Patents

Literature

41results about How to "Reduce lifting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

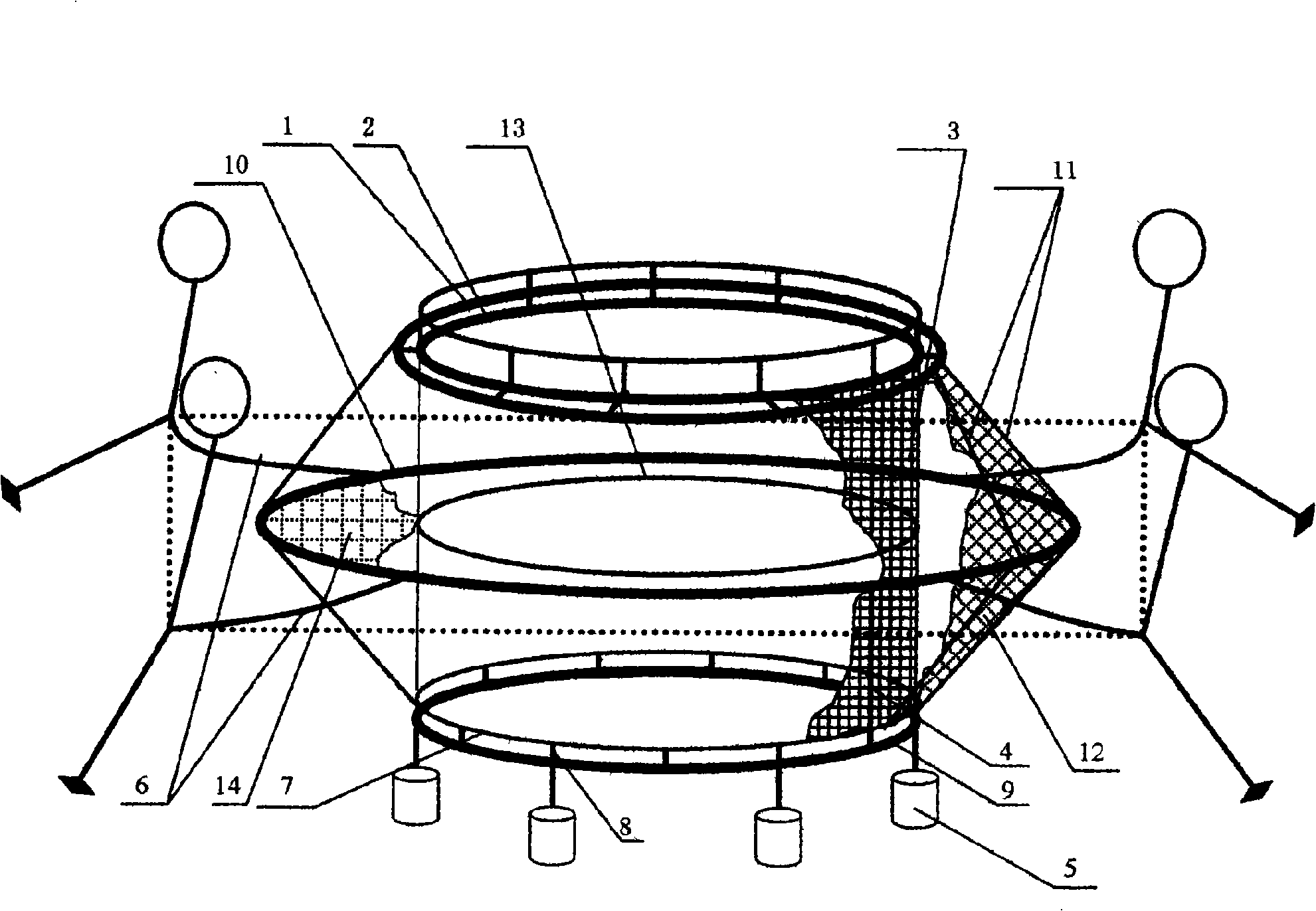

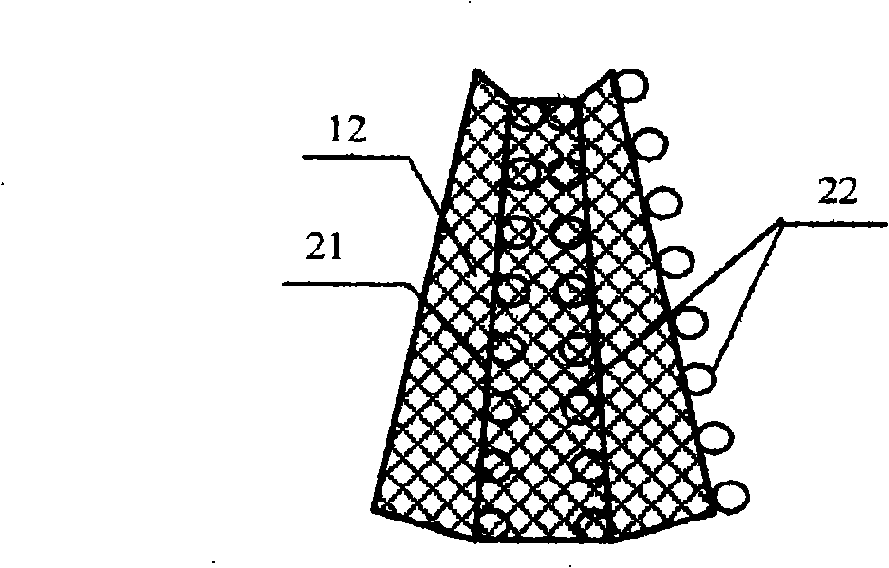

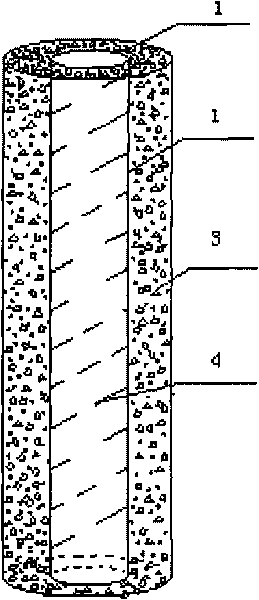

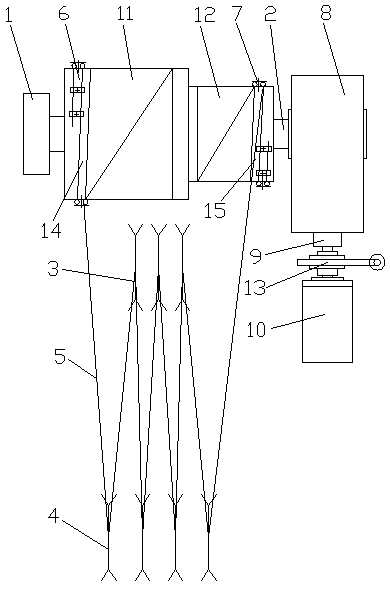

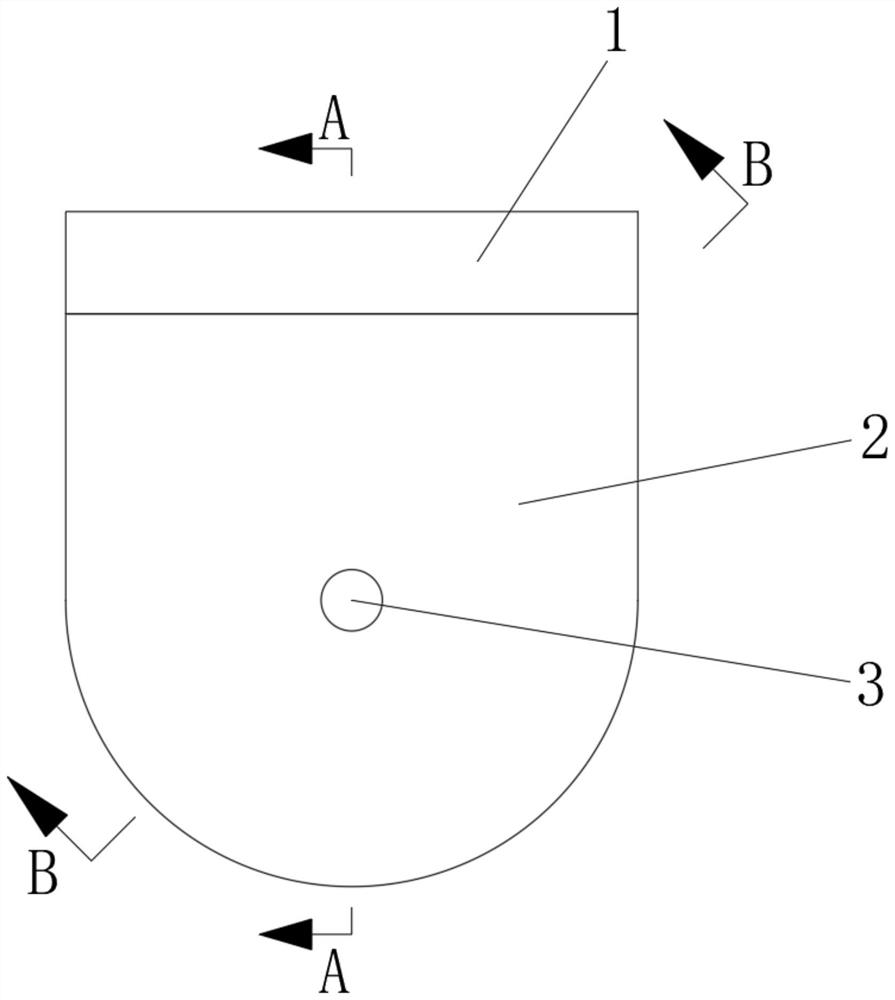

Self-reducing flow low-shape change off land deep water net cage

ActiveCN101326898AAdjust liftRegulation stateClimate change adaptationPisciculture and aquariaShape changeBand shape

