Light climbing mold steel frame system

A climbing formwork and steel frame technology, applied in the field of light-duty formwork steel frame systems, can solve the problems of increasing the overall quality of the climbing formwork, easily damaging the hydraulic cylinder, affecting the construction progress, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples.

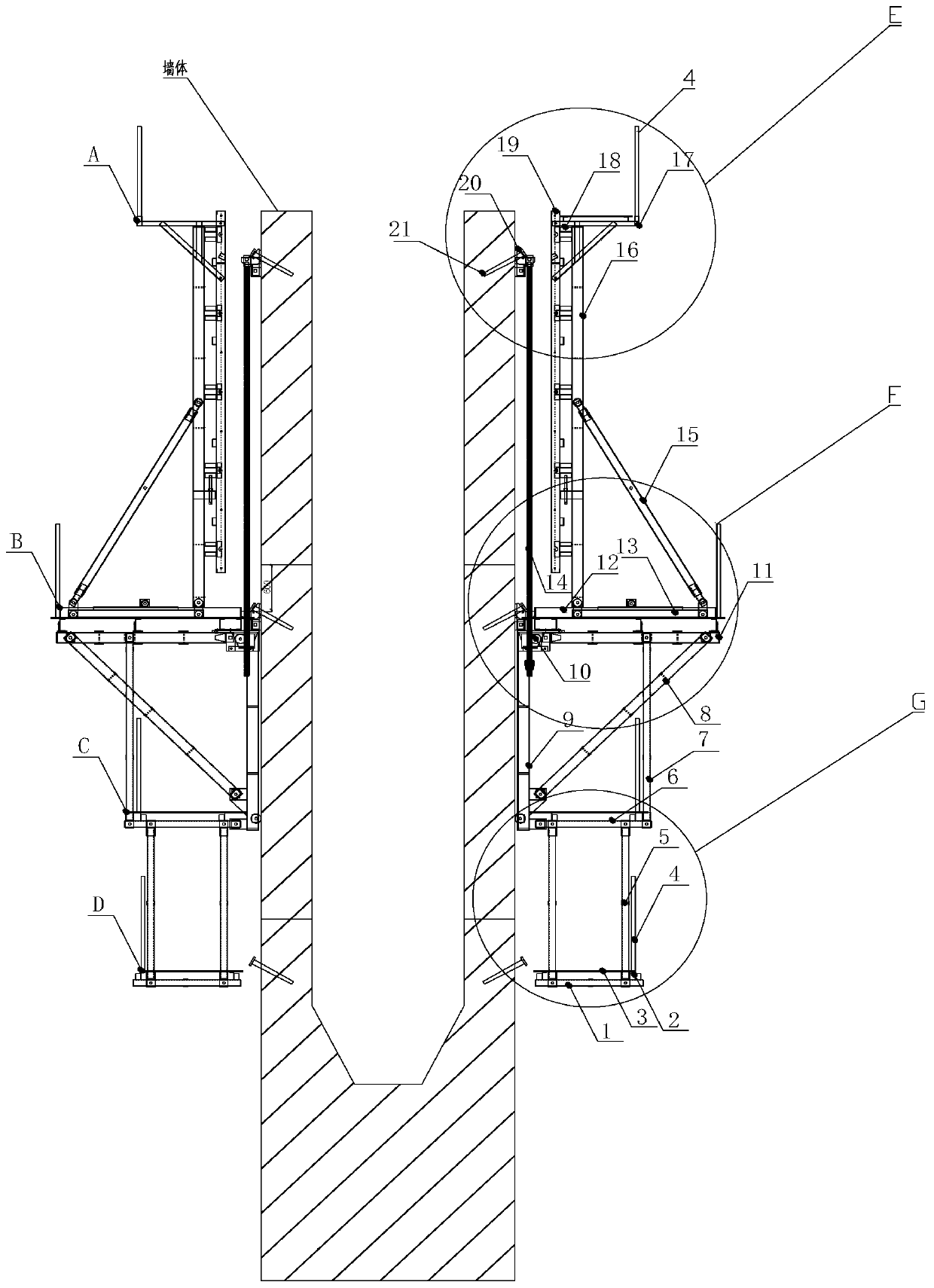

