Engine right-angle pipeline genetic algorithm planning method oriented to Manhattan space

A genetic algorithm and aero-engine technology, which is applied in the field of genetic algorithm planning of engine right-angle pipelines facing Manhattan space, which can solve the problems of repeated modification efficiency, long laying period, and no theory and method formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

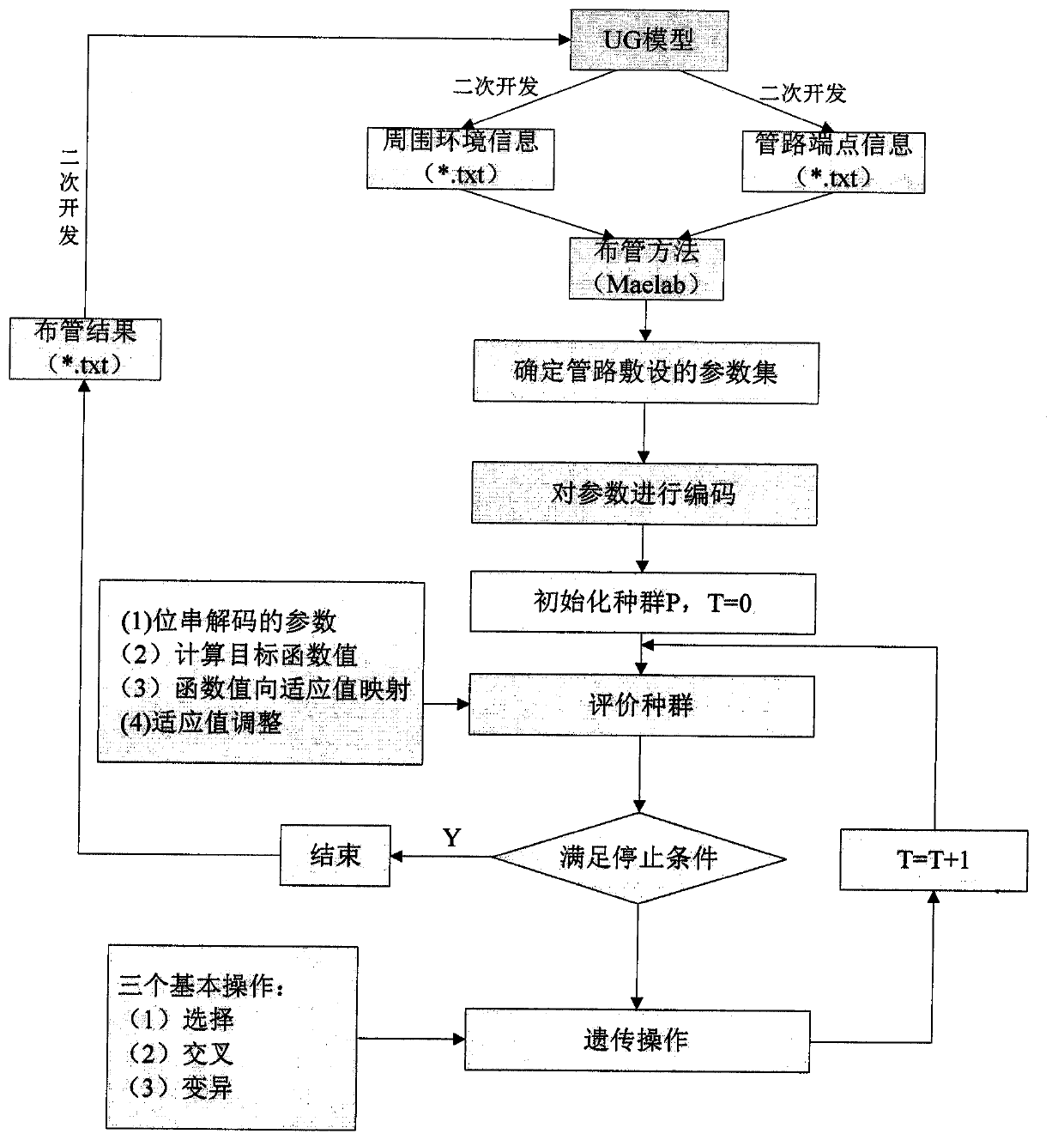

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] Taking the simplified engine pipeline laying model as an example, the feasibility of the present invention is verified. In this paper, the parameters of the genetic algorithm are selected as suggested values: the population size is M=80, the maximum number of iterations T=200; the crossover probability Fi=0.6, the mutation probability is Bi=0.05, and the objective function is set as:

[0077] f O (s)=2000 / (1*lsum+30*bend+2000*pe+10*nl) (10)

[0078] in:

[0079] lsum - path length;

[0080] bend - the number of pipe bends;

[0081] pe - penalty value;

[0082] nl - energy value.

