Patents

Literature

48results about How to "Adjust lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

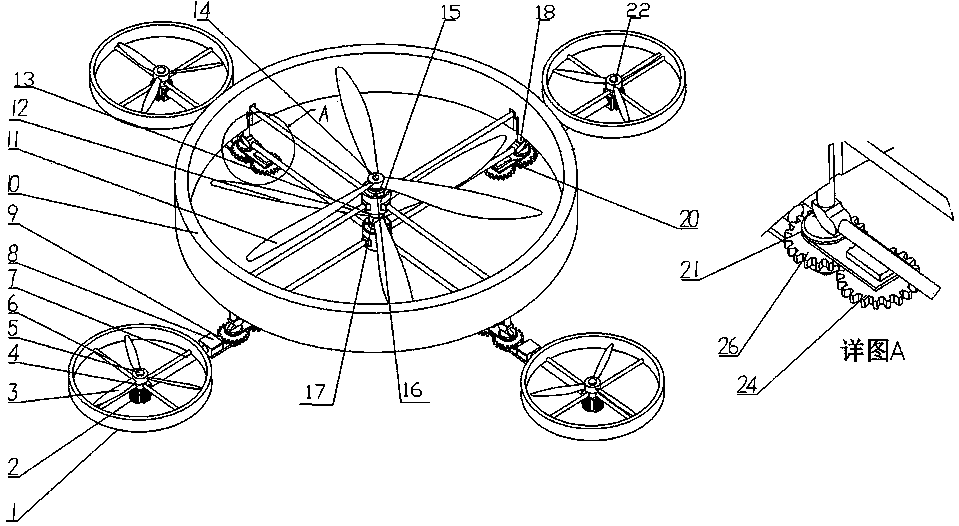

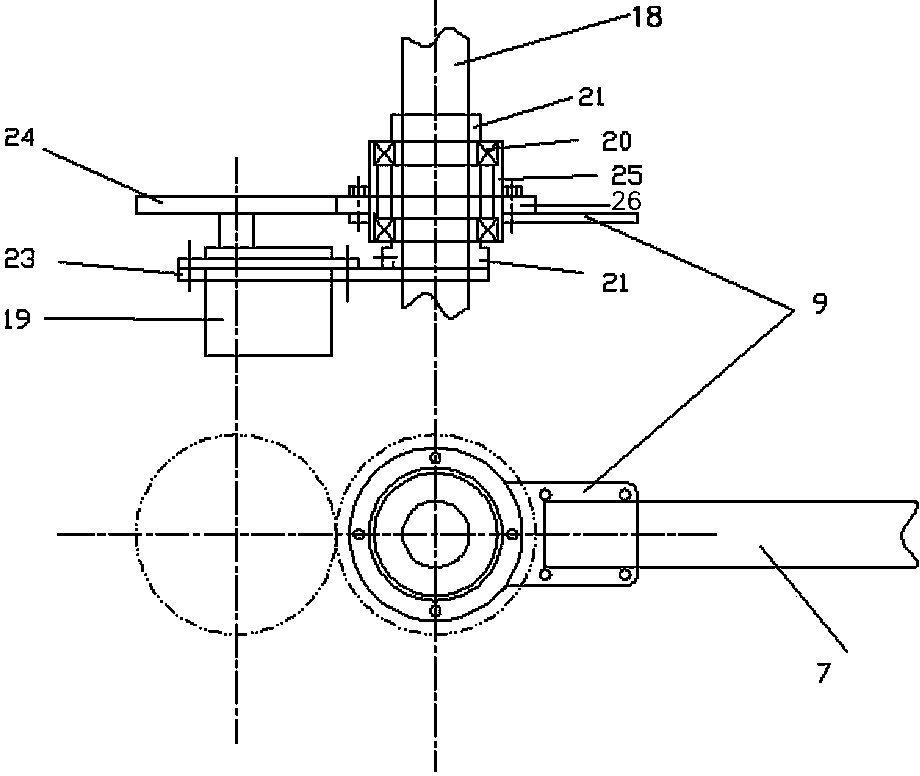

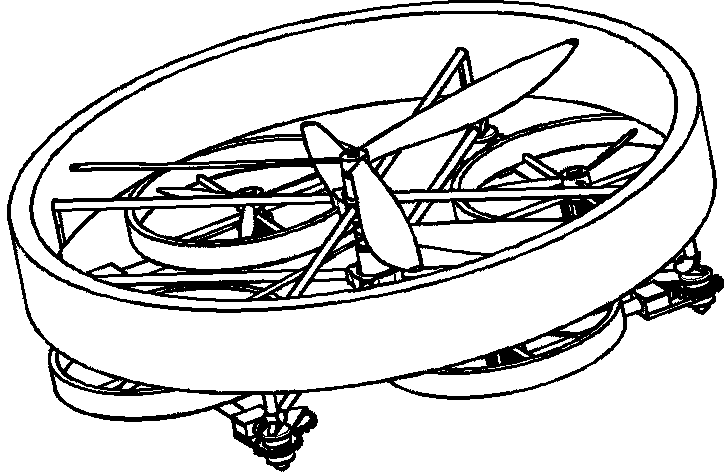

Ducted coaxial multi-rotor type aircraft

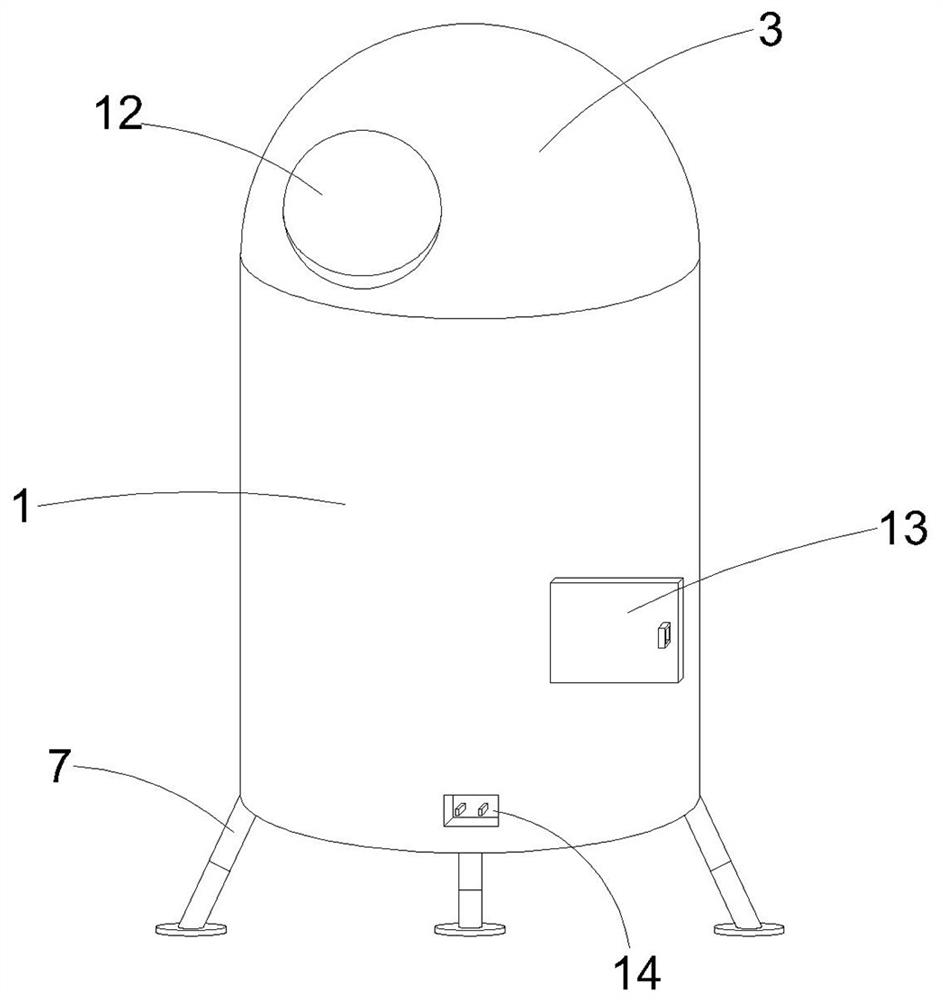

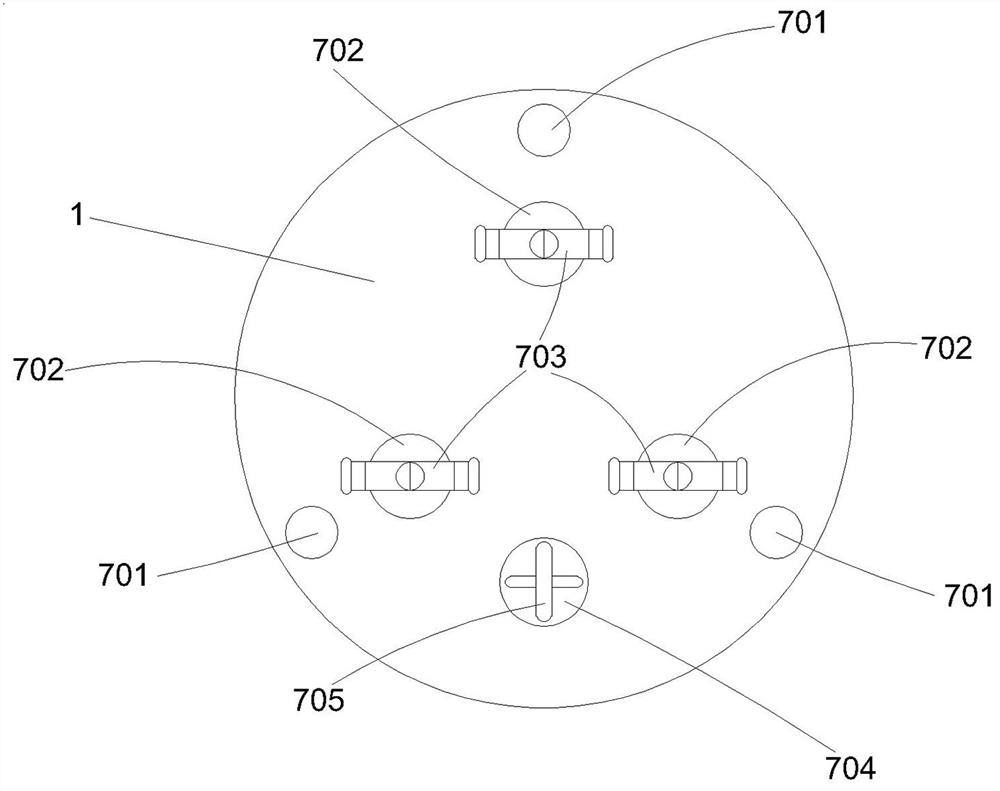

The invention discloses a ducted coaxial multi-rotor type aircraft and belongs to the field of special aircrafts. The multi-rotor type aircraft comprises an airframe structure, a power system and a control system. The airframe structure comprises a central duct, a main rotor and a plurality of assistant rotors evenly distributed at the peripheral of the central duct. The main rotor comprises an upper propeller and a lower propeller. The upper and lower propellers are fixed in the central duct. The centers of the upper and lower propellers are at the same vertical axis and the directions of the upper and lower propellers are opposite. A rotation device is connected to the outside of a supporting structure. The assistant rotors are connected to the rotation device through retractable rocker arms. The rotation device controls the rocker arms to drive the assistant rotors to rotate around connection points of the assistant rotors and the supporting structure. The assistant rotors can rotate and move freely, and therefore the aircraft can change the lift force distribution of the aircraft according to flight needs and a good maneuvering characteristic of the aircraft is achieved. The assistant rotors can be retracted into the inside of the central duct so as to reduce the size of the aircraft, thus facilitating flight in narrow spaces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

