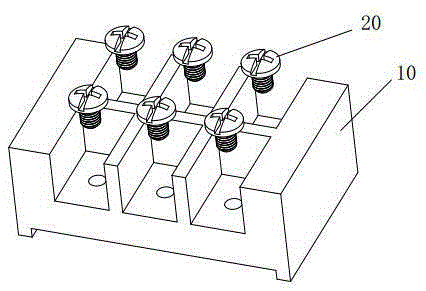

Automatic Screw Screwing Device for Terminal Blocks

A terminal block and screw-tightening technology, which is applied in the field of automatic screw-tightening devices, can solve problems such as low production efficiency and inability to meet the large demand for terminal blocks, and achieve the effects of improving production efficiency, solving shocks, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

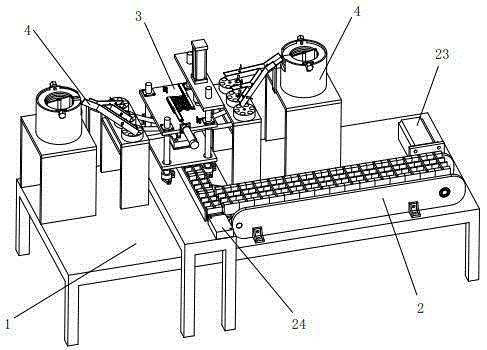

[0054] Such as figure 2As shown, the automatic screwing device of the terminal block of the present invention includes a machine base 1, a feeding mechanism 2 is arranged on the machine base 1, a screwing mechanism 3 is arranged above the output end of the feeding mechanism 2, and both sides of the screwing mechanism 3 A screw sorting mechanism 4 is provided respectively;

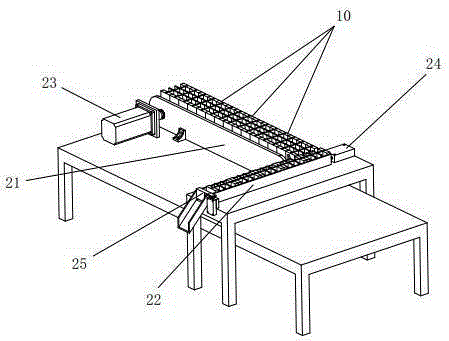

[0055] Such as image 3 As shown, the feeding mechanism 2 includes a conveyor belt 21, the conveyor belt 21 extends along the length direction of the machine base 1, the conveyor belt 21 is driven by the conveyor motor 23, and the conveyor belt 21 is used to transport the terminal block housing 10; the outlet of the conveyor belt 21 is connected to the terminal block positioning slot 22, a screw mechanism 3 is provided above the discharge port of the terminal row positioning groove 22 (that is, the output end of the feeding mechanism 2); The outlet end of the row positioning groove 22 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com