Blade perfusion process method and perfusion system

A process method and blade technology, applied to other household appliances, household appliances, household components, etc., can solve the problems of dry yarn, semi-dry yarn, pouring outflanking, and low operating time, so as to save consumption, improve stability, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

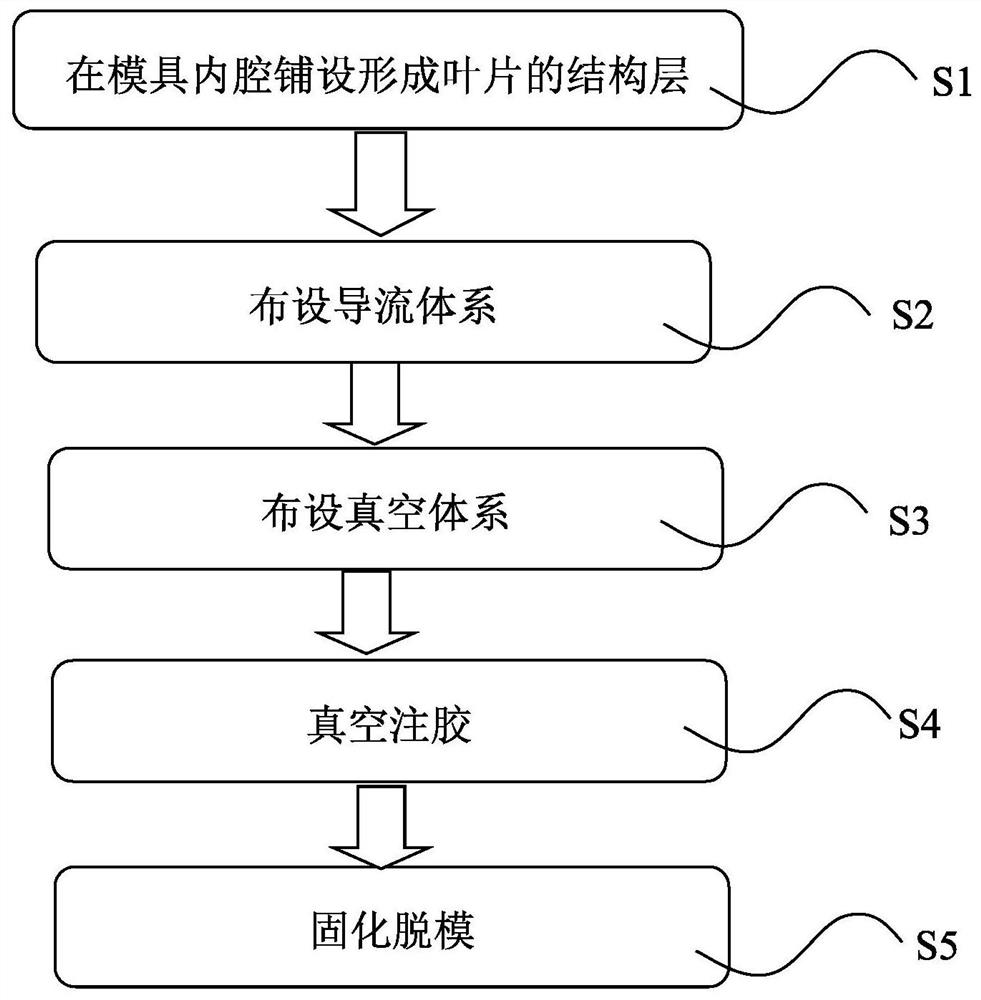

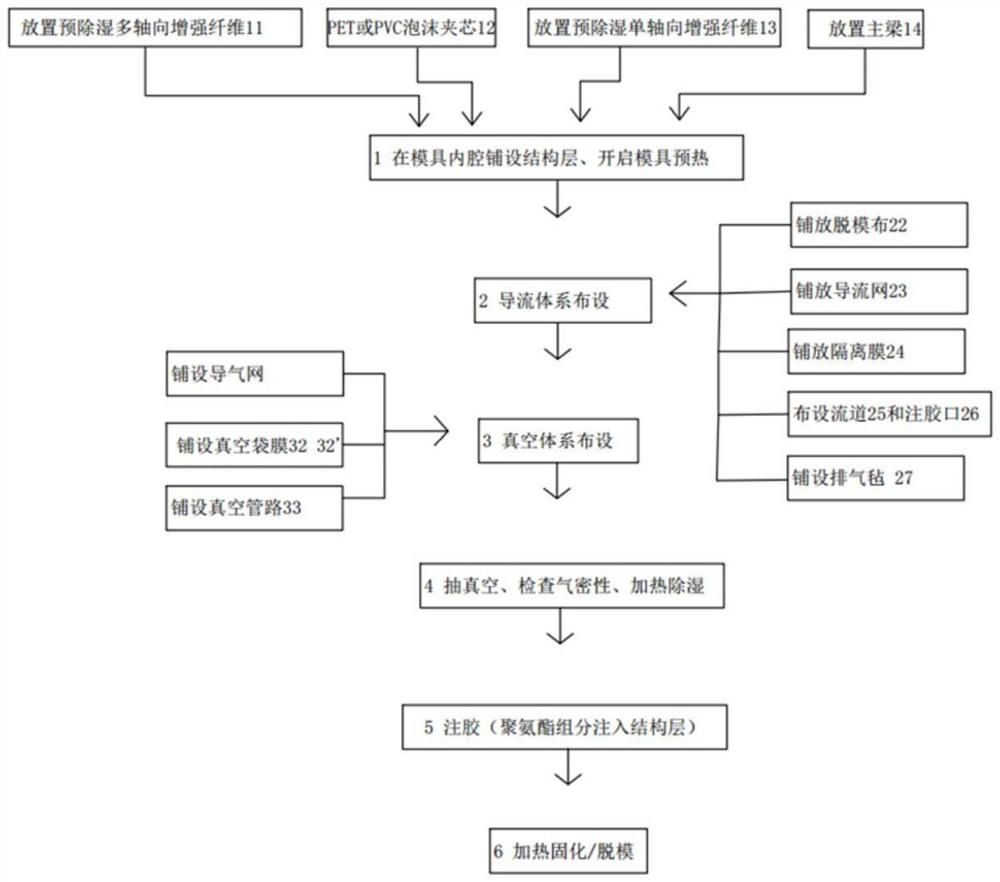

[0045] Polyurethane vacuum infusion process such as figure 2 Shown:

[0046] 1) Lay the structural layer in the inner cavity of the mold, open the mold for preheating:

[0047]The laying structure layer includes: pre-dehumidification multi-axial glass fiber fabric 11 , low-water lightweight sandwich material 12 , pre-dehumidification uniaxial reinforcement fiber 13 , and main beam 14 . Wherein, the low-moisture lightweight sandwich material 12 is preferably PVC or PET.

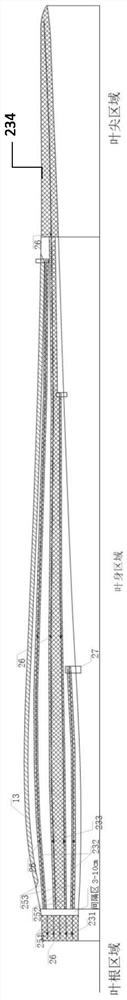

[0048] The specific laying method is: first lay 2-10 layers of multi-axial fiberglass fabrics on the blade body and tip area, in this example, 3 layers are laid, and 20-100 layers of pre-dehumidified multi-axial fiberglass fabrics are laid on the blade root area Fiberglass fabric 11; then lay 10-50 layers of pre-dehumidification uniaxial reinforcing fiber 13 and then place main beam 14 on the multiaxial fiberglass fabric and lay PET foam board (low-moisture lightweight sandwich material in a conventional ma...

Embodiment 2

[0080] A blade infusion system is used for infusing epoxy resin into a blade mold, and the system includes: a mold, a diversion system, and a vacuum system. The laying method and sequence of the mould, diversion system, and vacuum system are the same as in Example 1.

[0081] To sum up, the present invention discloses a blade vacuum infusion process method, in which guide nets are laid narrowly in other areas of the blade body, which has good technical effects. This method saves the amount of resin and the amount of guide net, avoids the defects of dry yarn or semi-dry yarn, improves the stability of blade forming, is conducive to protecting the environment, saving resources, and can reduce the pouring time. Glue injection for precise control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com