Optical cable

An optical cable and optical fiber technology, applied in optical cable. It can solve problems such as low efficiency of optical cable laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

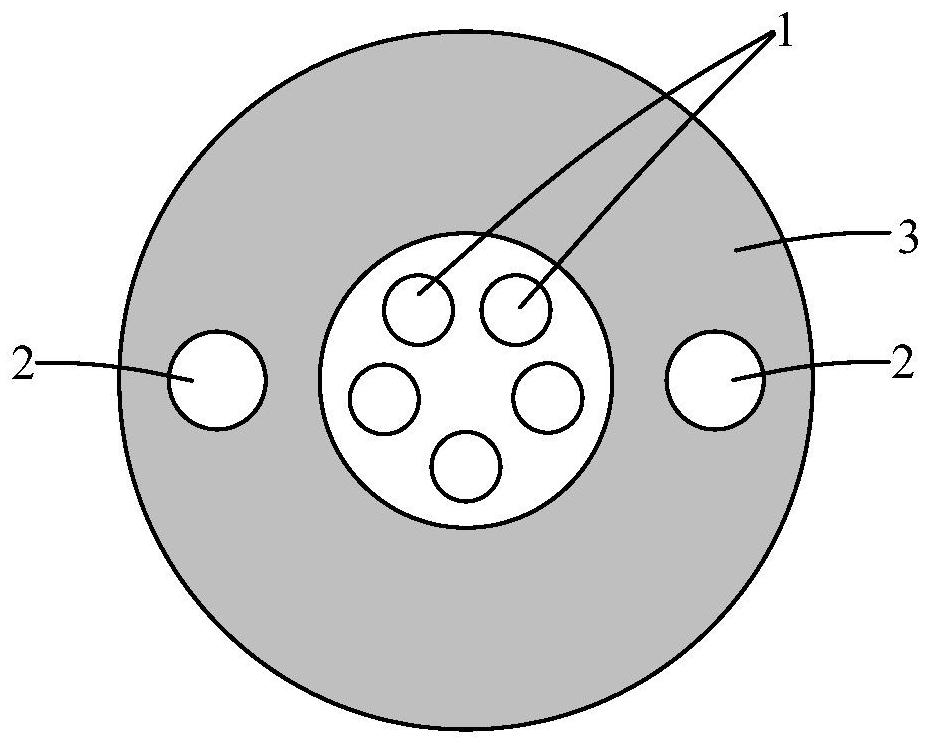

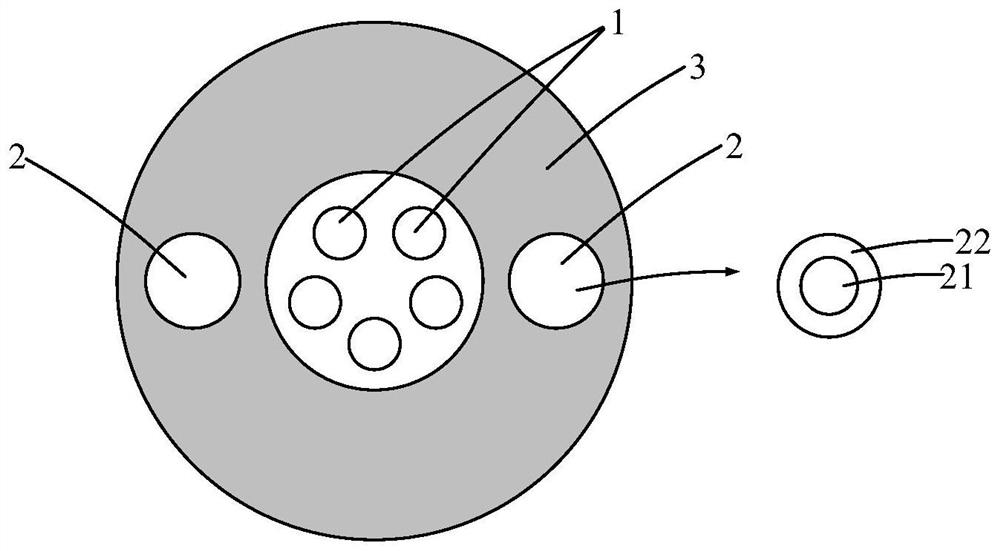

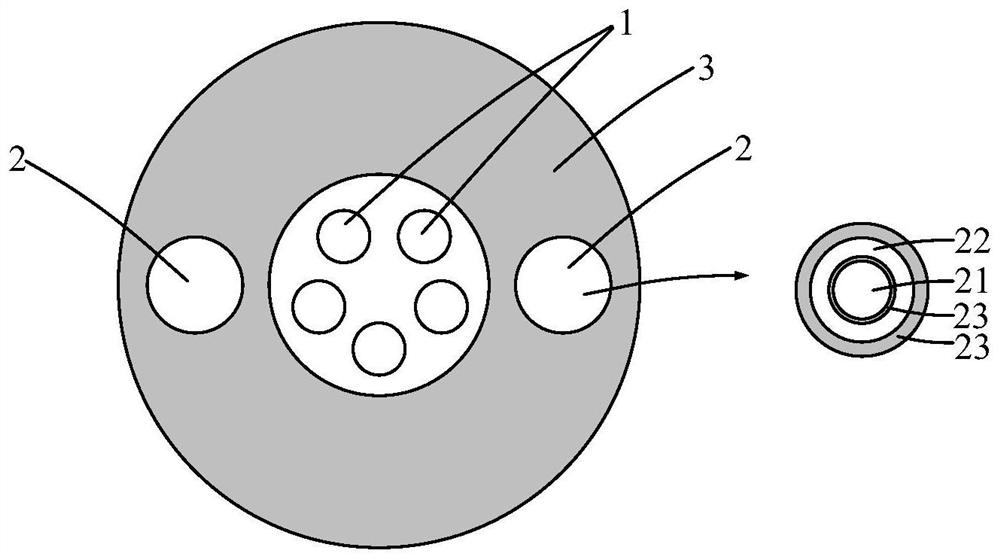

[0059] like figure 1 As shown, the optical cable may include an optical fiber 1 , at least one reinforcing rod 2 and an outer sheath 3 , and both the optical fiber 1 and the at least one reinforcing rod 2 are located in the outer sheath 3 .

[0060] The reinforcing rod 2 mostly uses steel wire or glass fiber reinforced plastic (GFRP, Glass Fiber-Reinforced Plastic). Among them, the steel wire is used as the reinforcing rod of the optical cable. The Young's modulus of the steel wire is relatively high, which makes the optical cable have better tensile elasticity. It is used in overhead laying and can resist a certain tensile stress. However, optical cables with steel wires are easy to bend and difficult to straighten after bending, so they are not easy to pass through pipes when they are used in pipe laying, and pipe threaders are needed.

[0061] Glass fiber reinforced plastic is used as the reinforcing rod of the optical cable. Glass fiber reinforced plastic can be bent, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com