automatic perfusion method

An automatic and defoaming technology, applied in the field of glue injection equipment, can solve the problems of reducing production efficiency, reducing product qualification rate, long filling time, etc., and achieving the effect of saving production cost, reducing filling time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It can be seen from the background art that when the current infusion equipment performs colloid infusion on molds such as blades, only single-point infusion can be used, resulting in too long infusion time.

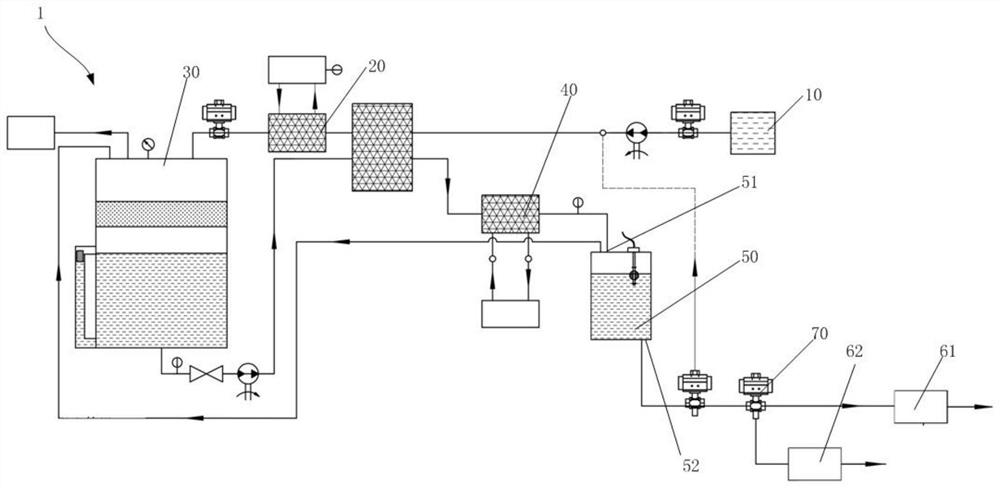

[0025] figure 1 A schematic structural diagram of an existing perfusion device is shown.

[0026] refer to figure 1 , the perfusion equipment 1 includes: a feeding unit 10 for providing materials; a heating device 20 for receiving the materials provided by the feeding unit 10 for heat treatment; a vacuum defoaming device 30 for receiving the heat-treated materials for degassing Bubble treatment; Cooling device 40, receives the material after defoaming treatment and carries out cooling treatment; Buffer device 50, described buffer device 50 comprises feed port 51 and discharge port 52, and described feed port 51 is connected with cooling device 40, The buffer device 50 receives the cooled material and outputs the material through the outlet 52 .

[0027] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com