Bone cement electric propulsion gun

A bone cement and electric technology, applied in the direction of fixator, can solve the problems of increased cost burden of patients, low fluidity of bone cement, high injection pressure, etc., to effectively control the injection speed, reduce the risk of curing, and reduce the difficulty of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

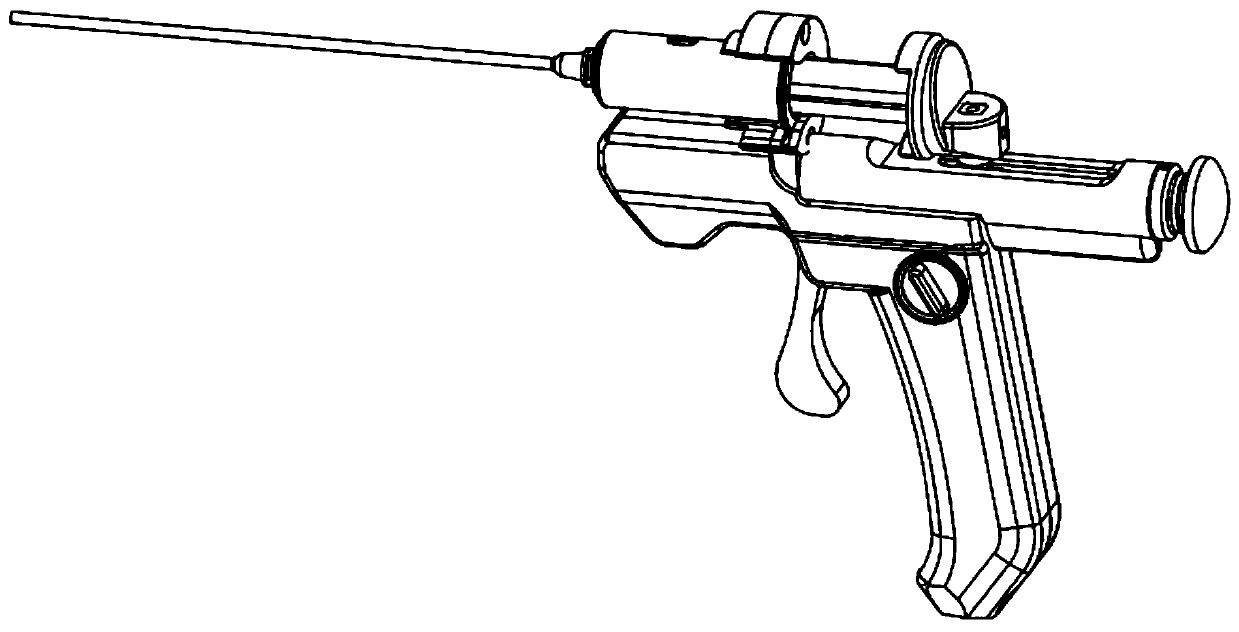

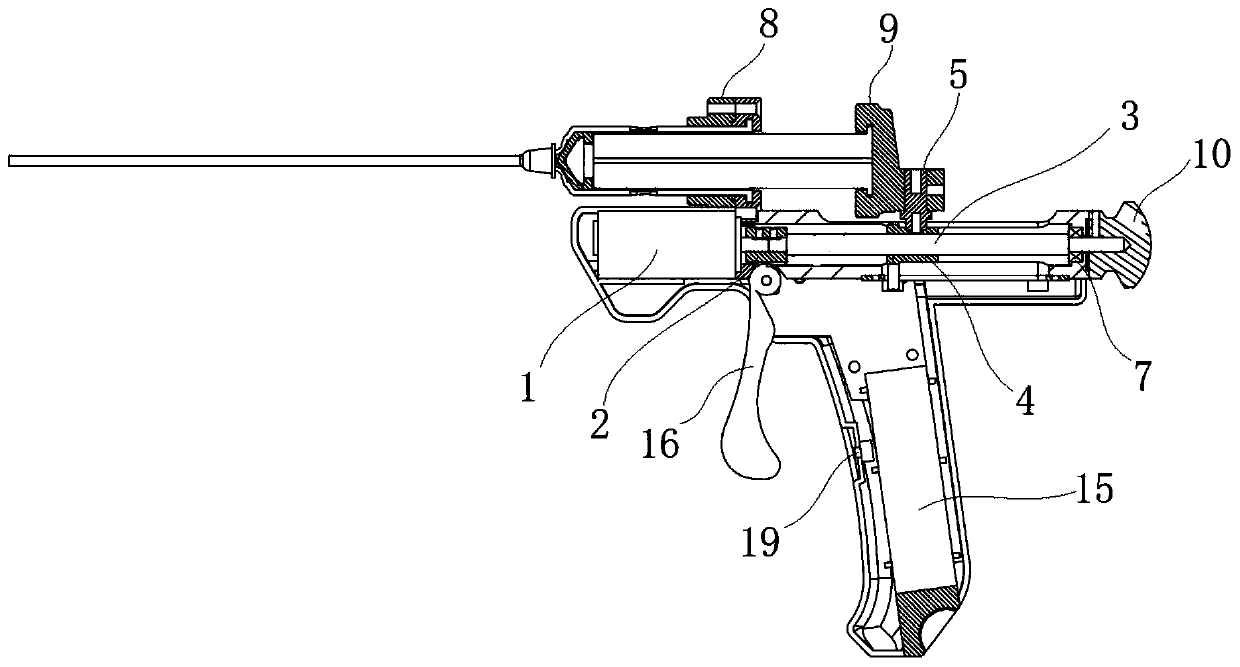

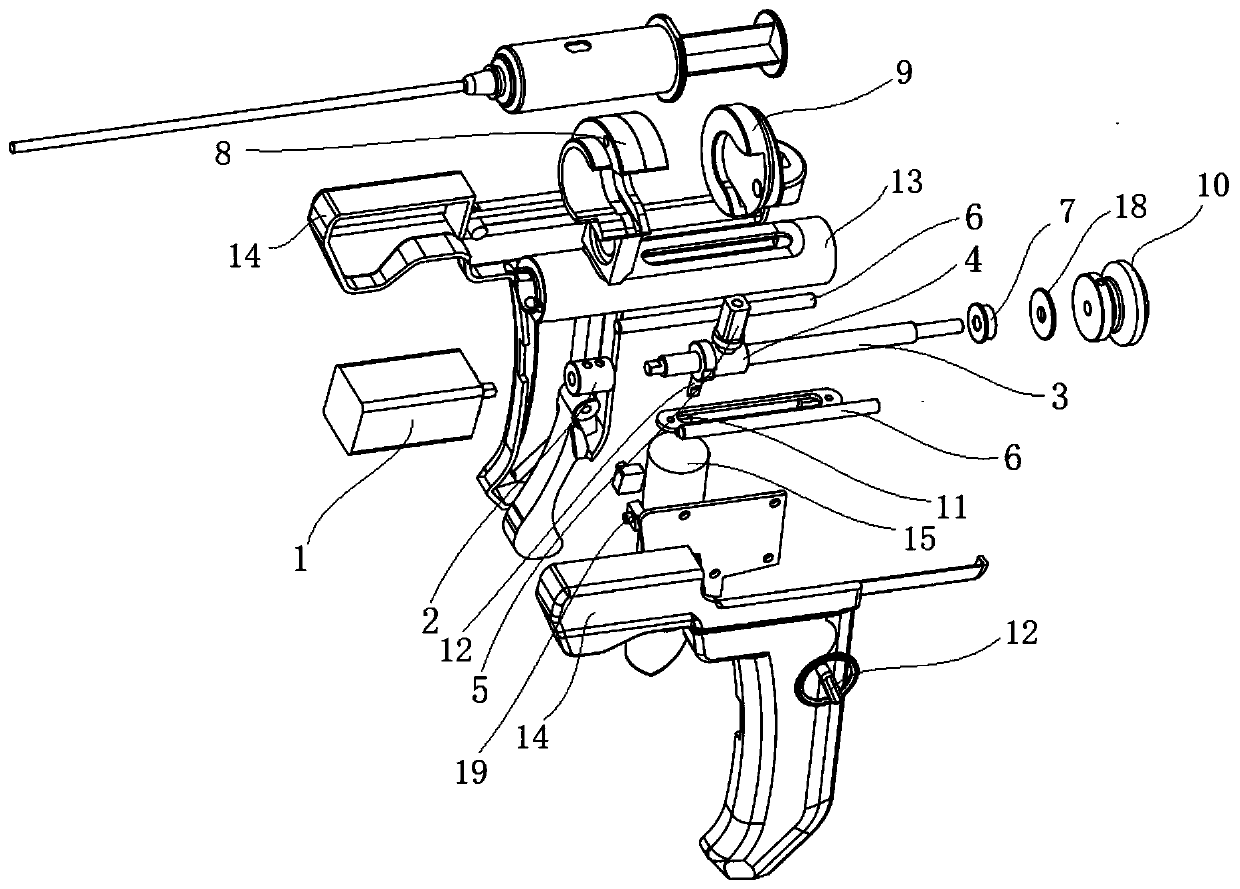

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 4 As shown, a bone cement electric propelling gun includes a syringe, a syringe holder 8, a syringe push rod 9, a casing, an electric drive linear motion mechanism, a battery 15, a trigger 16, a sensor, a controller, and a manual drive mechanism.

[0024] The electric drive linear motion mechanism includes a lead screw, a motor 1, a shaft coupling 2, a vertical rod 5, an optical shaft 6, and a bearing 7, and the lead screw is composed of a screw rod 3 and a nut 4. The output shaft of the motor 1 is fixedly connected to one end of the screw rod 3 through a coupling 2 , and the nut 4 is sleeved on the screw rod 3 . The two optical axes 6 are arranged parallel to the side of the screw 3 , the screw 3 and the two optical axes 6 are located in a cylindrical housing 13 , and the inner surface of the cylindrical housing 13 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com