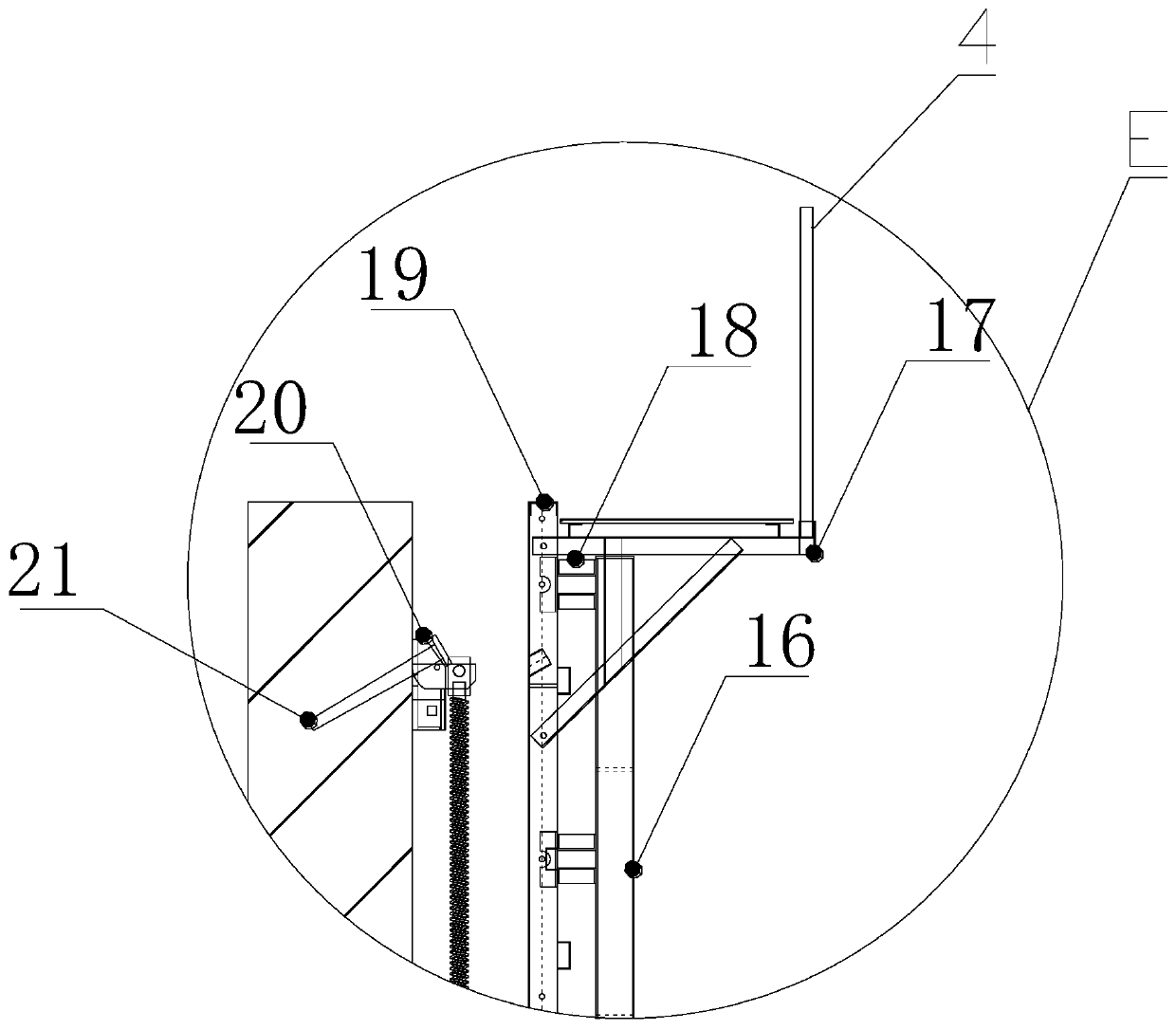

[0039] see figure 1 , The light climbing formwork steel frame system provided by this application includes: main platform, lower platform and repair platform. The main platform, the lower platform and the repair platform surround the area of the wall to be poured, and are arranged in the area of the wall to be poured to install the formwork 19.