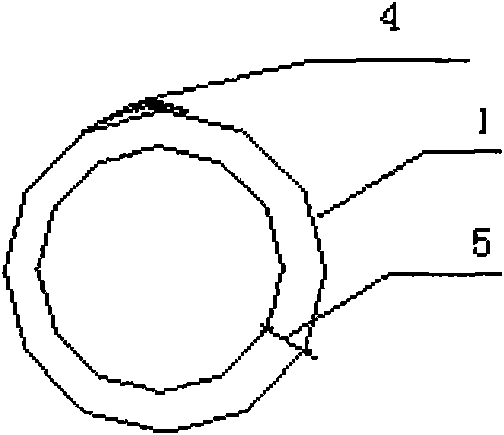

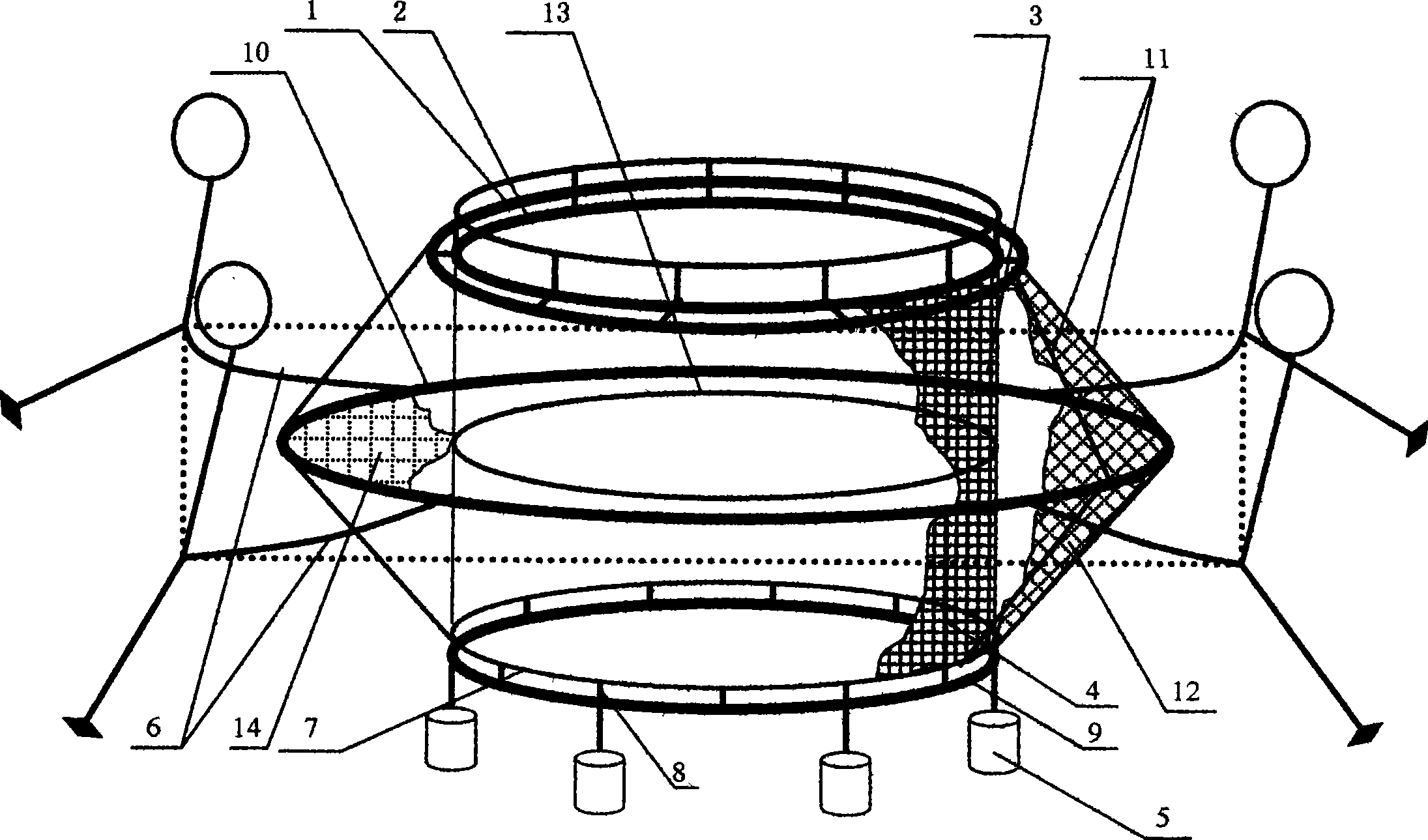

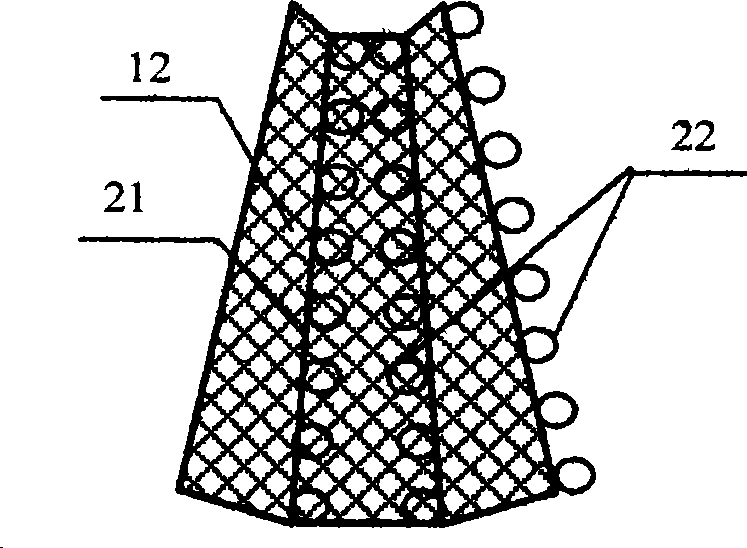

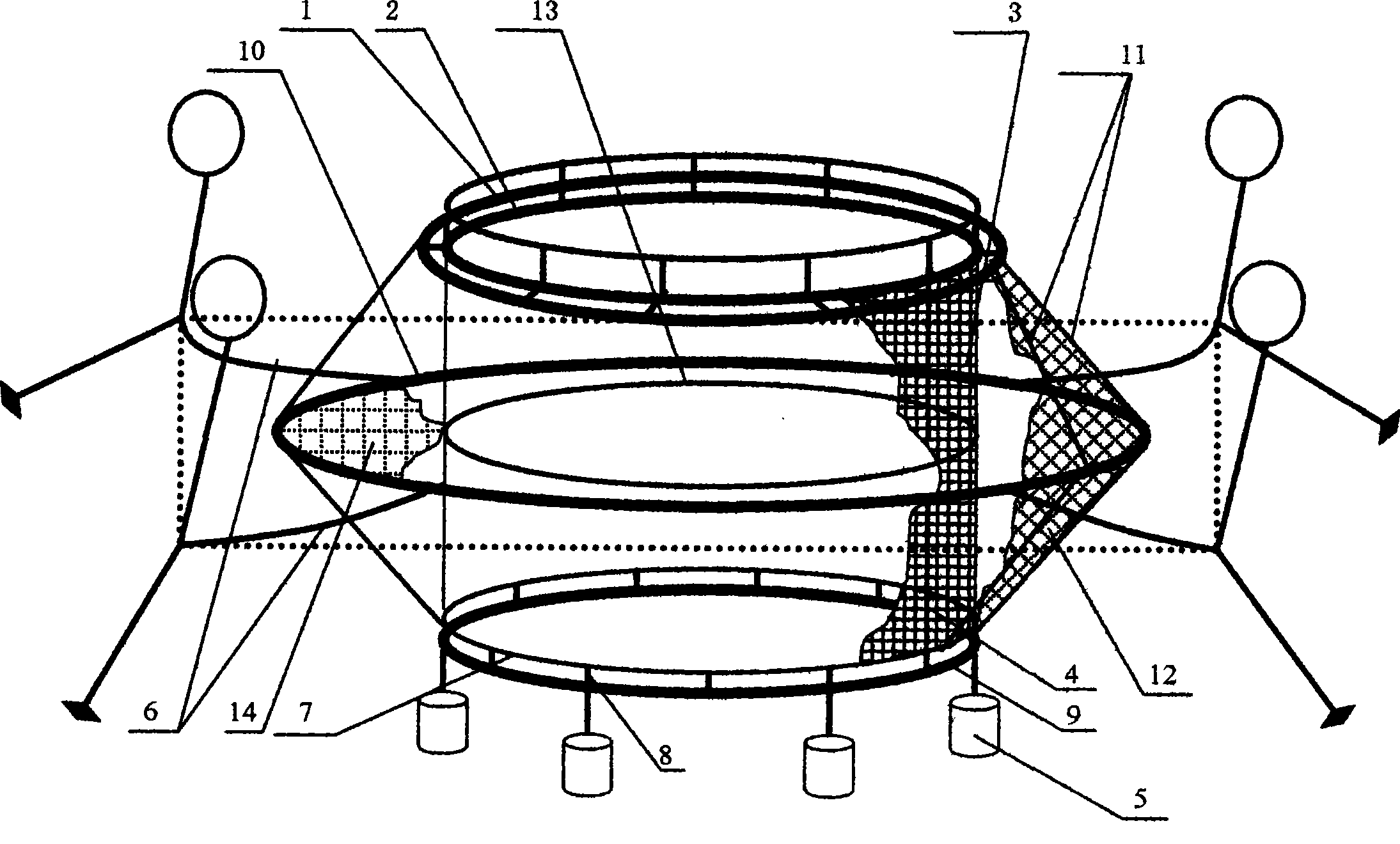

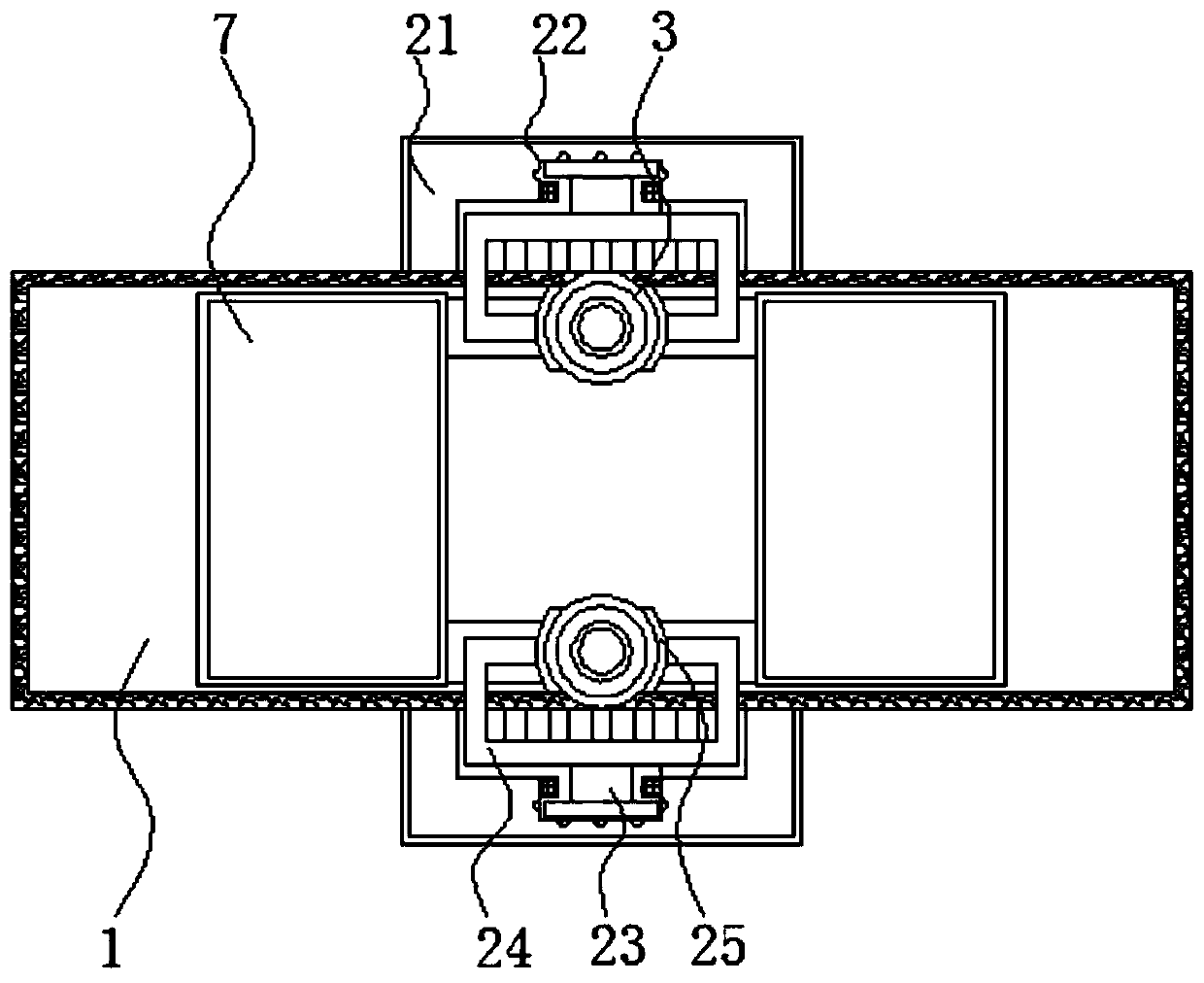

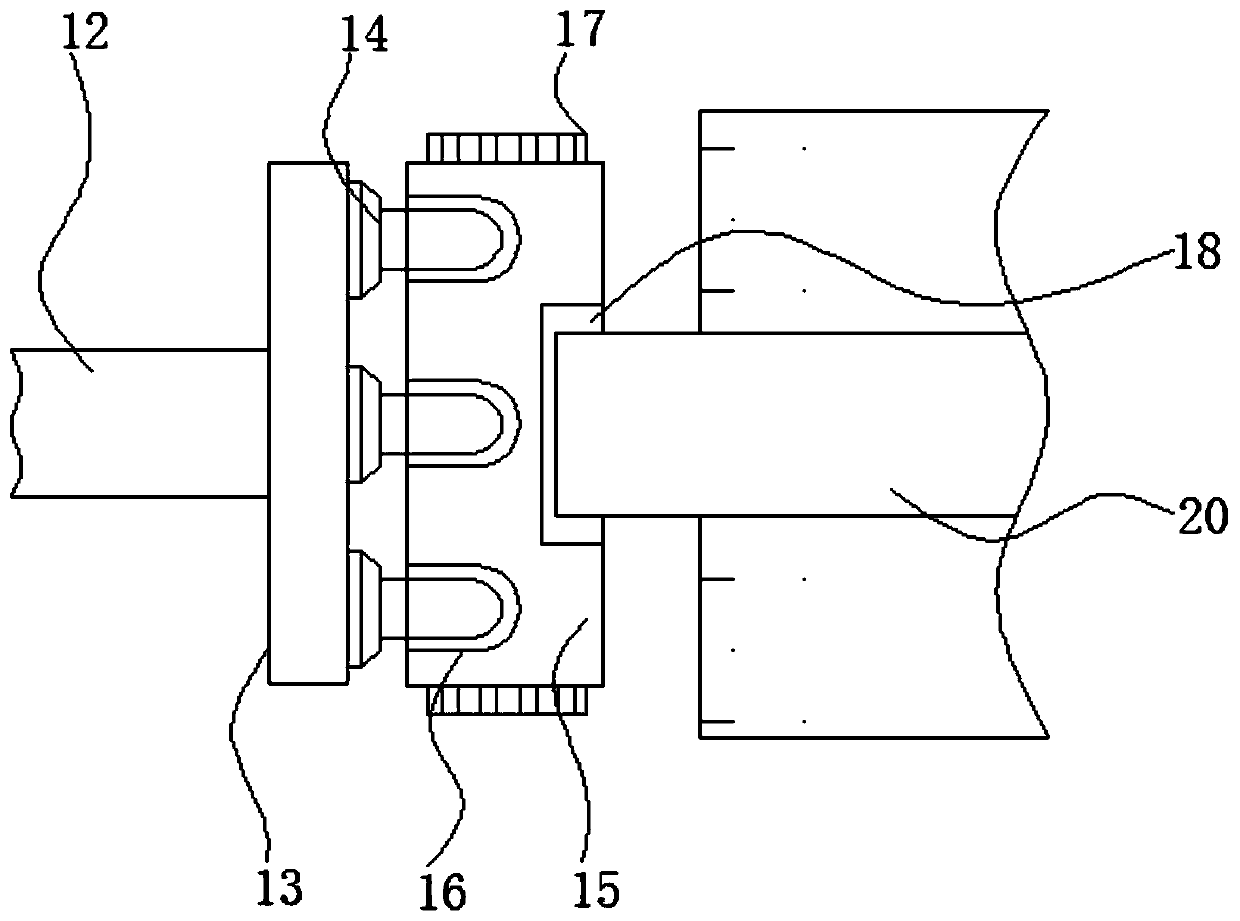

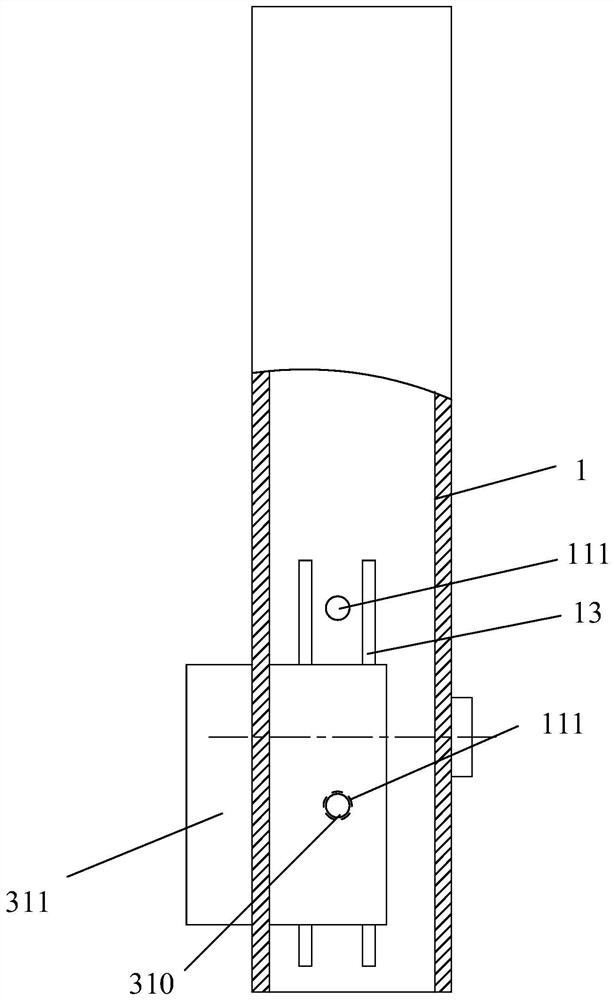

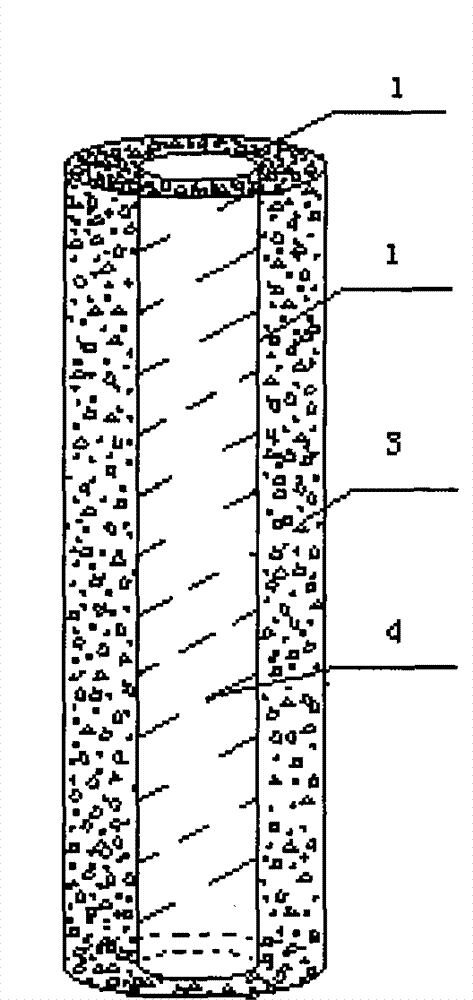

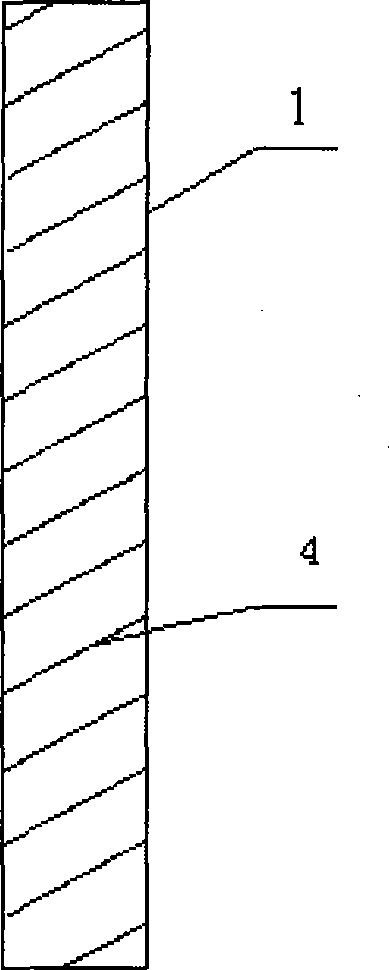

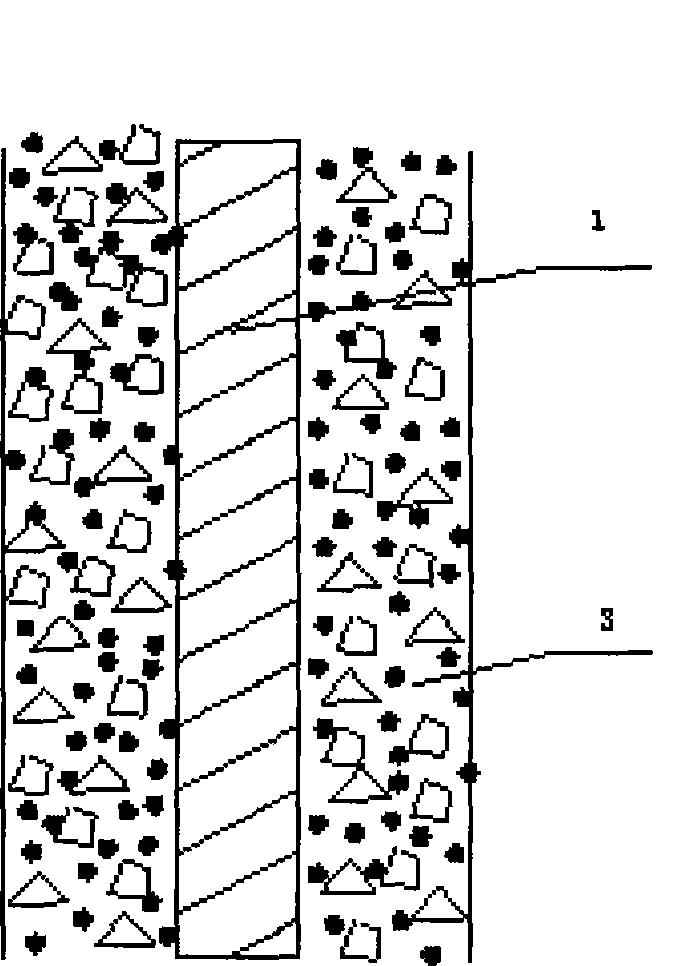

The invention discloses an automatic reducing low-deformation offshore deep-water cage, relating to a cage for marine aquiculture. The invention is capable to reduce the deformation of the cage and the flow rate of the sea water inside the cage. The invention comprises a buoyancy frame, a cage, a sinking ring, a sinking block and an anchoring rope. A supporting and lifting control ring bigger than the buoyancy frame and the diameter of the sinking ring is arranged at the one second depth of the cylindrical cage; a water inlet and a water outlet are arranged in the pipe wall of the supporting and lifting control ring; a girdle rubber inner bag which regulates the lifting and descending of the cage is arranged in the ring pipe; an air-valve is installed in the rubber inner bag and connected with the air supply by a pressure hose; between the outer ring and the supporting and lifting control ring of the double-ring buoyancy frame, the bottom outline of the cylindrical cage and the bottom sinking ring, a plurality of flexible ropes are located and connected according to the ring at geometric proportion, and a netting is arranged among the connecting ropes of the three rings; and finally, a flexibly connected automatic reducing low-deformation offshore deep-water cage with a cylindrical inside and a two-cone platform outside is formed, the stress point of the anchoring rope of the cage is arranged at the supporting and lifting control ring.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

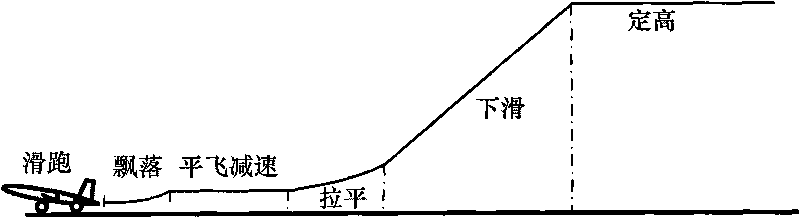

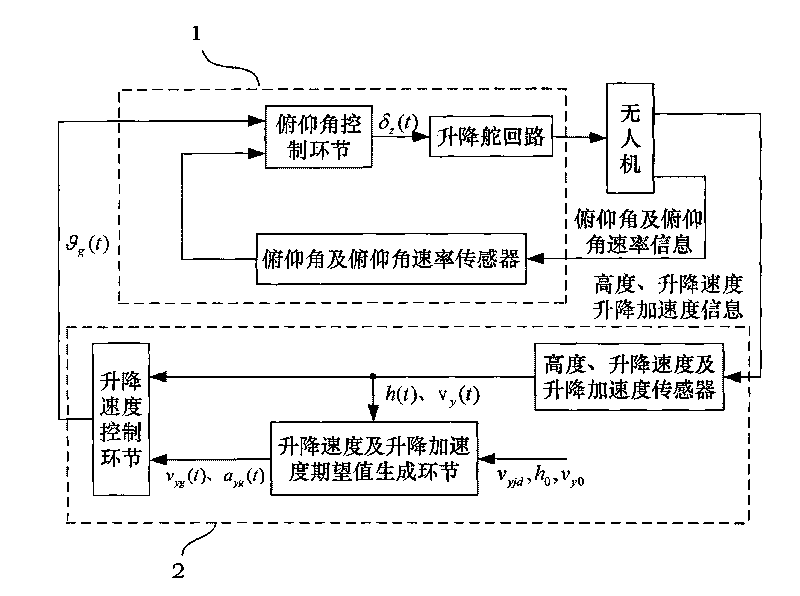

Method for controlling automatic landing and leveling of unmanned aerial vehicle

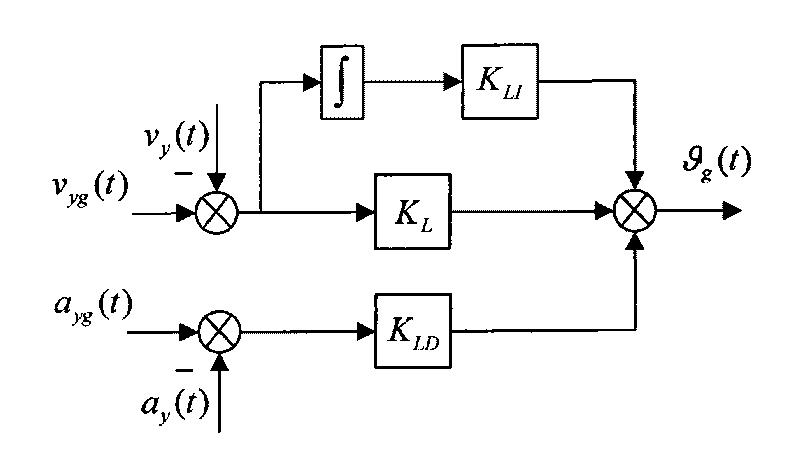

InactiveCN101718994AReduce lifting speedReduce the deviation from expected valueVehicle position/course/altitude controlPosition/direction controlClosed loop feedbackUncrewed vehicle

The invention discloses a method for controlling the automatic landing and leveling of an unmanned aerial vehicle, a control scheme combining with an open loop correction with a closed loop feedback control. Each control link in a control loop is realized by obtaining a lifting speed expected value vyg(t), a lifting acceleration expected value ayg(t), an expected pitching angle thetag(t) and an elevator skewness command Deltag (t), particularly, the lifting speed open loop integral correction vygSemi is introduced, thereby the deviation of the actual lifting speed and the expected value when the plane touches down is reduced. The correction has obvious physical meaning and strong engineering application, is easy to realize, is suitable for the automatic landing and leveling control with the requirement of high precision, and effectively improves the landing safety.

Owner:BEIHANG UNIV

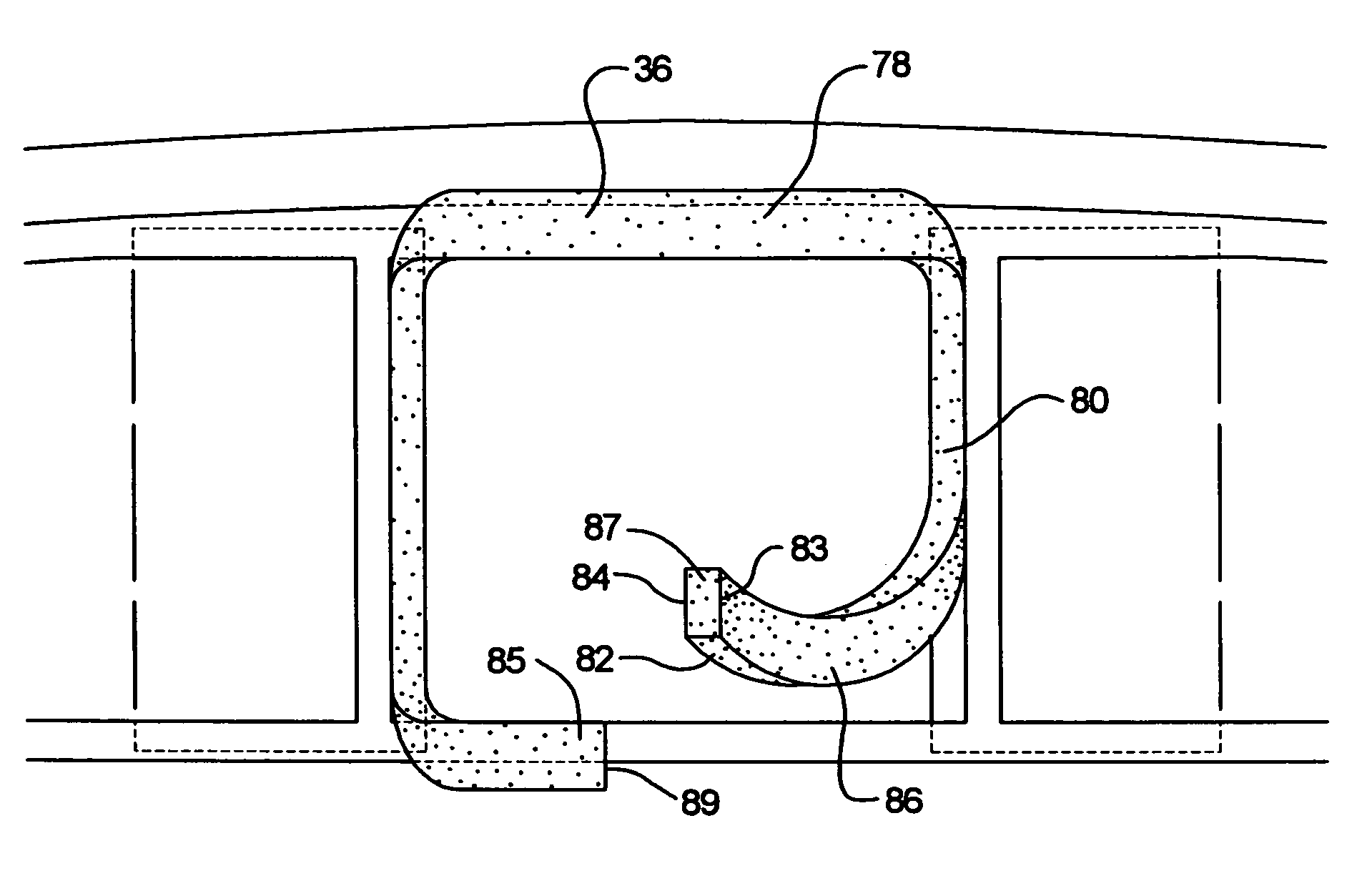

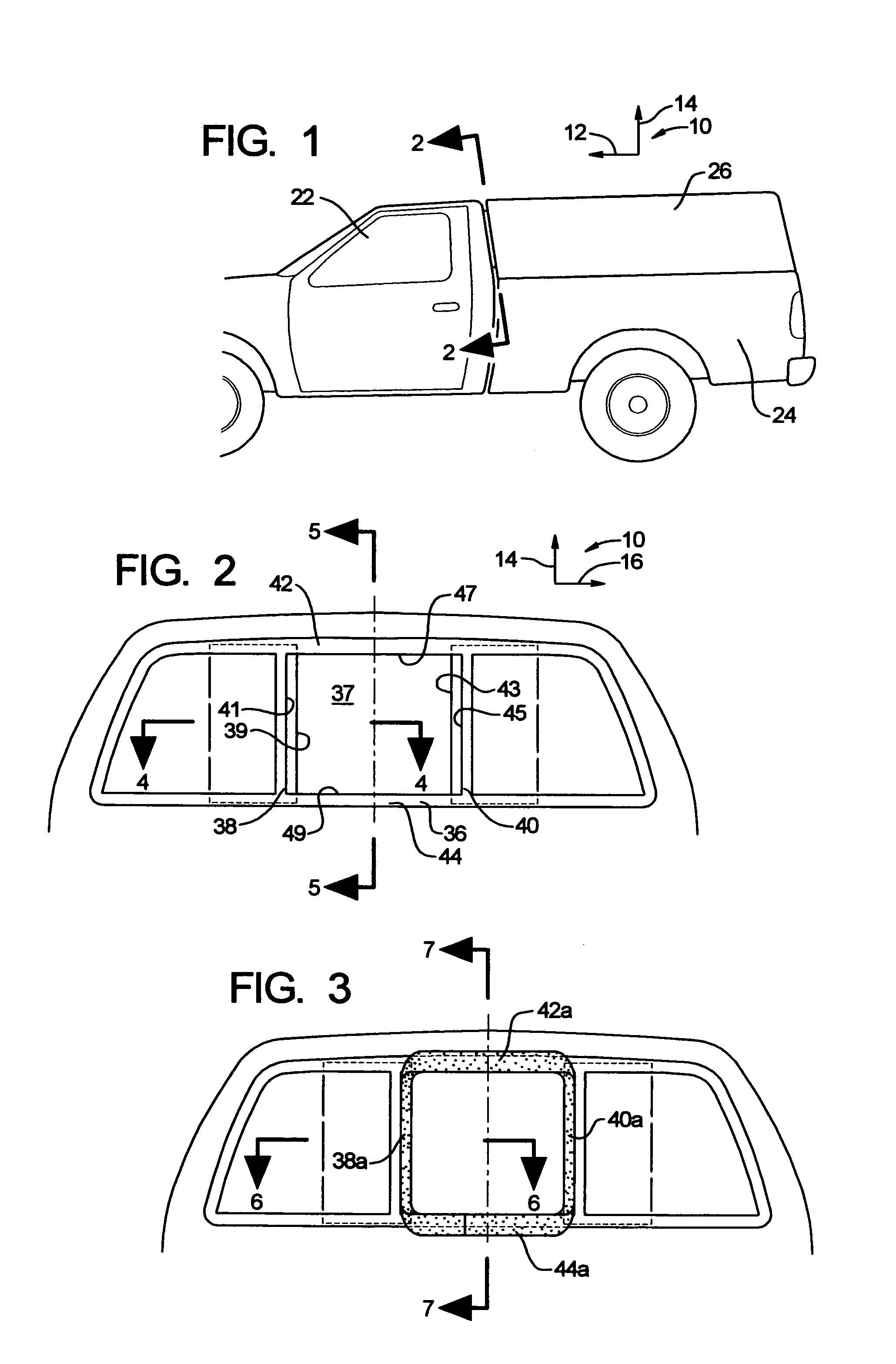

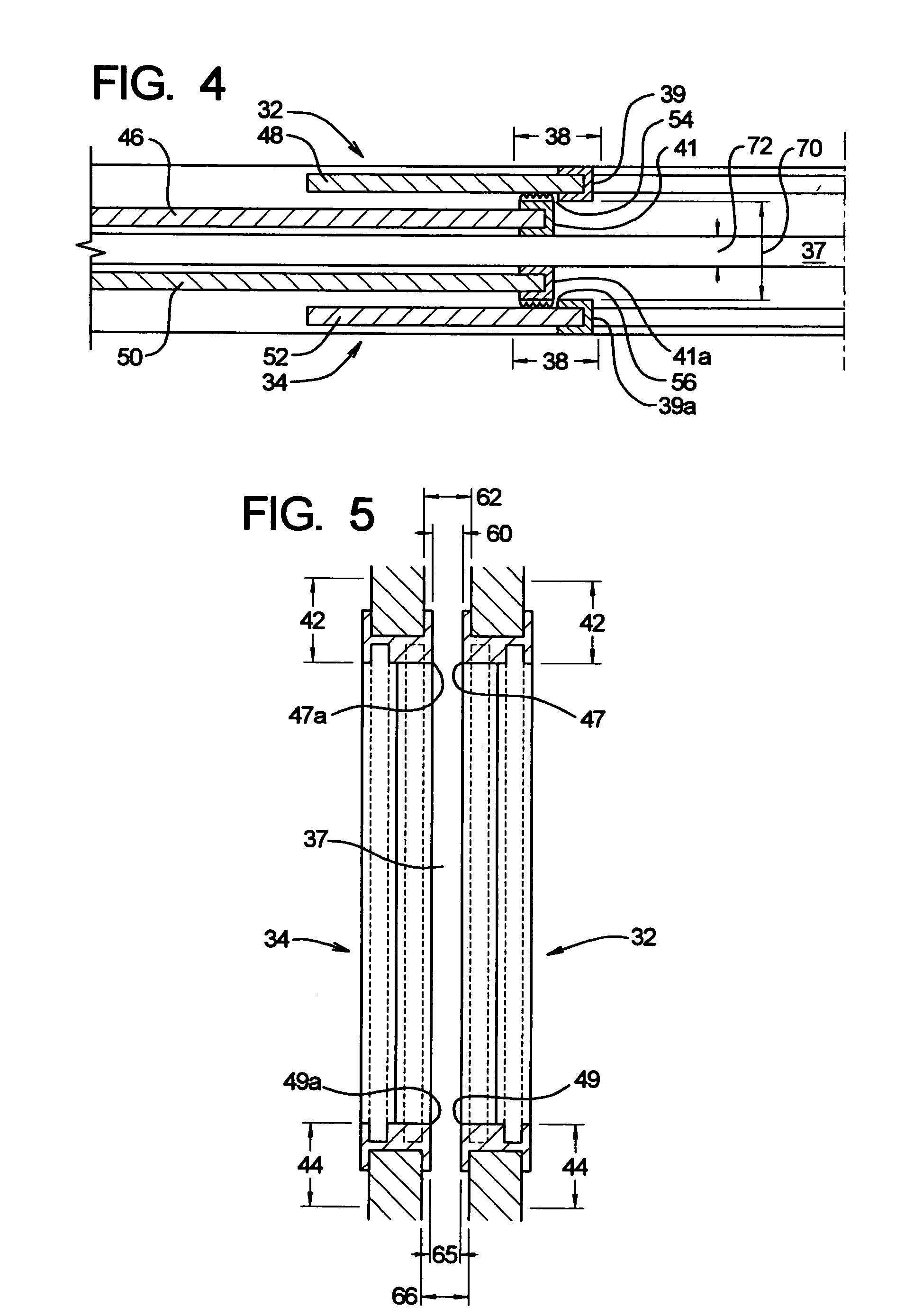

Window seal method and apparatus

InactiveUS7014251B1Quick and easy applicationAchieve communicationWindowsEngine sealsPickup truckEngineering

An elongate moldable, flexible material or sealing body positioned between adjacent walls of a pickup truck and canopy mounted to a pickup truck bed, to permit windows of the pickup cab and canopy to be open for communication between the cab space and the canopy space, as well as to keep out wind, rain, dust and debris. The sealing body encompassing the perimeter of the windows of the cab and canopy. The sealing body also having a width dimension greater than its thickness dimension. Further, the sealing body having the ability to rotate about its central axis to accommodate varying dimensions of gaps between the cab wall and the canopy wall. The sealing body also having a fast compression rate and a compression memory. The slow expansion rate or “slow memory” giving the added benefit of avoiding abrasion of the sealing body against the cab or canopy walls due to vibration of the cab or canopy structure.