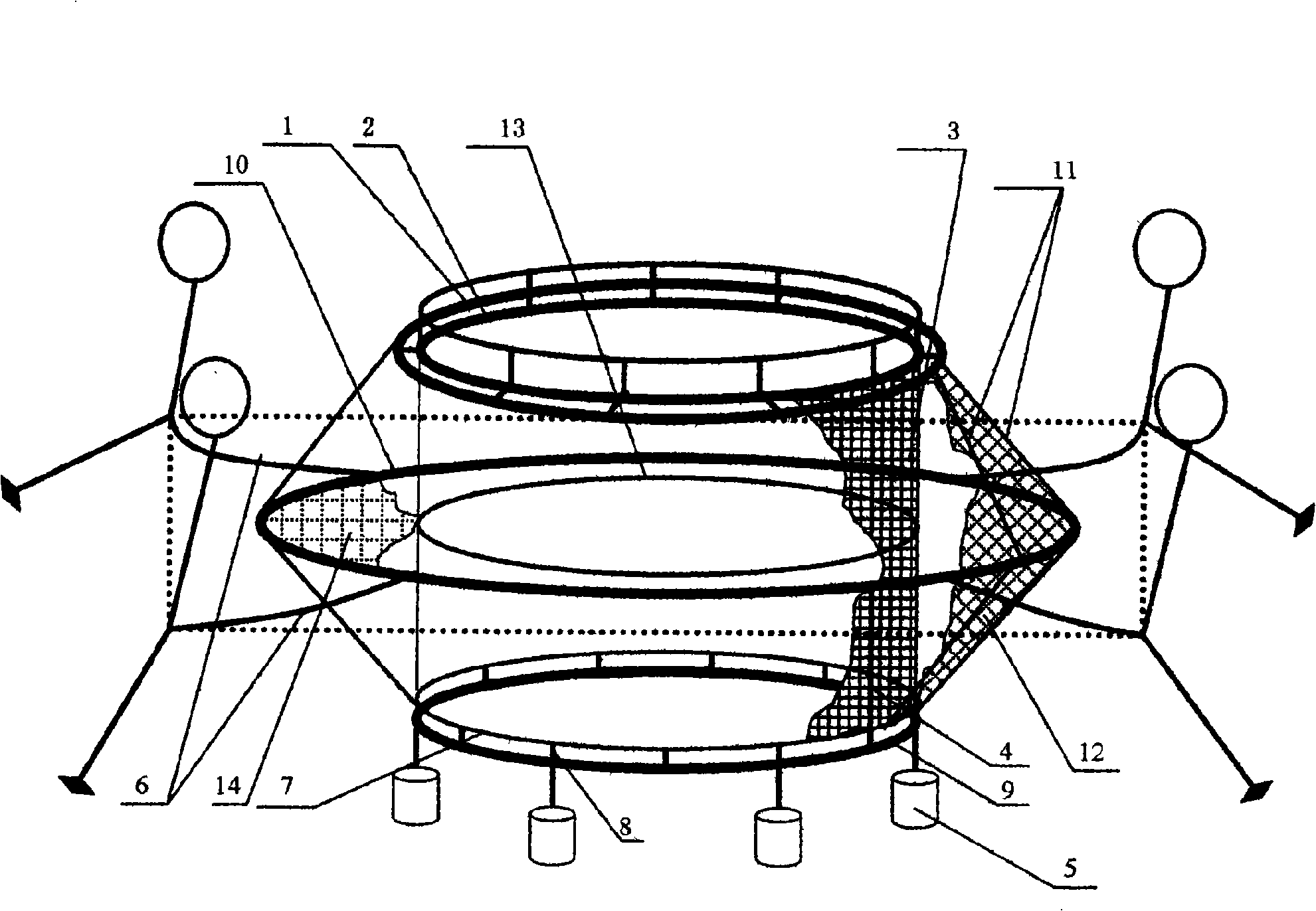

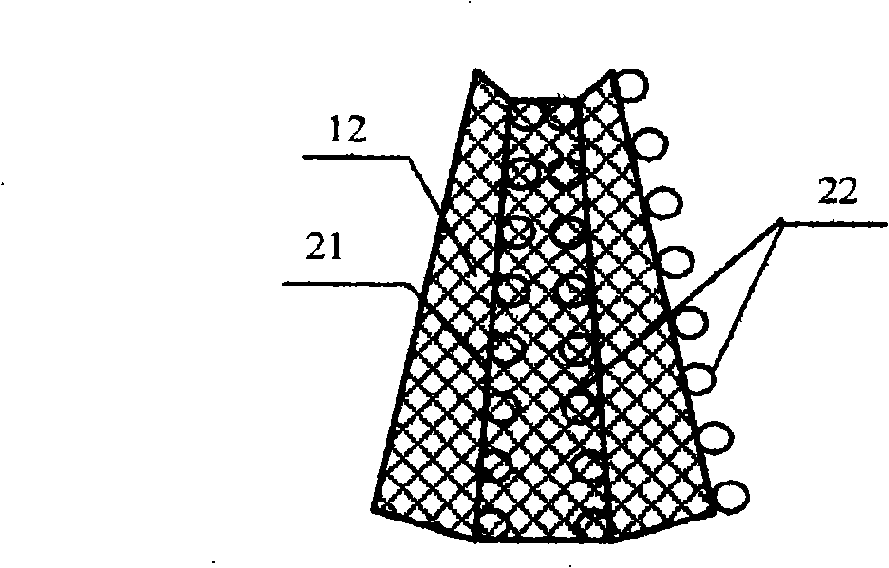

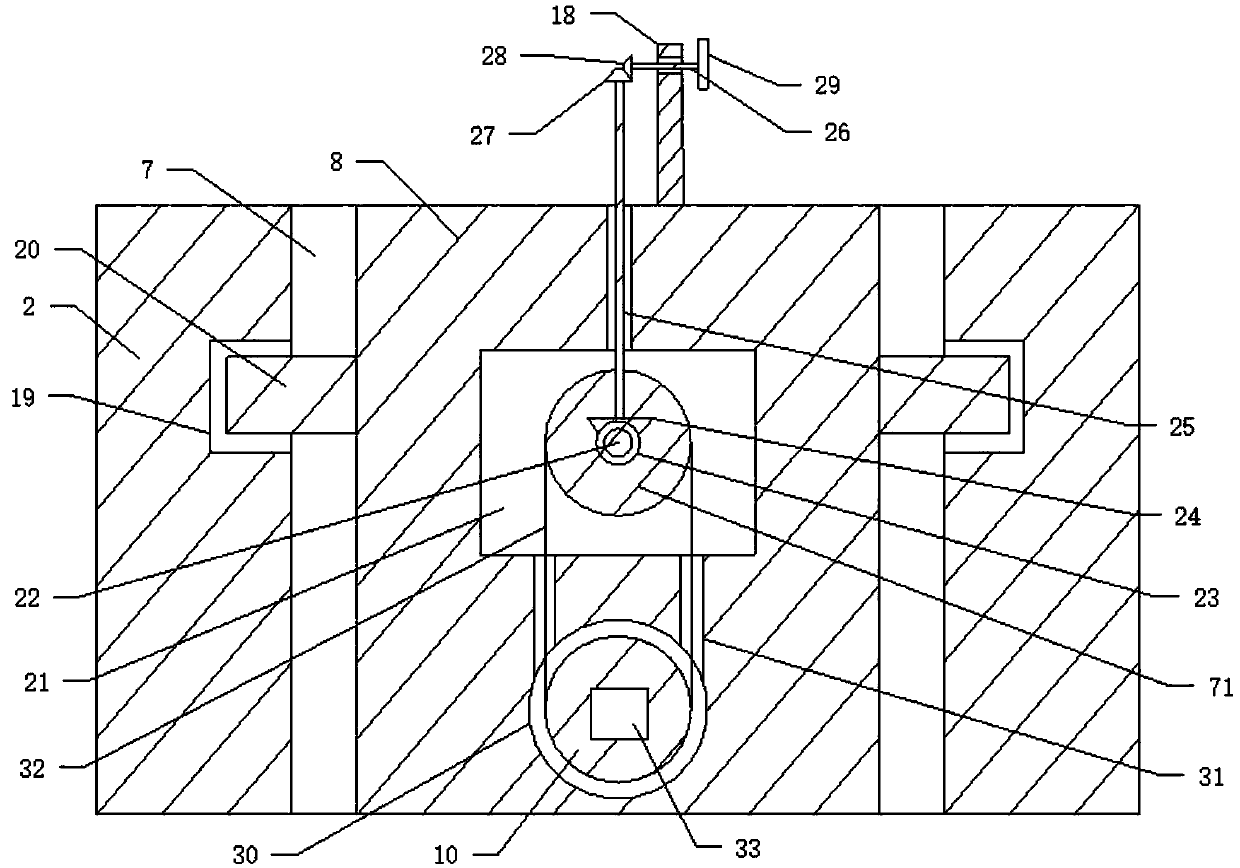

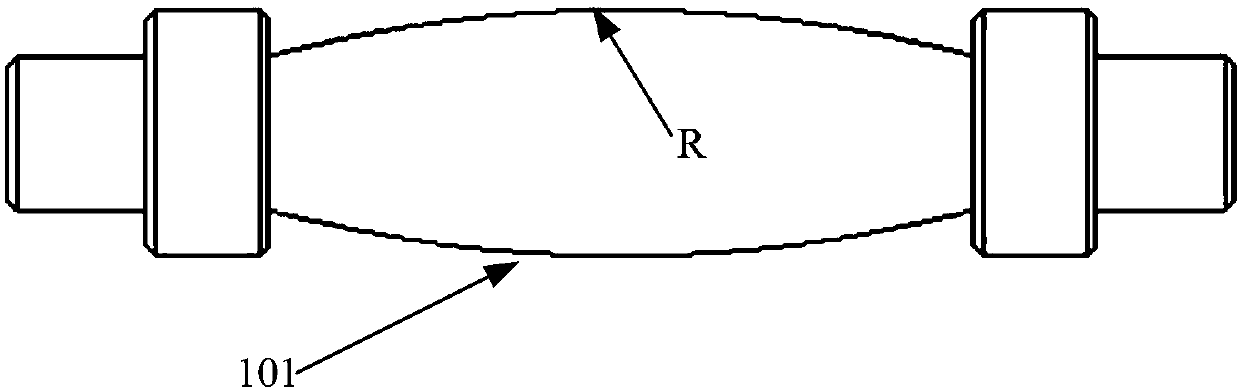

Self-reducing flow low-shape change off land deep water net cage

ActiveCN101326898AAdjust liftRegulation stateClimate change adaptationPisciculture and aquariaShape changeBand shape

The invention discloses an automatic reducing low-deformation offshore deep-water cage, relating to a cage for marine aquiculture. The invention is capable to reduce the deformation of the cage and the flow rate of the sea water inside the cage. The invention comprises a buoyancy frame, a cage, a sinking ring, a sinking block and an anchoring rope. A supporting and lifting control ring bigger than the buoyancy frame and the diameter of the sinking ring is arranged at the one second depth of the cylindrical cage; a water inlet and a water outlet are arranged in the pipe wall of the supporting and lifting control ring; a girdle rubber inner bag which regulates the lifting and descending of the cage is arranged in the ring pipe; an air-valve is installed in the rubber inner bag and connected with the air supply by a pressure hose; between the outer ring and the supporting and lifting control ring of the double-ring buoyancy frame, the bottom outline of the cylindrical cage and the bottom sinking ring, a plurality of flexible ropes are located and connected according to the ring at geometric proportion, and a netting is arranged among the connecting ropes of the three rings; and finally, a flexibly connected automatic reducing low-deformation offshore deep-water cage with a cylindrical inside and a two-cone platform outside is formed, the stress point of the anchoring rope of the cage is arranged at the supporting and lifting control ring.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

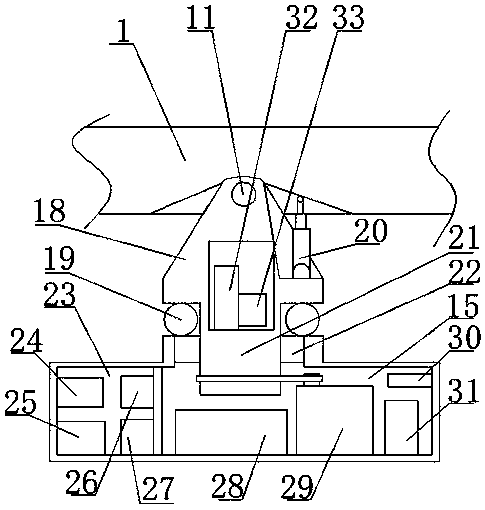

LED streetlamp capable of effectively enhancing radiation scope and with adjustable position

PendingCN107702022AExtended lighting rangeSolve the problem that the irradiation range becomes smallerMechanical apparatusLighting support devicesDrive shaftAgricultural engineering

The invention relates to the technical field of LED lamps, and discloses an LED streetlamp capable of effectively enhancing the radiation scope and with the adjustable position. The LED streetlamp comprises a stabilizing box, a drive motor is fixedly connected to the inner bottom wall of the stabilizing box, an output shaft of the drive motor is fixedly connected with a transmission shaft, the topend of the transmission shaft penetrates and extends to the top of the stabilizing box, the top end of the transmission shaft is fixedly connected with a thread rod, and the top end of the thread rodis in threaded connection with a thread pipe. According to the LED streetlamp capable of effectively enhancing the radiation scope and with the adjustable position, through normal work of a light-emitting bulb, lighting can be achieved, a first hydraulic telescopic rod stretches out and retracts, a sliding block slides in a sliding groove, lifting of a partition plate is adjusted, the distance between the light-emitting bulb and a convex lampshade is conveniently adjusted, the radiation scope can be conveniently adjusted, a second hydraulic telescopic rod stretches out and retracts, the angleof the light-emitting bulb is adjusted, and the radiation scope can be more conveniently enhanced.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