[0083] Set the starting point and end point of the given pipeline and the obstacle model, and the various performance indicators of the pipeline laying can be obtained through MATLAB simulation:

[0084] Evolution algebra: k=200;

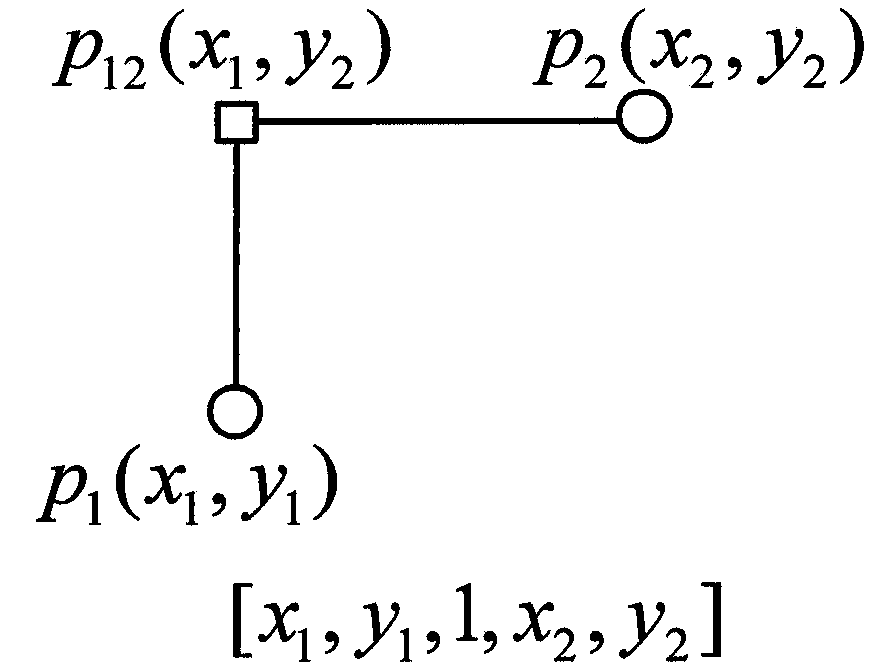

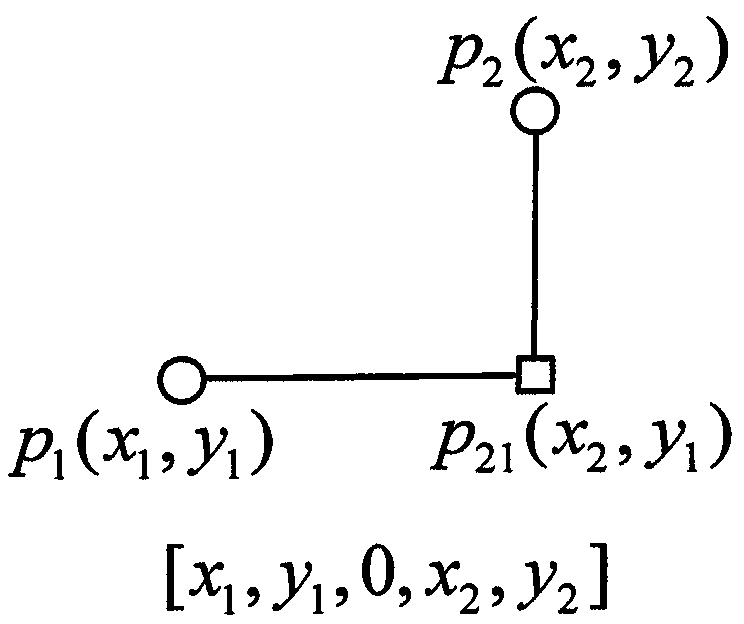

[0085] The real number form of the optimal individual corresponding code: xo=108.5000 83.5000 154.5000 109.5000 154.5000 109.5000 0 1.0000 0 1.0000;

[0086...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com