Pneumatic pressurizing cradle holding pipe and holding mounting mechanism

A technology of pneumatic pressurization and installation mechanism, applied in spinning machine, textile and papermaking, drafting equipment, etc., can solve the problems of inconsistent installation angle of six-sided twist cradle, cumbersome processing, cumbersome installation procedures, etc. The effect of installing labor intensity, simplifying pressure regulation procedures, and solving pressure regulation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

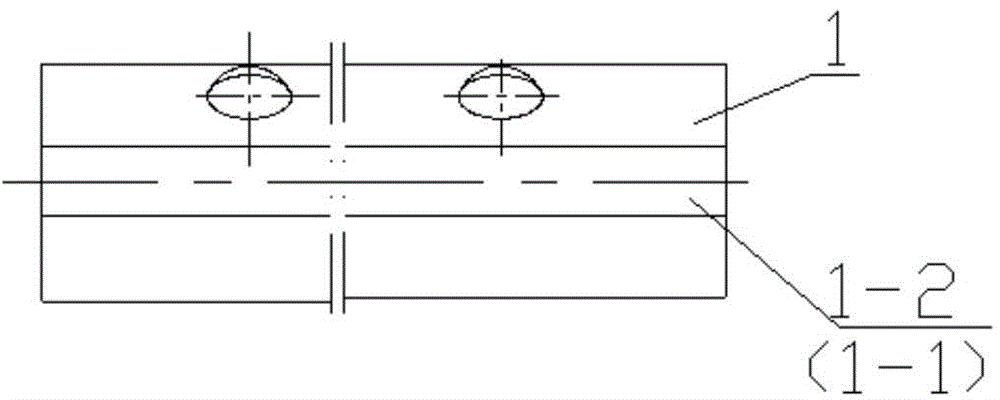

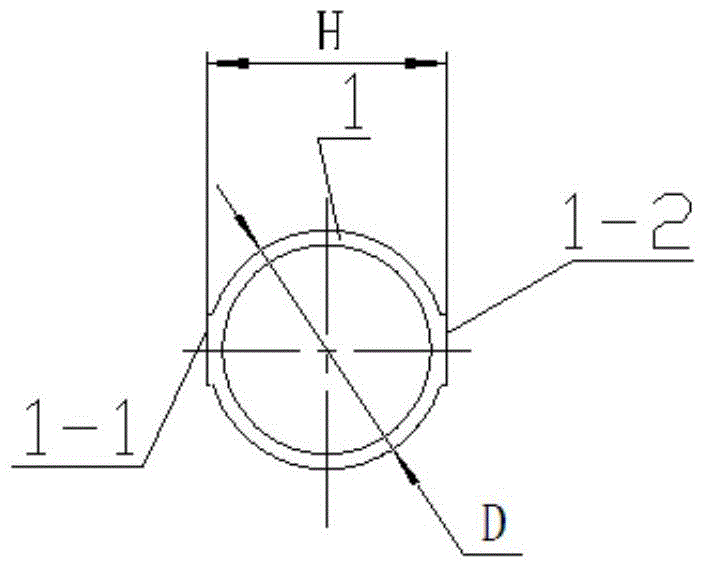

[0020] The pneumatic pressurized cradle holding tube described in this embodiment is as follows: figure 1 , figure 2 As shown, a special-shaped pipe fitting is provided with a left positioning plane 1-1 on the left outer wall of the round pipe and a right positioning plane 1-2 on the right outer wall. The left positioning plane and the right positioning plane are symmetrical to the axis of the special-shaped pipe fitting. The distance H between the positioning plane and the right positioning plane is equal to the outer diameter D of the circular tube forming the holding tube, the left positioning plane and the left side outer wall of the circular tube are integral structures, and the right positioning plane and the outer diameter of the circular tube are The right outer wall is an integrated structure.

Embodiment 2

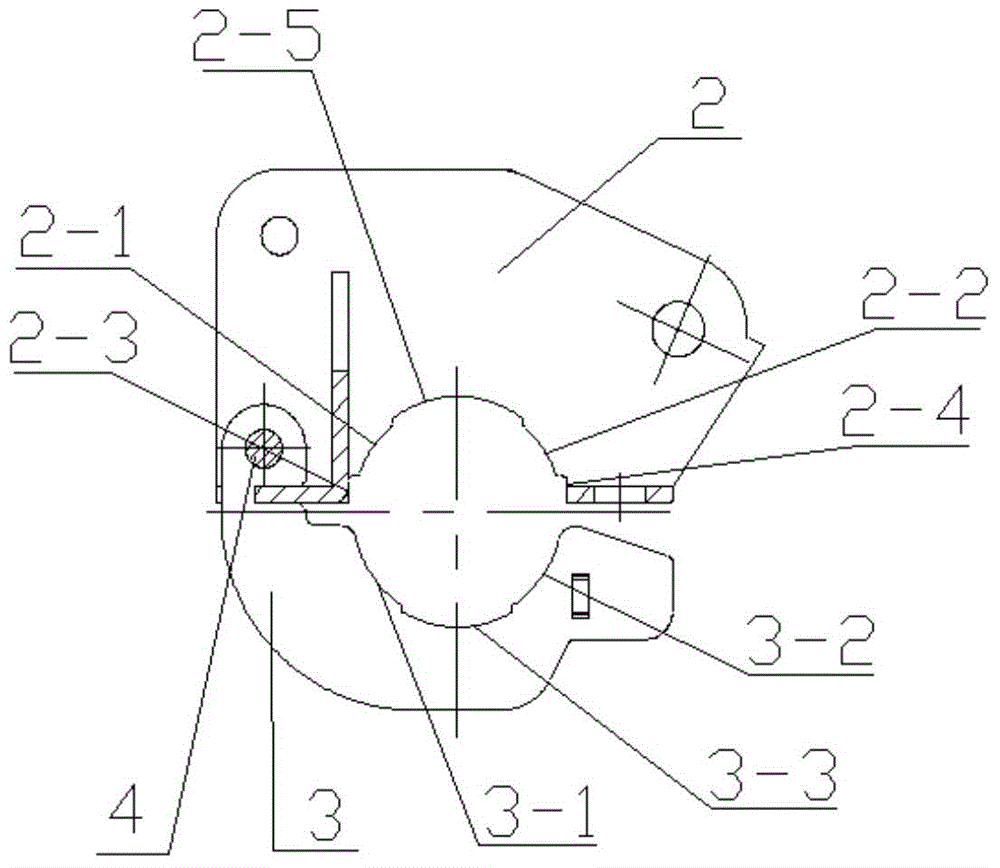

[0022] The grip and installation mechanism of the pneumatic pressurized cradle described in this embodiment is as follows: image 3 , Figure 4 As shown, it includes an upper fixing card 2, a lower fixing card 3 and a holding tube 1. The holding pipe 1 is a special-shaped pipe fitting with the shape and structure described in Embodiment 1; Surrounded by a free arc surface 2-5, a second positioning arc surface 2-2, and a second positioning plane 2-4, the first positioning plane 2-3 and the second positioning plane 2-4 are parallel to each other, between them The distance is equal to the distance H between the left positioning plane 1-1 and the right positioning plane 1-2 of the holding tube, the radius of the first positioning arc 2-1 and the second positioning arc 2-2 are the same and they The radius of is equal to the outer radius of the round tube that forms the holding tube, and the radius of the first free arc surface 2-5 is 1.5mm larger than the outer radius of the roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com