Crystal pouring device and method for flexible liquid crystal cell

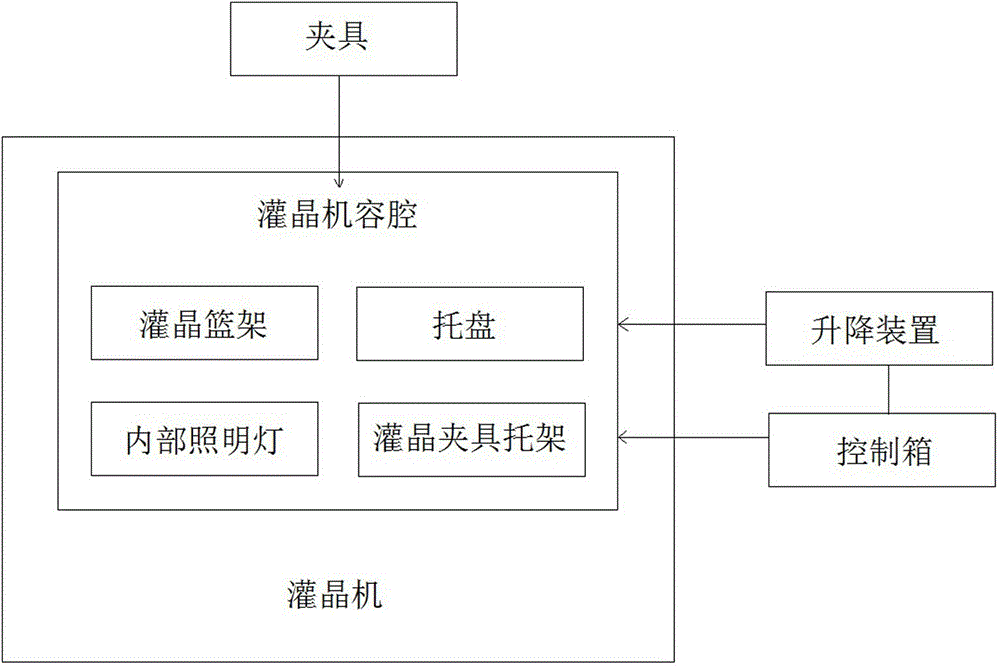

A flexible liquid crystal and pouring technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of increased production costs, long pouring time, poor pouring effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