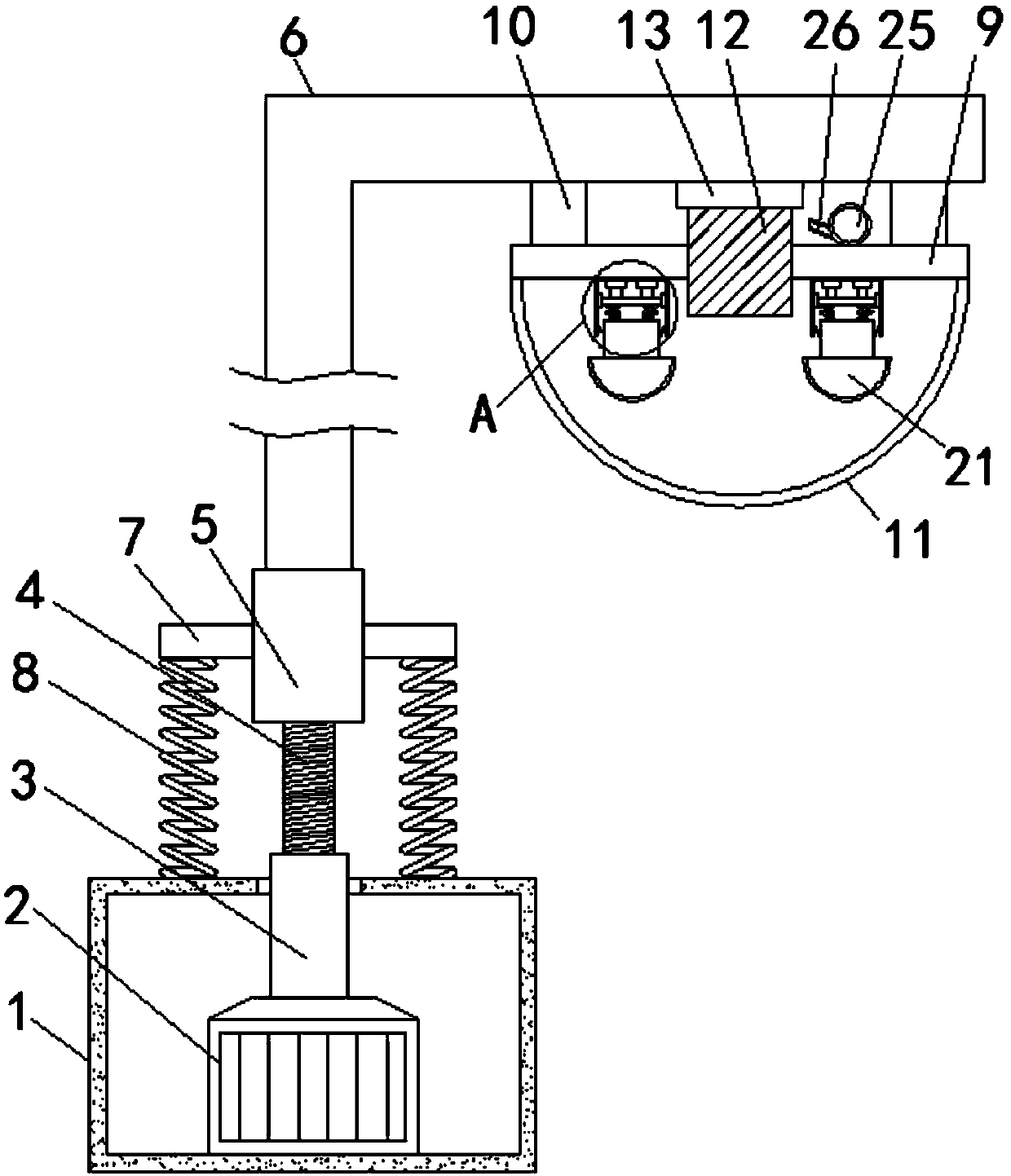

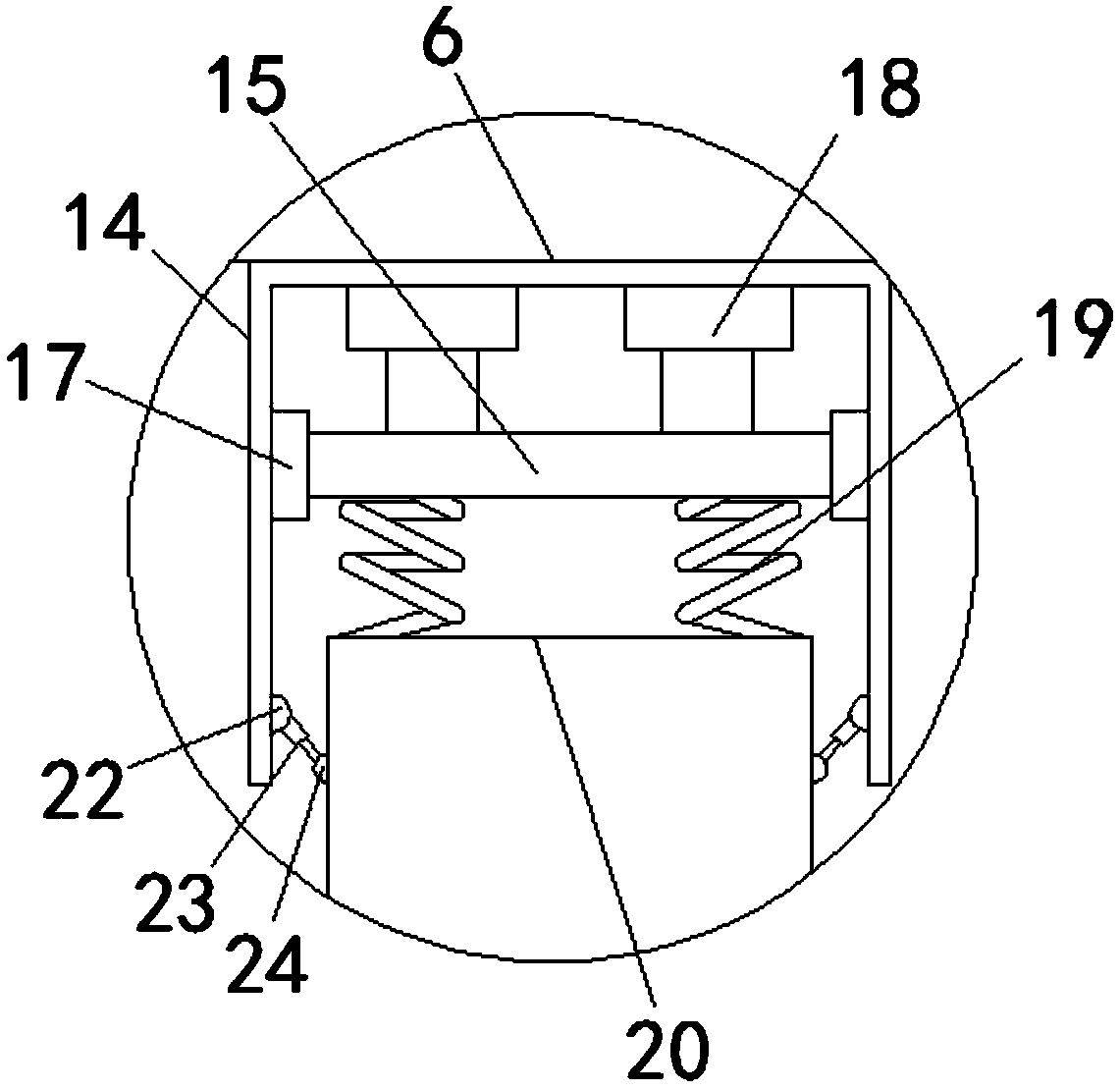

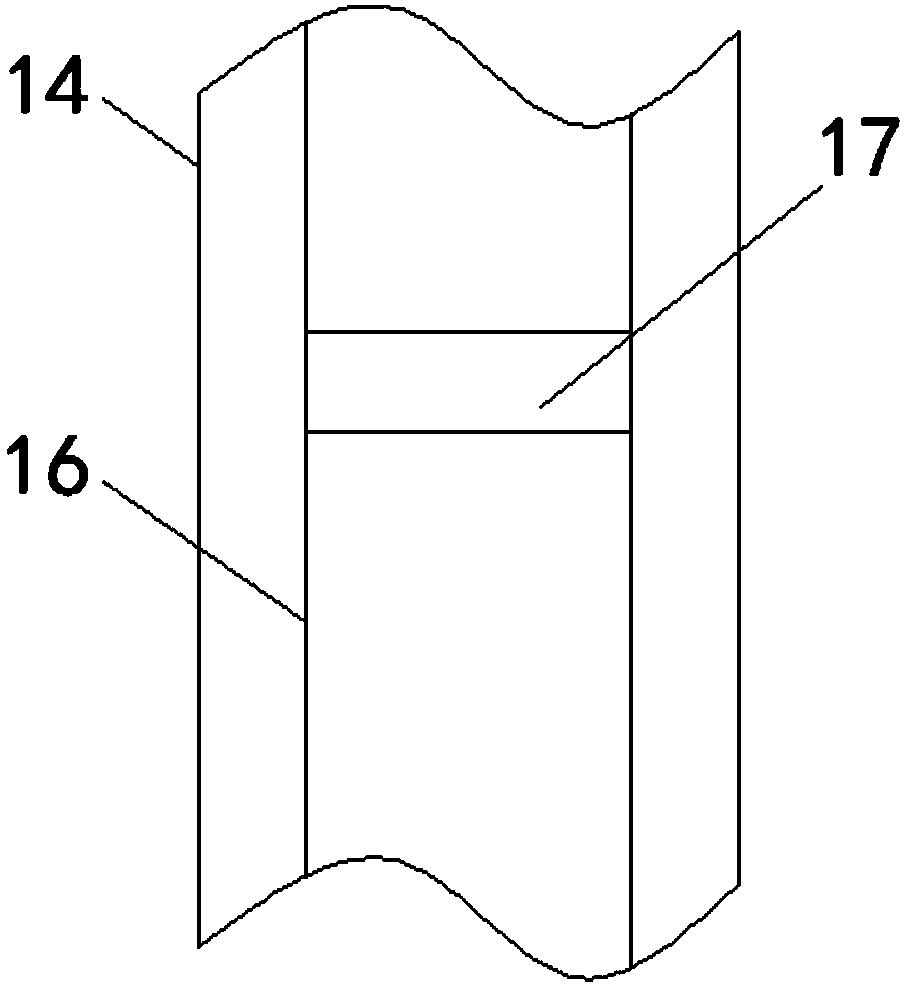

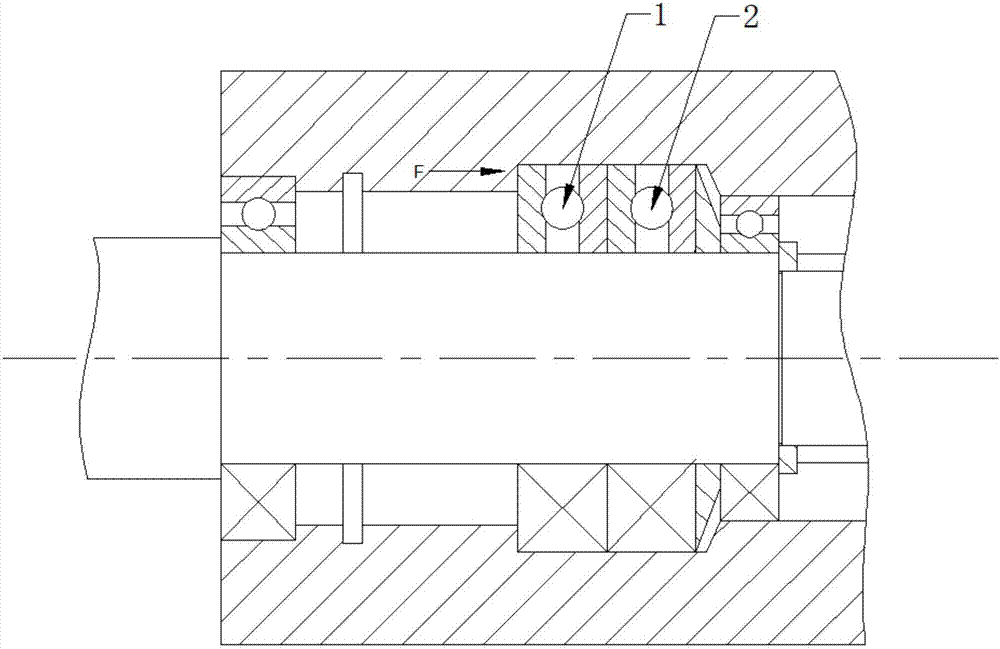

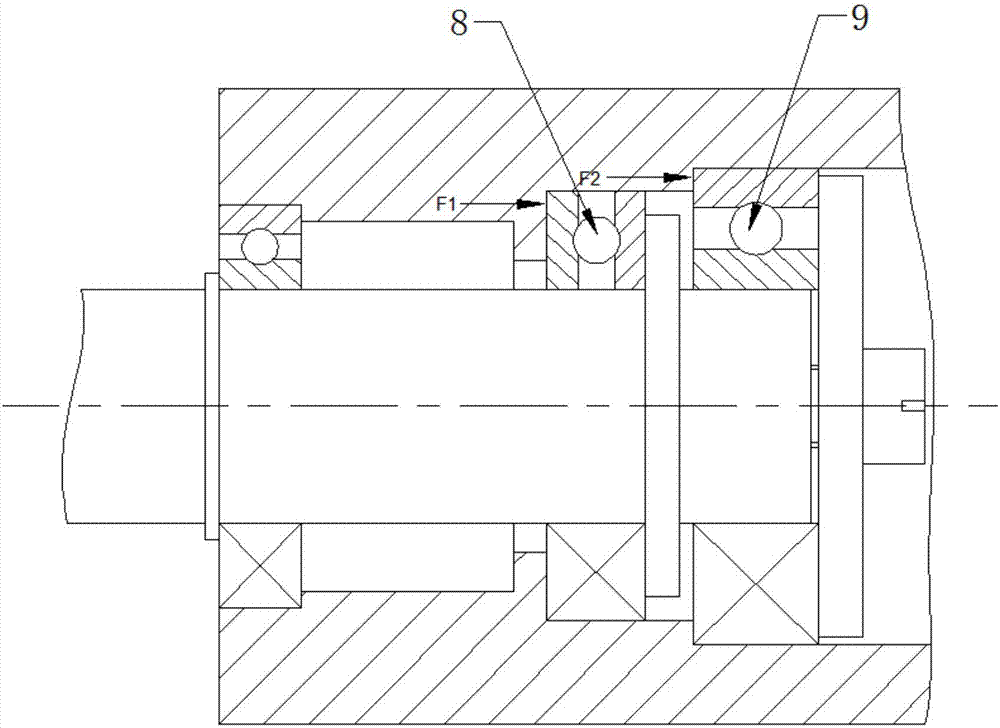

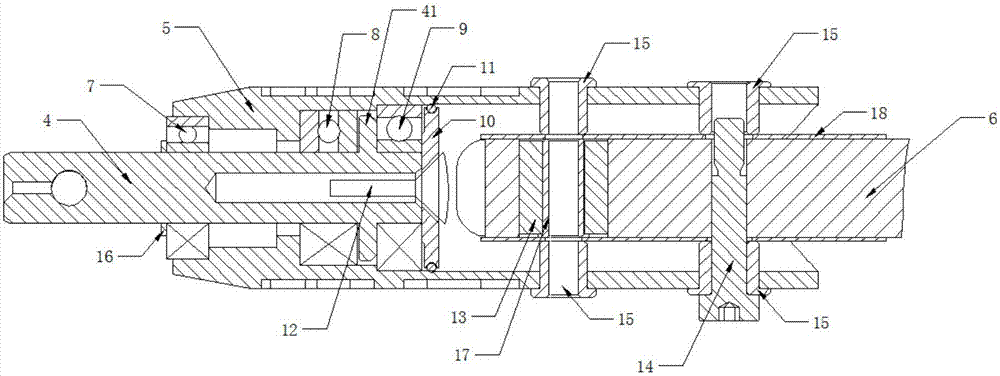

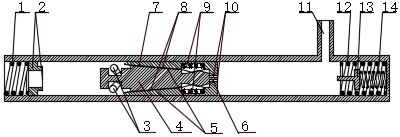

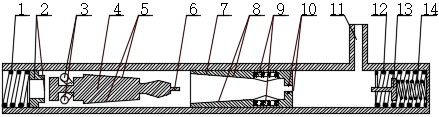

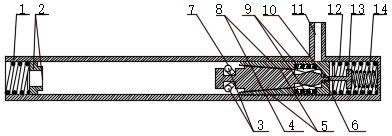

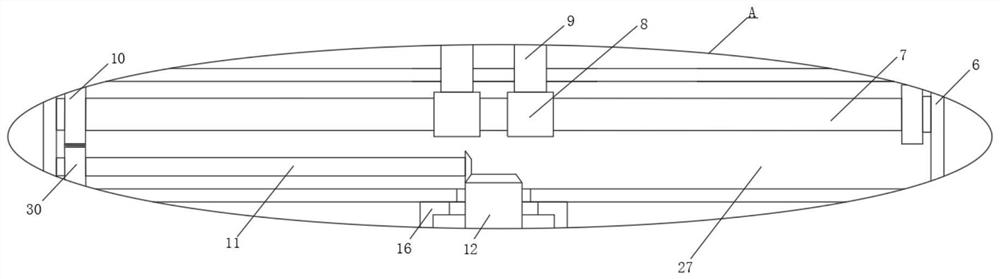

Split type intelligent plunger with pulley mechanism

InactiveCN109723408AReal-time control of motion speedAvoid damageFlexible member pumpsFluid removalDual mechanismButterfly valve

The invention relates to the field of gas well drainage and gas production, in particular to a split type intelligent plunger with a pulley mechanism. The split type intelligent plunger with pulley mechanism is characterized in that the intelligent plunger comprises a plunger body, a pulley mechanism at the lower end of the plunger body, a plunger sleeve, a spring slip arranged in the plunger sleeve, an open butterfly valve with a locking device, an upper buffer, a lower buffer, a self-adaptive valve mechanism arranged in the lower buffer and a pressure sensor, a temperature sensor, a speed sensor and a microprocessor control attached to the plunger body and the plunger sleeve; the speed of the plunger body and the plunger sleeve in the ascending or descending process is controlled by controlling the action of the pulley mechanism. Compared with the prior art, the split type intelligent plunger with pulley mechanism has the advantages that the defect that the speed of the plunger usedfor draining water in the prior continuous production operation without closing the well is not controllable is solved, and the problem that an underground or wellhead accident is caused due to serious collision between the plunger body and the plunger sleeve in the a ascending or descending process is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