Owner:HUSK VERNON RUSS

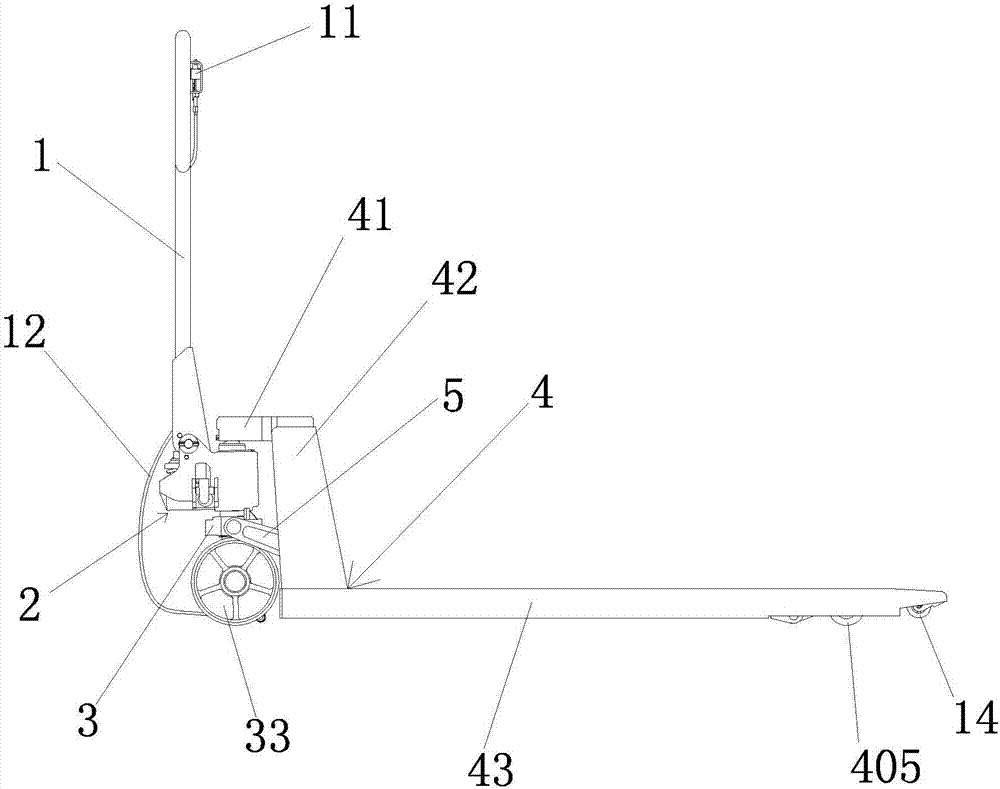

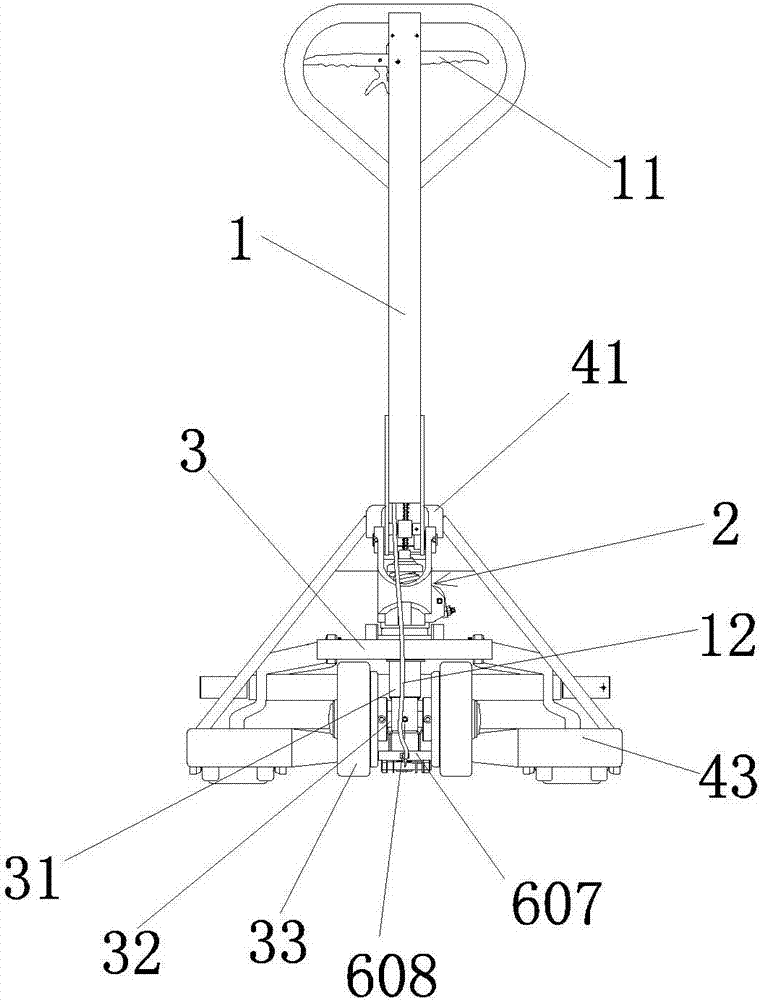

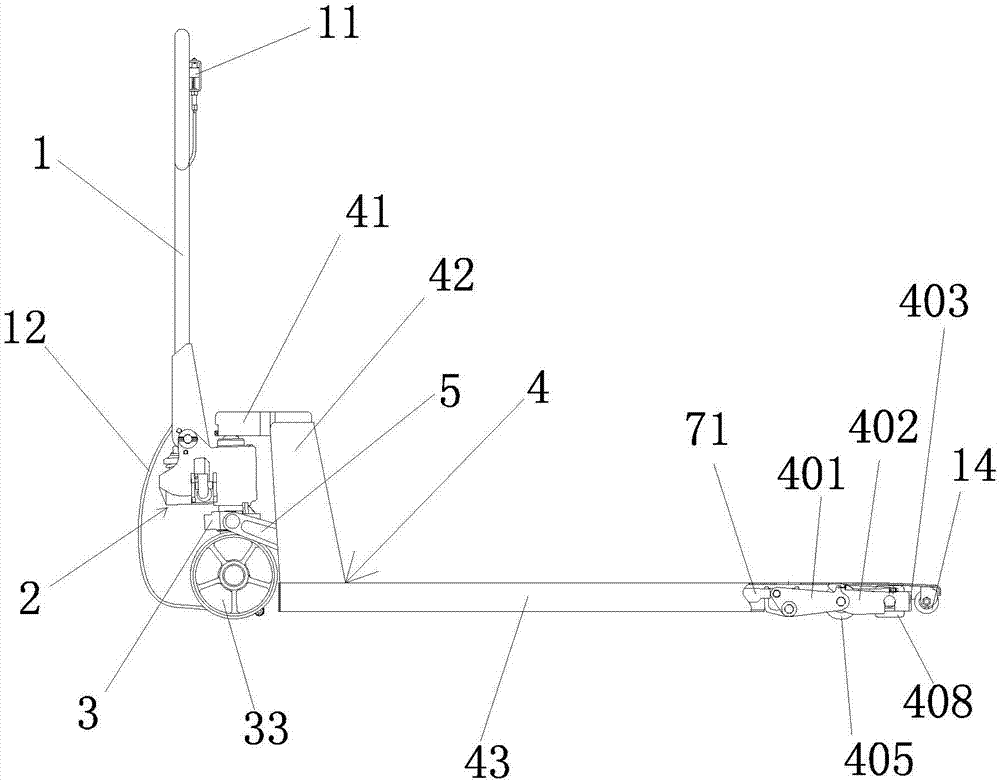

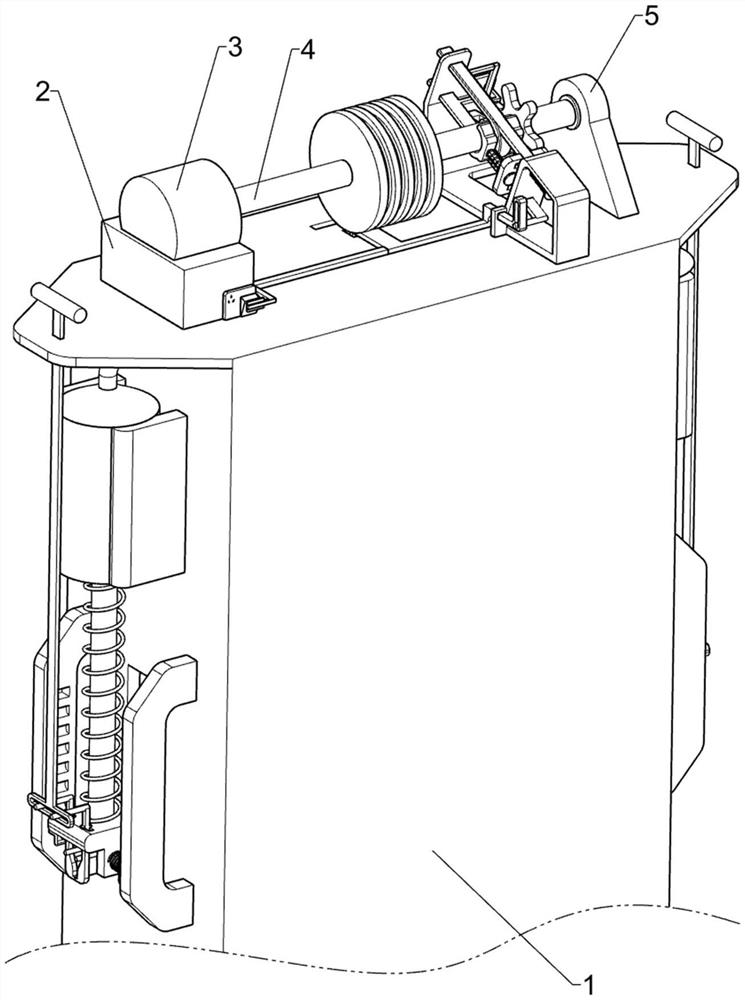

Hydraulic hand pallet truck

InactiveCN106966323APrevent slippery slopeLifting speed is slowSafety devices for lifting equipmentsBraking membersEngineeringTruck

The invention provides a hydraulic hand pallet truck according to the defect that in the prior art, a hydraulic hand pallet truck is constant in lifting speed, cannot automatically adjust the lifting speed according to the cargo weight, and is inconvenient to steer and poor in braking performance, and belongs to the technical field of carrying equipment. The hydraulic hand pallet truck can be automatically adjusted to be at a low lifting speed when the cargo is heavy, so that the stability of the lifting process is guaranteed. The hydraulic hand pallet truck can be automatically adjusted to be at a high lifting speed when the cargo is light, so that the carrying efficiency of the pallet truck is guaranteed. Meanwhile, the bottom of a pallet fork of the hydraulic hand pallet truck is improved, and therefore the hydraulic hand pallet truck can conduct transverse movement, has good braking performance, and is prevented from sliding on the slope in the using process.

Owner:JINHUA WINNER MECHANICAL&ELECTRICAL CO LTD ZHEJIANG

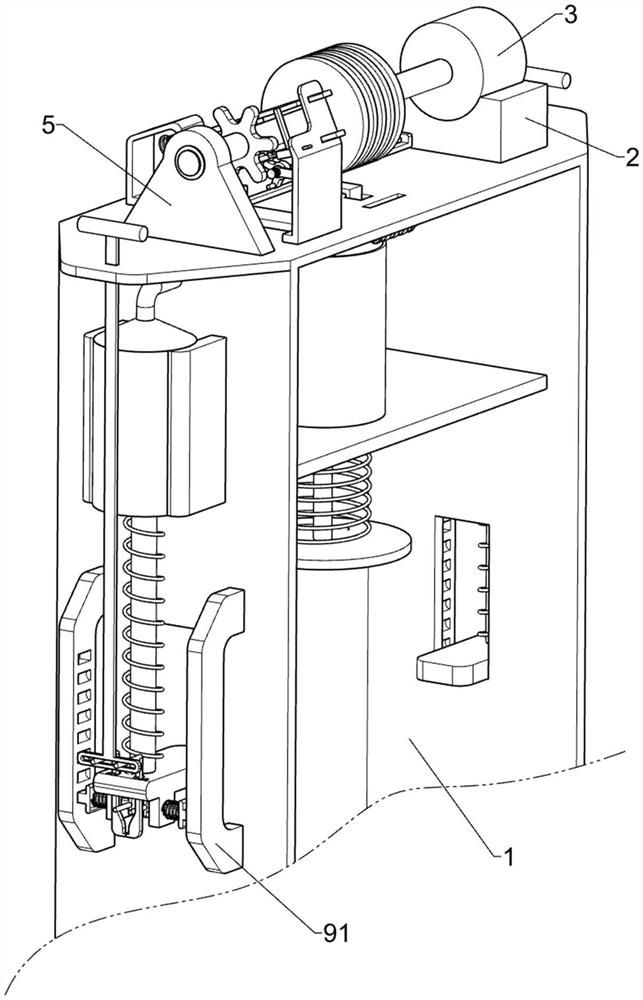

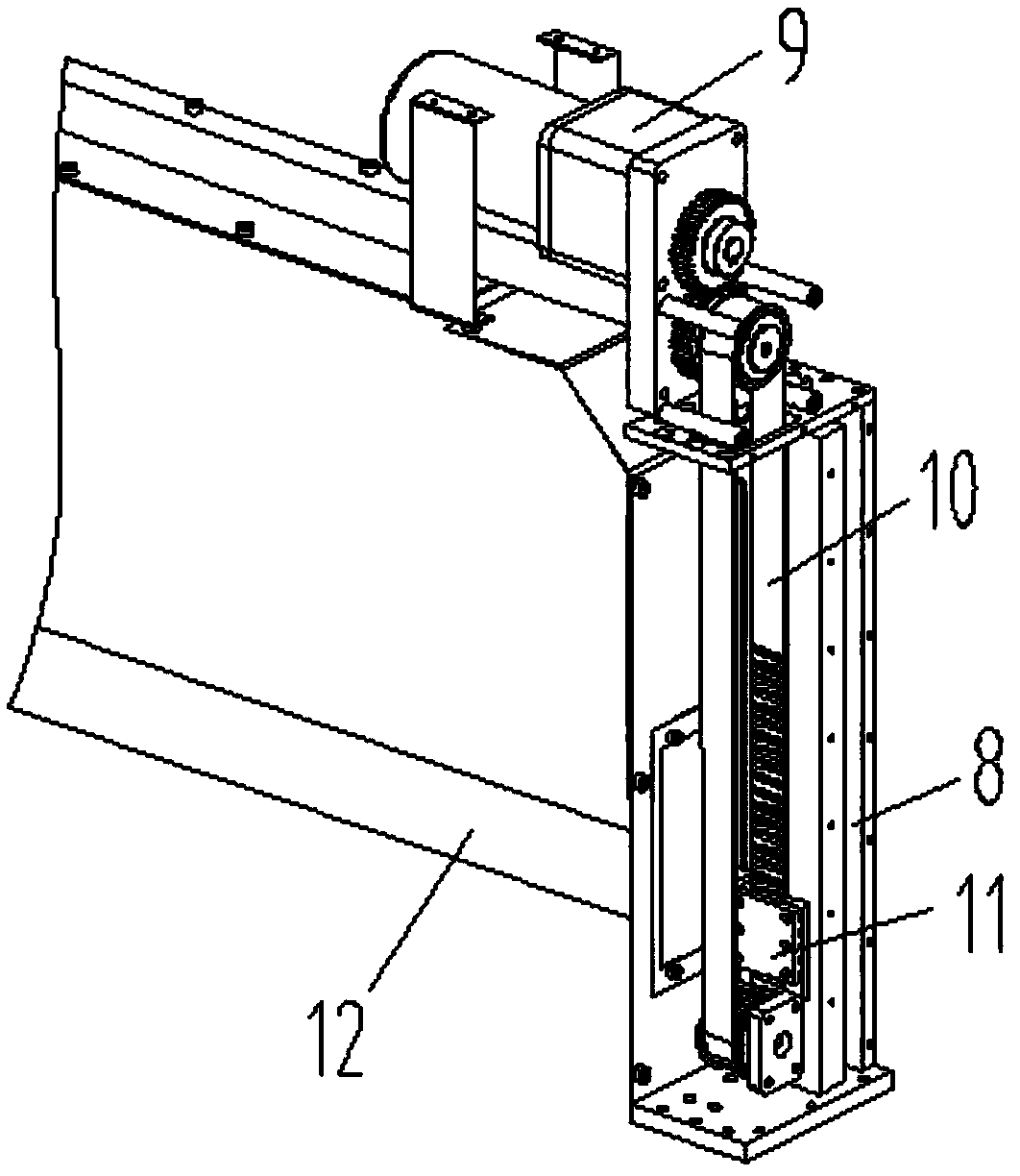

Emergency buffer device capable of preventing lift car from rushing to top and elevator using emergency buffer device

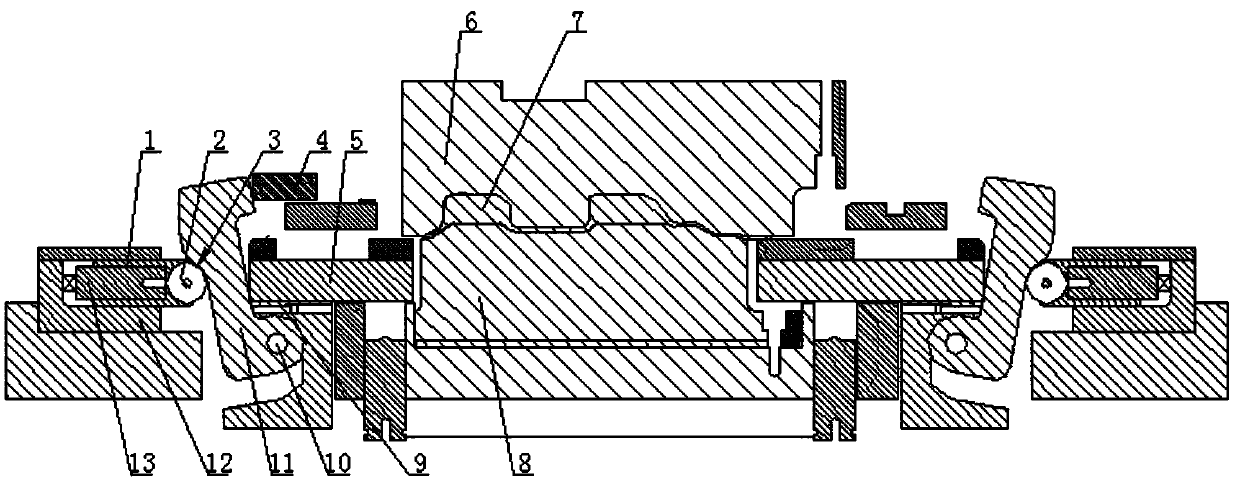

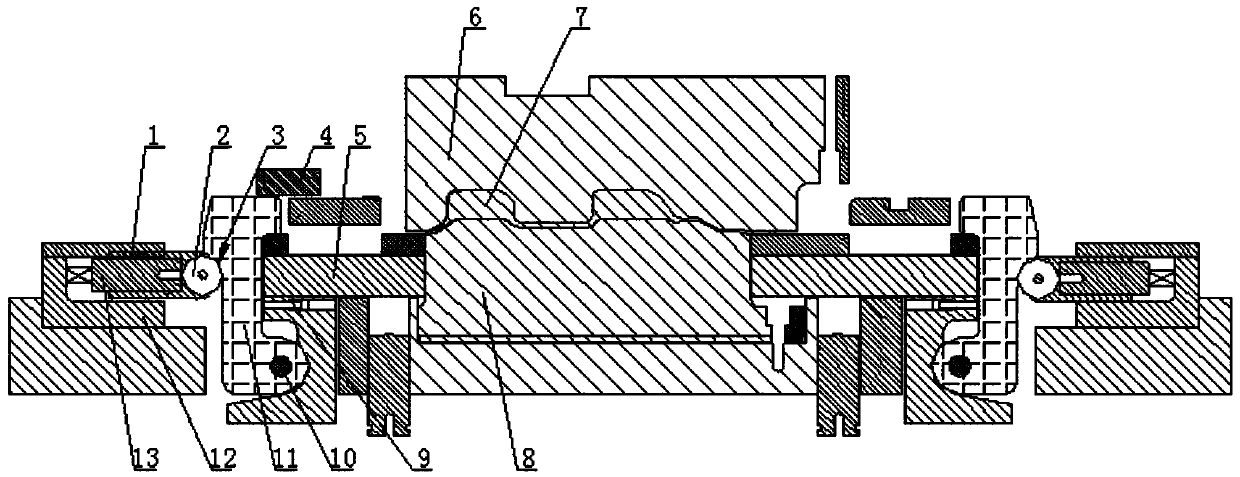

InactiveCN113602931AReduce rotation speedReduce lifting speedElevatorsHoisting equipmentsBrakeCalipers

The invention discloses an emergency buffer device capable of preventing a lift car from rushing to the top and an elevator using the emergency buffer device. The emergency buffer device comprises an elevator derrick, a mounting seat, a servo motor, a power shaft and the like. The mounting seat is fixedly mounted on the right side of the top face of the elevator derrick, the servo motor is fixedly mounted on the mounting seat, and the power shaft is welded to the left end of an output shaft of the servo motor. Speed reduction calipers make contact with the power shaft, the speed reduction calipers exert resistance on the power shaft, so that the rotating speed of the power shaft and the rotating speed of devices on the power shaft are gradually decreased, meanwhile, through the effect of a first compression spring, a shifting clamping rod limits a movable limiting wheel, the rotating speed of the movable limiting wheel is decreased, the lifting speed of the lift car is decreased, then the lift car can stop in the gradual deceleration process, and the phenomenon that the lift car ascends too fast and rushes to the top when the braking effect of a brake is insufficient is prevented.

Owner:广州元坤新材料有限公司

Construction process of floral tube dry filling piles

InactiveCN101713189AReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

The invention relates to a construction process of floral tube dry filling piles with obvious engineering effect, low economic cost, high technical content and high resource utilization by improving the inherent characteristics of cement, soil strata, materials and the like. The process comprises the following steps of: (1) pore-forming process: 1, using dry pore-forming process for pore-forming piles above underground water level; 2, positioning a pore opening machine and a drill for pore-forming piles below underground water level; drilling in at low stroke and high rotary speed with clean water; reaching a drilling-in depth; lifting to a pore opening at unified stroke and high rotary speed with clean water; drilling into a pore bottom at unified stroke and high rotary speed with clean water; rotating at high speed and filling with cement mortar; and lifting to the pore opening at high rotary speed and low stroke after cement mortar returns to the pore opening; moving the drill; (2) the process of installation and pile molding by filling: adopting the following steps for installing pile pores and filling dry cement above or below water level: installing floral tubes; correcting the pore position of the floral tubes; filling the dry cement; and filling the dry cement to an elevation required by the design.

Owner:HENAN UNIVERSITY

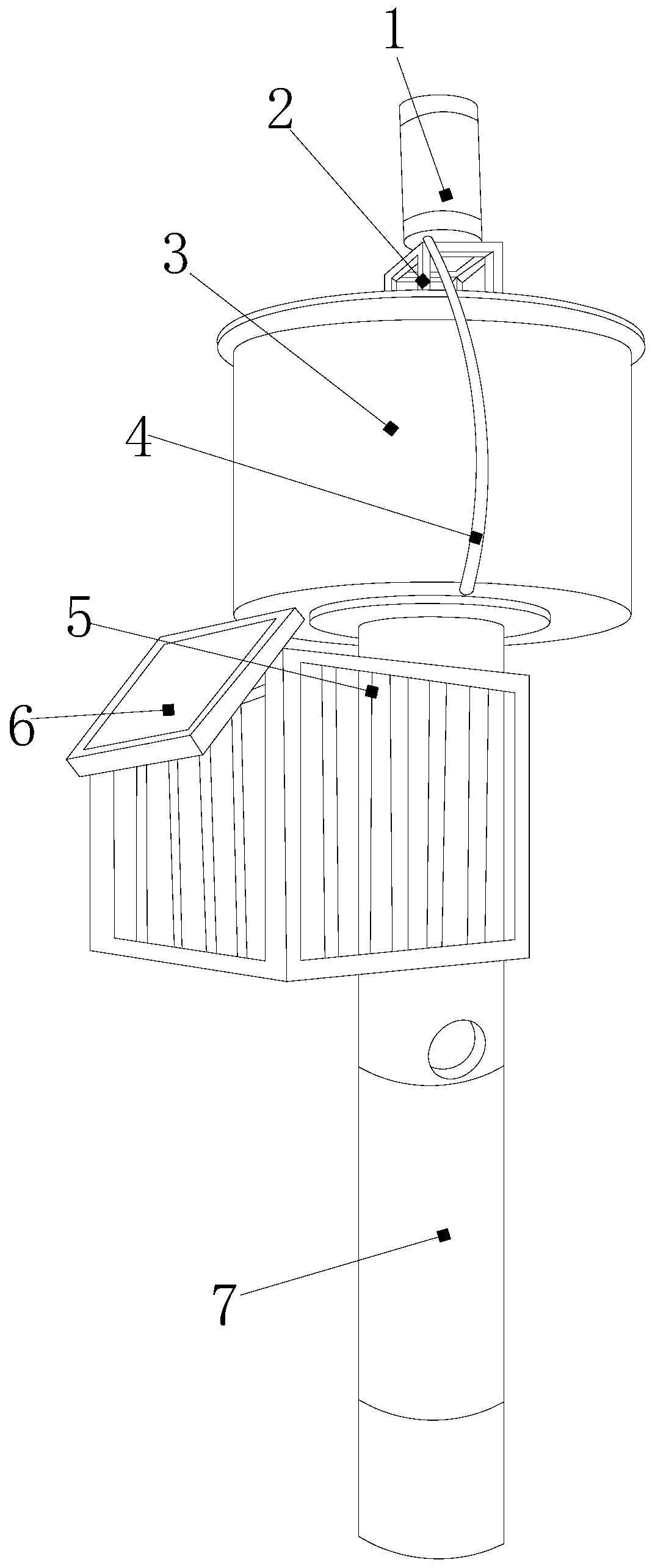

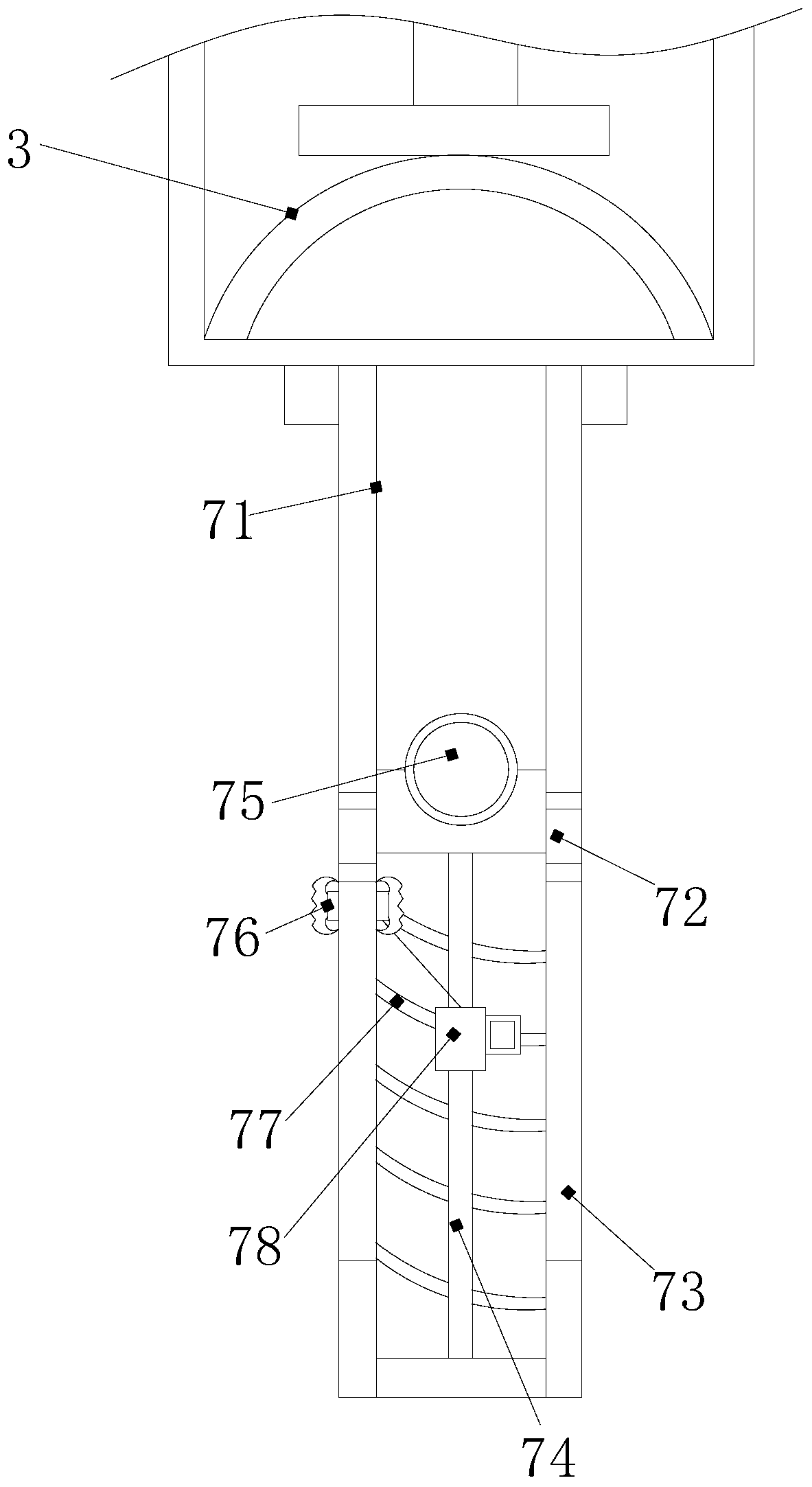

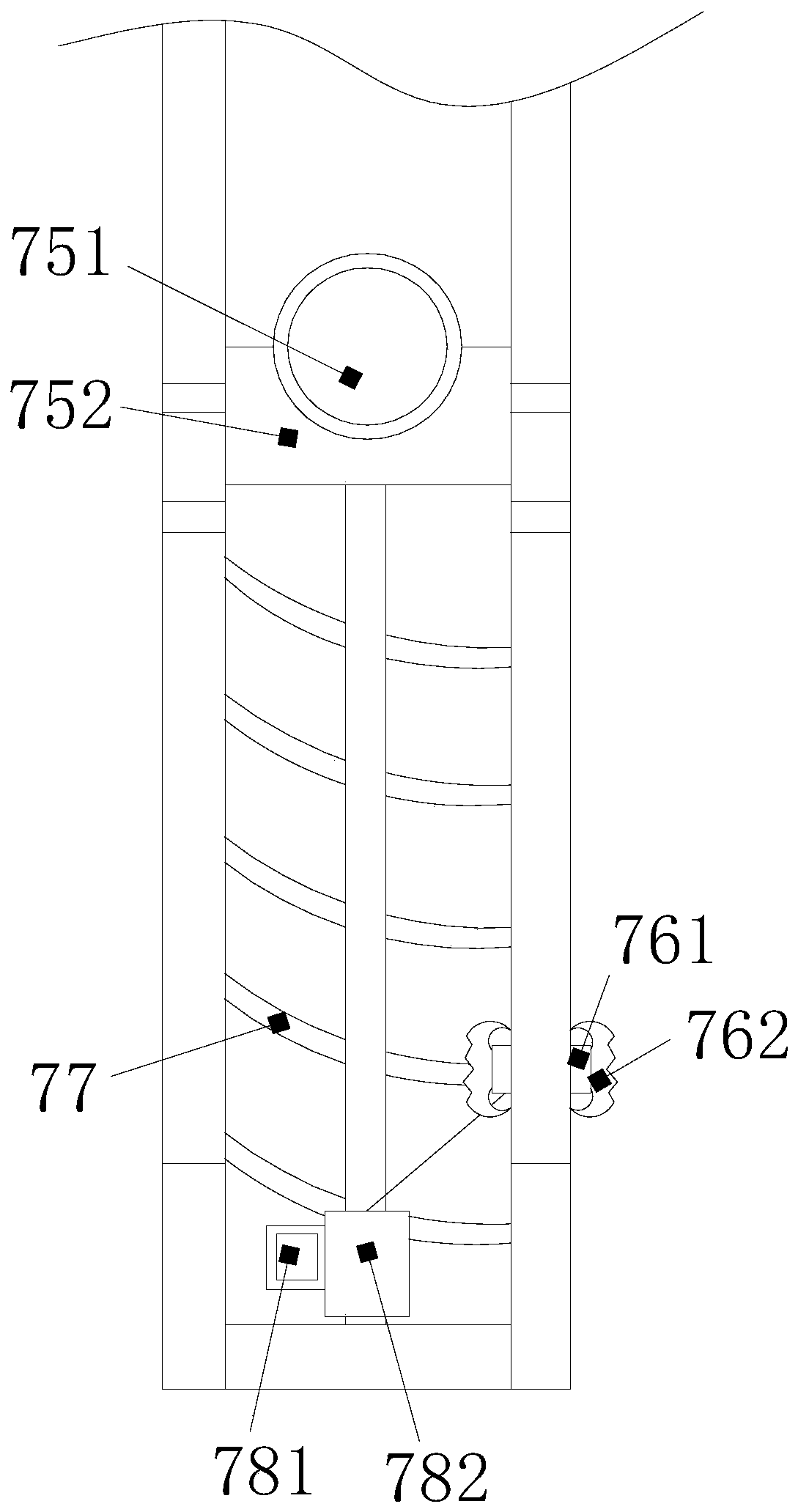

Anti-coiled water level monitoring device at coastal duckweeds of dam used for water conservancy project

