Smooth cutting equipment for petroleum pipeline

A technology for cutting equipment and oil pipelines, used in metal processing and other directions, can solve problems such as troublesome operation and uneven ports, and achieve the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

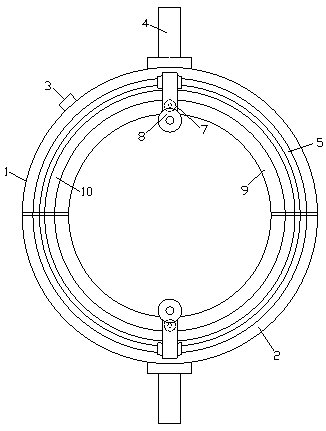

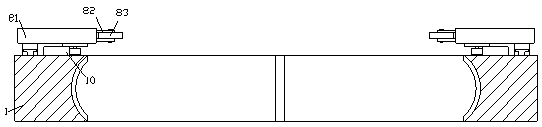

Embodiment 1

[0025] see Figure 1-Figure 4 , the present invention provides a technical solution for leveling and cutting equipment for oil pipelines: its structure consists of an upper deck 1 and a lower deck 2, the upper deck 1 and the lower deck 2 have the same structure and the two are fastened and connected , the upper card seat 1 is composed of a power connector 3, a handle 4, an arc-shaped slide rail 5, a rotating device 7, a cutting device 8, a ring road 9, and an arc-shaped ring gear 10. The handle 4 is connected to the upper card seat by bolts The top edge of 1 is threaded, and the upper deck 1 is connected with a power connector 3, and the top surface of the upper deck 1 is sequentially installed with an arc-shaped slide rail 5 and an arc-shaped ring gear 10. The cutting device 8 is engaged with the arc ring gear 10 and matches with the arc slide rail 5, and the inner side of the upper deck 1 is provided with a ring road 9, and the cutting device 8 is cut by a rotator 81, a chai...

Embodiment 2

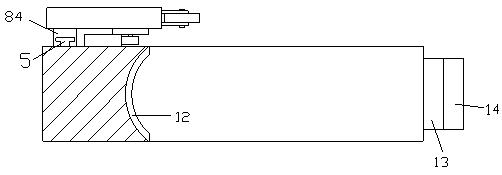

[0028] Such as image 3 and Figure 4 As shown, on the basis of Embodiment 1, a protruding shaft 13 is provided on both ends of the upper deck 1, and a second electromagnet 14 is connected to the protruding shaft 13, and the lower deck 2 Grooves 15 are provided on both ends of the groove 15, and a third electromagnet 16 is installed inside the groove 15, and the upper deck 1 and the lower deck 2 are engaged with each other through the protruding shaft 13 and the groove 15. Connect to form a circle.

[0029] The upper deck 1 and the lower deck 2 are connected together by buckling, the protruding shaft 13 on the upper deck 1 matches the groove 15 of the lower deck 2, and when the power connector 3 is energized, the second electromagnet 14 The third electromagnet 16 is energized to generate magnetism with opposite polarity, and the two attract each other, so that the upper deck 1 and the lower deck 2 are firmly fastened on the pipeline, preventing shaking during cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com