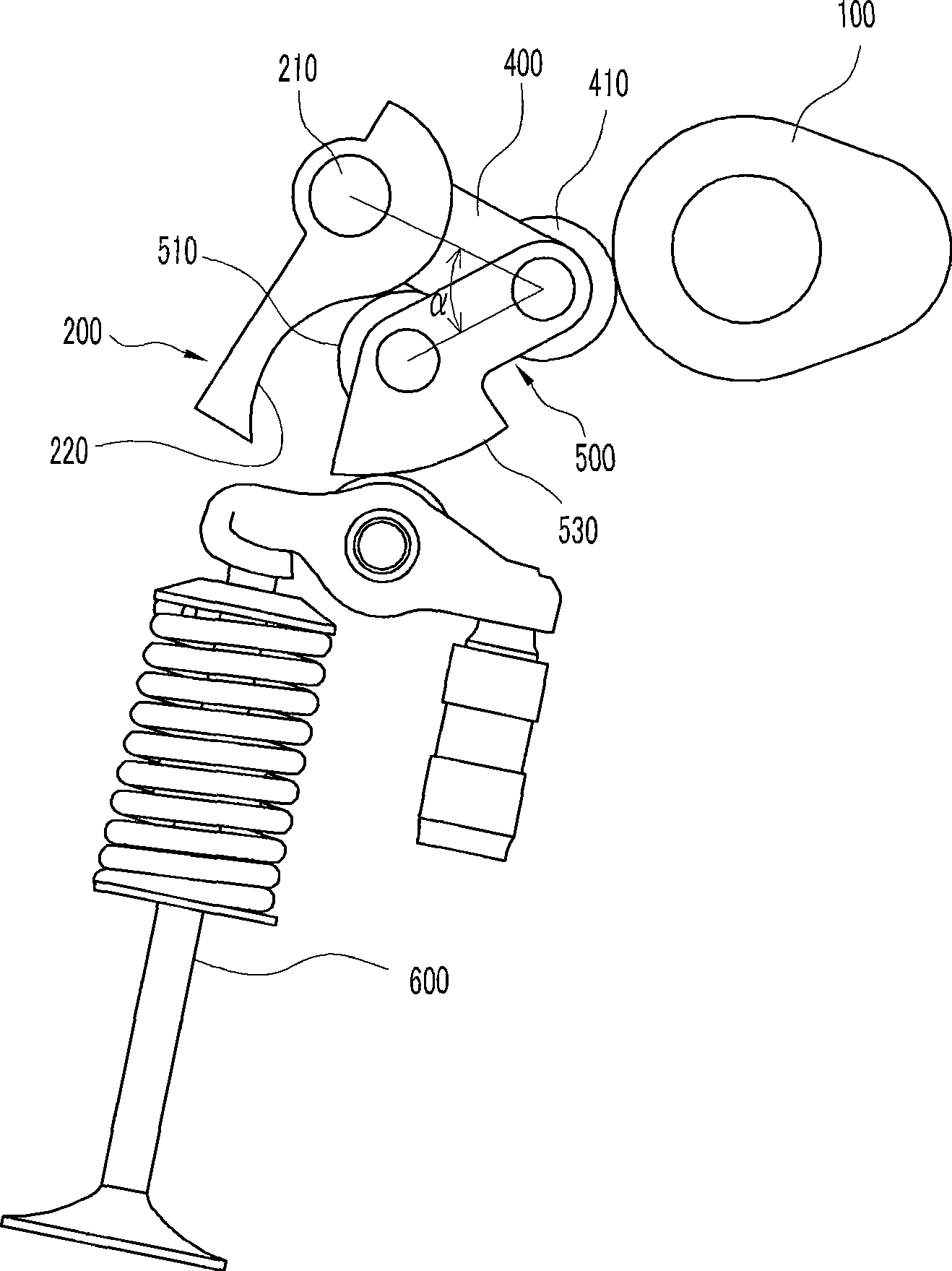

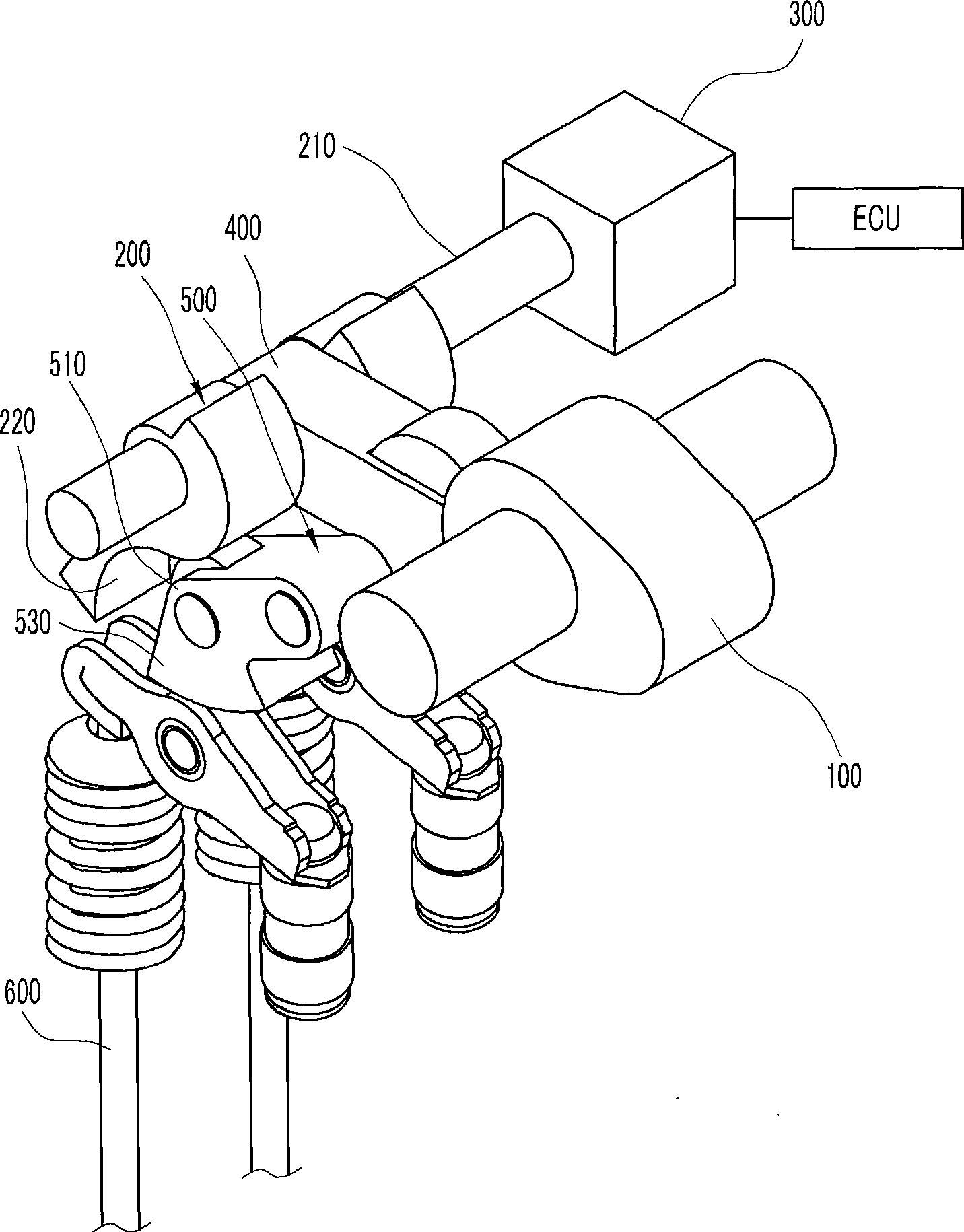

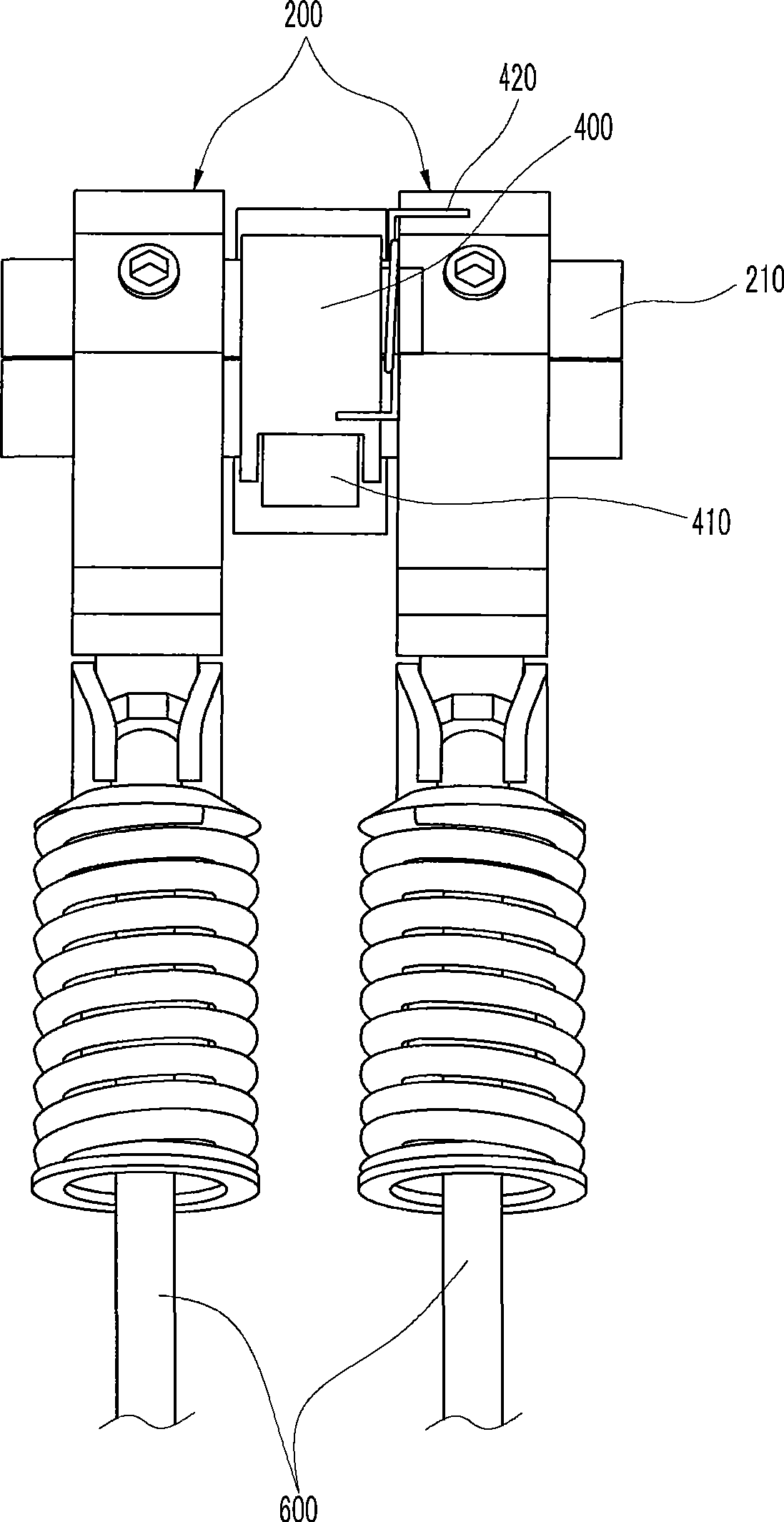

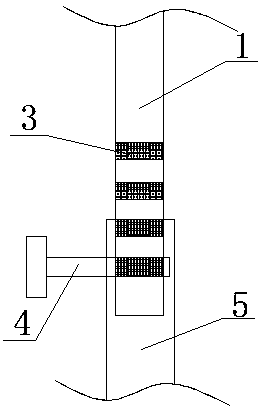

Continuous variable valve lift apparatus

Based on one Embodiment of the invention, a continuous variable valve lift apparatus includes an input cam; a control lever rotating shaft; a control lever with a contact portion, provided on the control lever rotating shaft; a control portion that controls the angle between the control lever and the control lever rotating shaft; a first link rotatably connected to the control lever rotating shaft; a second link rotatably connected to the first link, that contacts the contact portion; an output cam on the second link, to open and close a valve; and an elastic portion provided such that a connecting portion of the first link and the second link contact the input cam.

Owner:HYUNDAI MOTOR CO LTD

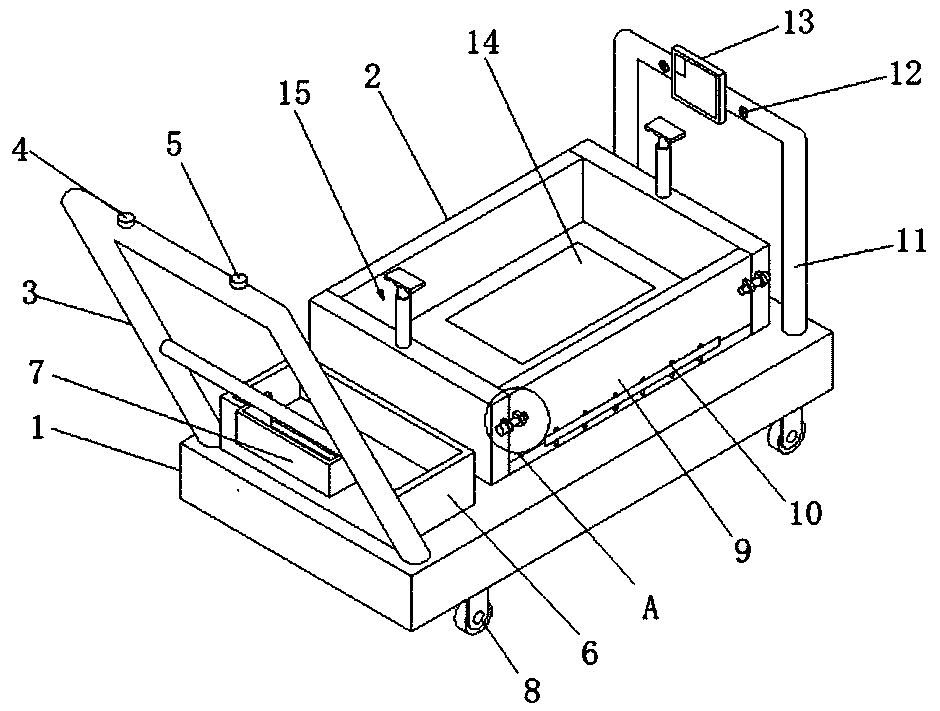

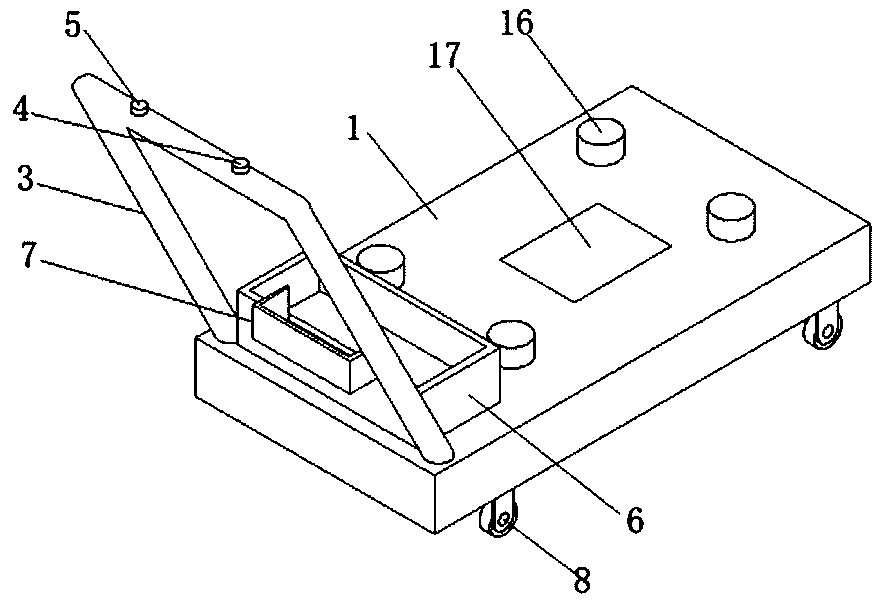

Intelligent handcart for meeting service

PendingCN109017951AEasy to useAdjust liftHand carts with multiple axesHand cart accessoriesEngineeringChild protection

The invention discloses an intelligent handcart for meeting service, include a handcart body, the handcart body comprises a pushing bottom plate and a holding box and a child protection box arranged above the pushing bottom plate, the holding box is fixedly installed on one side of the upper end face of the pushing bottom plate through an electric telescopic rod, A manual push rod is also arrangeon one side of that upper end face of the pushing bottom plate, the child protection box is arranged on the pushing bottom plate between the hand pushing rod and the holding box, the bottom end of thechild protection box is welded and fixed with the top end of the pushing bottom plate, and a horizontal fixing seat is welded to the top end of one side of the child protection box toward the push rod, the upper end face of the fixing seat is not connected with the three side ends of the child protection box, and a fixing front frame is also arranged at the edge of the upper end face of the pushing bottom plate of the holding box opposite to the child protection box. Smart trolley is used for meeting service, which is convenient for member users to choose when purchasing, and can be used fordifferent quantities of goods and for members of different heights.