ActiveCN110260950ALinkage stabilityAvoid interferenceWater cleaningLevel indicators by floatsIsolation effectWater flow

The invention discloses an anti-coiled water level monitoring device at coastal duckweeds of a dam used for a water conservancy project. The structure comprises a water purifier, an iron frame pedestal, an airbag metering tank, a suction pipe, a maintenance fence frame, a solar panel, and a liquid level buoy cylinder. The airbag metering tank and the liquid level buoy cylinder are cooperated. A liquid level rises and is flowed into a lower support column cylinder to raise a floating plate rod frame so as to detect liquid level data, and water is released through a drain hole and depressurization is performed. A heavy-duty drum pulls a razor magnet seat to go down around a spiral track to shave and clean duckweed attachments. At this time, the airbag metering tank obtains the liquid level data through the lifting of the floating plate rod frame, and a dredging effect is formed through surrounding sliding. A crescent knife edge of a razor plate is attached to a wall, and then a double-sided scraper synchronization effect of inner and outer wall magnetic absorption is formed through a magnet slot seat. Upper and lower displacements are prompted to form a gap isolation effect, an interference of water flow impurities is avoided and a liquid surface is effectively sucked from a bottom. And an effect of increasing equipment work precision is achieved.

Owner:山东水发工程质量检测有限公司

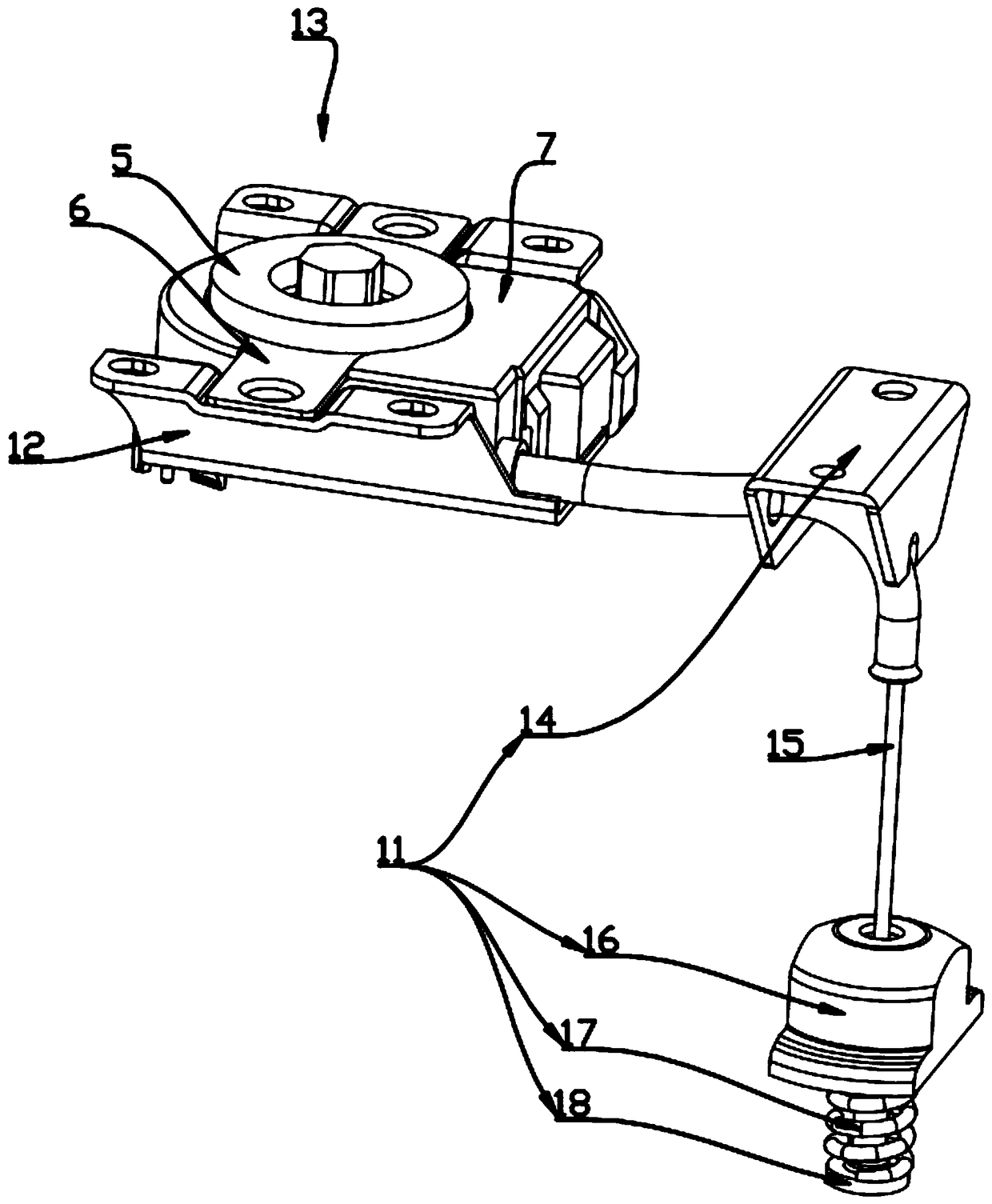

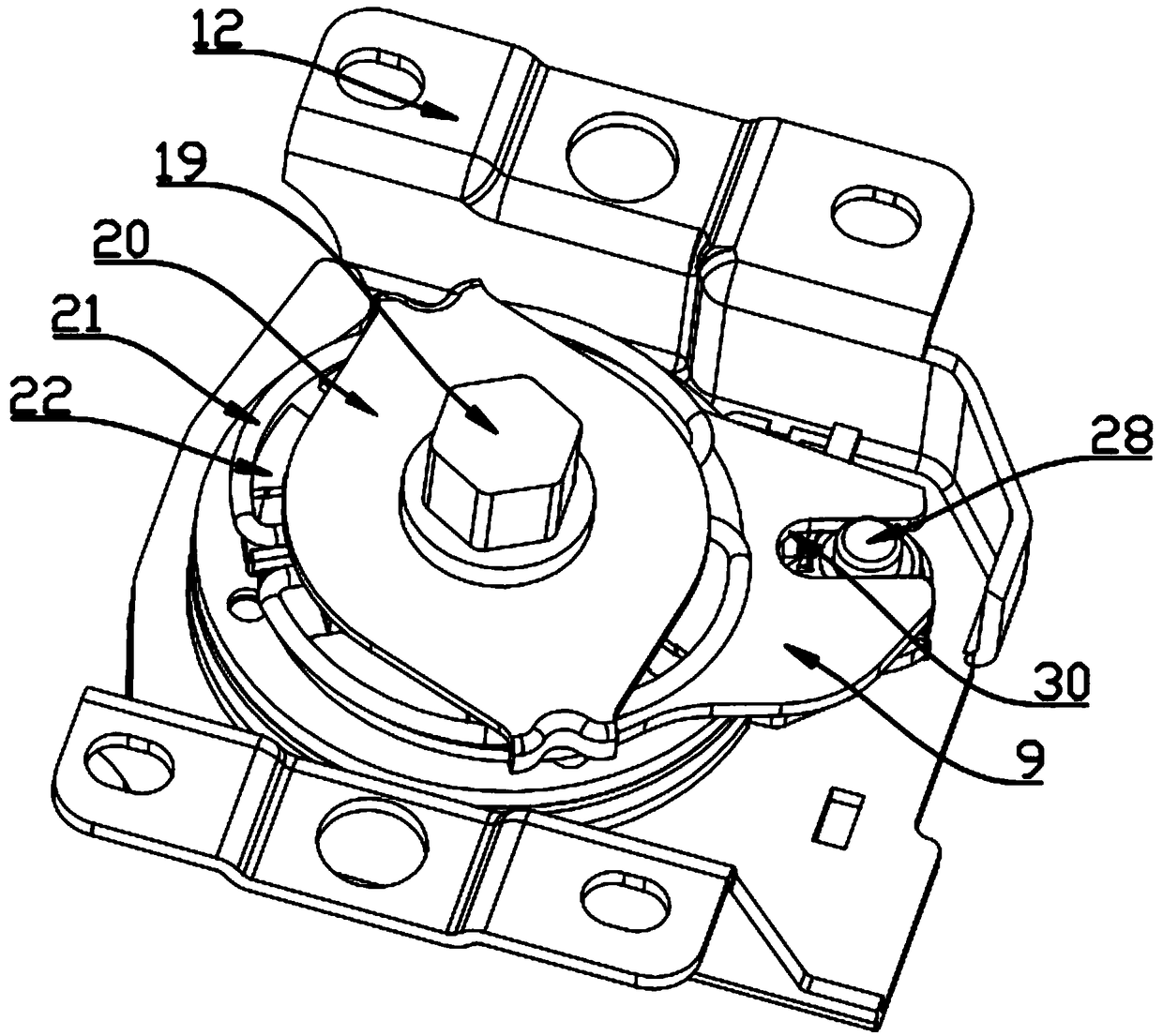

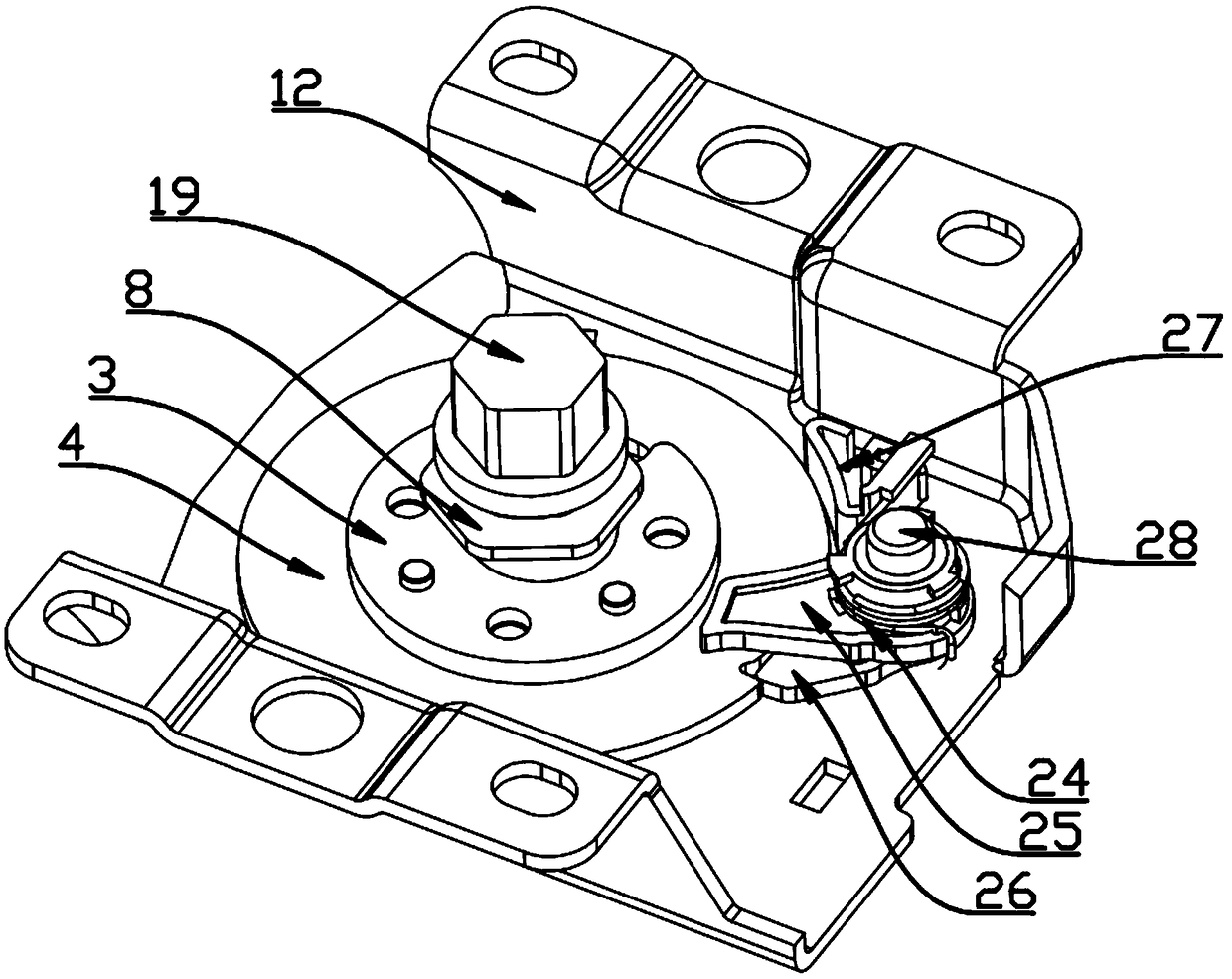

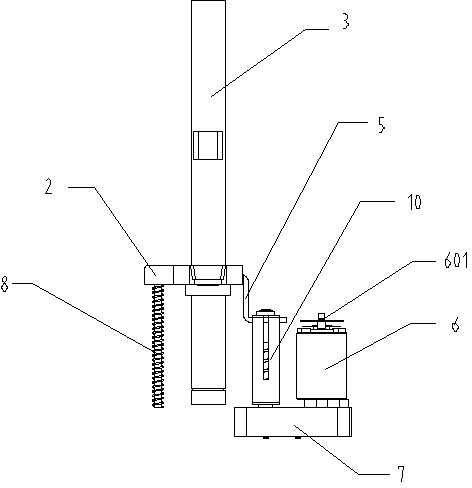

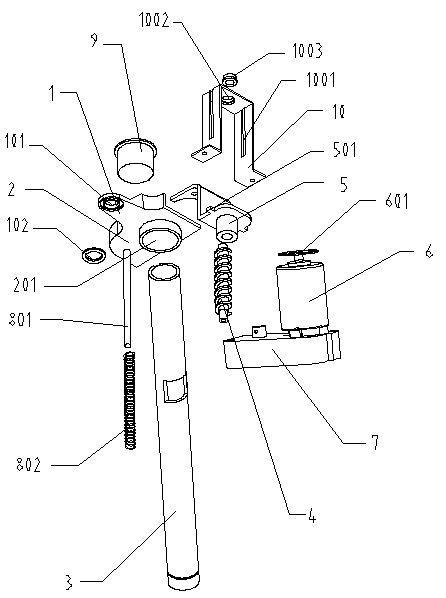

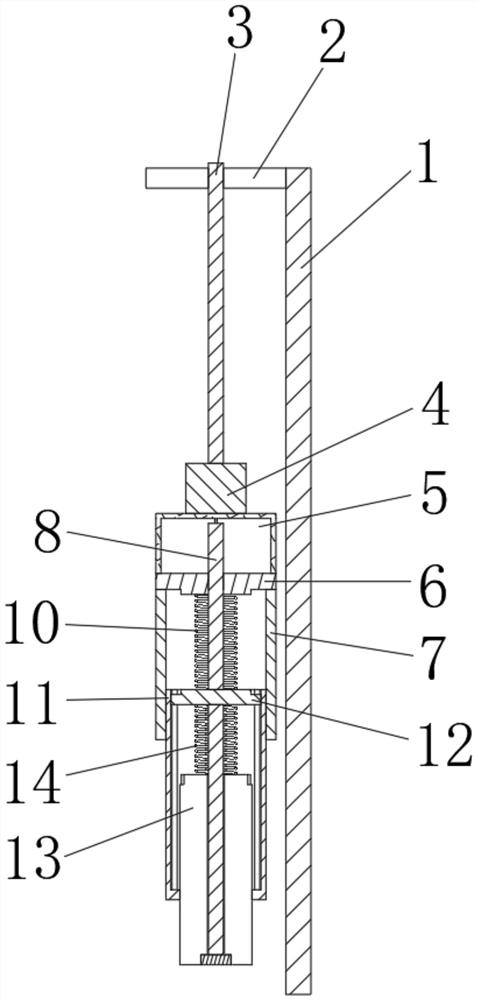

Novel lower limit spare tire lifter

PendingCN109109986AOutstanding and Beneficial Technical EffectsPrevent reverse riseSpare wheel arrangementsLower limitDrive shaft

The invention belongs to the technical field of automobile equipment, in particular to a novel lower limit spare tire lifter. The lifter includes a spare tire mount and a spare tire driving device mounted on the vehicle body, a spare tire mount is connected to the spare tire driving device by a wire rope, the spare tire driving device comprises a bracket, a driving shaft is pierced on the bracket,a rope rotary table is sleeved on the driving shaft, a rope notch is arranged on the rope rotary table, one end of the steel rope is fixed in the rope notch, and the rope rotary table is rotated to drive the spare tire mount to rise and fall through the steel rope; a lower limit locking mechanism is also installed in that spare tire driving device, the lower limit locking mechanism comprises a pawl rotatably arranged on the periphery of the rope rotary table, the front end of the pawl is matched with the rope notch, a torsion spring is arranged on the pawl, and the pawl is pressed down on therope rotary table through the torsion spring. The lower limit locks the spare tire lifter to increase the lower limit structure to avoid further reverse rise after the spare tire is lowered to the bottom.

