beam and a guiding and supporting element (40) of a pipe, sliding on the beam toward and away from the self-propelled chassis, in which the self-propelled chassis can travel on a track (P) at the edge of the trench, the moving chassis (30) can travel on the bottom of the trench, and the guiding and supporting element can translate to carry the pipe to the trench so that by moving the machine forward along a direction of forward movement the cantilevered portion of pipe is laid on the bottom of the trench.

Owner:LAURINI OFF MEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com