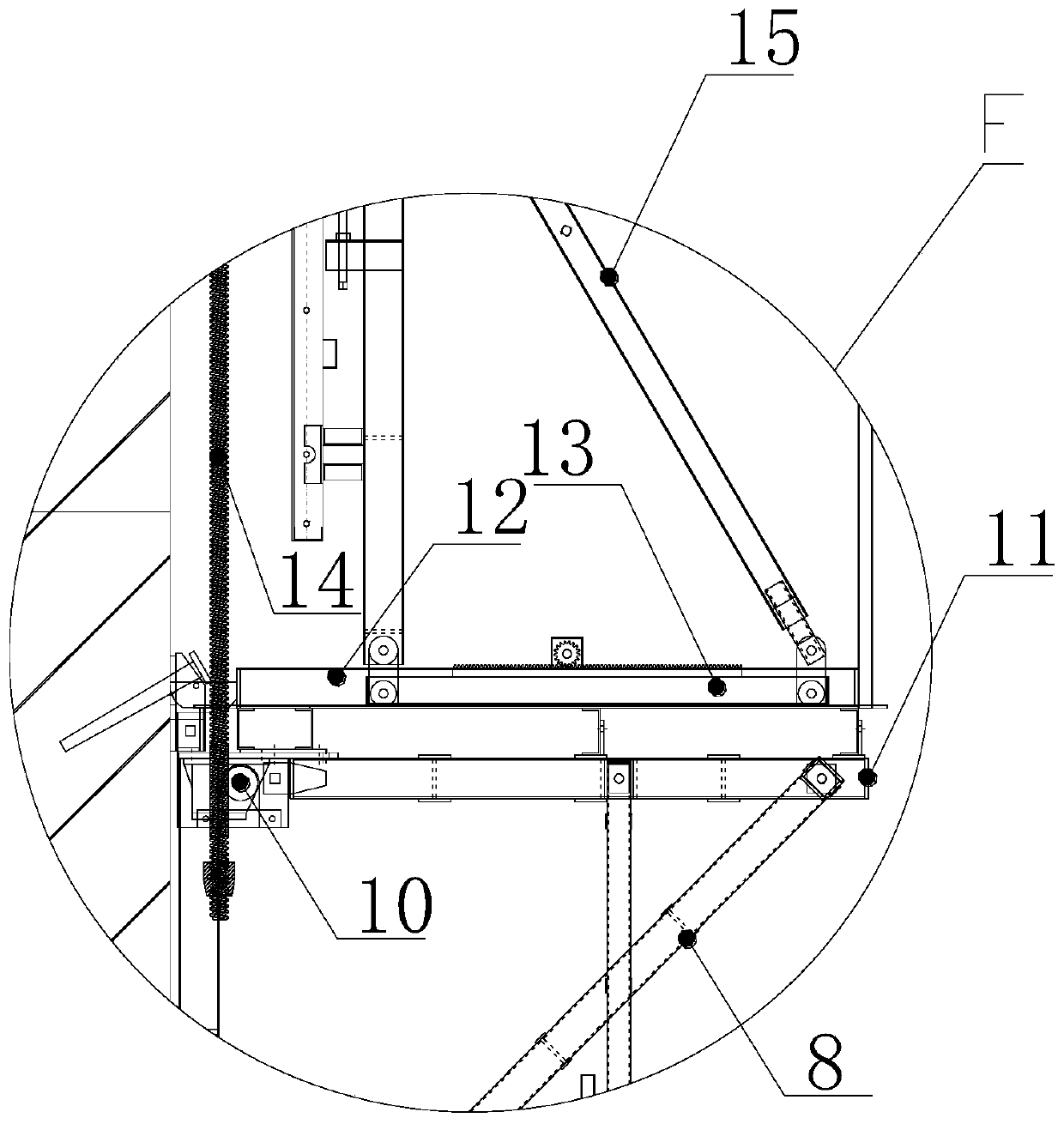

[0040] The main platform includes: main frame vertical beams 9 and main frame beams 11, and the main frame vertical beams 9 are installed on the outer wall of the poured wall. The fixed end of the main frame crossbeam 11 is installed on the top of the main frame vertical beam 9, and the other end extends outwards perpendicular to the wall to form a free end. The two ends of the main frame slanting beam 8 are respectively fixedly connected with the bottom end of the main fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com