Owner:ZHEJIANG DINGLI TIANYI AUTO PARTS CO LTD

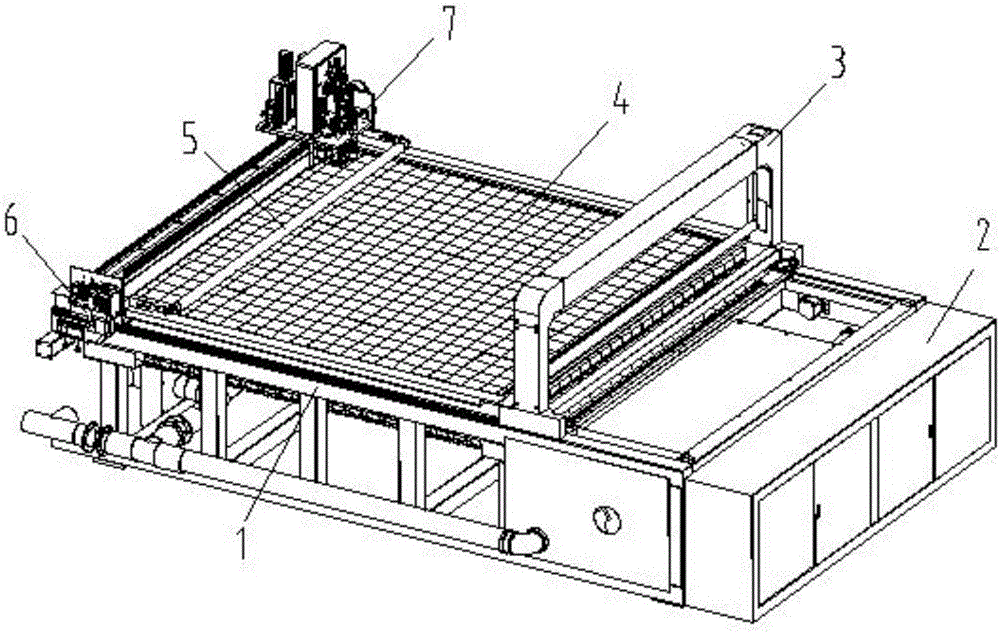

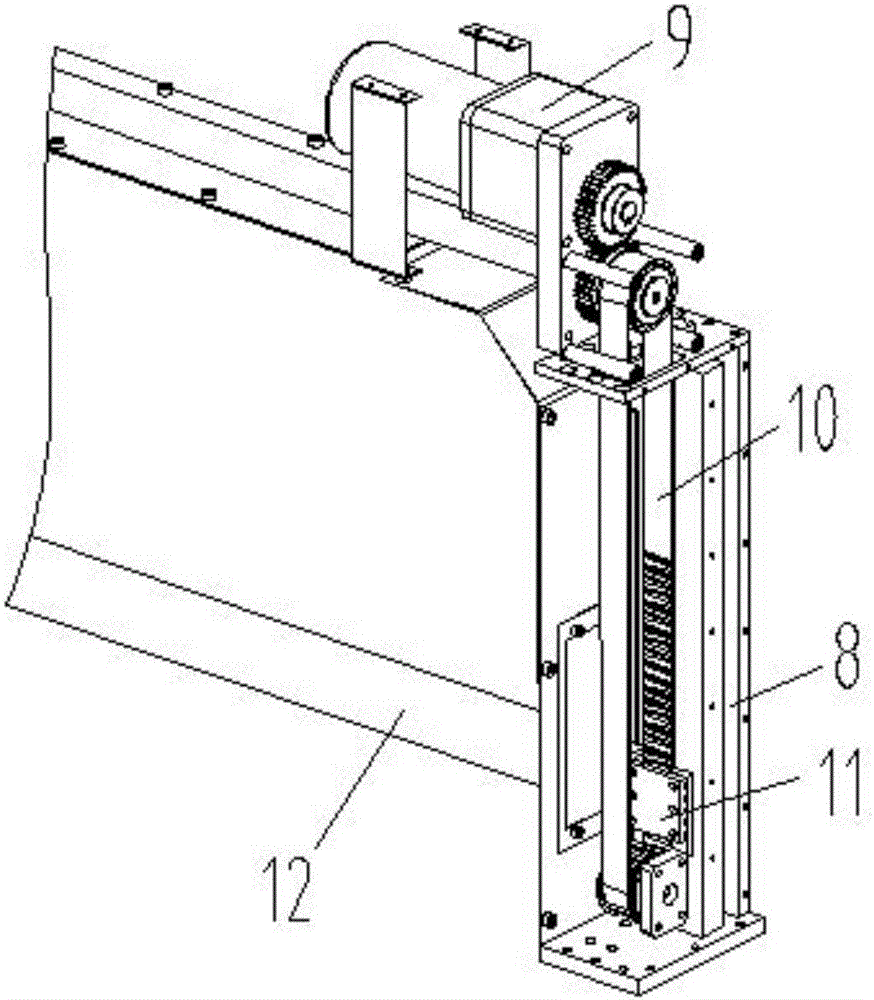

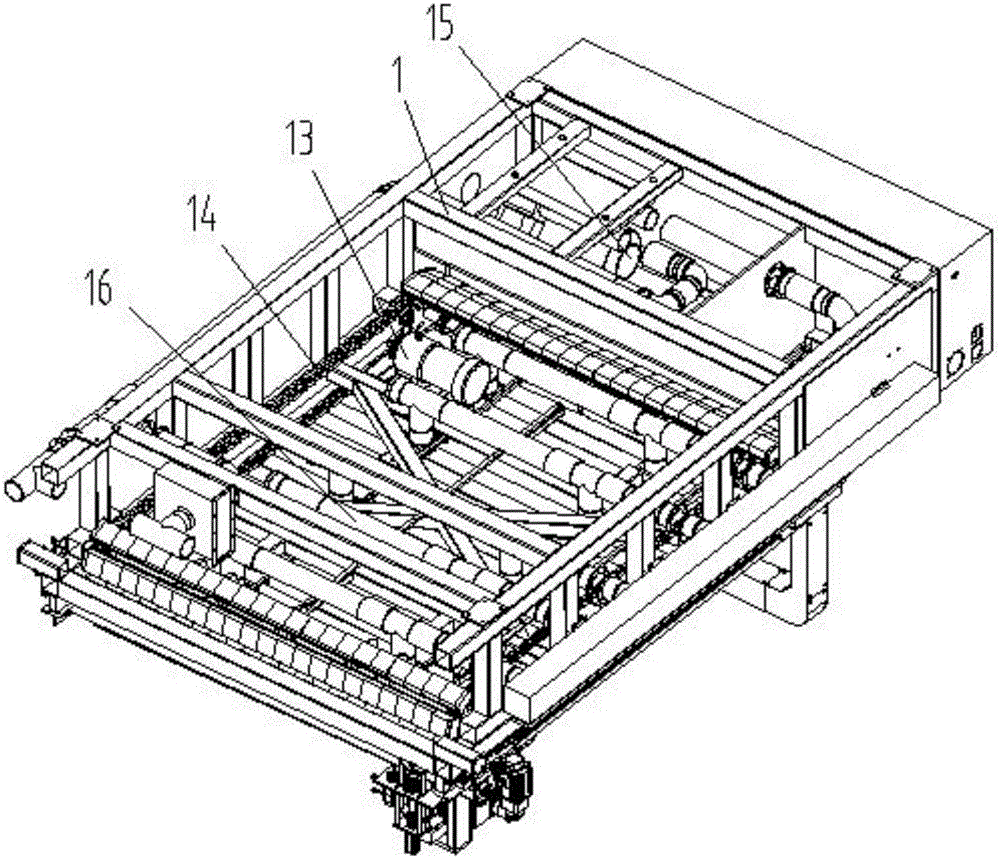

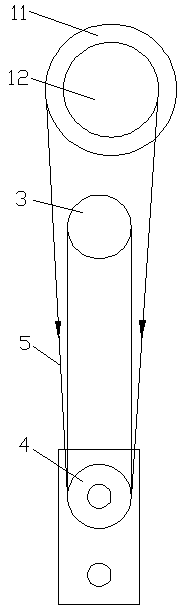

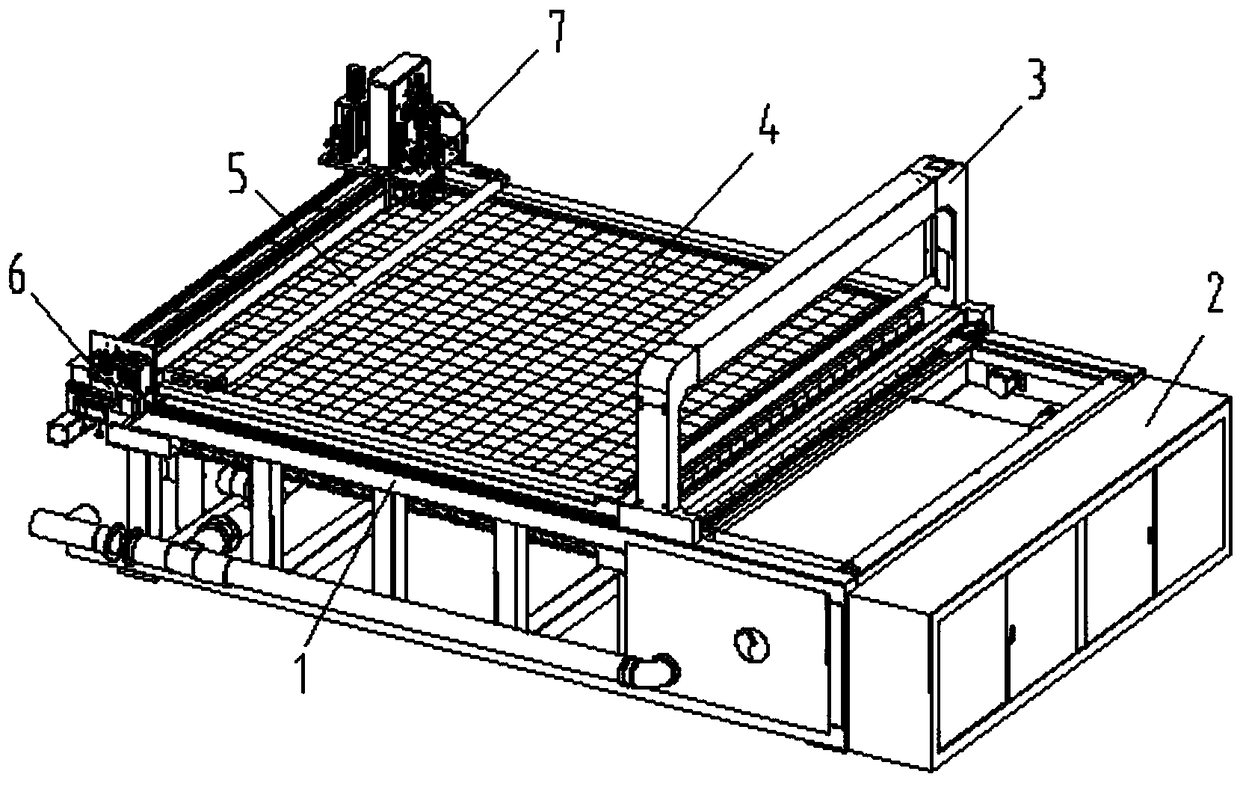

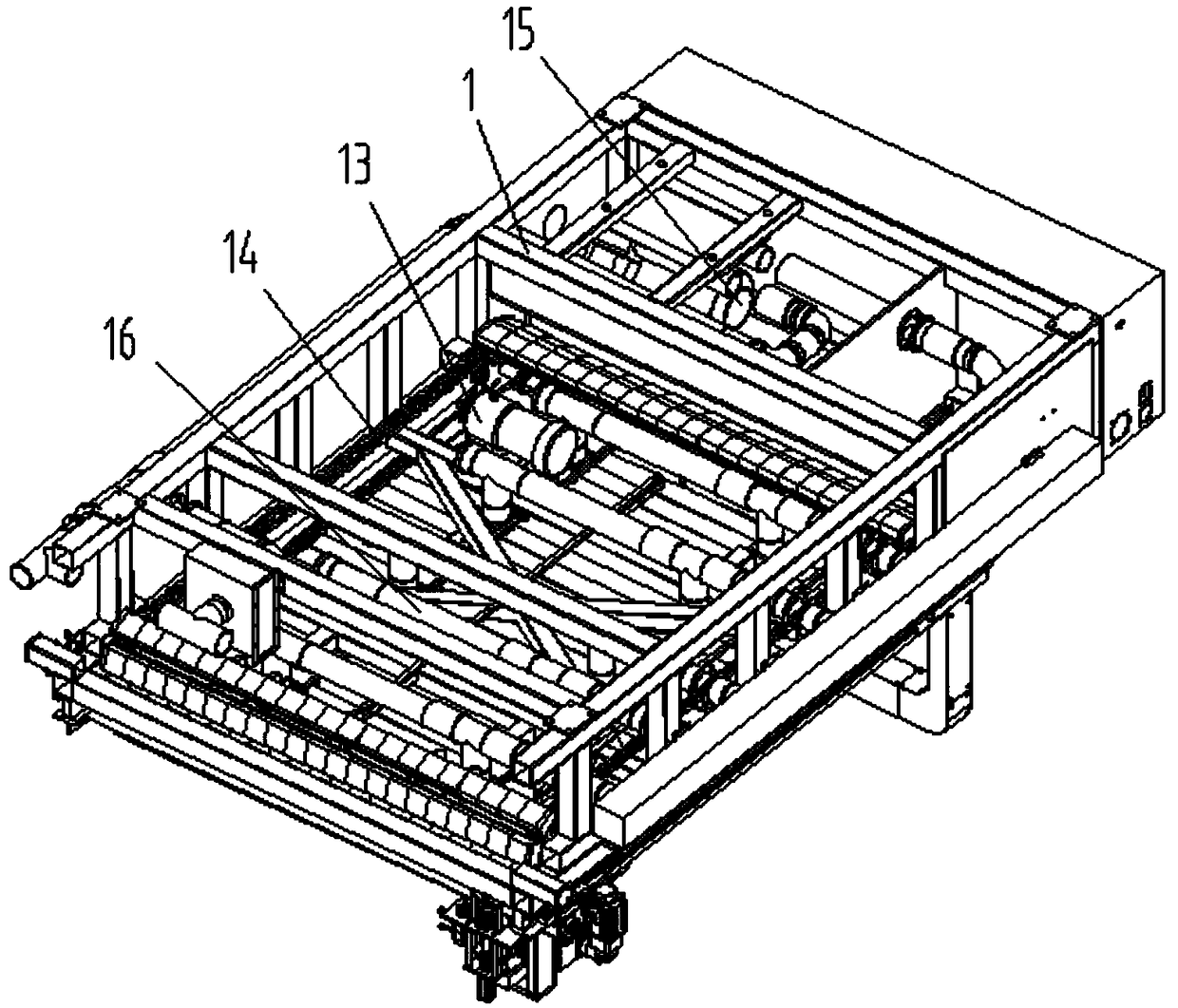

Full-automatic fabric cutting machine

ActiveCN106758113AAvoid situations that damage the conveyor beltGood transportabilityConveyorsSevering textilesConveyor belt

The invention relates to a full-automatic fabric cutting machine. A machine frame is provided with a horsehair conveyor belt, a feeding device is arranged above the machine frame, the feeding device is provided with a cutting mechanism, the cutting mechanism comprises a fabric cutting frame, the fabric cutting frame is provided with a cutting knife sleeve, the lower part of the cutting knife sleeve is provided with a cutting knife groove, the cutting knife groove is communicated with the cutting knife sleeve, the cutting knife sleeve is internally provided with a cutting knife lifting pulling rod which is matched with the cutting knife in the cutting knife groove, the upper part of the cutting knife lifting pulling rod is connected to a cutting rotating seat in a hinged mode, the cutting rotating seat is also connected to a cutting rotating rod in a hinged mode, the other end of the cutting rotating seat is arranged on a sleeving connecting shaft on a cutting installing plate of the fabric cutting frame in a sleeving mode, the other end of the cutting rotating shaft is connected to a cutting rotating sleeve, and the cutting rotating sleeve is matched with a cutting lifting motor on the cutting installing plate. According to the full-automatic fabric cutting machine, the biggest lifting range is limited, the speed capable of slowing down lifting is adjusted at the same time, and the situation that the cutting knife destroys the conveyor belt is sharply avoided.

Owner:扬州鸿炜高新材料科技有限公司

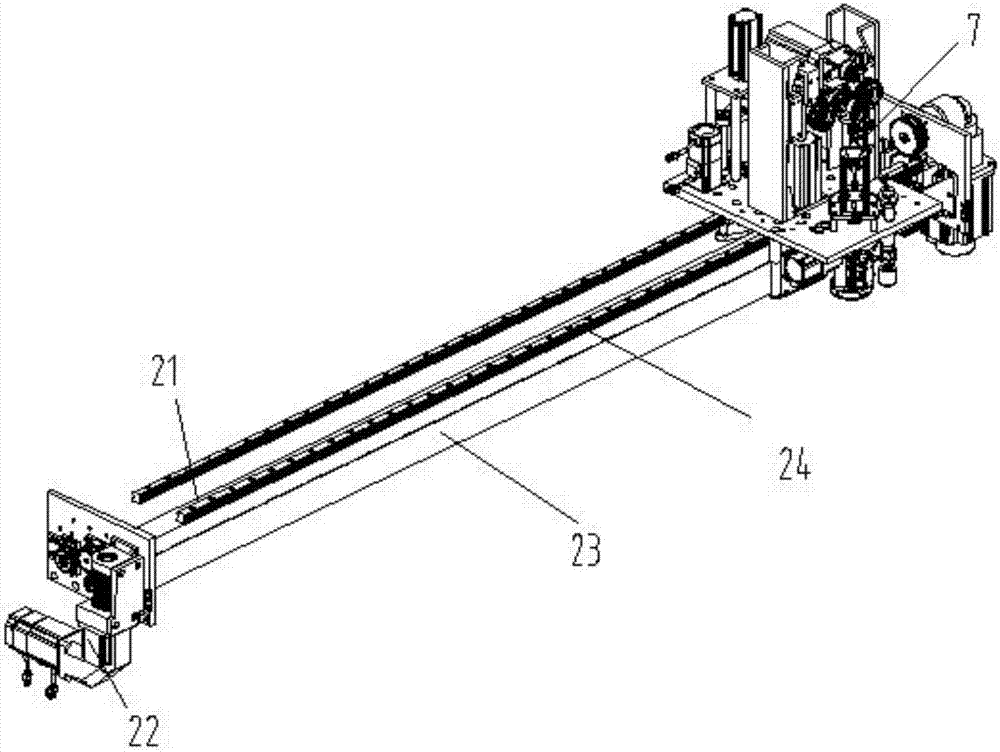

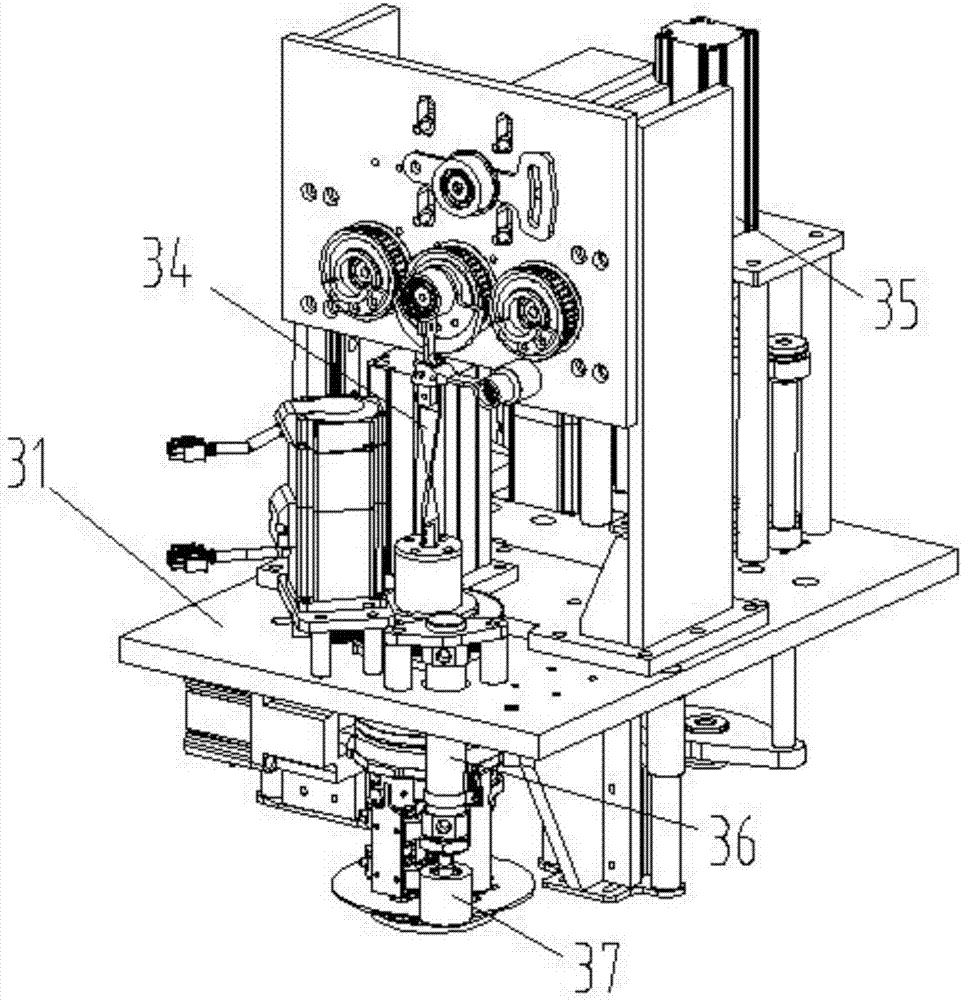

Fabric cutting device capable of adapting to belt conveying

ActiveCN106854830AReduce lifting speedAvoid situations that damage the conveyor beltSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to a fabric cutting device capable of adapting to belt conveying. The fabric cutting device comprises a feeding device, the feeding device is provided with a fabric cutting frame, the fabric cutting frame is provided with a cutting device, the cutting device comprises a cutter sleeve on the fabric cutting frame, the lower portion of the cutter sleeve is provided with a cutter groove, the cutter groove is communicated with the cutter sleeve, and a cutter lifting pull rod matched with a cutter in the cutter groove is arranged in the cutter groove, the upper portion of the cutter lifting pull rod is hinged to a cutting rotating base, a cutting rotating rod is further hinged to the cutting rotating base, the other end of the cutting rotating base sleeves a sleeving shaft on a cutting mounting plate on the fabric cutting frame, the other end of the cutting rotating rod is connected to a cutting rotating sleeve, and the cutting rotating sleeve is matched with a cutting lifting motor on the cutting mounting plate. The cutter lifts or descends through the hinged cutter lifting pull rod, the cutting rotating rod and the cutting rotating base, a maximum lifting and descending range is limited, the lifting or descending speed can be slowed down through regulation, and damage to a conveying belt by the cutter is avoided greatly.

