Control method of clothes treatment device

A technology of a clothes treatment device and a control method, which is applied to the control device of a washing machine, a washing device, textiles, and papermaking, and can solve problems such as waste of water resources and unsatisfactory moisture removal effects, and achieve water conservation and good clothes cleaning effect , good dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for controlling a clothes treatment device, where the clothes treatment device includes an inner cylinder and a heat pump module. The laundry treatment device in this embodiment has an air washing program. During the execution of the air washing program, the heat pump module is controlled to be turned on to dehumidify the circulating air passing into the inner cylinder.

[0046] In this embodiment, during the execution of the air washing procedure, the clothes treatment device dehumidifies the circulating air through the heat pump module. Compared with the method of removing moisture by entering condensed water in the prior art, water resources are saved, and the The cooling effect of the circulating air is significant, resulting in a better dehumidification effect.

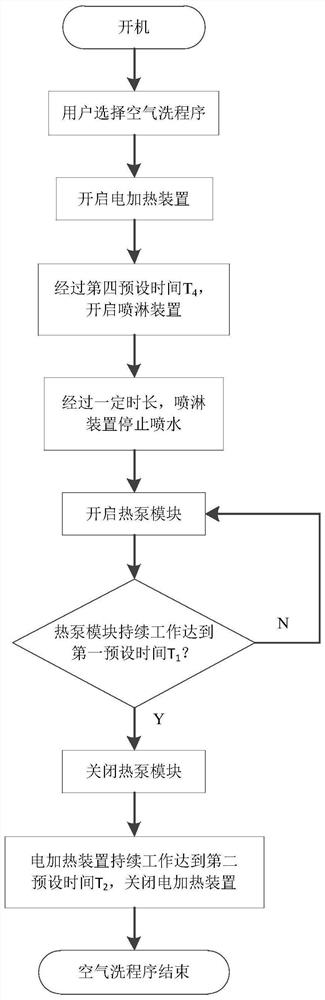

[0047] Further, the laundry treatment device of this embodiment further includes an electric heating device, which is controlled to be turned on during the execution of th...

Embodiment 2

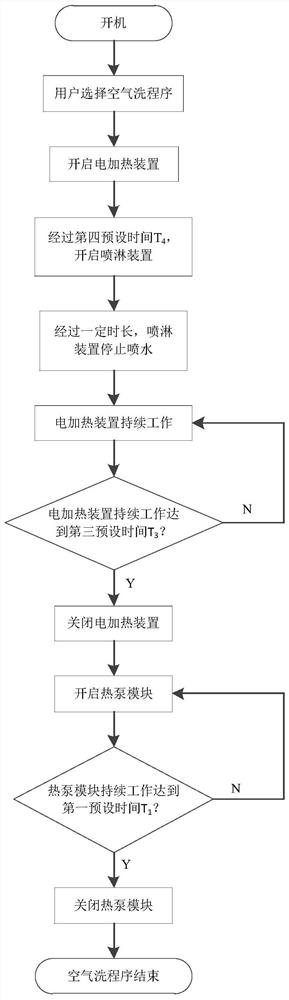

[0074] The difference between this embodiment and the first embodiment above is that during the operation of the air washing program, the electric heating device is turned off first, and then the heat pump module is turned on. The heat pump module dehumidifies the circulating air and independently heats the circulating air.

[0075] Specifically, such as figure 2 As shown, after the air washing program is started, the electric heating device is controlled to turn on to heat the circulating air passing into the inner cylinder. The air is dehumidified and the dehumidified air is heated.

[0076] In a further solution of this embodiment, after the electric heating device is turned on, it continues to work for a third preset time T 3 After that, control the electric heating device to turn off, and turn on the heat pump module.

[0077] In another solution of this embodiment, the laundry treatment device further includes a temperature sensor for detecting the temperature of the ...

Embodiment 3

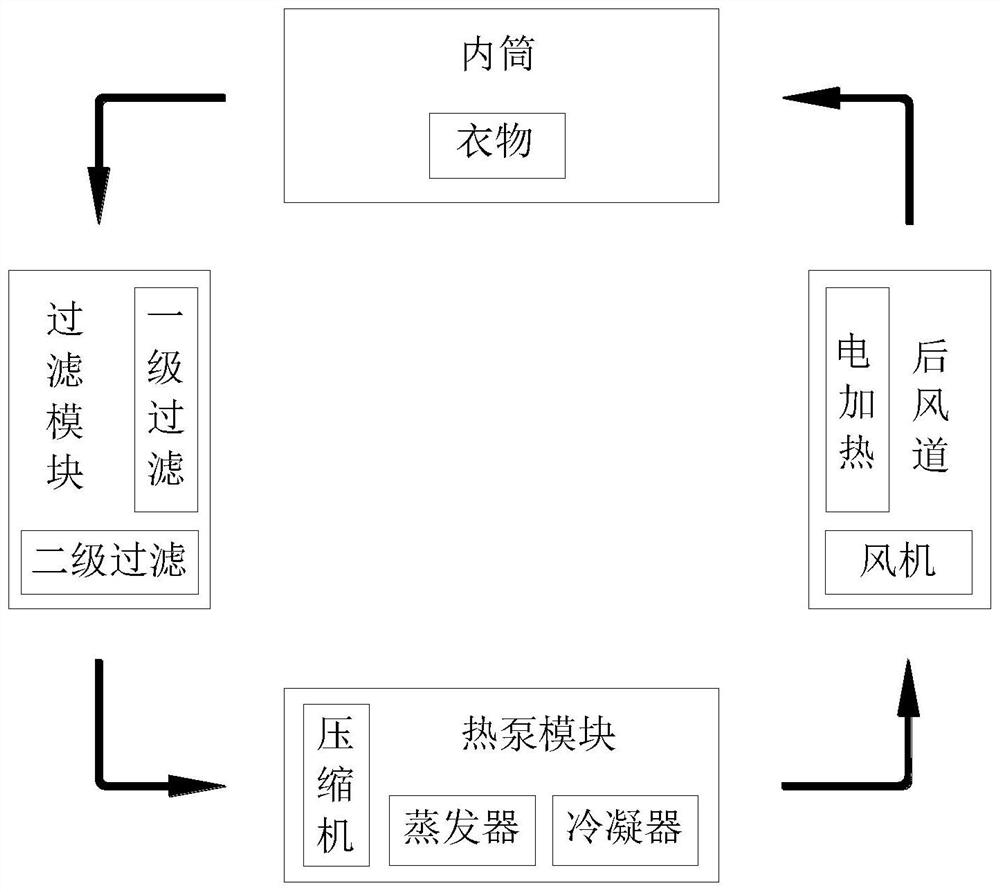

[0086] Such as image 3 As shown, this embodiment provides a clothes treatment device adopting the control method described in the first or second embodiment above, including an inner cylinder and an air duct communicating with the inner cylinder, and a fan is arranged in the air duct. The air passage includes a rear air passage arranged outside the bottom of the inner cylinder, and the rear air passage has an air outlet. An air inlet is arranged on the bottom of the inner cylinder, and the air outlet communicates with the air inlet. Both the blower fan and the electric heating device are arranged in the rear air duct.

[0087] The air passage also includes an air supply passage connecting the mouth of the inner cylinder and the rear air passage, under the action of the fan, the air in the inner cylinder is drawn into the air supply passage through the mouth of the inner cylinder, Then it is sent to the rear air passage, and then returns to the interior of the inner cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com