Housing integrated in a wall for receiving sliding doors or windows

A technology of screen window and load-bearing structure, applied in the direction of door/window protection device, window/door, wing sash arrangement, etc., can solve the problem of occupying useful space and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

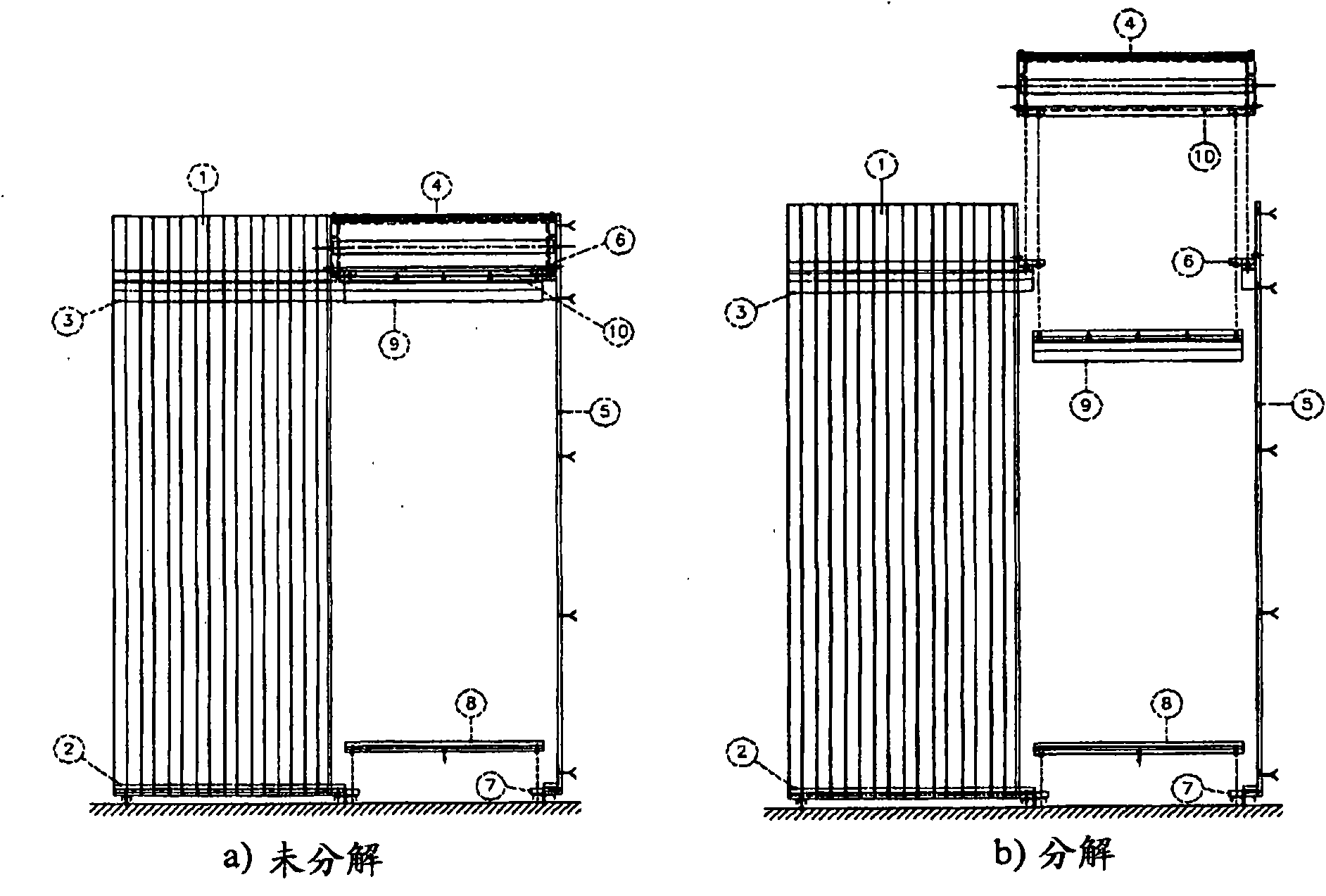

[0017] · figure 1 An assembled view of the non-conductive box is shown in figure a) and figure b), which figure a) is not exploded so that the invention can be seen as a whole from the front, while figure b) is an exploded view, which is useful for identifying the following different Components are useful, such as: non-conductive box 1, a single column 5, the channel or outlet of the column 5 limiting frame; top rail 3, the height of the channel space is limited by the top rail 3, and the self-propelled profile 9 of the top rail is connected to Thereon; a sill 2, in a metal profile, defining the structure of the bottom part, to which a self-propelled bottom or sill profile 8 is attached; a bottom U-bolt 7, to which the sill 2 is fixedly attached on the U-bolt 7; and the top bolt 6 to which the non-conductive roller shutter box 4 is fixedly attached, said shutter box 4 containing the external screen 10 on the upright 5; the other two Supports, the two supports on the non-condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com