Owner:华清(扬州)织物有限公司

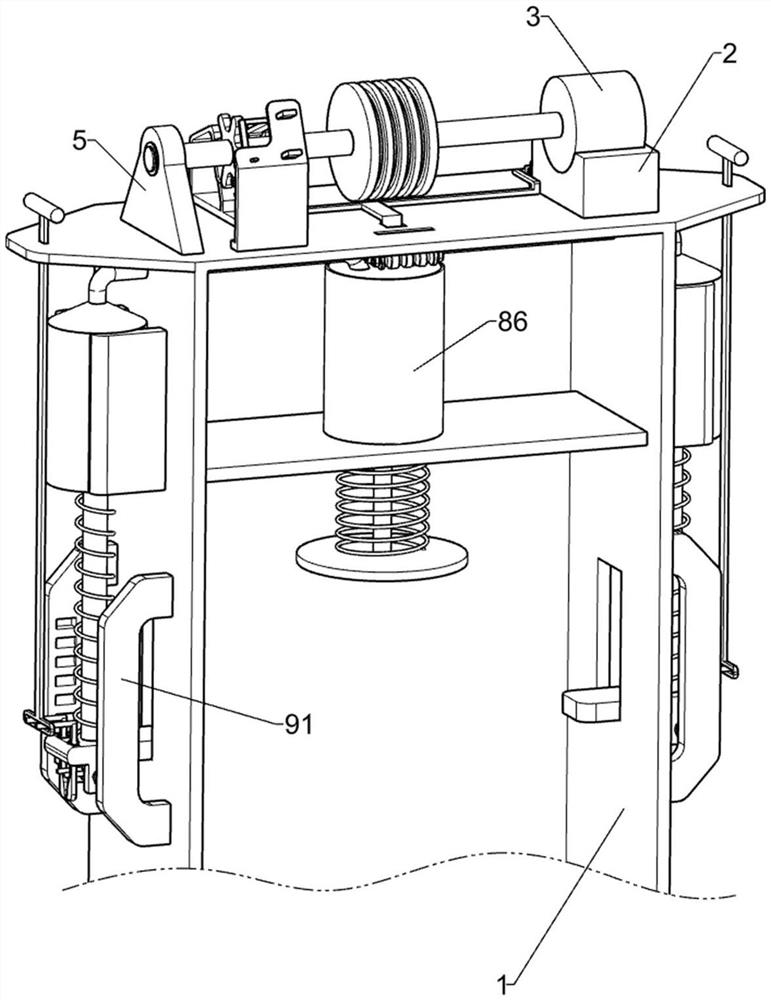

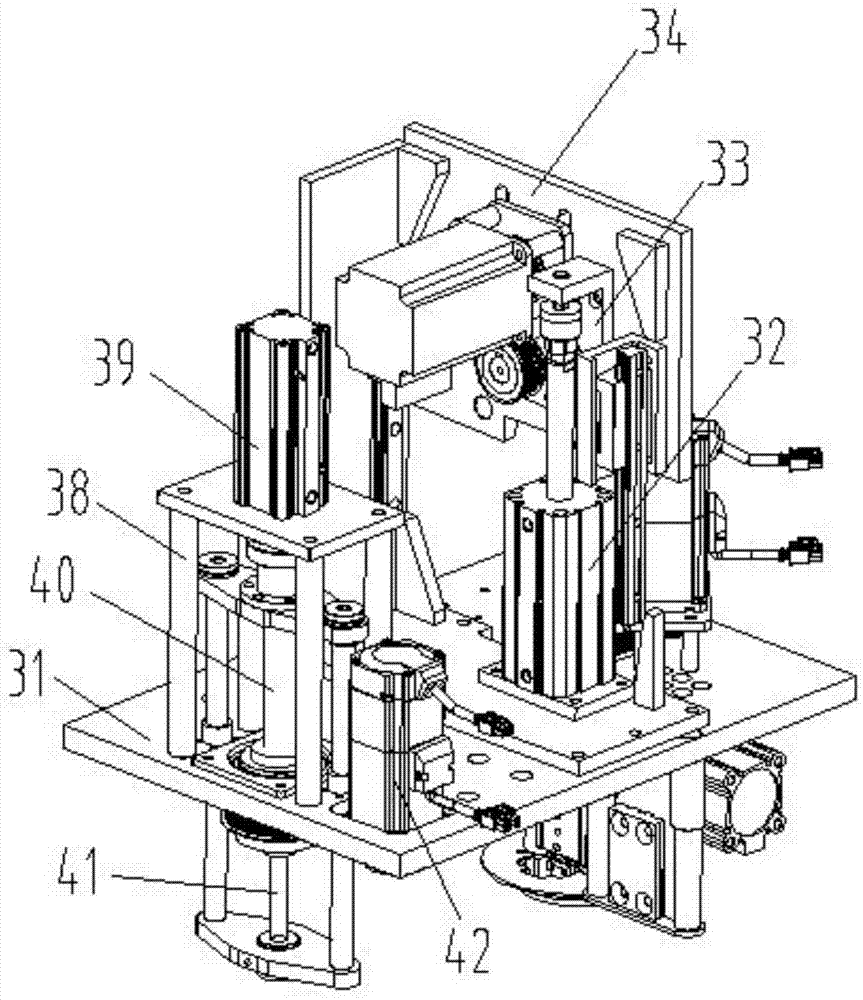

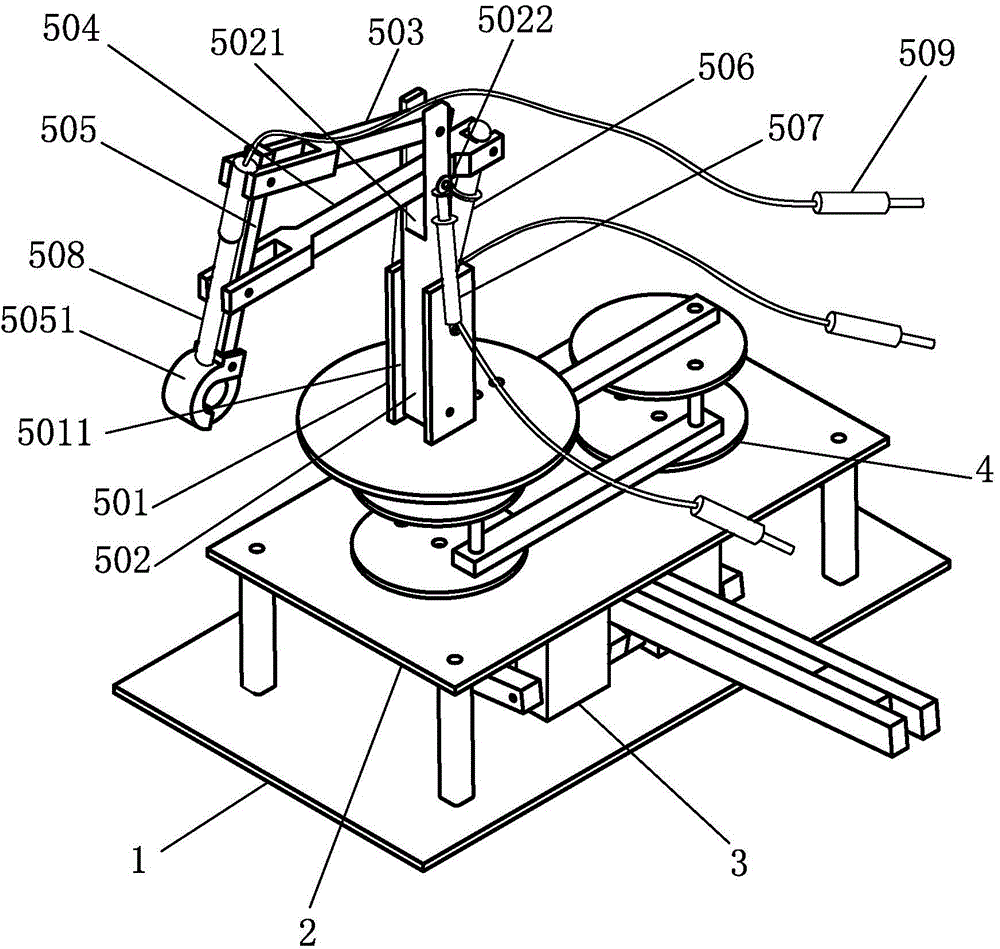

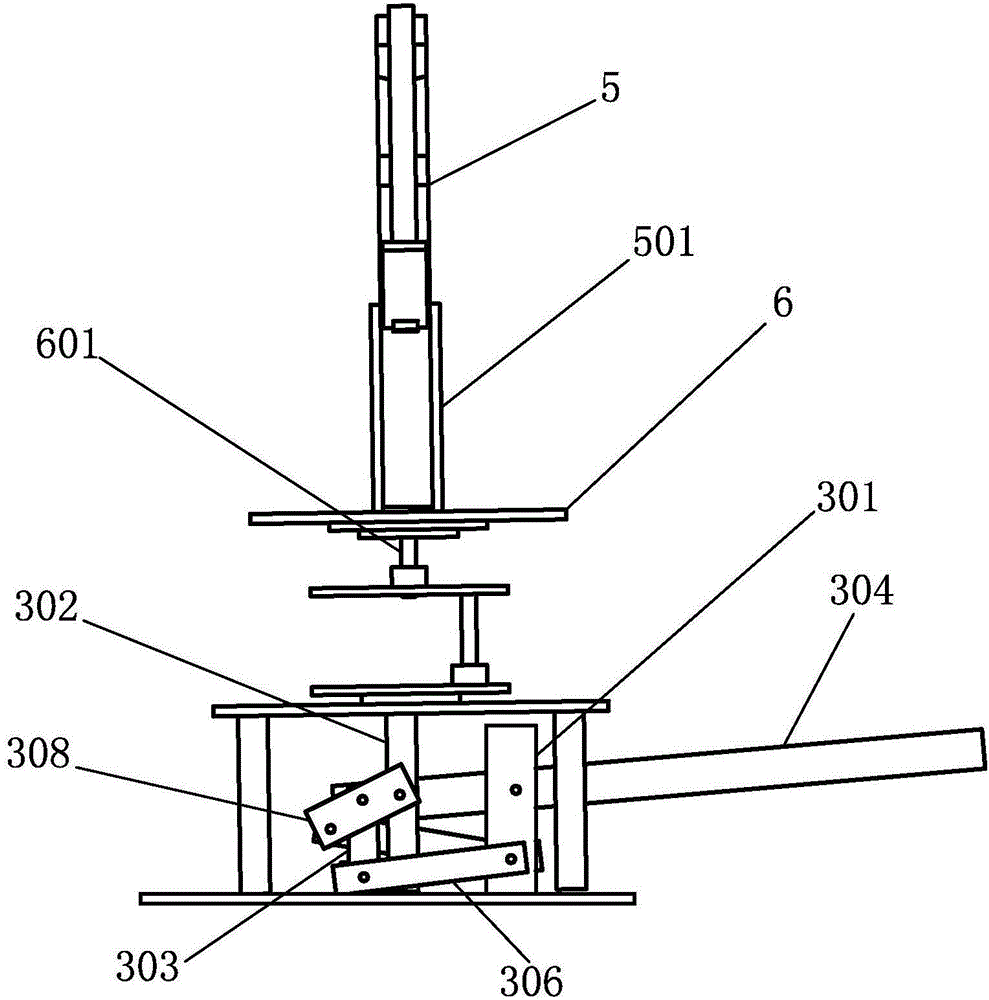

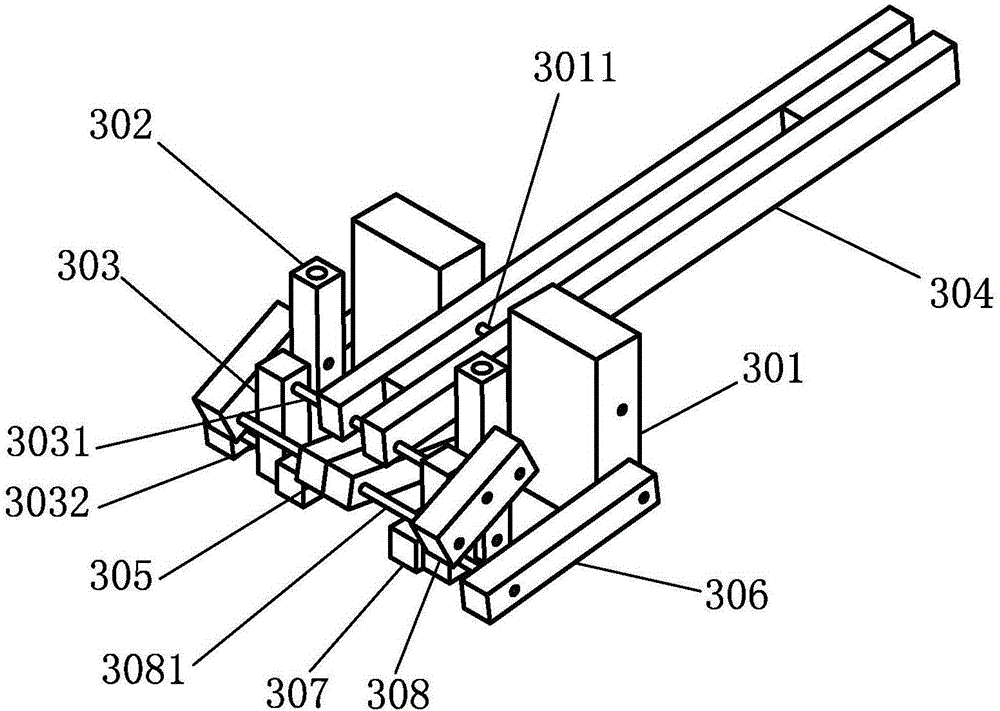

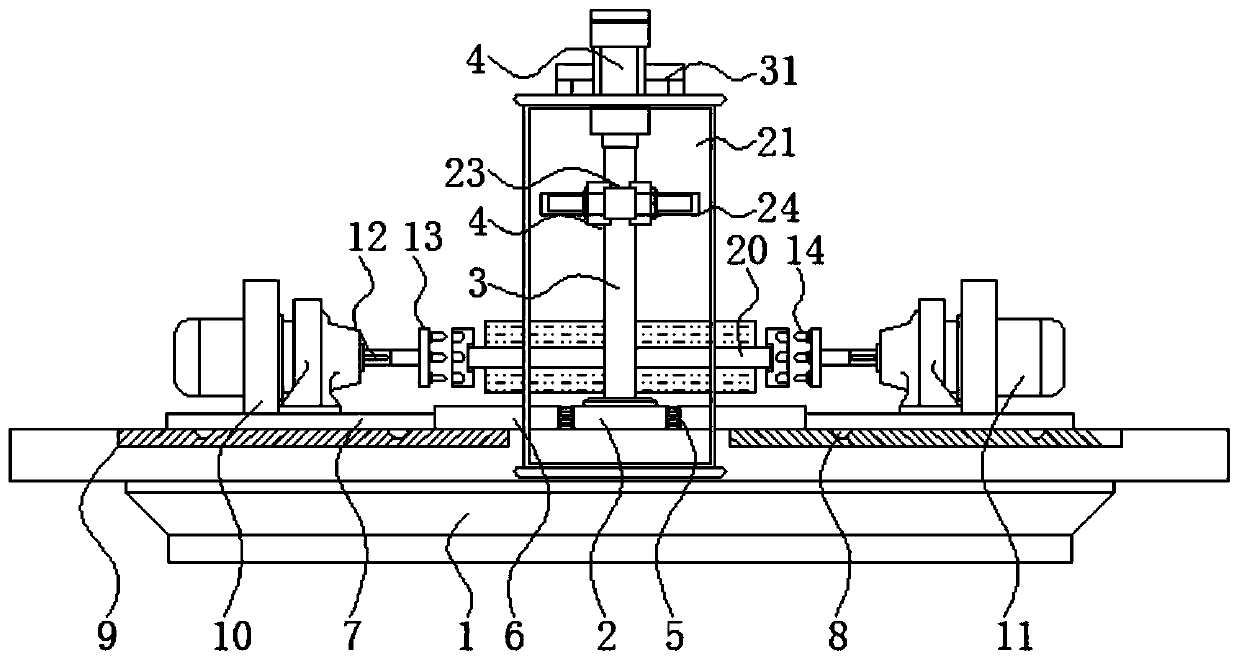

Multi-freedom manipulator teaching aid

The invention discloses a multi-freedom manipulator teaching aid. The multi-freedom manipulator teaching aid comprises a base plate and a platform. An elevating mechanism is arranged between the base plate and the platform, the upper end surface of the platform is provided with a rotary base, the rotary base comprises a driven rotating disk and a driving rotating disk, a linkage rod is arranged between the driven rotating disk and the driving rotating disk, the driven rotating disk and the driving rotating disk are respectively rotationally fixed to the upper surface of the platform, the driven rotating disk is provided with a hydraulic driving type manipulator, and the hydraulic driving type manipulator comprises a clamping seat and a manipulator. The multi-freedom manipulator teaching aid has the following advantages: vertical ascending and descending of the rotary base can be realized, the stability of an elevating process is improved, the part structure and the hydraulic system of the manipulator are simpler, and the multi-freedom manipulator teaching aid is more suitable for a teaching aid.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Paper pressing mechanism for bookbinding machines

ActiveCN104175740AFully automatedPress paper at a constant speedSheet bindingIndustrial engineeringBalance spring

The invention provides a paper pressing mechanism for bookbinding machines. The paper pressing mechanism is characterized in that a lifting perpendicularity degree guiding device is arranged on a lifting bracket and comprises a guiding strut and a balance spring, the guiding strut is arranged under the lifting bracket and used for adjusting of perpendicularity degree, the balance spring sleeves the guiding strut and used for balancing action force, generated from a lifting screw during the course of lifting, of the balance bracket and ensuring smoothness of lifting of the lifting bracket, and the guiding strut is parallel to a lifting spindle with each other. The paper pressing mechanism provided with an independent power is simple in structure, good in paper pressing effect and free of impact and noise during operation.

Owner:ZHEJIANG ZHIYUAN OFFICE EQUIP MFG

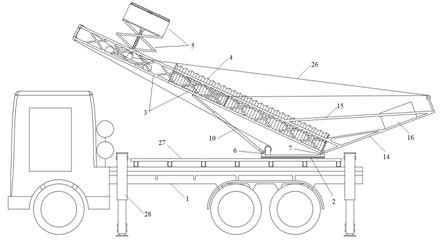

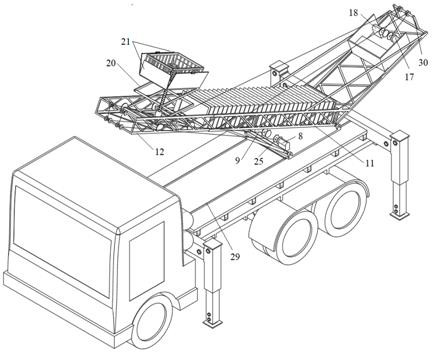

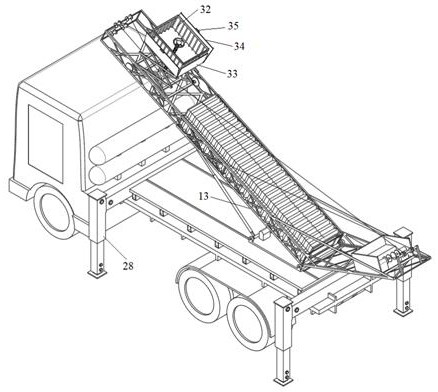

Multifunctional scaling ladder truck and working method

ActiveCN114263429AComplex structureLifting speed is slowFire rescueItem transportation vehiclesStructural engineeringControl theory

The invention discloses a multifunctional scaling ladder truck and a working method.The multifunctional scaling ladder truck comprises a scaling ladder truck base, a rotary working platform, a scaling ladder set, an organ air bag channel and a scaling ladder transporting trolley, the scaling ladder set comprises a supporting scaling ladder and a movable scaling ladder, the supporting scaling ladder is sleeved with the movable scaling ladder, and the movable scaling ladder extends out of one end of the supporting scaling ladder; the supporting scaling ladder is of a V-shaped structure and is divided into a guide rail scaling ladder part and a counterweight scaling ladder part, the scaling ladder transportation trolley comprises a trolley underframe, an X-shaped connecting rod support and a trolley bearing cabin, and the organ air bag channel is of a convex structure and is laid between the supporting scaling ladder and the movable scaling ladder; the scaling ladder transportation trolley and the movable scaling ladder both adopt a traction rope driving mode, the speed is high, the efficiency is high, the lever effect generated in the working process of the scaling ladder transportation trolley is balanced through the design of the guide rail scaling ladder part and the balance weight scaling ladder part, and an air cushion scheme is automatically formed through the design of an organ air bag channel and a one-way door to provide buffering.

Owner:QINGDAO JITE HEAVY IND MACHINERY CO LTD

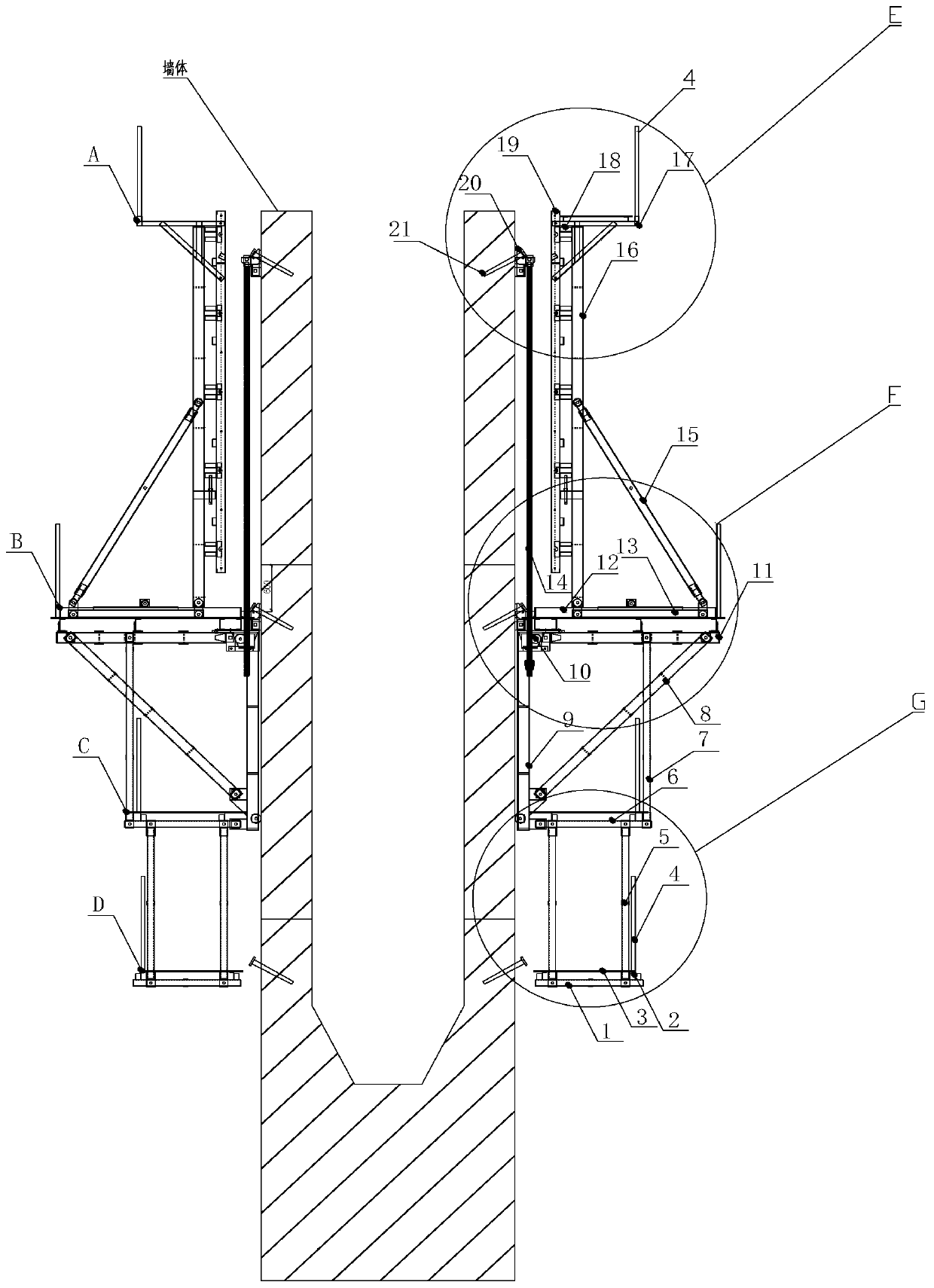

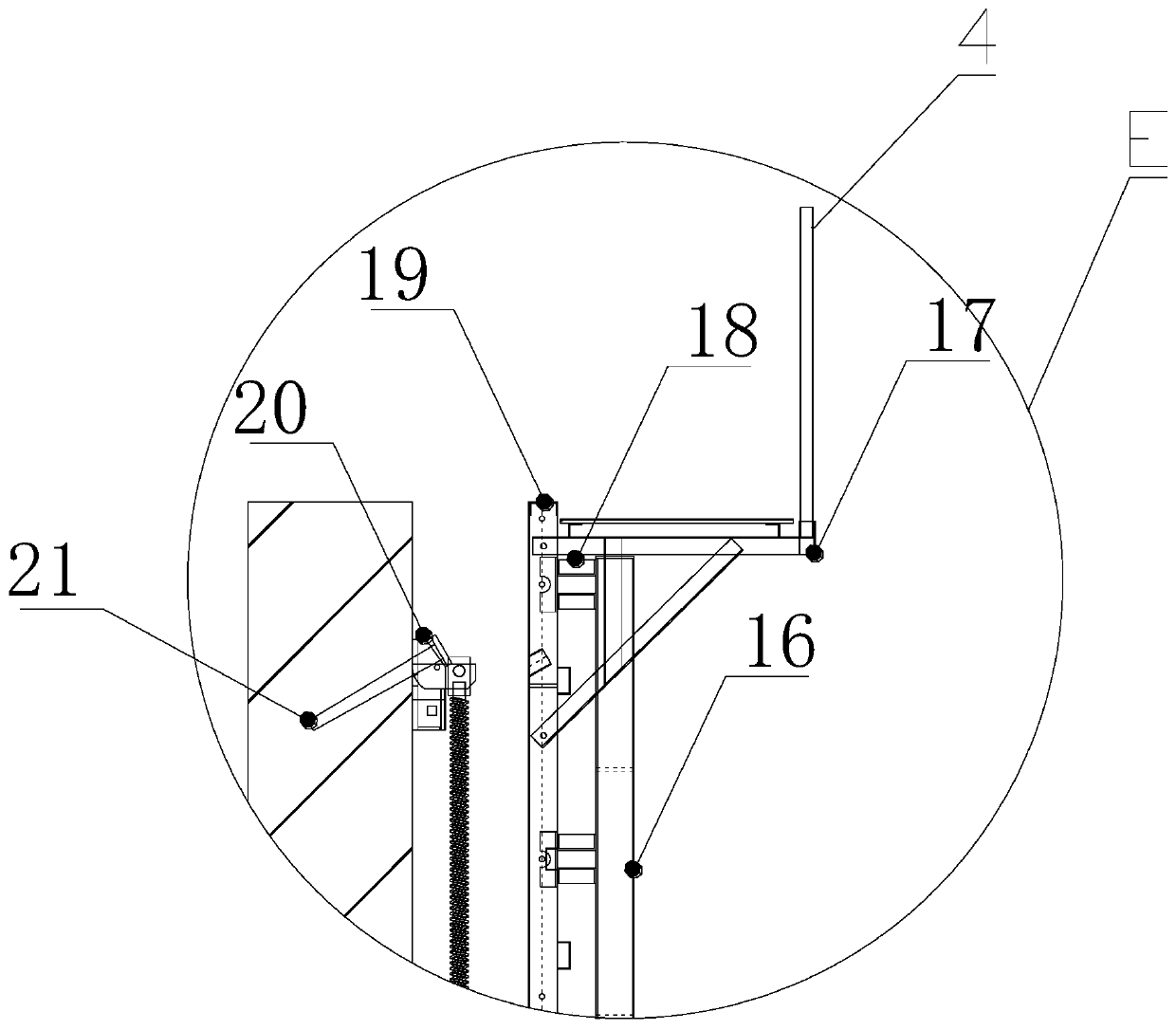

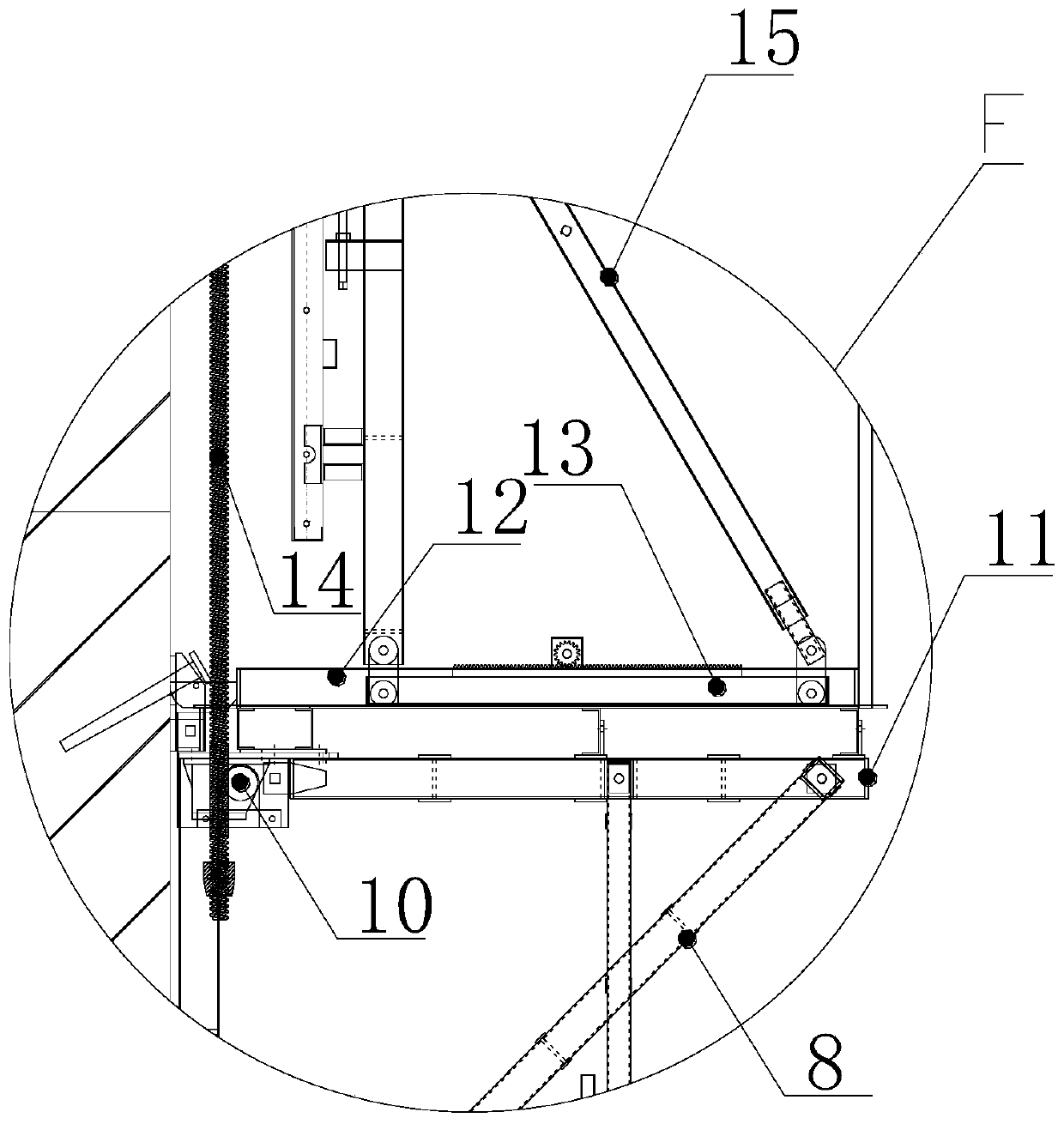

Light climbing mold steel frame system

PendingCN110714611AEasy to operateImprove securityForms/shuttering/falseworksHydraulic ramEngineering

The invention discloses a light climbing mold steel frame system. The system comprises a main platform, a lower platform and a repair platform; the main platform comprises multiple climbing lead screws, a main support frame and a template support sliding module; the main support frame is detachably connected with a cast wall outer wall; the template support sliding module is slidingly mounted on the top surface of the main support frame, and moves in the transverse direction of the main support frame; a template is mounted on the side surface, towards a wall, of the template support sliding module; the climbing lead screws are mounted parallel to the wall; one ends of the climbing lead screws are detachably fixed on the wall, and the other ends are detachably connected with the main support frame; and the main support frame moves in the longitudinal direction of the climbing lead screws. The climbing system needs no operation of a climbing rod penetrating in a hydraulic oil cylinder; and the lead screws are adopted as climbing mechanisms, so that the fixation of the wall and the lead screws can be finished only by needing pins, the operation is simple, and the safety is high.

Owner:昆明市银桥钢模有限公司

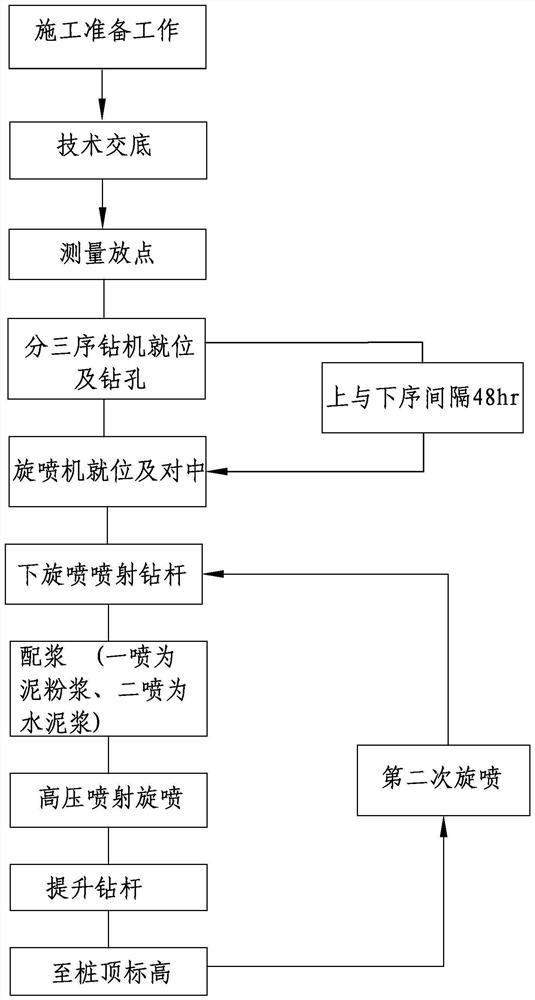

Pile forming method for jet grouting pile in flowing water sand layer

The invention discloses a pile forming method for a jet grouting pile in a flowing water sand layer. The pile forming method comprises the steps that S1, a geological drilling rig is adopted for drilling; S2, clay powder is adopted and mixed with efficient high-foaming bentonite, and first-time jet grouting jetting is conducted in a drilled hole; and S3, cement paste and water glass are adopted for conducting second-time jet grouting jetting in the drilled hole at the same time, the pressure of the second-time jet grouting jetting is smaller than that of the first-time jet grouting jetting, and the lifting speed of the second-time jet grouting jetting is larger than that of the first-time jet grouting jetting. According to the pile forming method, the second-time jet grouting jetting is adopted in the flowing water sand layer; the second-time jet grouting jetting is adopted in the same drilled hole, the clay powder and the bentonite paste of the first-time jet grouting jetting are used for stabilizing gaps between the sand layer and sand grains filling the sand layer firstly, and the sand layer is changed into a sand and soil mixture; and an efficient water reducing agent is added in the cement paste of the second-time jetting, the cement paste of the second-time jet grouting jetting can be prevented from being diluted or washed away or taken away by underground water before being solidified, the success rate of pile forming is increased, and the quality of the jet grouting pile is guaranteed.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS +1

Self-reducing flow low-shape change off land deep water net cage

ActiveCN101326898BAdjustable level statusReduce lifting speedClimate change adaptationPisciculture and aquariaShape changeStress point

The invention discloses an automatic reducing low-deformation offshore deep-water cage, relating to a cage for marine aquiculture. The invention is capable to reduce the deformation of the cage and the flow rate of the sea water inside the cage. The invention comprises a buoyancy frame, a cage, a sinking ring, a sinking block and an anchoring rope. A supporting and lifting control ring bigger than the buoyancy frame and the diameter of the sinking ring is arranged at the one second depth of the cylindrical cage; a water inlet and a water outlet are arranged in the pipe wall of the supporting and lifting control ring; a girdle rubber inner bag which regulates the lifting and descending of the cage is arranged in the ring pipe; an air-valve is installed in the rubber inner bag and connectedwith the air supply by a pressure hose; between the outer ring and the supporting and lifting control ring of the double-ring buoyancy frame, the bottom outline of the cylindrical cage and the bottomsinking ring, a plurality of flexible ropes are located and connected according to the ring at geometric proportion, and a netting is arranged among the connecting ropes of the three rings; and finally, a flexibly connected automatic reducing low-deformation offshore deep-water cage with a cylindrical inside and a two-cone platform outside is formed, the stress point of the anchoring rope of the cage is arranged at the supporting and lifting control ring.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

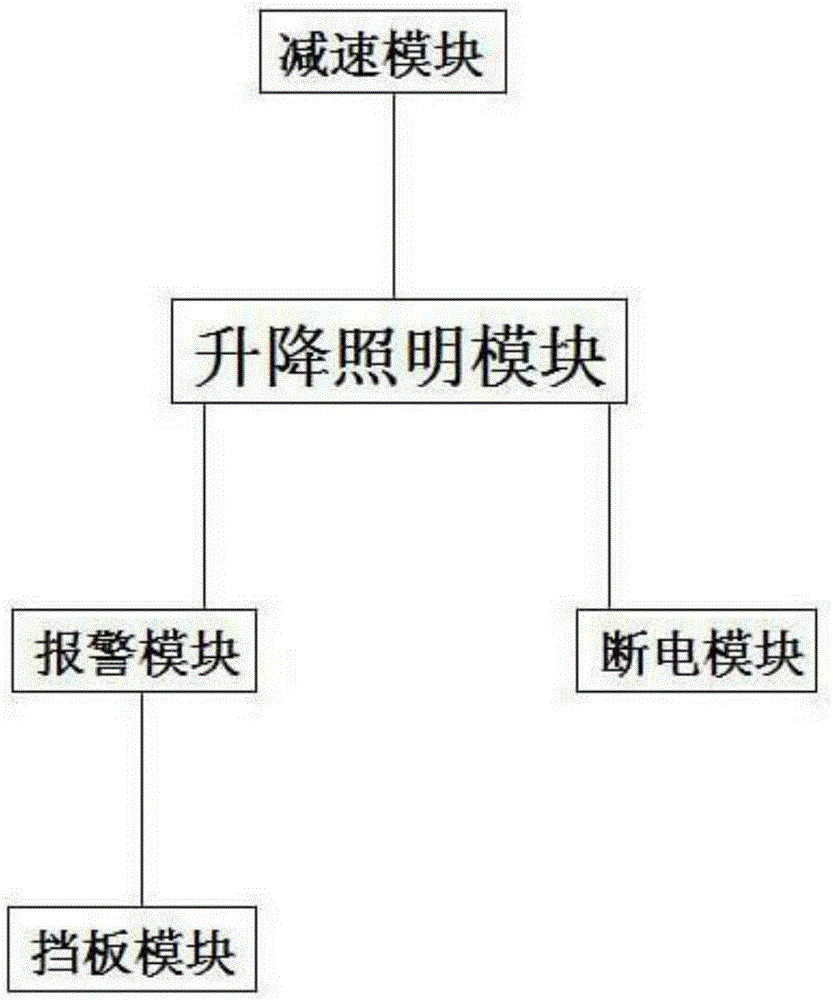

Anti-falling system for lifting illumination device

InactiveCN106764971ATimely power outage processingReduce lifting speedElectrical apparatusElectric light circuit arrangementEngineeringElectric shock

The invention discloses an anti-falling system for a lifting illumination device. The anti-falling system for the lifting illumination device is characterized in that the anti-falling system comprises a lifting illumination module, a baffle module, an alarm module, a speed reduction module and a power-off module; and the lifting illumination module is connected with the power-off module and also connected with the speed reduction module and the alarm module, and the alarm module is connected with the baffle module. Since the alarm module and the power-off module are connected to the lifting illumination module, the lifting illumination module can be powered off in time when falling suddenly, and electric shocks are avoided; and the speed reduction module can decrease the lifting speed of the lifting illumination module. The anti-falling system for the lifting illumination device is simple in structure, convenient to use, safe, efficient, and stable in operation.

