Differential windlass lifting device

A differential type, reel technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems such as the inability to realize the large capacity of the hoisting mechanism, the low-speed hoisting, the poor hoisting stability and safety, etc. The effect of lifting stability and safety, improving lifting stability and smoothness, and reducing load-bearing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

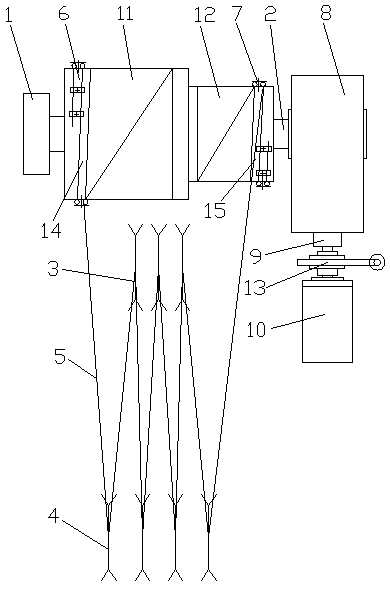

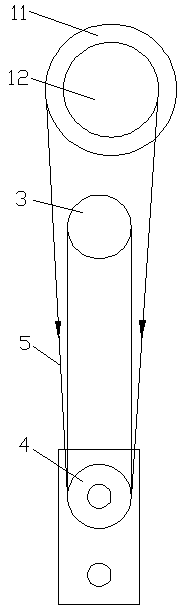

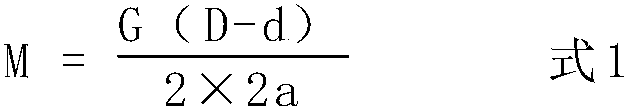

[0038] A differential winch lifting device, comprising a bearing seat 1, a drum shaft 2, a fixed pulley assembly 3, a movable pulley assembly 4, a hoisting rope 5, a first rope pressing plate assembly 6, a second rope pressing plate assembly 7 and a reducer 8. The hoisting rope 5 is wound on the movable pulley assembly 4 and the fixed pulley assembly 3, and also includes a differential drum set, a coupling 9 and a motor 10, and the differential drum set is fixed on the drum shaft 2, The differential reel set is integrally formed by a first differential reel 11 and a second differential reel 12, the diameter of the first differential reel 11 is larger than the diameter of the second differential reel 12, the One end of the hoisting rope 5 is fixed on the end of the first differential drum 11 through the first rope clamp assembly 6, and the other end of the hoisting rope 5 is fixed on the end of the second differential drum 12 through the second rope clamp assembly 7. One end of...

Embodiment 2

[0041] A differential winch lifting device, comprising a bearing seat 1, a drum shaft 2, a fixed pulley assembly 3, a movable pulley assembly 4, a hoisting rope 5, a first rope pressing plate assembly 6, a second rope pressing plate assembly 7 and a reducer 8. The hoisting rope 5 is wound on the movable pulley assembly 4 and the fixed pulley assembly 3, and also includes a differential drum set, a coupling 9 and a motor 10, and the differential drum set is fixed on the drum shaft 2, The differential reel set is integrally formed by a first differential reel 11 and a second differential reel 12, the diameter of the first differential reel 11 is larger than the diameter of the second differential reel 12, the One end of the hoisting rope 5 is fixed on the end of the first differential drum 11 through the first rope clamp assembly 6, and the other end of the hoisting rope 5 is fixed on the end of the second differential drum 12 through the second rope clamp assembly 7. One end of...

Embodiment 3

[0045] A differential winch lifting device, comprising a bearing seat 1, a drum shaft 2, a fixed pulley assembly 3, a movable pulley assembly 4, a hoisting rope 5, a first rope pressing plate assembly 6, a second rope pressing plate assembly 7 and a reducer 8. The hoisting rope 5 is wound on the movable pulley assembly 4 and the fixed pulley assembly 3, and also includes a differential drum set, a coupling 9 and a motor 10, and the differential drum set is fixed on the drum shaft 2, The differential reel set is integrally formed by a first differential reel 11 and a second differential reel 12, the diameter of the first differential reel 11 is larger than the diameter of the second differential reel 12, the One end of the hoisting rope 5 is fixed on the end of the first differential drum 11 through the first rope clamp assembly 6, and the other end of the hoisting rope 5 is fixed on the end of the second differential drum 12 through the second rope clamp assembly 7. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com