Gantry program control type crane

A crane and gantry-type technology, which is applied to cranes, trolley cranes, traveling mechanisms, etc., can solve problems such as poor flexibility, low safety factor, and material shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

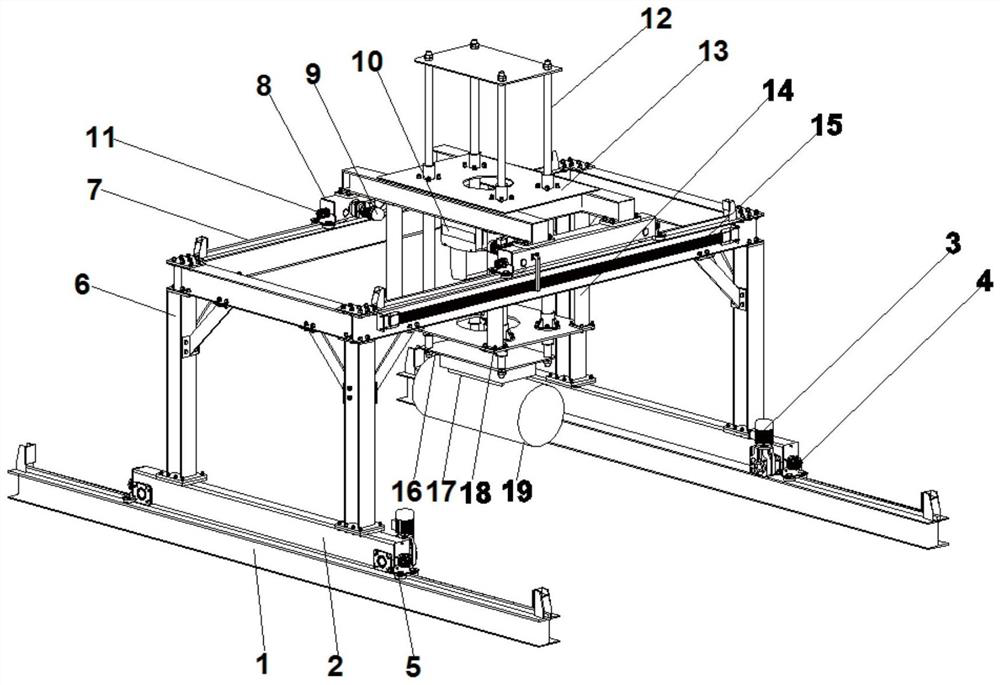

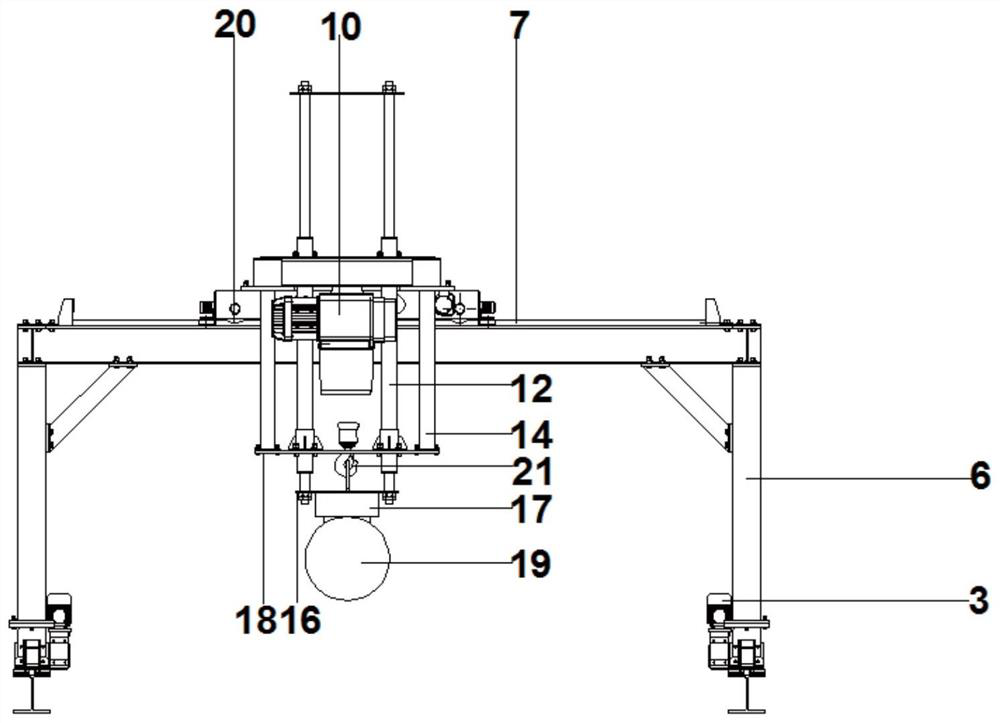

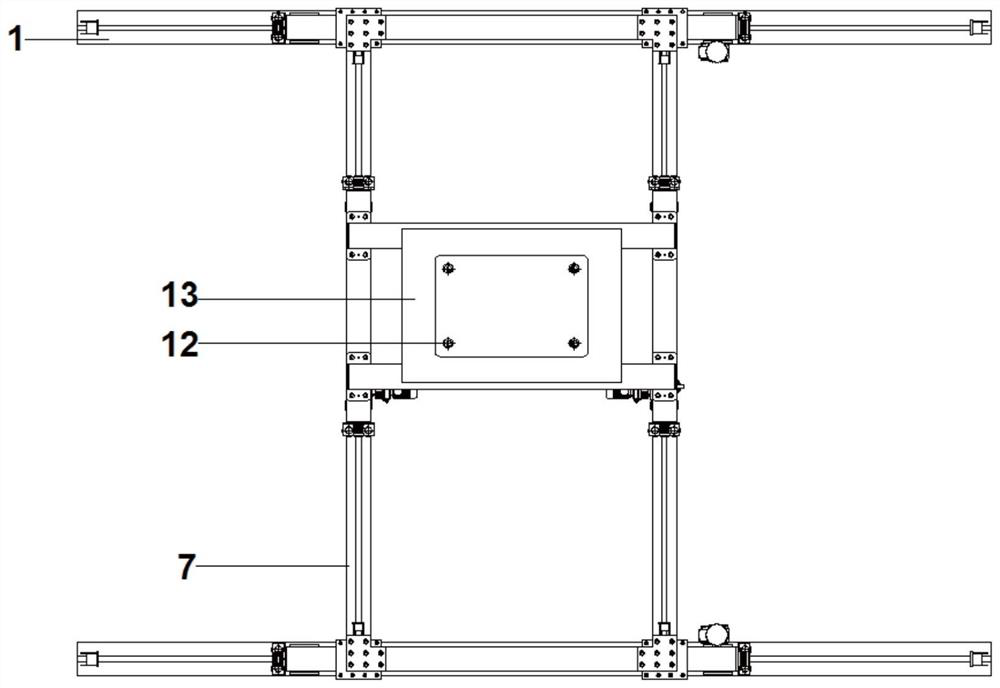

[0020] refer to Figure 1-3 , a gantry program-controlled crane, including a frame 6, a guiding mechanism, a lifting mechanism, a cart track 1, a cart walking module 2 (set along the X-axis direction), a trolley track 7, and a trolley walking module 8 (along the Y-axis Direction setting), the cart walking module is connected with the cart track, driving it to walk along the X-axis direction on the cart track, and the frame is fixed on the top of the cart walking module, driving it along the Y axis on the trolley track Traveling in the axial direction, the trolley track is fixed on the top of both sides of the frame, the trolley walking module is connected with the trolley track running, the guiding mechanism includes a guiding base 13 and a guide post 12, and the guiding base is fixed on the top of the trolley walking module. The lifting mechanism includes a chain hoist 10 (to drive goods up and down along the Z-axis direction), a fixed rod, an electromagnet 17, a limit base p...

Embodiment 2

[0022] continue to refer Figure 1-3 , Embodiment 2 of the present invention is implemented based on Embodiment 1;

[0023] The cart walking module includes encoder one 4, cart driving device 3 and cart wheels. The cart driving device is connected with the cart wheels through a suit, and the encoder one is coaxially connected with the cart driving device to accurately align the cart. to locate.

[0024] The trolley walking module includes an encoder 2 11, a trolley driving device and a trolley wheel 20. The trolley device 9 is connected to the cart wheel through a suit, and the encoder 2 is coaxially connected to the trolley driving device to accurately position the trolley.

[0025] Both the trolley track and the trolley track are equipped with a grating ruler 15 along their length, which enables the electronic control system to detect the traveling distance of the cart and trolley, and can intelligently control the accuracy of the traveling distance of the trolley or trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com