Owner:临汾市德益天成信息科技服务有限公司

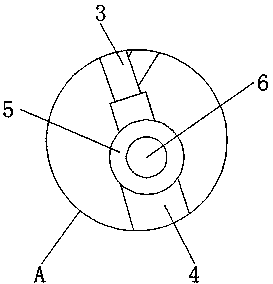

Full-service-life propeller hub structure

PendingCN107985586ASimple structure improvementEasy to installPropellersRotocraftPropellerCentrifugal force

The invention provides a full-service-life propeller hub structure. The full-service-life propeller hub structure comprises a propeller hub center piece, a blade spindle, a propeller clamp and blades,wherein the blade spindle is connected with the propeller hub center piece and the propeller clamp, the blades are arranged on the tail end of the propeller clamp, a first bearing, a second bearing and a third bearing are successively arranged on the blade spindle along the tail end of the propeller clamp, the blade spindle is provided with a step surface, and the second bearing and the third bearing are respectively arranged on two sides of the step surface. Two mounting bearings of a helicopter rotary wing propeller hub are used for sharing a centrifugal force of the rotation of the propeller blades, so that the service life of the bearing is greatly prolonged, and the full-service-life use of an unmanned helicopter can be satisfied.

Owner:重庆驼航科技有限公司

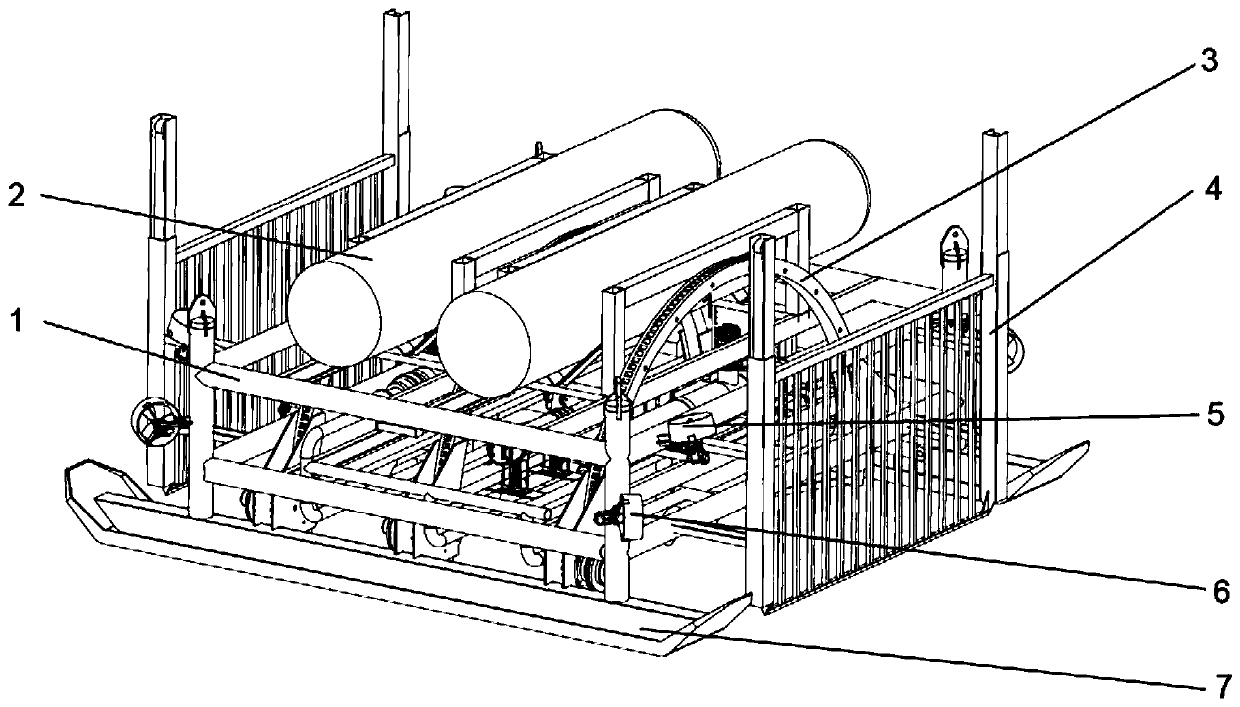

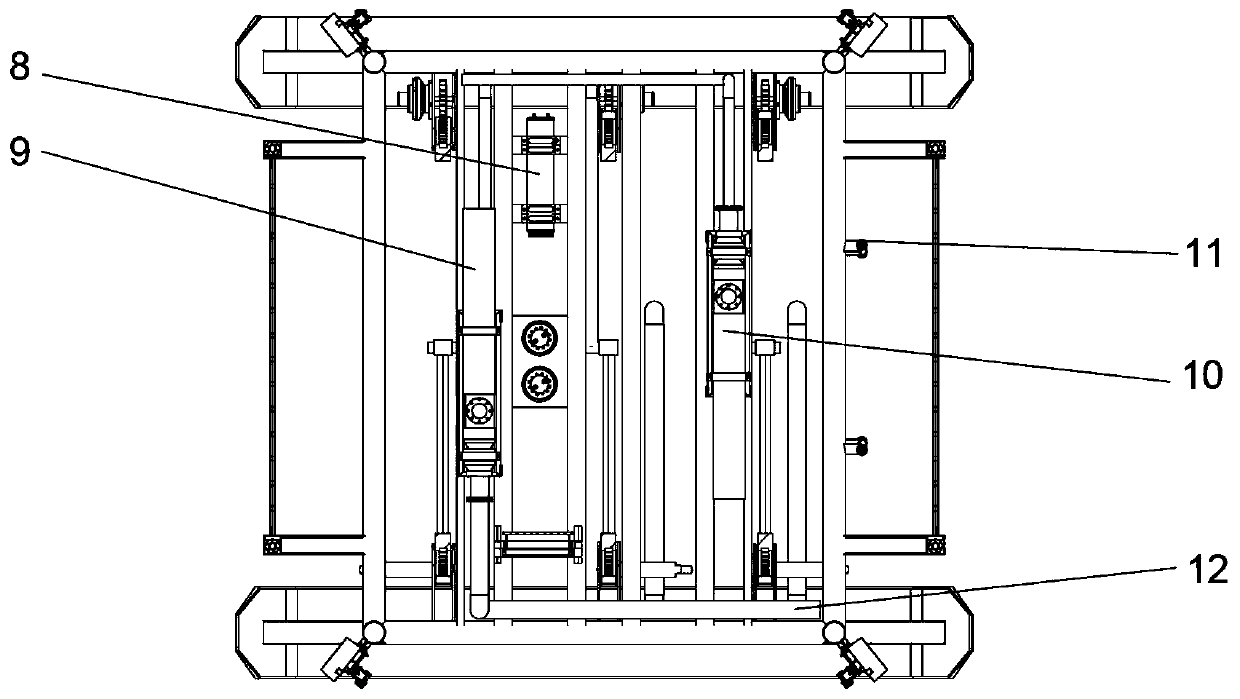

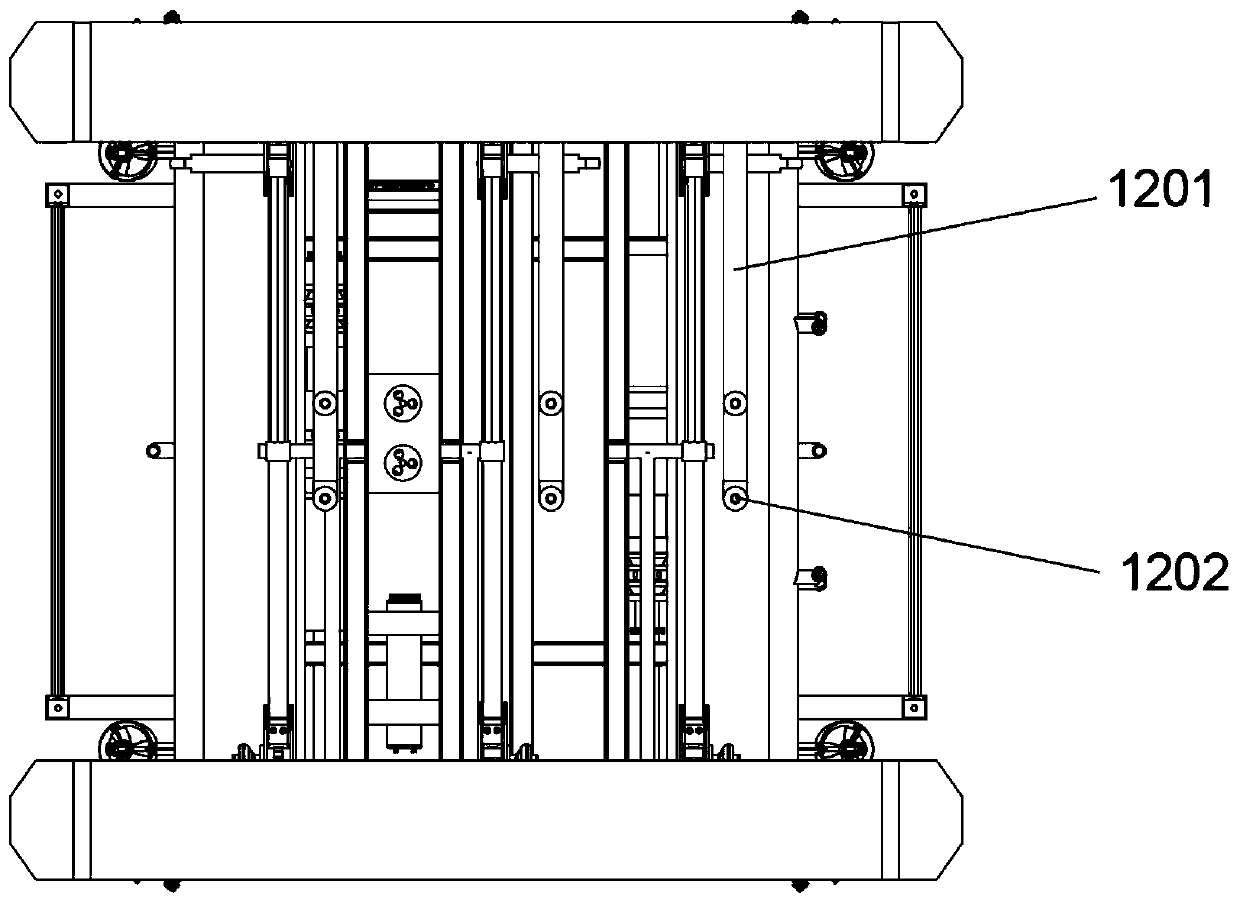

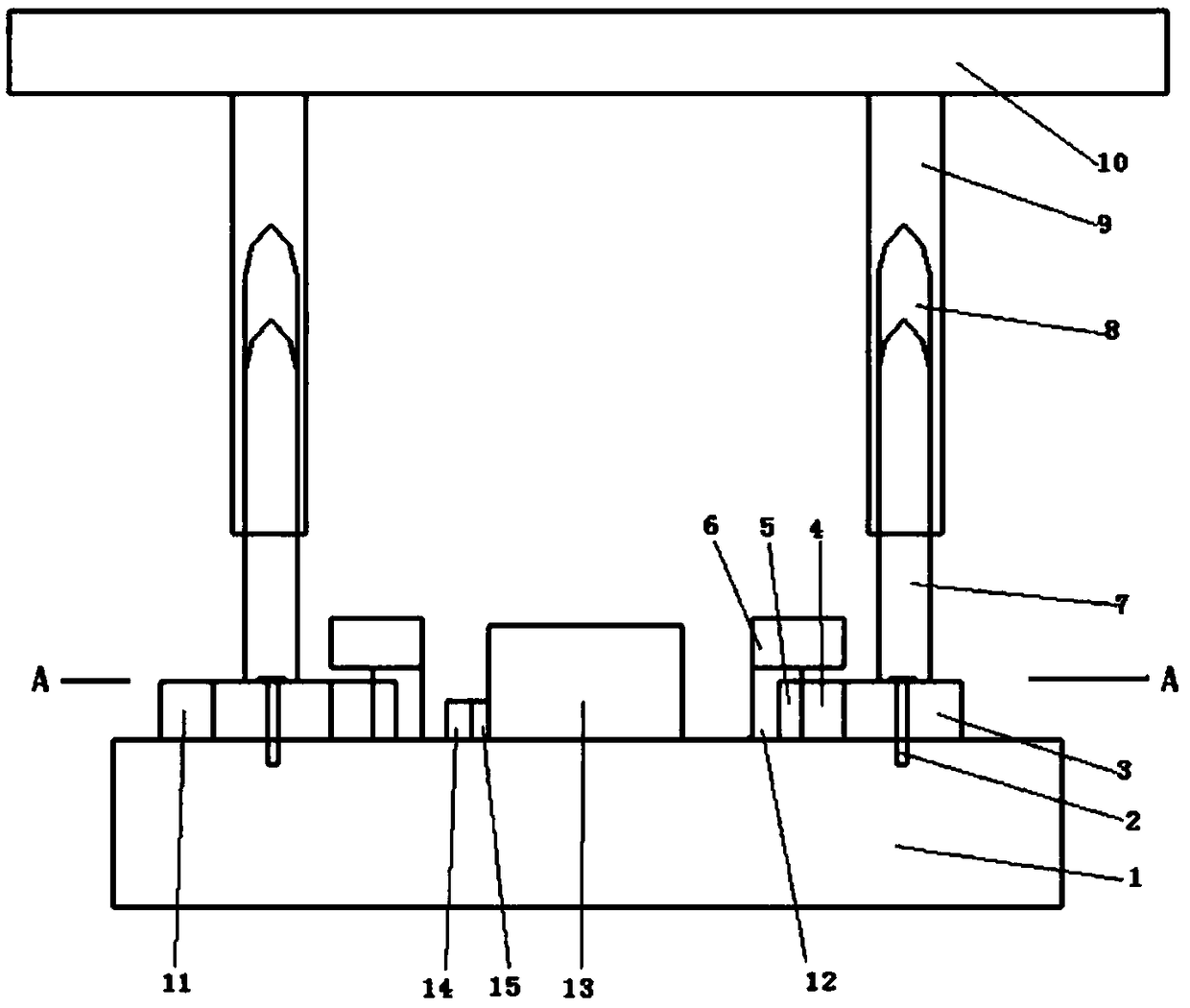

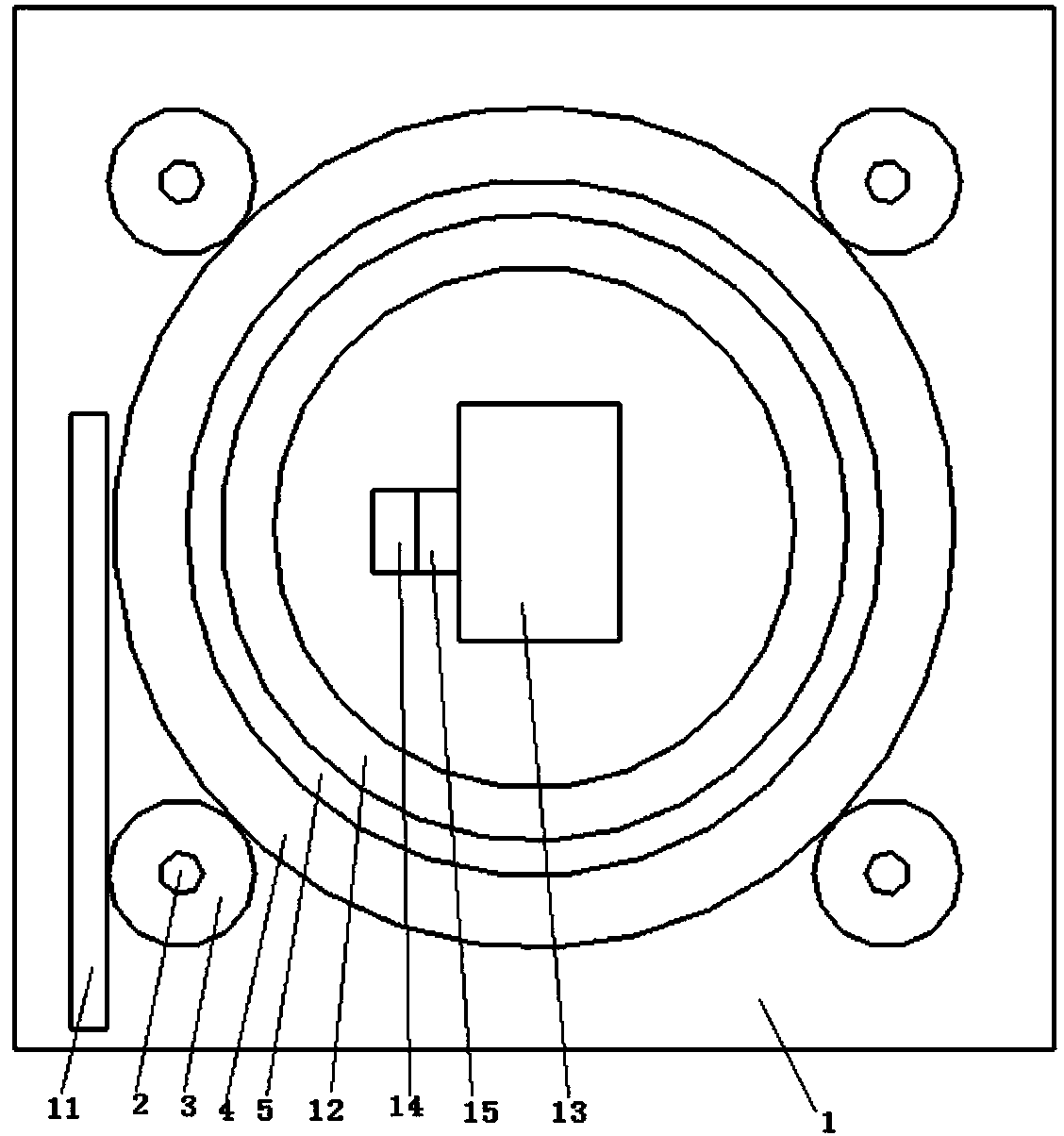

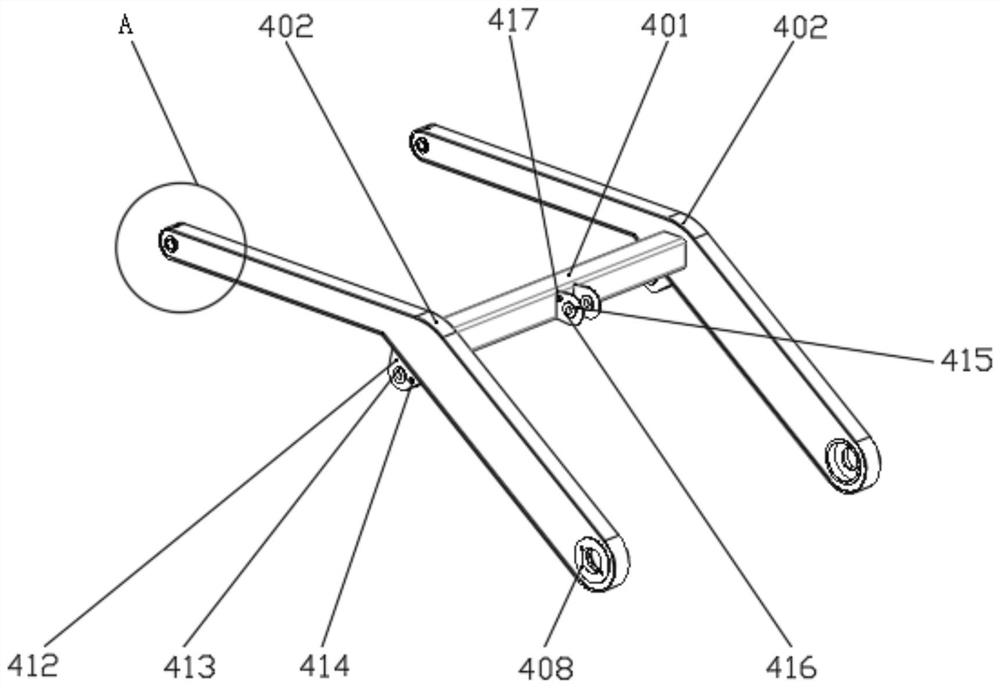

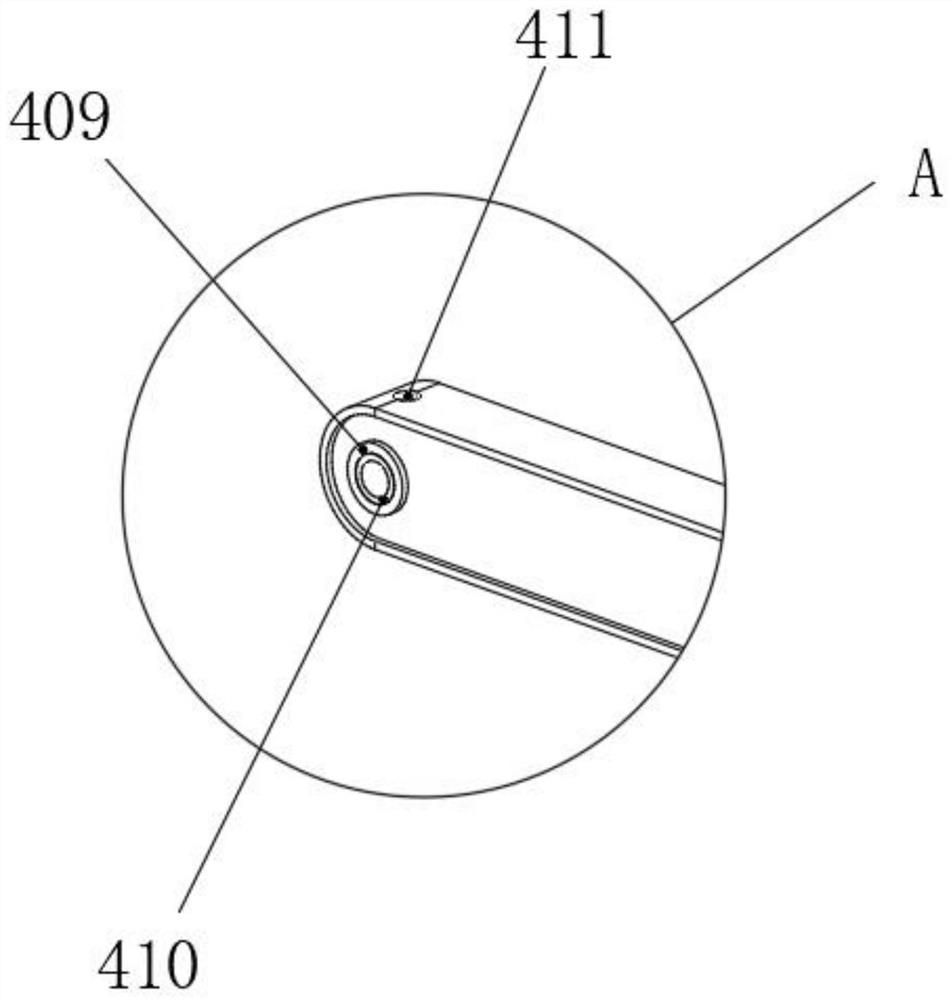

Floating type fishing device suitable for underwater long columnar objects

The invention provides a floating type fishing device suitable for underwater long columnar objects, and belongs to the technical field of salvage operation. The device comprises a main body rack, a buoy, a plurality of annular fishing arms, a propeller assembly and a control system, wherein the buoy, the propeller assembly, the annular fishing arms and the control system are all installed on themain body rack, the control system controls actions of the buoy, the annular fishing arms and the propeller assembly, the fishing device can autonomously and stably adjust