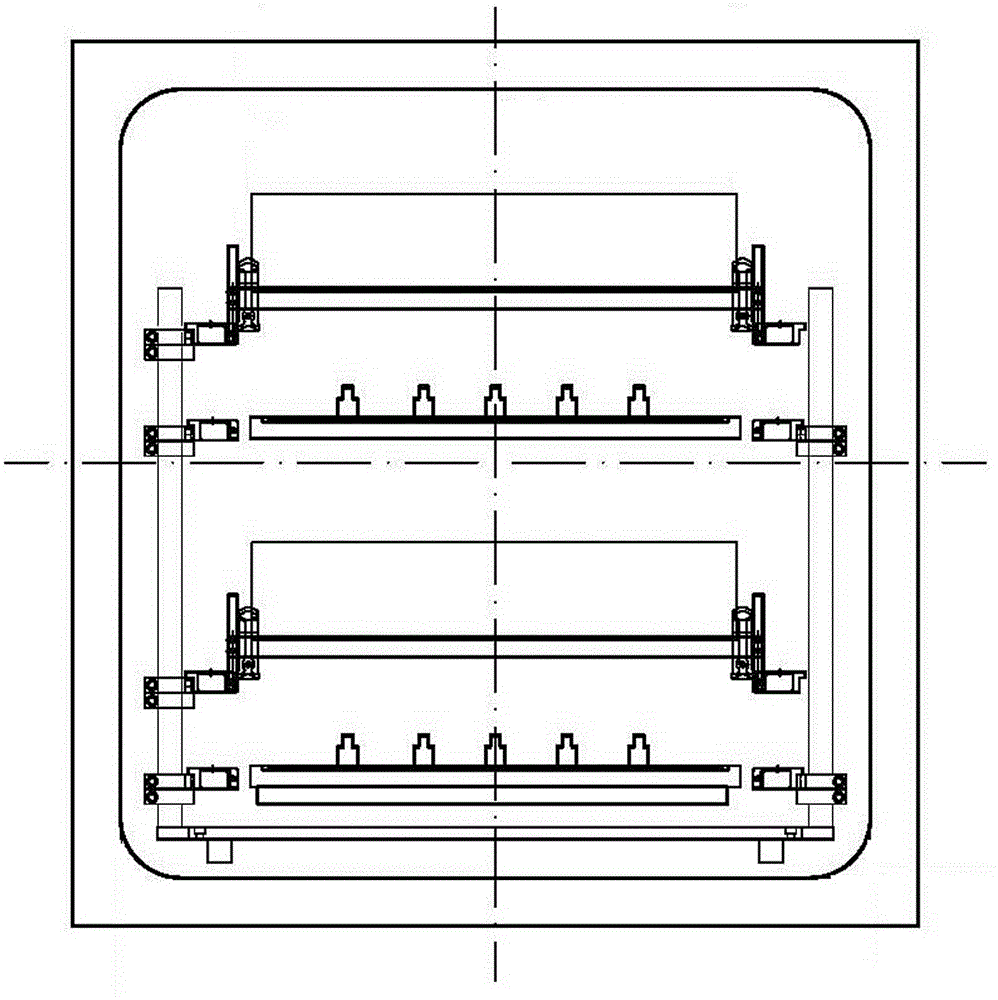

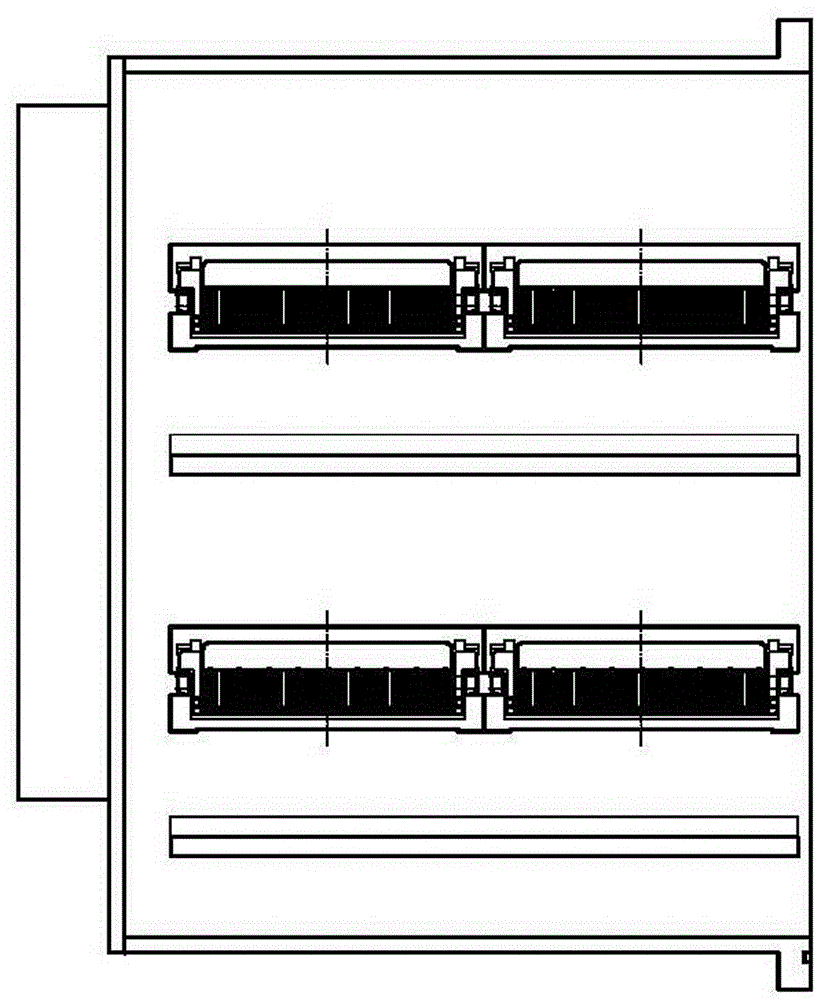

Embodiment 1

[0090] Before pouring the crystal, press 0.03Mpa on the surface of the flexible liquid crystal cell, and then put the pouring port down into the pouring basket. When pouring the crystal, add the liquid crystal to the crystal strip in the tray of the crystal pouring machine, so that it is inserted in the pouring basket Place the crystal filling port of the flexible liquid crystal box downward on the tray, so that the crystal filling bar and the crystal filling port are in a straight line. The liquid crystal cell and the liquid crystal are heated at the same time, and the heating temperature is 50℃, and then the crystal filling machine door is closed and vacuumed Operation, the vacuum degree is set to 3pa. Make the crystal filling port of the flexible liquid crystal cell fully contact the liquid crystal; then inflate the inside of the crystal filling machine with a gas pressure of 1 atmosphere. Use the air pressure to press the liquid crystal from the crystal filling port into the...

Embodiment 2

[0092] Before crystal filling, press 0.04Mpa on the surface of the flexible liquid crystal cell, and then put the crystal filling port down into the crystal filling basket. When filling the crystal, add liquid crystal to the crystal strip in the tray of the crystal filling machine to insert it into the crystal filling basket. Place the crystal filling port of the flexible liquid crystal cell downward on the tray, so that the crystal filling bar and the crystal filling port are in a straight line. The liquid crystal cell and the liquid crystal are heated at the same time, the heating temperature is 55℃, and then the crystal filling machine door is closed and vacuumed Operation, the vacuum degree is set to 5pa. Make the crystal filling port of the flexible liquid crystal cell fully contact with the liquid crystal; then inflate the inside of the crystal filling machine, the inflation amount is 2 atmospheres, use the air pressure to press the liquid crystal from the crystal filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com