Owner:TIANJIN BSTEX EXPLOSION PROOF ELECTRICAL APPLIANCE

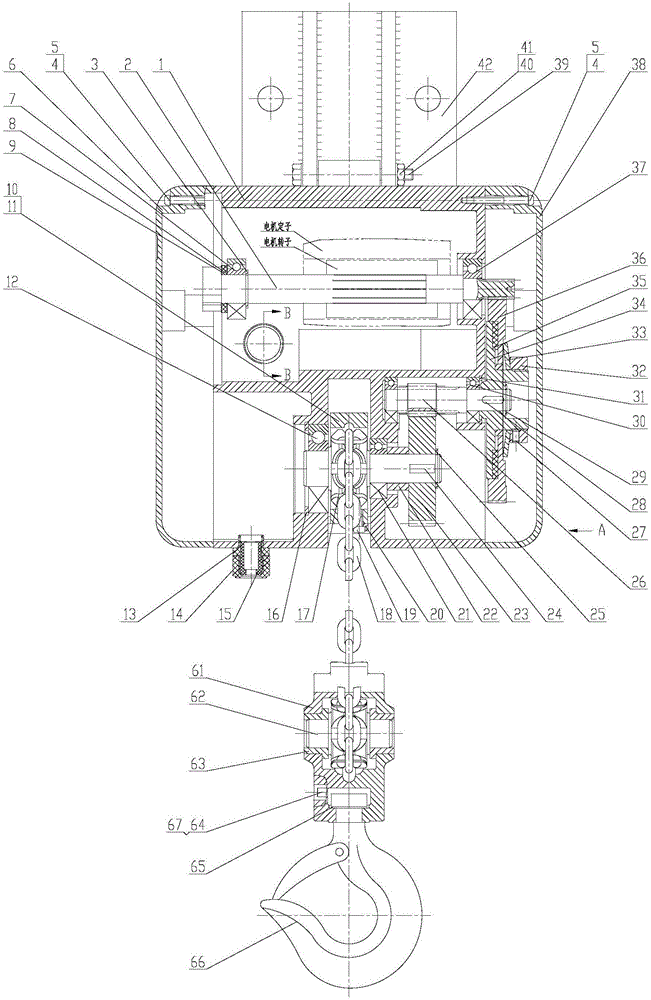

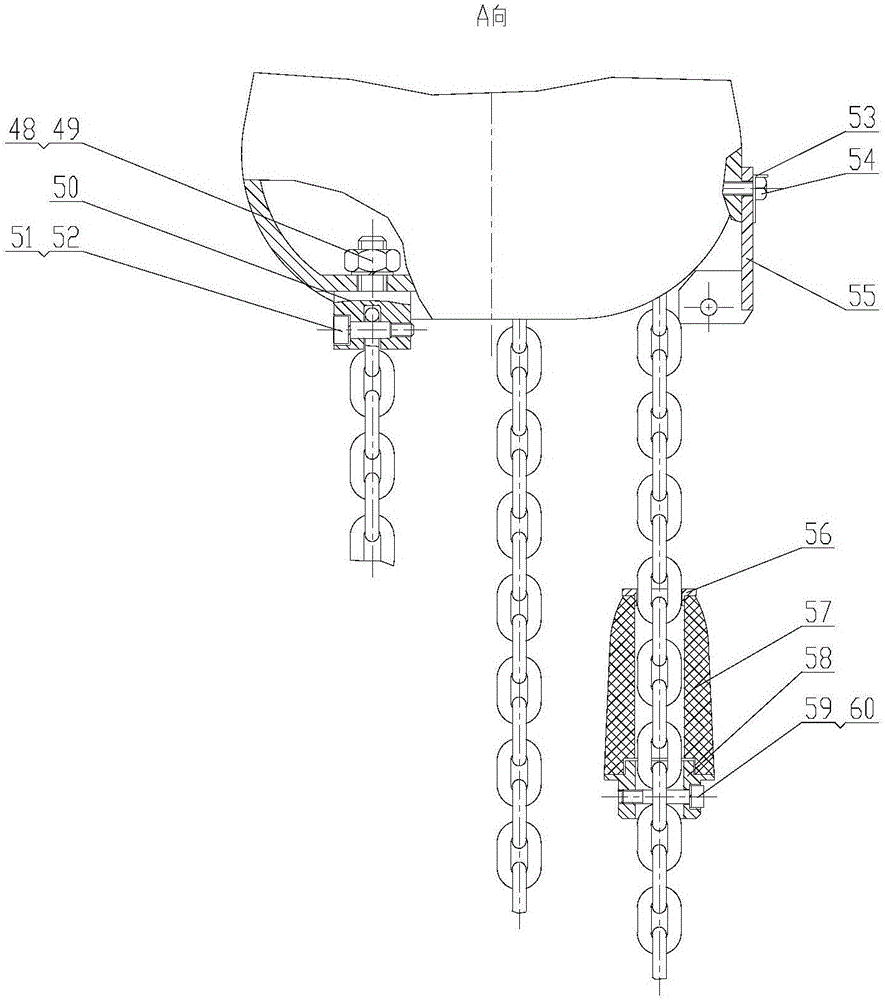

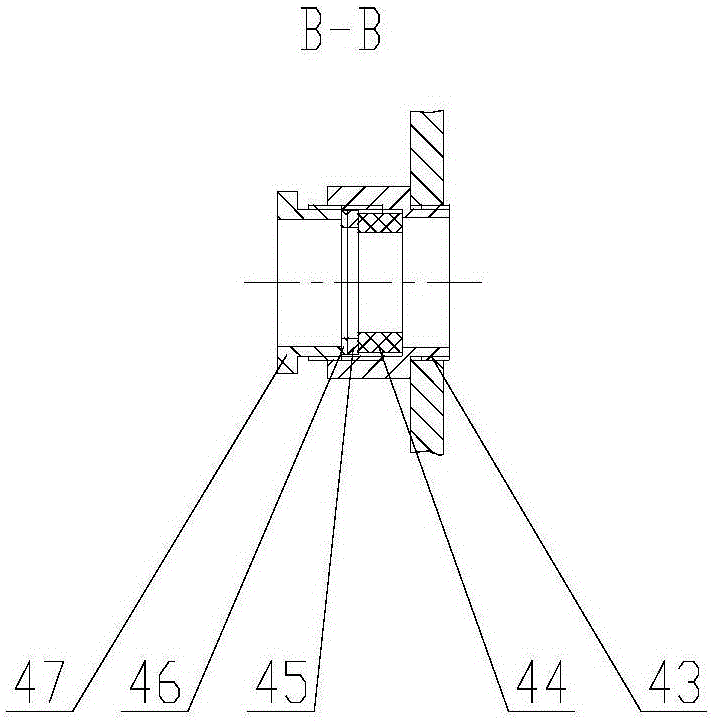

Pelletizer lifter

The invention discloses a pelletizer lifter. The pelletizer lifter comprises a mounting frame, and a speed reducer shell mounted on the mounting frame, wherein the left and right ends of the speed reducer shell are both opened, and the left and right opened ends of the speed reducer shell are respectively provided with a left cover and a right cover; a motor, a gear shaft, a driving chain wheel shaft, a first gear, a hub friction disc, a second gear, a driving chain wheel and the like are mounted in the speed reducer shell; and in addition, the pelletizer lifter further comprises a chain, a lifting hook and the like. When the pelletizer lifter is used, and the motor is started, stopped and reversed, rigid impact is generated in the engaged place of the gear, and the friction disc can achieve an effect of cushion protection; in addition, when a lifted weight is overload, the friction disc generates relative rotation with a second-level gear and a hub to prevent the blockage and the burn down of the motor; and moreover, a lifting mechanism realizes the lifting of a pelletizer through engaging the annular chain by the chain wheel which is driven by motor input torque through the deceleration of the gear, so that the purpose of deceleration precise lifting is achieved, and the effect of transmission stability is achieved.

Owner:惠东恒泰塑业有限公司

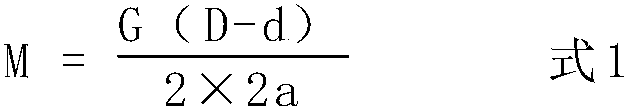

Differential windlass lifting device

The invention discloses a differential windlass lifting device, and belongs to the field of lifting machinery. The differential windlass lifting device comprises a bearing base, a drum shaft, a fixedpulley module, a movable pulley module, a lifting rope and a speed reducer. The differential windlass lifting device is characterized by further comprising a differential drum set, a coupling and a motor; the differential drum set is fixed on the drum shaft, and is integrally molded by a first differential drum and a second differential drum; the diameter of the first differential drum is larger than the diameter of the second differential drum; one end of the lifting rope is fixed at the end part of the first differential drum, and the other end is fixed at the end part of the second differential drum; one end of the drum shaft is connected with the bearing base, and the other end is connected with the speed reducer; one end of the coupling is connected with the speed reducer, and the other end is connected with the motor; and a brake is mounted on the coupling. Through use of the differential drum set and a specific rope winding mode, the high-capacity and low-speed lifting of the lifting mechanism can be realized, and the lifting stability and safety are guaranteed.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

Even lubricating device for mechanical automation spinning

InactiveCN109778356AIncrease flexibilityEasy to installContinuous wound-up machinesCircular discDrive shaft

The invention discloses an even lubricating device for mechanical automation spinning, and relates to the technical field of spinning machines. The even lubricating device specifically comprises a spinning winding table, placing plates and fixed side plates, wherein a movable plate is arranged on the edge of the upper surface of the spinning winding table, the left side and the right side of the movable plate are each provided with a hinge mechanism, the placing plates are located on the outer sides of connecting rods, fixing clamping devices are welded to the upper ends of the placing plates,one ends of transmission shafts are connected to the outlet ends of motors, limiting columns are integrally arranged on one sides of movable discs, and the lower ends of the fixed side plates are welded to the edge of the spinning winding table. Baffles in the device drive a main rod to rotate, the main rod in the rotating process can wind a spun-formed fabric, it can be avoided that the fabric slides down from the main rod by arranging the baffles, and through mutual matching between a first oil pipe and second oil pipes, lubricating oil can be evenly dispersed inside a second sliding rail so that hydraulic rods can continuously lift.

Owner:张曼莉

Structure used for eliminating reverse ejection action of lower pressing plate of progressive die

InactiveCN111346969AReduce lifting speedThe swing process is continuous and stableShaping toolsClassical mechanicsEngineering

The invention belongs to the field of die manufacture and particularly provides a structure used for eliminating the reverse ejection action of a lower pressing plate of a progressive die. The structure comprises an upper pressing plate and the lower pressing plate, wherein friction blocks are mounted on two opposite sides of the lower pressing plate respectively, a feeding device is connected with the end surface, opposite to the lower pressing plate, of each friction block, and the feeding device can drive the friction block on the same side to transversely reciprocate and realizes tight press connection of the friction block and the end surface of the lower pressing plate; each feeding device comprises a swing block and a slider, the swing block is mounted in a swing block fixing seat which is arranged on the side of the corresponding friction block, a slider fixing seat is arranged on one side, opposite to the friction block, of the swing block fixing seat, the slider is mounted inthe slider fixing seat, an opening is formed in the end part, located on the same side with the swing block, of the slider fixing seat, the slider extends out from the opening, and a nitrogen springis mounted at the end part, located in the slider fixing seat, of the slider.

Owner:天津世亚模具股份有限公司

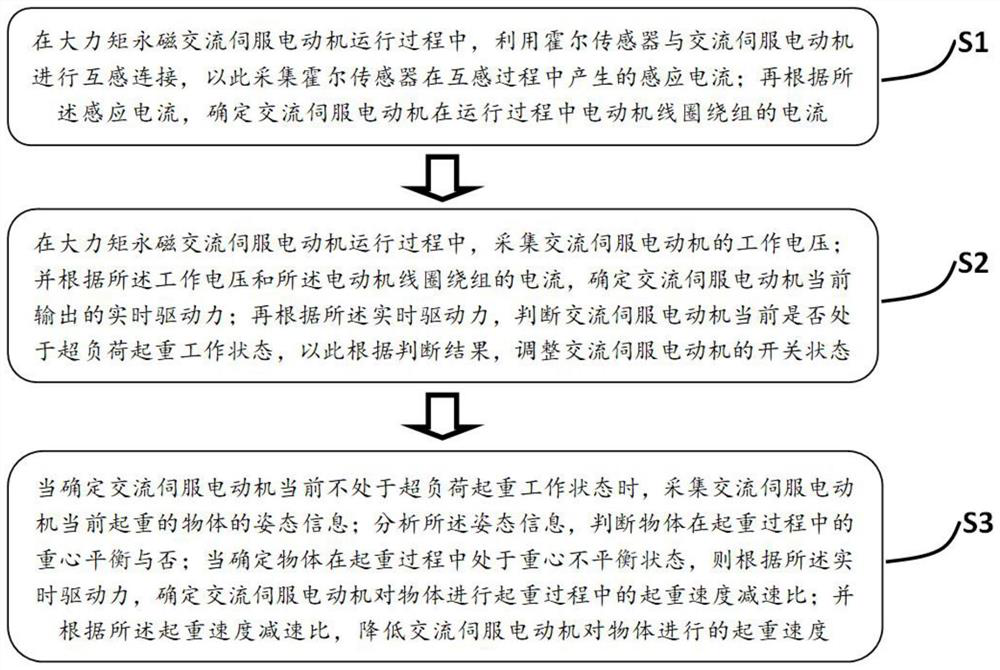

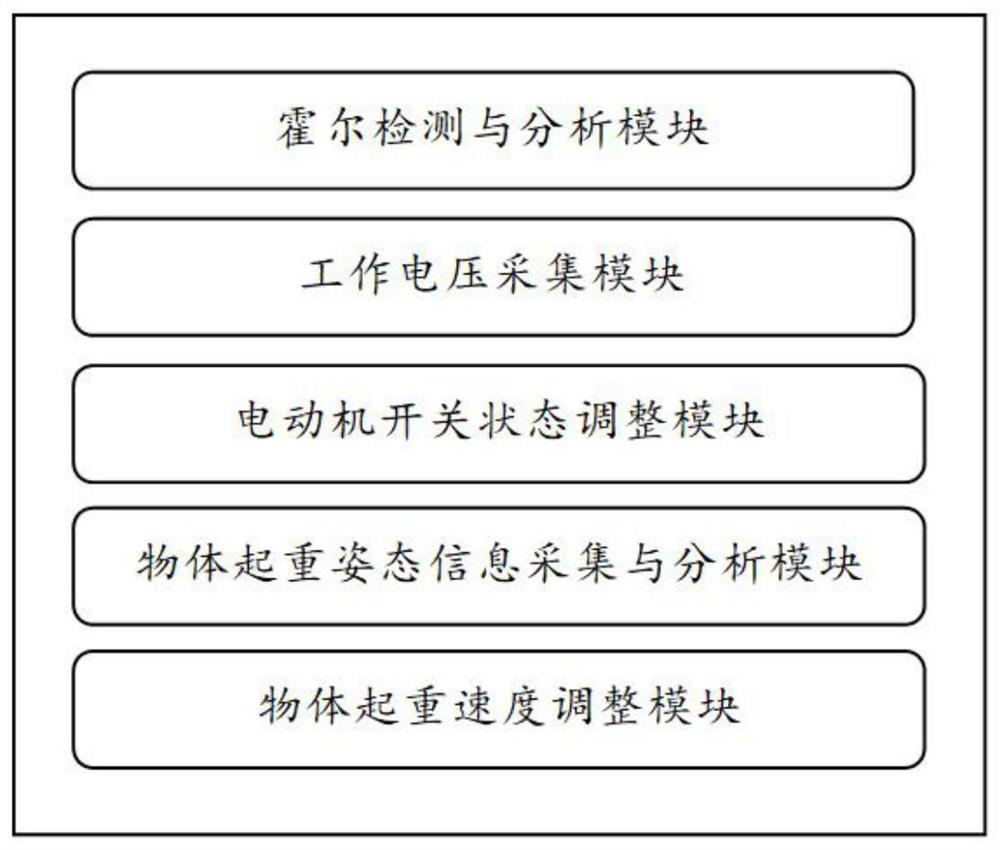

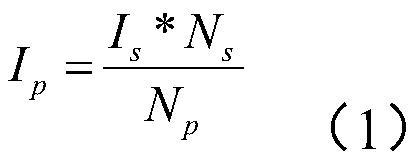

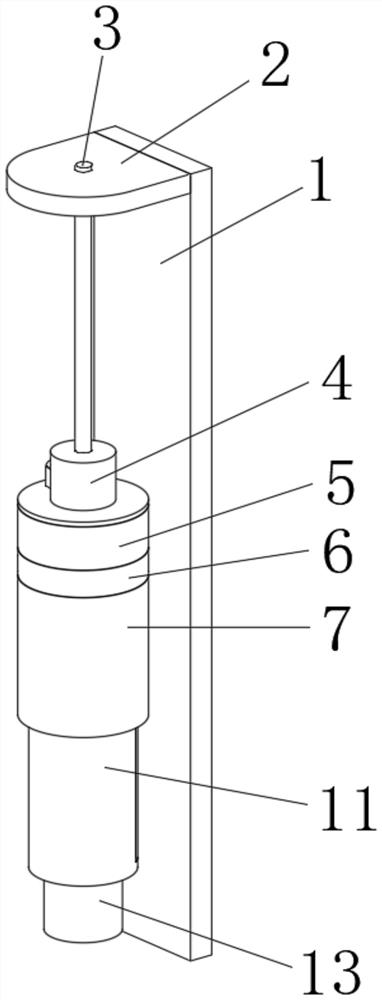

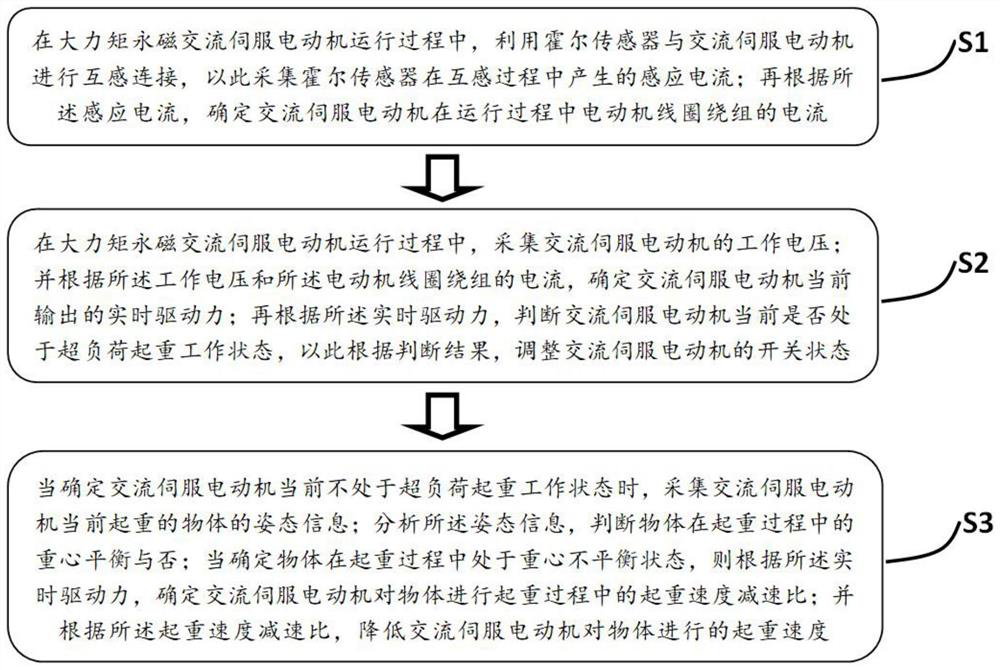

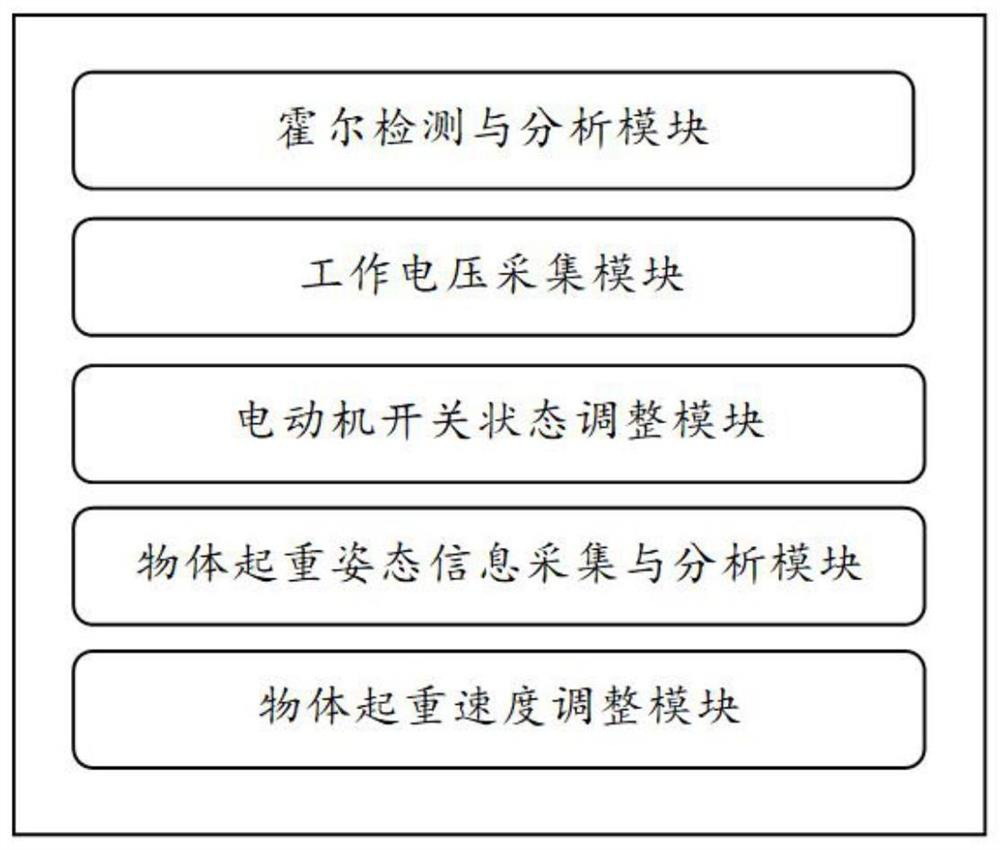

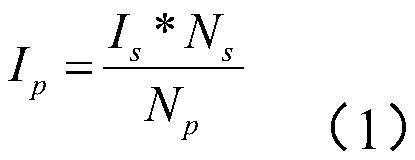

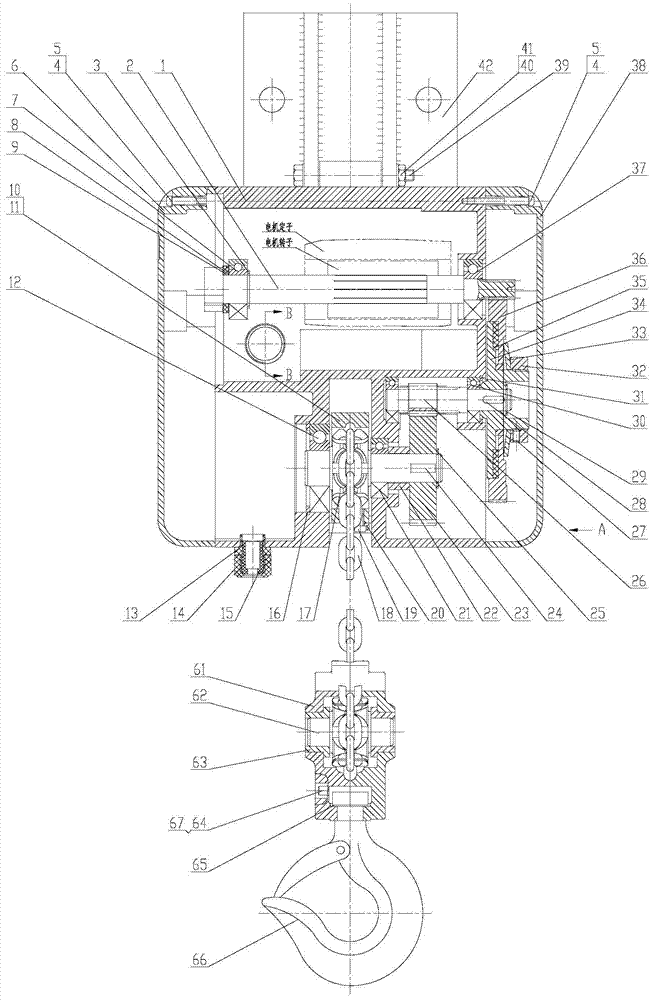

Drive control method and system for high torque permanent magnet AC servo motor

ActiveCN113460885BReduce the size of the output driving forceSmooth liftAC motor controlLoad-engaging elementsStability of motionElectrical current

The invention provides a drive control method and system for a high-torque permanent magnet AC servo motor. During the operation of the AC servo motor, the current of the coil winding of the motor and the working voltage of the motor are collected by mutual inductance, so as to determine the real-time driving force and judgment of the motor output. Whether the motor is currently in an overloaded lifting state, thereby controlling the on-off state of the motor; in addition, when the object in the motor is currently in an unbalanced center of gravity, the lifting speed of the object can be adaptively reduced, which can reduce the output drive of the motor. The magnitude of the force ensures that the object can be lifted smoothly, thereby effectively avoiding the object from swinging greatly during the lifting process, improving the stability of the lifting motion of the object, and maximizing the normal and continuous output of the driving force by the motor.