lifting of the equipment inwater through a buoyancy adjusting function of the buoy, and the fished equipment can be prevented from sliding out of the bearing range of an annular support during fishing operation lifting througha longitudinal blocking device; and a nozzle on the annular support is communicated with a high-lift water pump, so that the resistance of the annular support penetrating through the equipment to be fished is greatly reduced. The fishing device can adapt to various fishing environments, the fishing efficiency is high, the danger caused by manual work in the prior art is avoided, and the operationsafety is improved.

Owner:SHANGHAI JIAO TONG UNIV

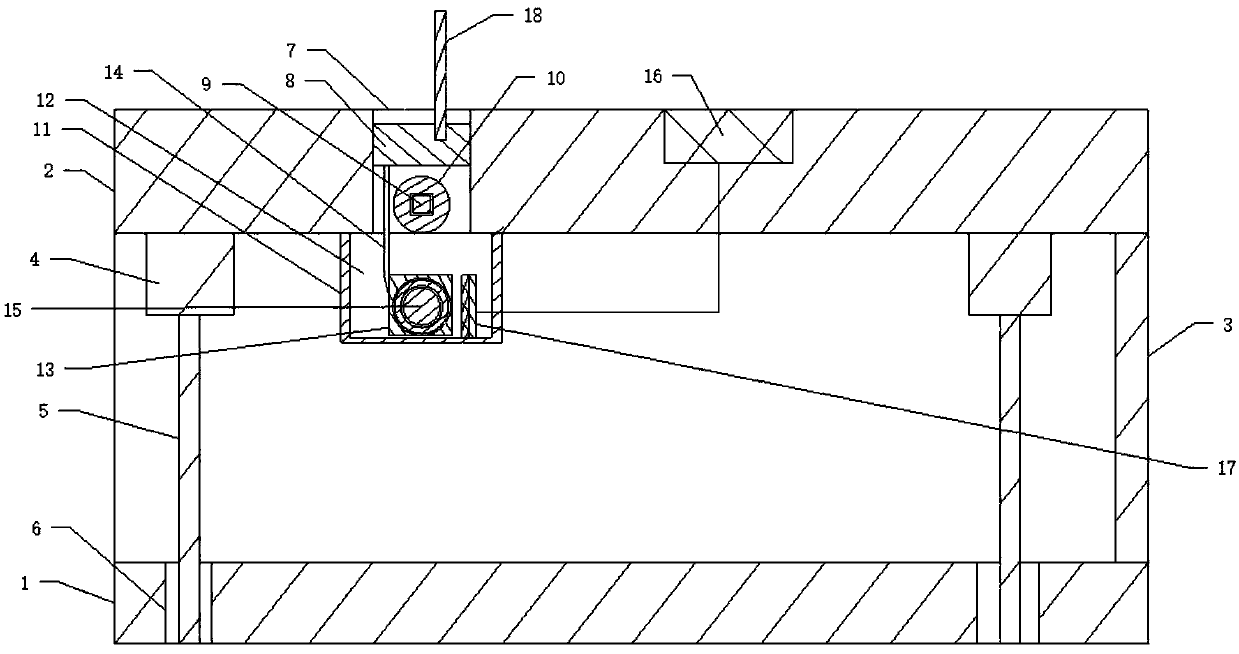

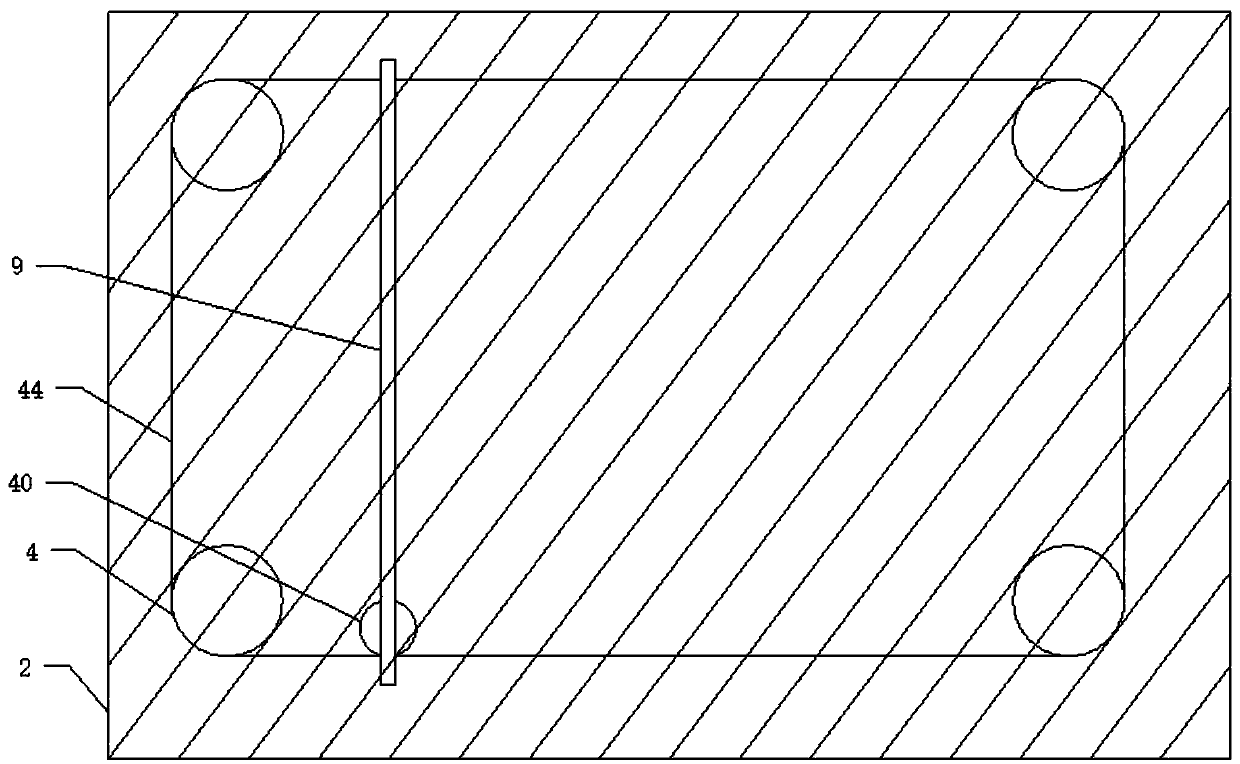

Power equipment supporting seat

InactiveCN108233217AAdjust liftImprove cooling effectSubstation/switching arrangement cooling/ventilationEngineeringPower equipment

The invention discloses a power equipment supporting seat which comprises a base station, four first gears positioned at four corners of the base station and an electric fan positioned in the middle of the base station. A mounting platform is arranged on the base station and fixedly connected with a big gear, a chain meshed with the big gear is arranged outside the big gear, each first gear is meshed with the chain, and one of the four first gears is meshed with a rack; a controller and temperature and humidity sensors are arranged on the base station, a screw is fixedly connected on each first gear, a supporting frame sleeves each screw, a threaded hole matched with the corresponding screw is arranged at one end of each supporting frame, the other end of each supporting frame is fixedly connected with an equipment baseplate, and the temperature and humidity sensors and the electric fan are connected with the controller. Lifting and lowering of the supporting seat can be adjusted; a cooling fan is arranged, so that convenience is brought to cooling of power equipment, working intensity of maintaining personnel is lowered, and working efficiency of the maintaining personnel is improved.

