A granulator elevator

A technology of elevators and granulators, applied in the direction of clockwork mechanism, winch device, etc., can solve the problems of increased human factors, reduced production efficiency, increased scrap rate in the production process, etc., and achieves long reuse cycle and low manufacturing cost , the effect of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the drawings.

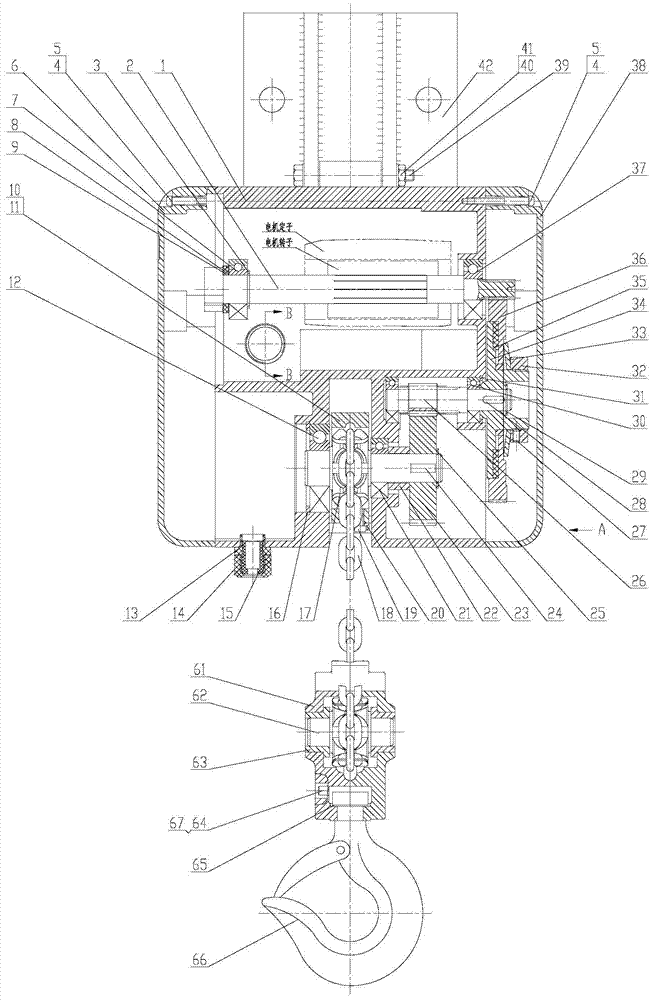

[0032] See figure 1 , A granulator elevator of the present invention includes a mounting frame 42 and a reducer housing 1 mounted on the mounting frame 42. The left and right ends of the reducer housing 1 are open, and the left and right openings of the reducer housing 1 The ends are respectively provided with a left cover 6 and a right cover 38, and both the left cover 6 and the right cover 38 are mounted on the reducer housing 1 by the first screw 4 and the first washer 5.

[0033] Among them, a motor is installed in the reducer housing 1, which includes a motor shaft 2, a motor stator, and a motor rotor. The left and right ends of the motor shaft 2 are respectively installed with a first bearing 7 and a fifth bearing 37, and both bearings are installed At the partition in the reducer housing 1, in addition, a spacer 8 and a felt ring 9 are provided between the first bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com