Owner:上海莘汭驱动技术有限公司

A crystal pulling device for the preparation of heating electronic components

ActiveCN114059151BShorten the lengthProtrusion length unchangedPolycrystalline material growthBy pulling from meltMolten stateElectronic component

The invention relates to the technical field of chip production, and discloses a crystal pulling device for preparing heating electronic components. In the compressed state, when the crystal nucleus is in contact with the molten silicon material in the molten state, if the temperature of the molten silicon material is too high at this time, the crystal nucleus in contact with the molten silicon material is subject to a higher temperature than its own. The melting point begins to melt, so that the total length of the crystal nucleus is reduced. At this time, the compression spring II is in a compressed state, and the crystal nucleus is pushed out from the inside of the fixed sleeve to ensure that the bottom of the crystal nucleus can always be kept in contact with the stroke rod. The bottom is in contact with each other, so that the extension length of the crystal nucleus from the inside of the fixed sleeve remains unchanged, which avoids the problem that the crystal nucleus is melted and the length is shortened due to the high temperature of the molten silicon material in the traditional crystal pulling equipment. The stability of the device when working.

Owner:SHENZHEN HAOOU ELECTRONICS CO LTD

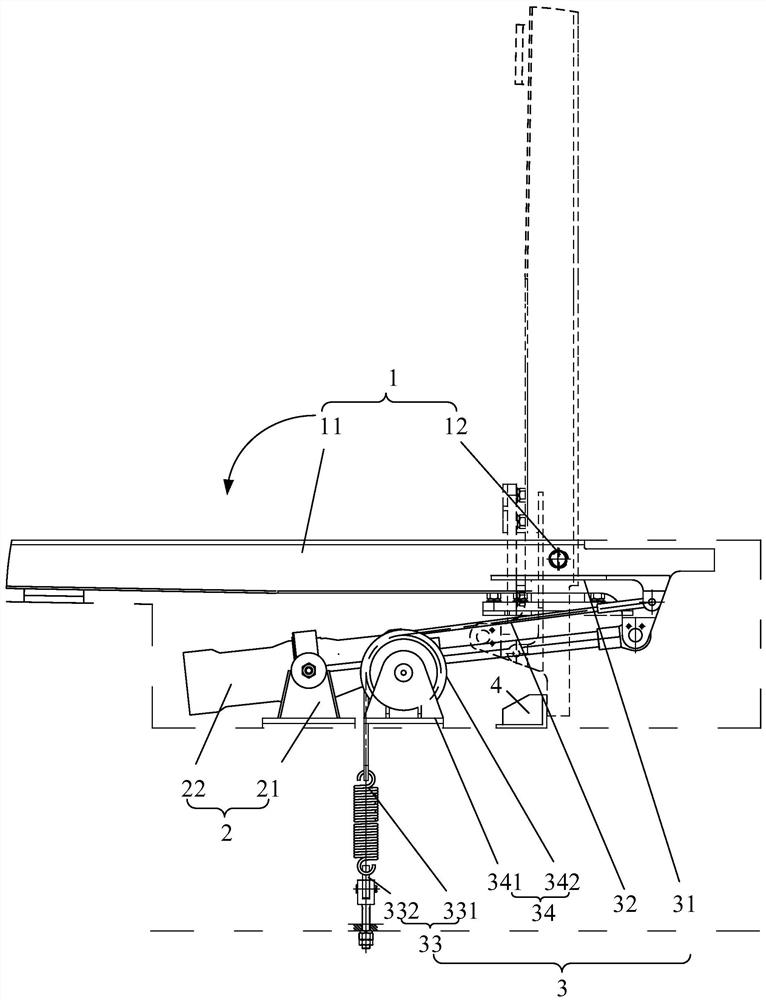

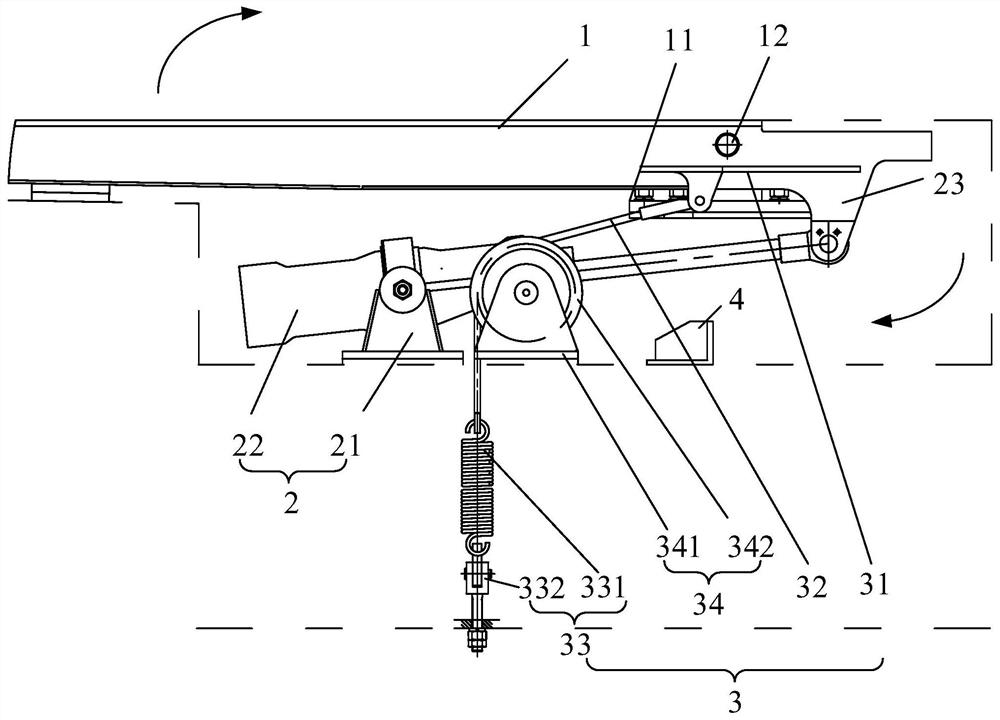

Lifting device

ActiveCN113845061AGuaranteed stabilityReduce lifting speedNon-rotating vibration suppressionLifting framesEngineeringStructural engineering

The invention provides a lifting device, and belongs to the technical field of ship equipment. The lifting device comprises a lifting assembly, a driving assembly and a buffering assembly; the lifting assembly comprises a main body and a rotating shaft, and the rotating shaft is rotatably connected with the main body; the fixed end of the driving assembly is located on the first side of the rotating shaft, the driving end of the driving assembly is located on the second side of the rotating shaft, the buffering assembly comprises a sliding part, an inhaul cable and an elastic part, the sliding part is connected with the main body, the sliding part can move relative to the main body in the direction perpendicular to the rotating shaft, the first end of the inhaul cable is connected with the sliding part, the second end of the inhaul cable is connected with the first end of the elastic part, the second end of the elastic part is a fixed end, and the elastic part is located on the first side of the rotating shaft. Through the lifting device, the lifting assembly can stably ascend and descend.

Owner:WUHAN MARINE MACHINERY PLANT

A fully automatic cloth cutting machine

ActiveCN106758113BAvoid situations that damage the conveyor beltGood transportabilityConveyorsSevering textilesEngineeringFully automatic

The invention relates to a full-automatic fabric cutting machine. A machine frame is provided with a horsehair conveyor belt, a feeding device is arranged above the machine frame, the feeding device is provided with a cutting mechanism, the cutting mechanism comprises a fabric cutting frame, the fabric cutting frame is provided with a cutting knife sleeve, the lower part of the cutting knife sleeve is provided with a cutting knife groove, the cutting knife groove is communicated with the cutting knife sleeve, the cutting knife sleeve is internally provided with a cutting knife lifting pulling rod which is matched with the cutting knife in the cutting knife groove, the upper part of the cutting knife lifting pulling rod is connected to a cutting rotating seat in a hinged mode, the cutting rotating seat is also connected to a cutting rotating rod in a hinged mode, the other end of the cutting rotating seat is arranged on a sleeving connecting shaft on a cutting installing plate of the fabric cutting frame in a sleeving mode, the other end of the cutting rotating shaft is connected to a cutting rotating sleeve, and the cutting rotating sleeve is matched with a cutting lifting motor on the cutting installing plate. According to the full-automatic fabric cutting machine, the biggest lifting range is limited, the speed capable of slowing down lifting is adjusted at the same time, and the situation that the cutting knife destroys the conveyor belt is sharply avoided.

Owner:扬州鸿炜高新材料科技有限公司

Driving control method and system of high-torque permanent magnet alternating current servo motor

ActiveCN113460885AReduce the size of the output driving forceSmooth liftAC motor controlLoad-engaging elementsAC - Alternating currentGravity center

The invention provides a driving control method and system of a high-torque permanent magnet alternating current servo motor. The current of a motor coil winding and the working voltage of the motor are collected in a mutual inductance mode in the operation process of the alternating current servo motor, so that the real-time driving force output by the motor is determined, and whether the motor is in an overload lifting state or not is judged, so that the on-off state of the motor is controlled; and in addition, when the gravity center of an object in a device with the motor is unbalanced, the lifting speed of the object can be adaptively reduced, so that the output driving force of the motor can be reduced, meanwhile, the object can be stably lifted, so that the object is effectively prevented from swinging greatly in the lifting process, the stability of lifting motion of the object is improved, and it is guaranteed that the motor normally and continuously outputs driving force to the maximum extent.

Owner:上海莘汭驱动技术有限公司

A granulator elevator

ActiveCN105000489BReduce lifting speedEasy to implementWinding mechanismsGear wheelElectric machinery

Owner:惠东恒泰塑业有限公司

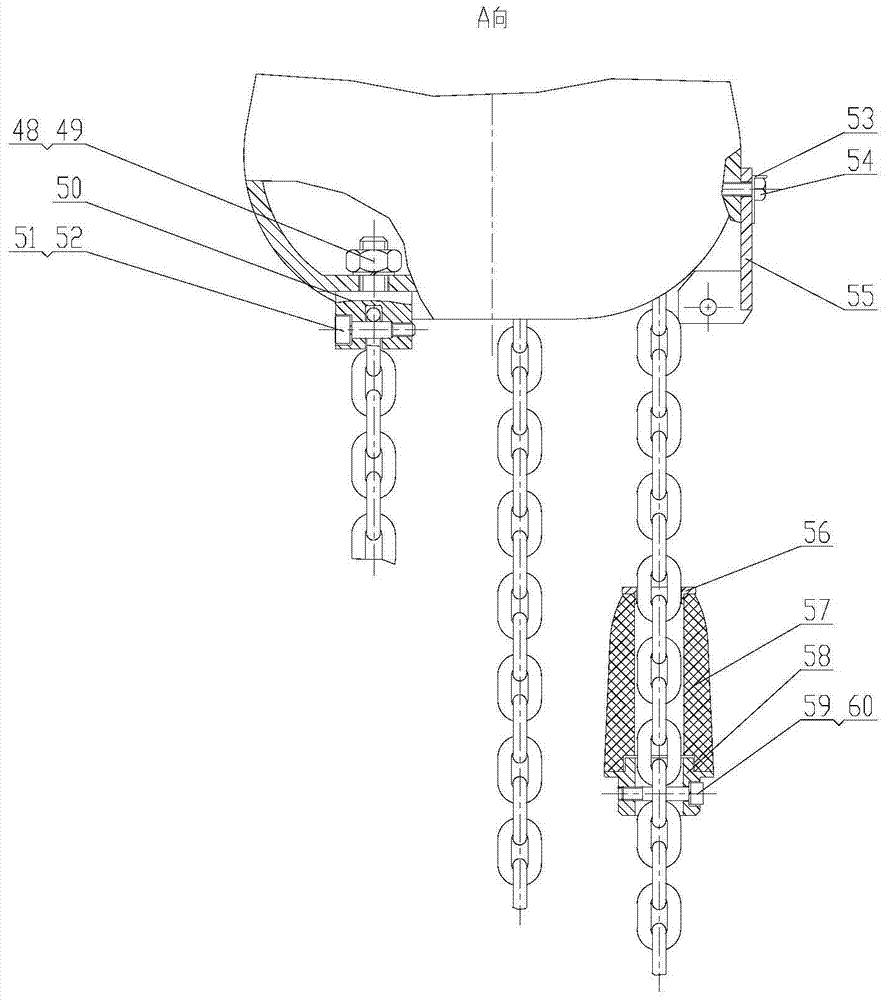

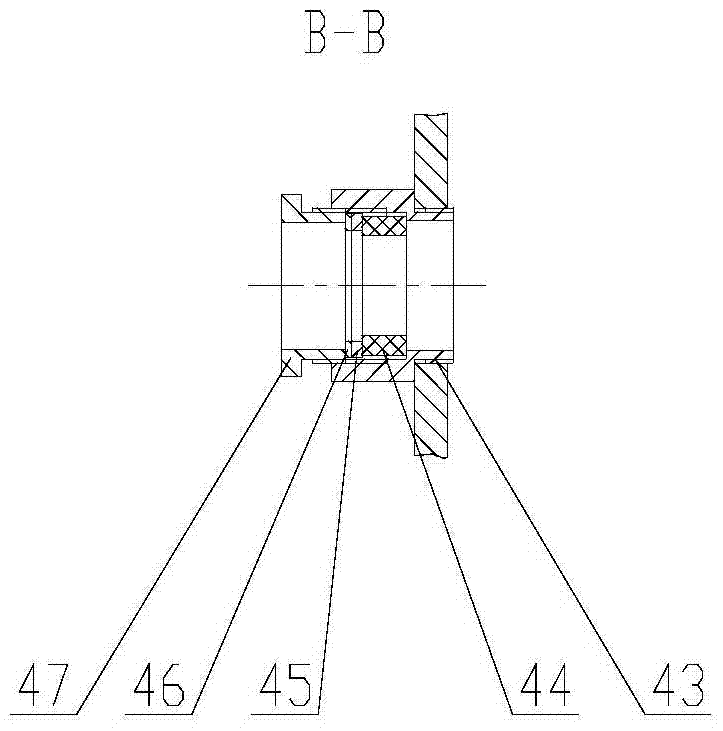

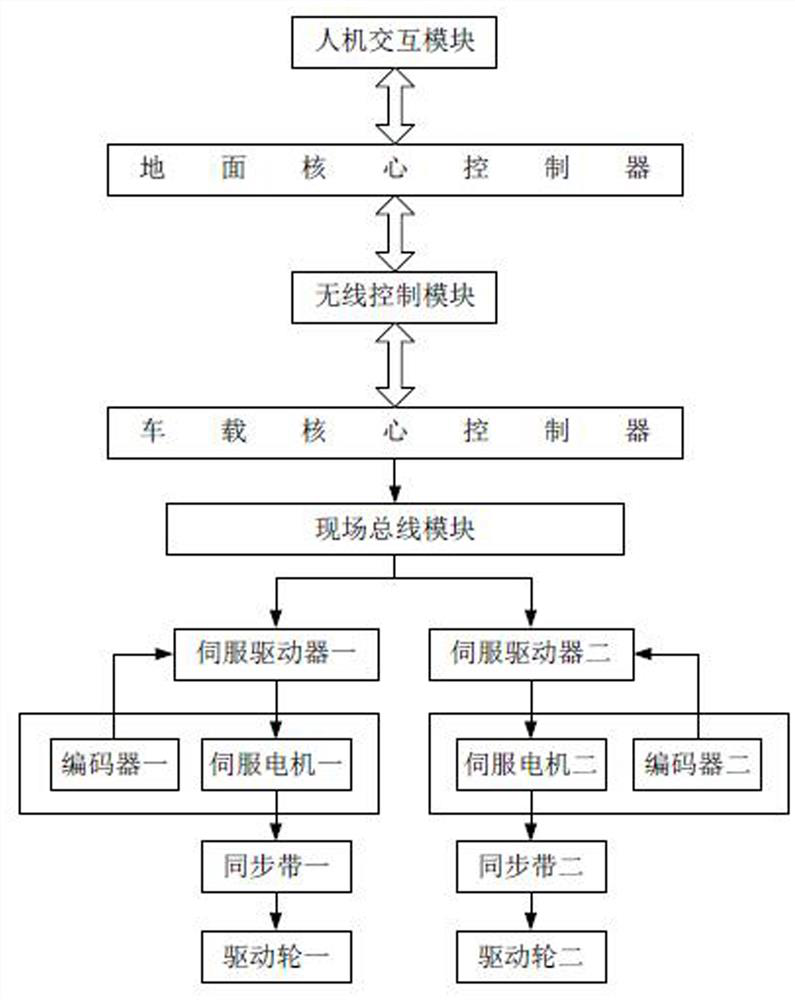

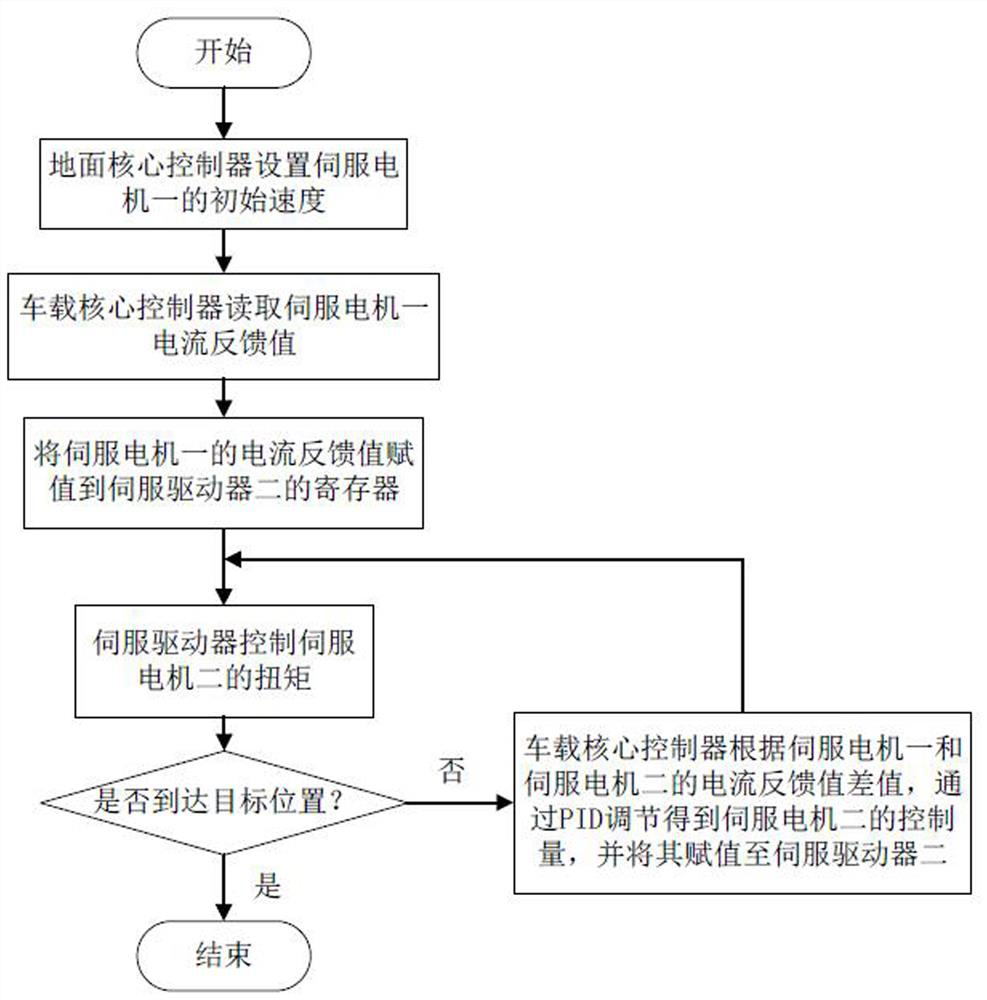

A dual servo motor control method for track detection device of amusement facilities

ActiveCN110995066BReduce output torqueGuaranteed uptimeMultiple dynamo-electric motors speed regulationDrive wheelControl engineering

The invention discloses a dual-servo motor control method for a track detection device of an amusement facility. Two motors are used to respectively drive the drive wheels on the left and right sides, wherein the first servo motor is the master, the second servo motor is the slave, and the second servo motor works In the torque mode, adjust the output torque of the servo motor 2 according to the current feedback value of the servo motor 1, so that the current feedback values of the two are close to each other, so as to ensure that the working states of the two are similar, and avoid the close situation between the two. The structure is simple, the response speed is fast, the reliability is high, and the flexibility is good. It can effectively and stably control the running of the track detection device of the amusement facility, and better realize the comprehensive detection of the track by the track detection device of the amusement facility.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Construction process of floral tube dry filling piles

InactiveCN101713189BReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

Owner:HENAN UNIVERSITY

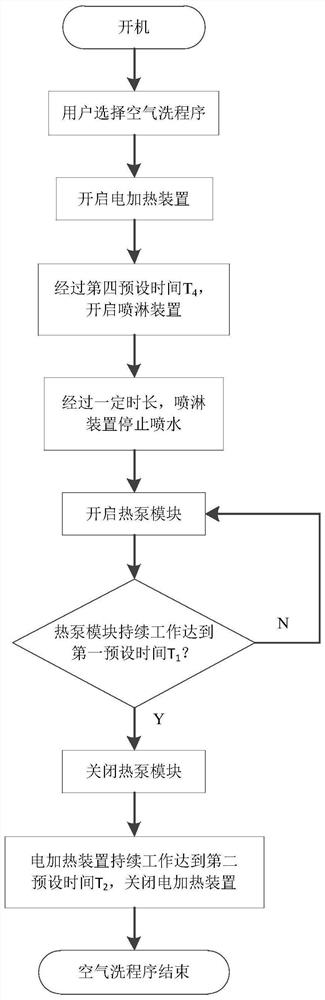

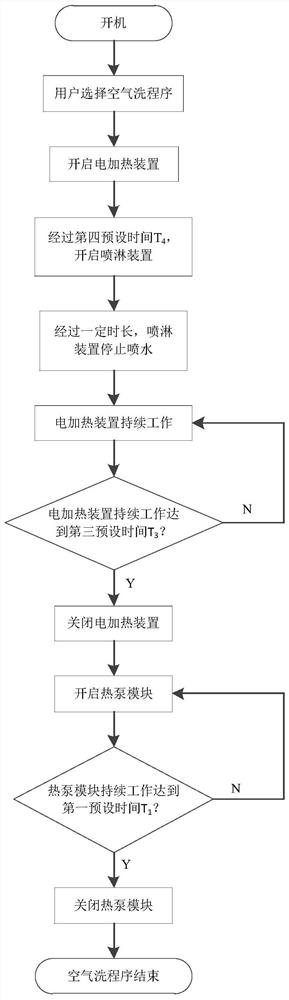

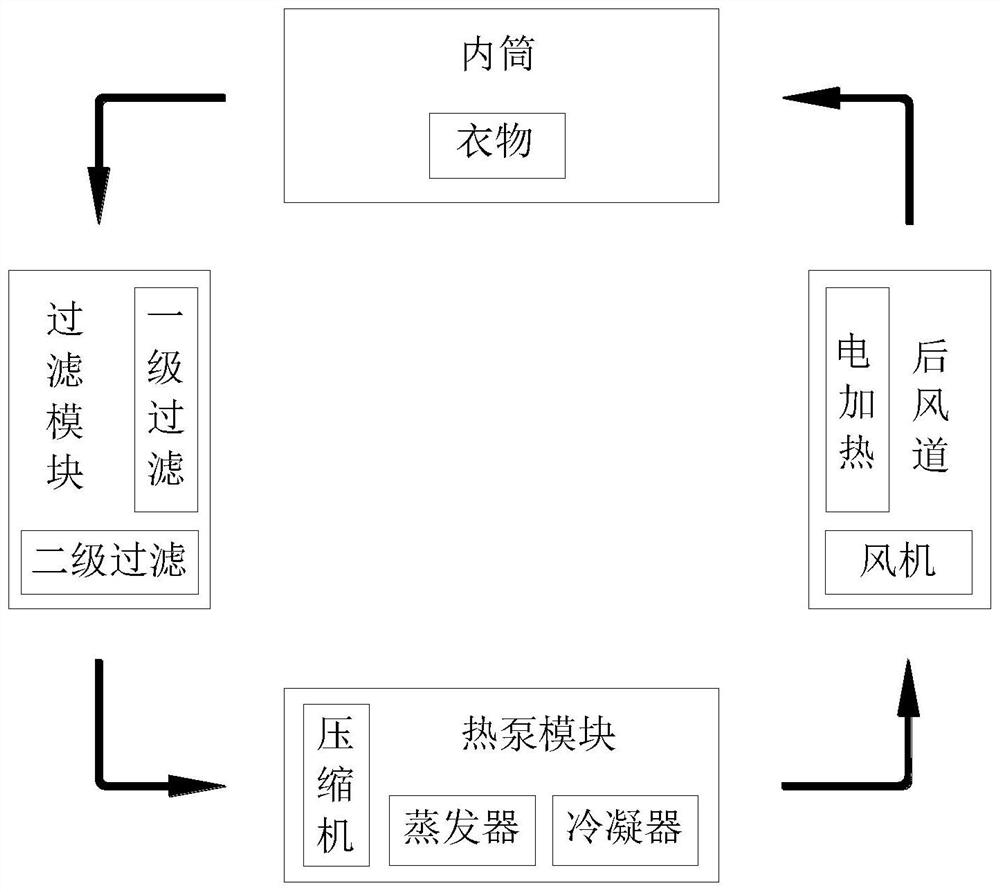

Control method of clothes treatment device

PendingCN114438712AImprove cooling effectSave waterControl devices for washing apparatusTextiles and paperCooling effectEngineering

The invention belongs to the technical field of clothes processing devices, and discloses a control method of a clothes processing device.The clothes processing device comprises an inner barrel and a heat pump module, the clothes processing device has an air washing program, and in the process of executing the air washing program, the heat pump module is controlled to be started to dehumidify circulating air introduced into the inner barrel. The heat pump module is arranged in the clothes treatment device, in the process that the clothes treatment device executes the air washing procedure, the circulating air is dehumidified through the heat pump module, compared with a method for removing moisture by feeding condensate water in the prior art, water resources are saved, the cooling effect on the circulating air is remarkable, and the clothes treatment device has the beneficial effects that the heat pump module is used for conducting dehumidification treatment on the circulating air; therefore, a better dehumidification effect is achieved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com