Owner:WUHU XIAOSHENG ELECTROMECHANICAL TECH CO LTD

Derusting device for machining die steel

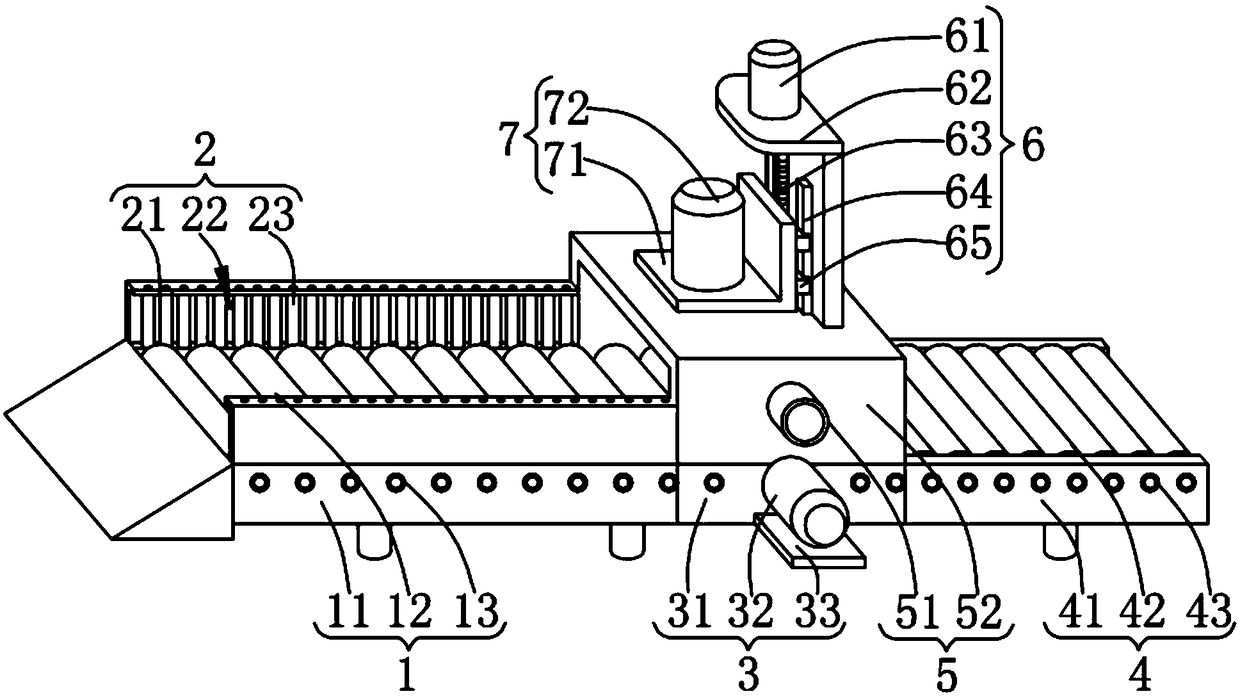

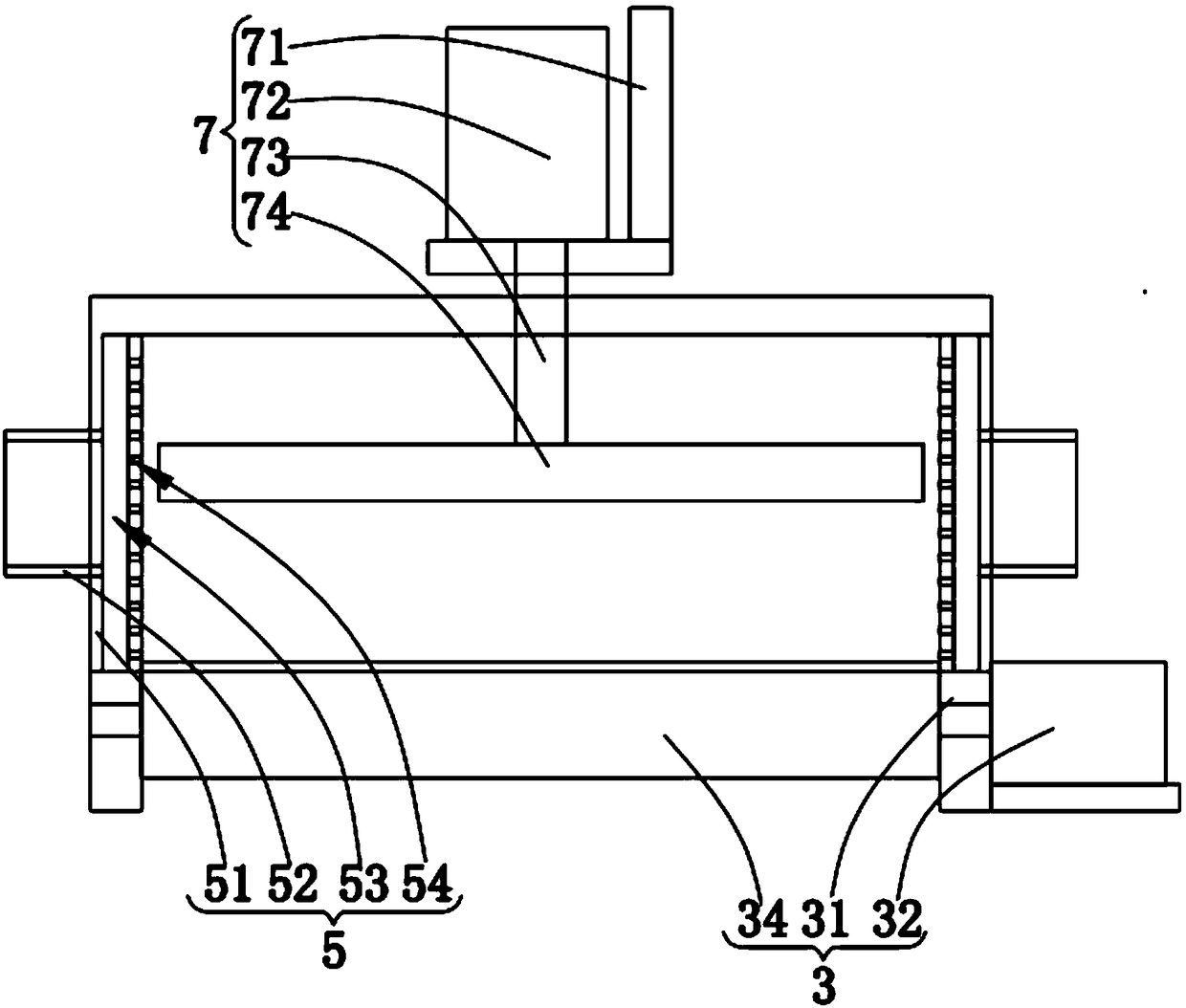

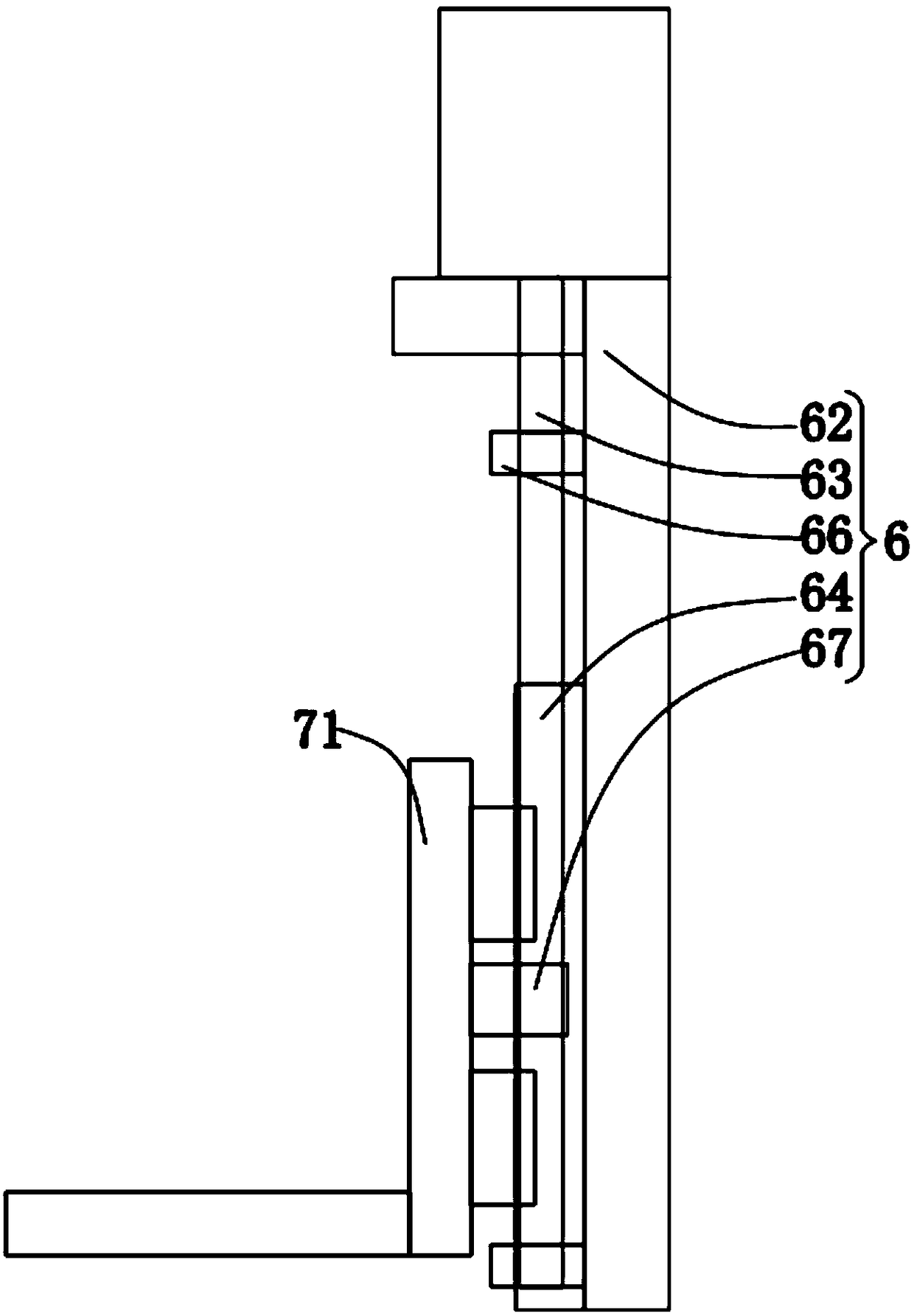

InactiveCN109277926AAdjust liftAvoid pollutionGrinding machinesGrinding feedersEngineeringMechanical engineering

The invention provides a derusting device for machining a die steel. The derusting device for machining the die steel comprises a feeding structure, a conveying structure, a dust suction structure, anadjusting structure, a grinding structure and a discharging structure; the grinding structure is slidably connected to the interior of the dust suction structure, the grinding structure comprises a mounting plate, a third motor, a rotating shaft and a grinding disc; the mounting plate is slidably connected to one end of the adjusting structure, and the mounting plate is of an L-shaped structure;the third motor is fixed at the top end of the mounting plate, the rotating shaft is slidably connected to the dust suction structure, and the rotating shaft is fixedly connected to a transmission shaft of the third motor; the grinding disc is fixed at one end, deviating from the third motor, of the rotating shaft; and the discharging structure is arranged at one end, deviating from the feeding structure, of the conveying structure. The derusting device for machining the die steel has the advantages that grinding and derusting can be automatically carried out, and time and labor are saved.

Owner:湖北三冶重工集团有限公司

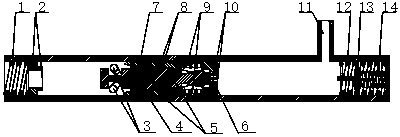

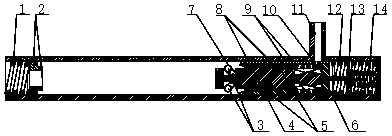

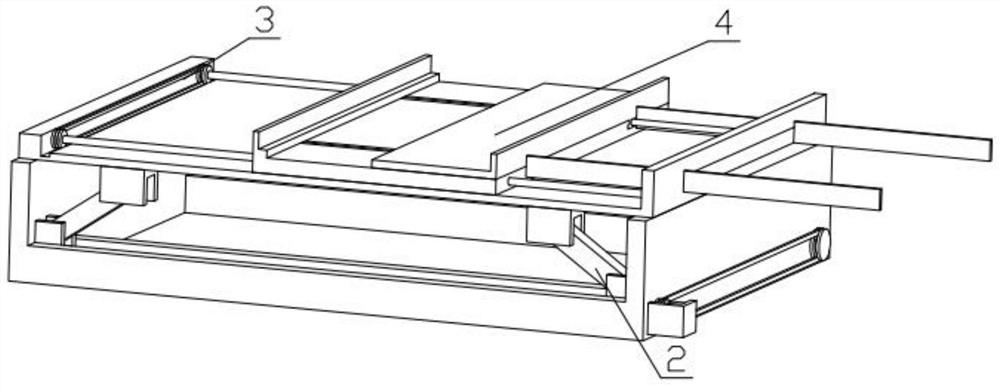

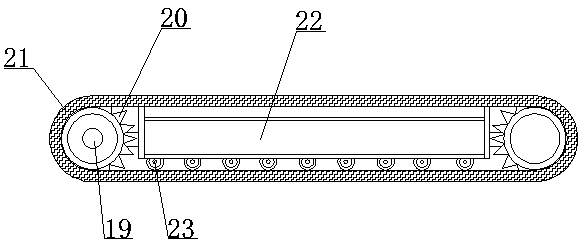

Flat metal heald double-row punching line finished product cutting and left-right conveying device

PendingCN110947849AHeight adjustableAdjust liftShaping toolsMetal-working feeding devicesPunchingGear wheel

The invention relates to the technical field of flat metal heald double-row punching, and discloses a flat metal heald double-row punching line finished product cutting and left-right conveying device. The flat metal heald double-row punching line finished product cutting and left-right conveying device comprises a conveying track, supporting plates are fixedly connected to the left end and the right end of the bottom of the conveying track, multiple groups of supporting legs are fixedly connected to the lower surface of the conveying track, and an adjusting device is arranged in the middle ofthe conveying track. According to the flat metal heald double-row punching line finished product cutting and left-right conveying device, a handle rod can drive a rotating rod to rotate, and then a threaded rod can rotate; auxiliary limiting can be conducted on the threaded rod through a limiting block and an auxiliary block; and through cooperation of the threaded rod and an adjusting rod, firstracks and second racks can be moved, first gears and second gears can rotate, the height of a top plate can be adjusted through cooperation of first lifting rods, second lifting rods and auxiliary supporting rods, and then punching blocks can be adjusted.

Owner:江苏万意节能科技有限公司

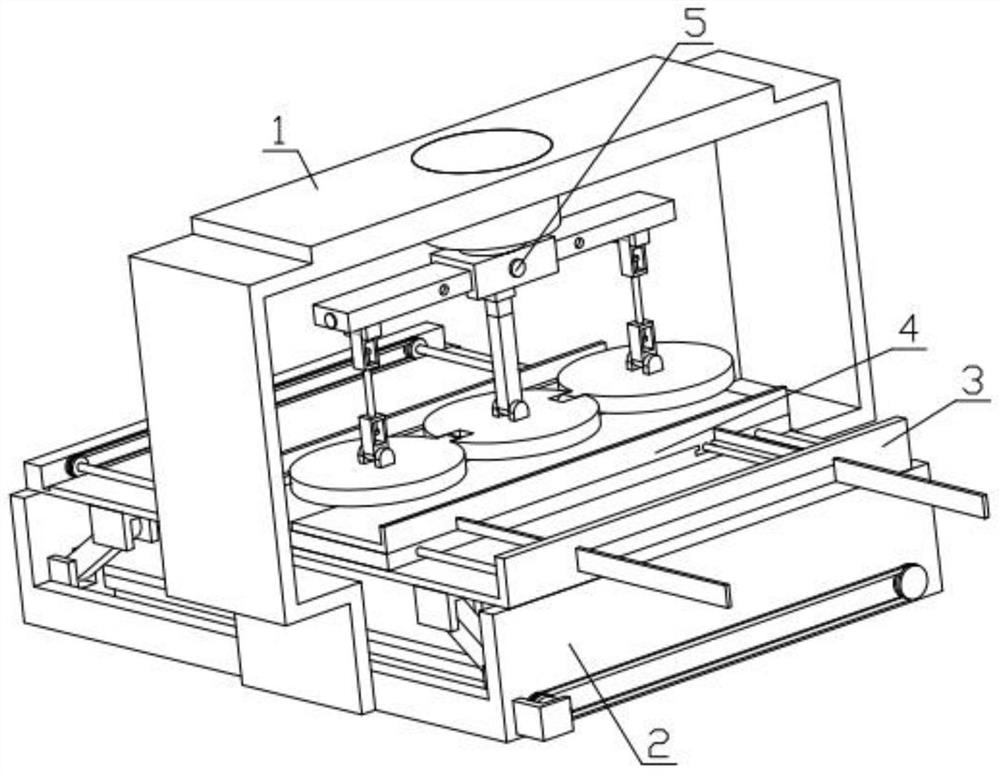

Stone three-step polishing device

InactiveCN112338778AControl the moving distanceAvoid breakingGrinding carriagesPolishing machinesPolishingStructural engineering

The invention relates to a building material processing device, in particular to a stone three-step polishing device. The stone three-step polishing device comprises an installing frame, a stone lifting mechanism, a stone moving mechanism, a stone adjusting mechanism and a three-step polishing mechanism, wherein the stone lifting mechanism is fixedly installed on the installing frame, the stone moving mechanism is fixedly installed on the stone lifting mechanism, the stone adjusting mechanism is fixedly installed on the stone moving mechanism, and the three-step polishing mechanism is fixedlyinstalled on the installation frame. According to the stone three-step polishing device, the device is readjusted to adapt to stones during stone grinding each time, guarantees the grinding and polishing effect, has the function of adjusting the grinding depth, has the function of adapting to the stones with different sizes and thicknesses, has the function of assisting in improving the grinding and polishing effect, and has the function of adjusting the grinding range according to the sizes of the stones.

Owner:卞智昆

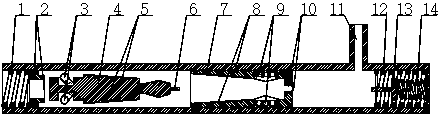

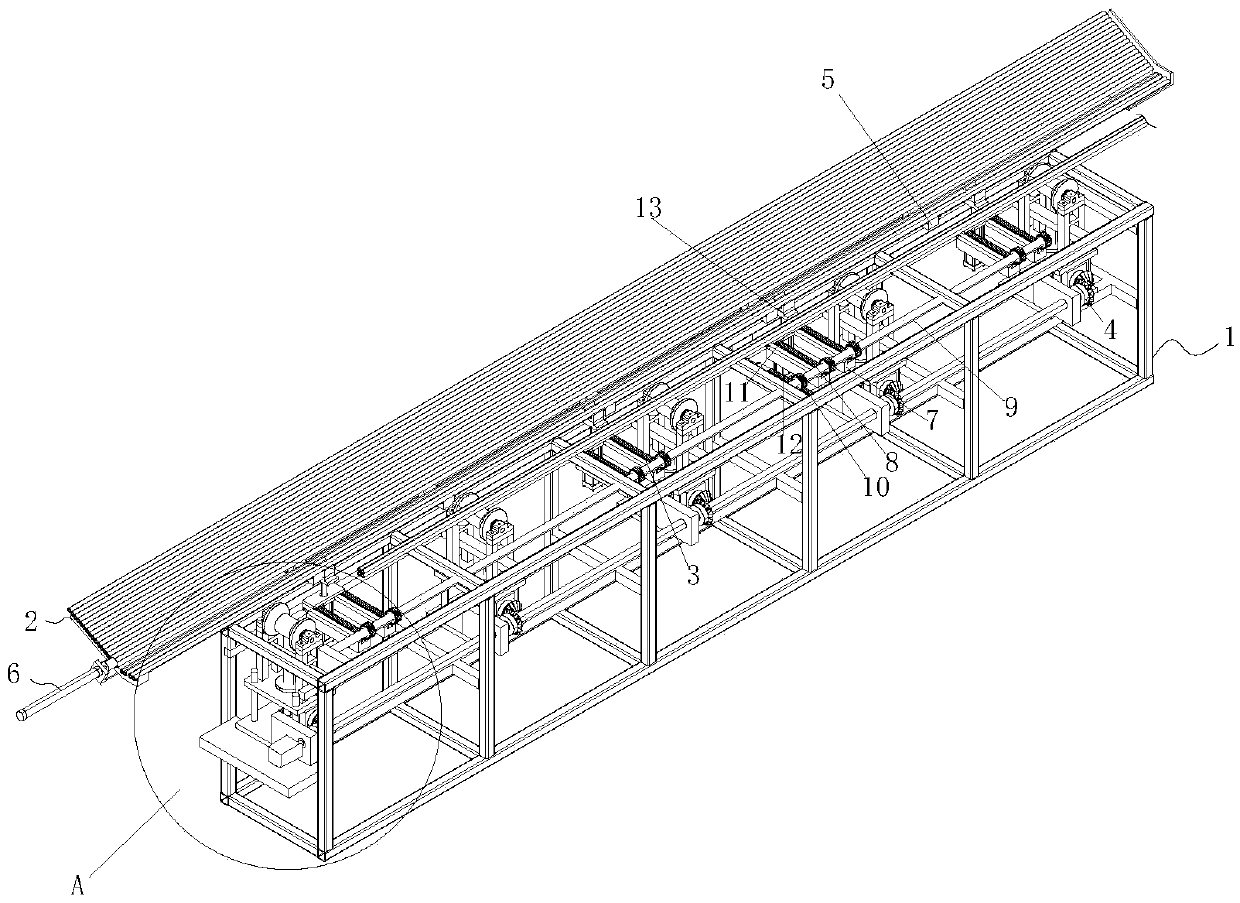

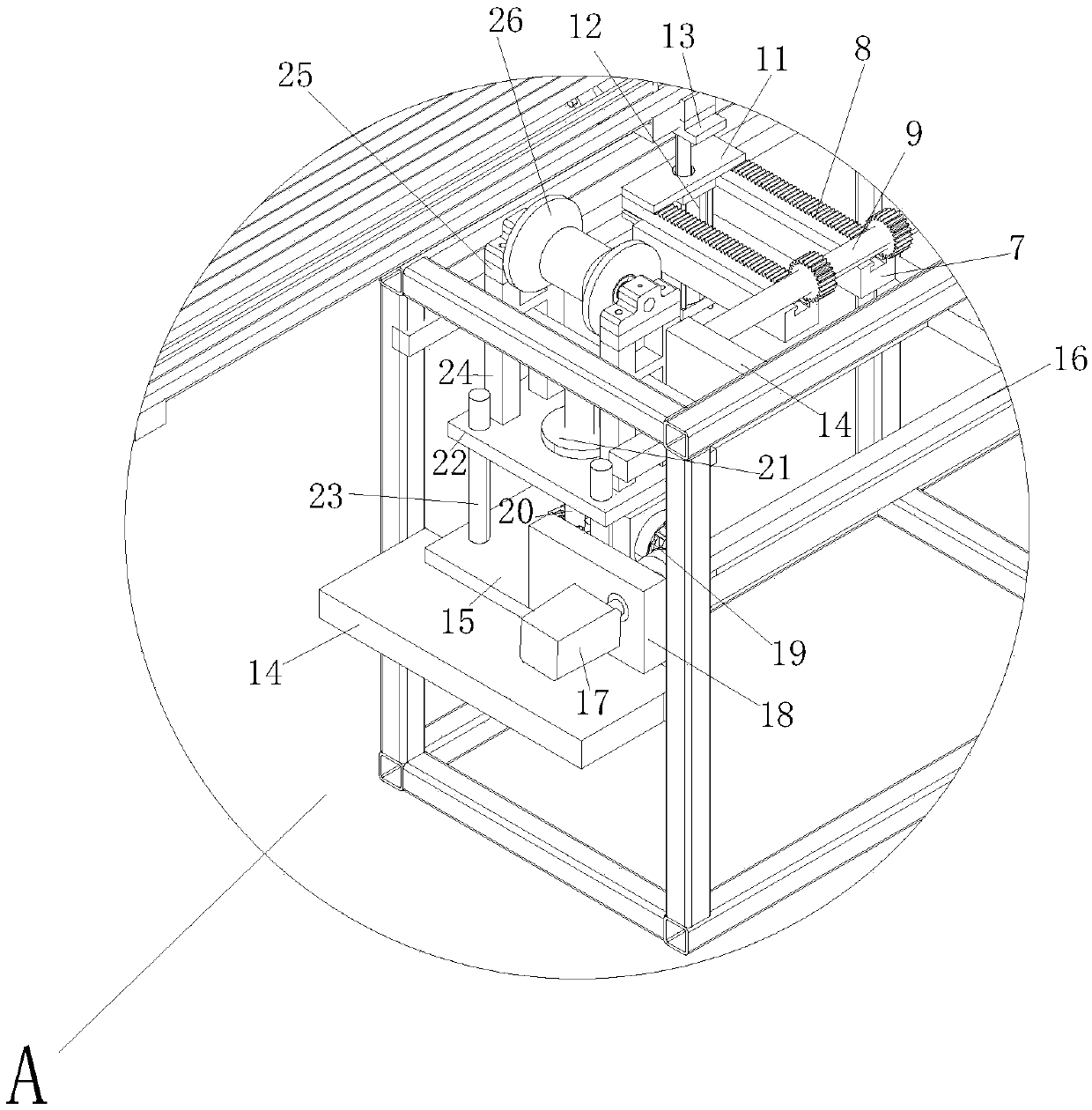

Feeding device of steel pipe cutting machine

The invention relates to a feeding device of a steel pipe cutting machine. The feeding device of the steel pipe cutting machine comprises a feeding frame. A storage unit, a pipe transferring unit anda pipe conveying unit are arranged on the feeding frame. The storage unit is fixedly connected to the feeding frame, and the pipe conveying unit is arranged on the outer side of the storage unit. Thepipe transferring unit is located between the storage unit and the pipe conveying unit and is used for transferring steel pipes on the storage unit to the pipe conveying unit. The pipe transferring unit comprises a first rack support, a first rack, a pipe transferring base plate, a first gear shaft and a pipe transferring support. The pipe conveying unit comprises a pipe conveying base plate, a pipe conveying supporting plate, a pipe conveying positioning plate, a second gear shaft and a lead screw. The lead screw is connected with the first gear shaft through a bevel gear. A sliding sleeve isarranged on the lead screw. A connecting plate is fixedly connected to the sliding sleeve. Two supporting rods are arranged on the connecting plate. Roller bases are fixedly connected to the upper ends of the supporting rods. Pipe conveying rollers are arranged on the roller bases. The feeding device of the steel pipe cutting machine is good in universality and high in efficiency.

Owner:TIANJIN JUXINGXIANGHAI MACHINERY CO LTD

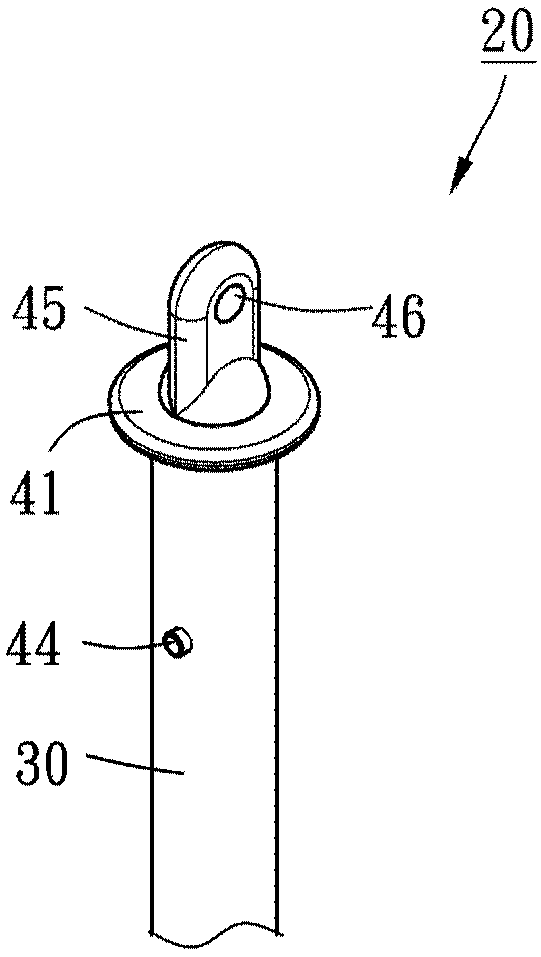

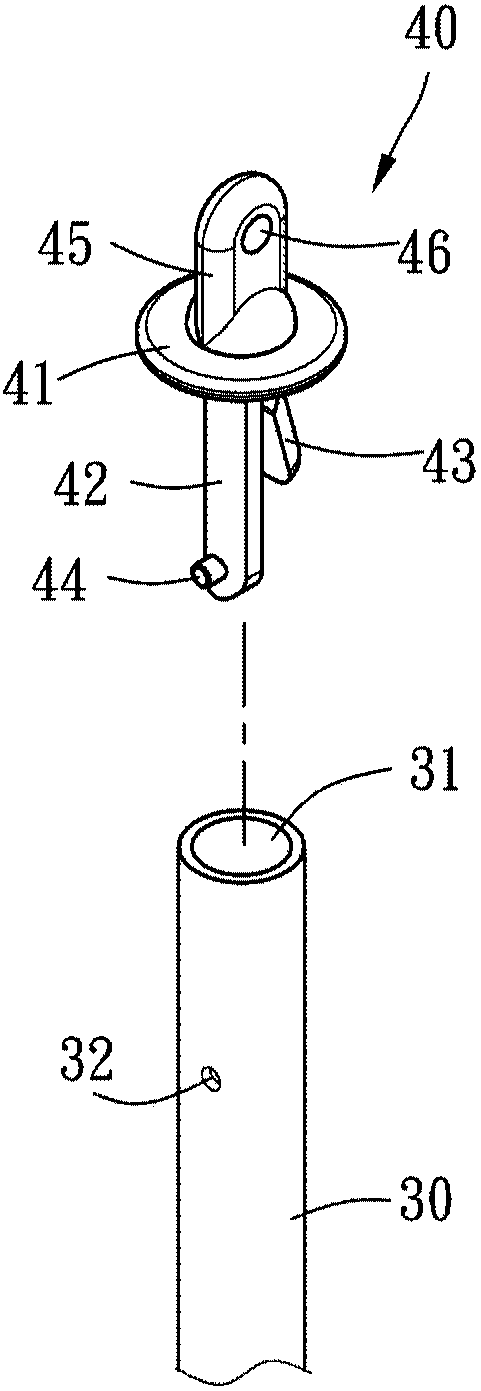

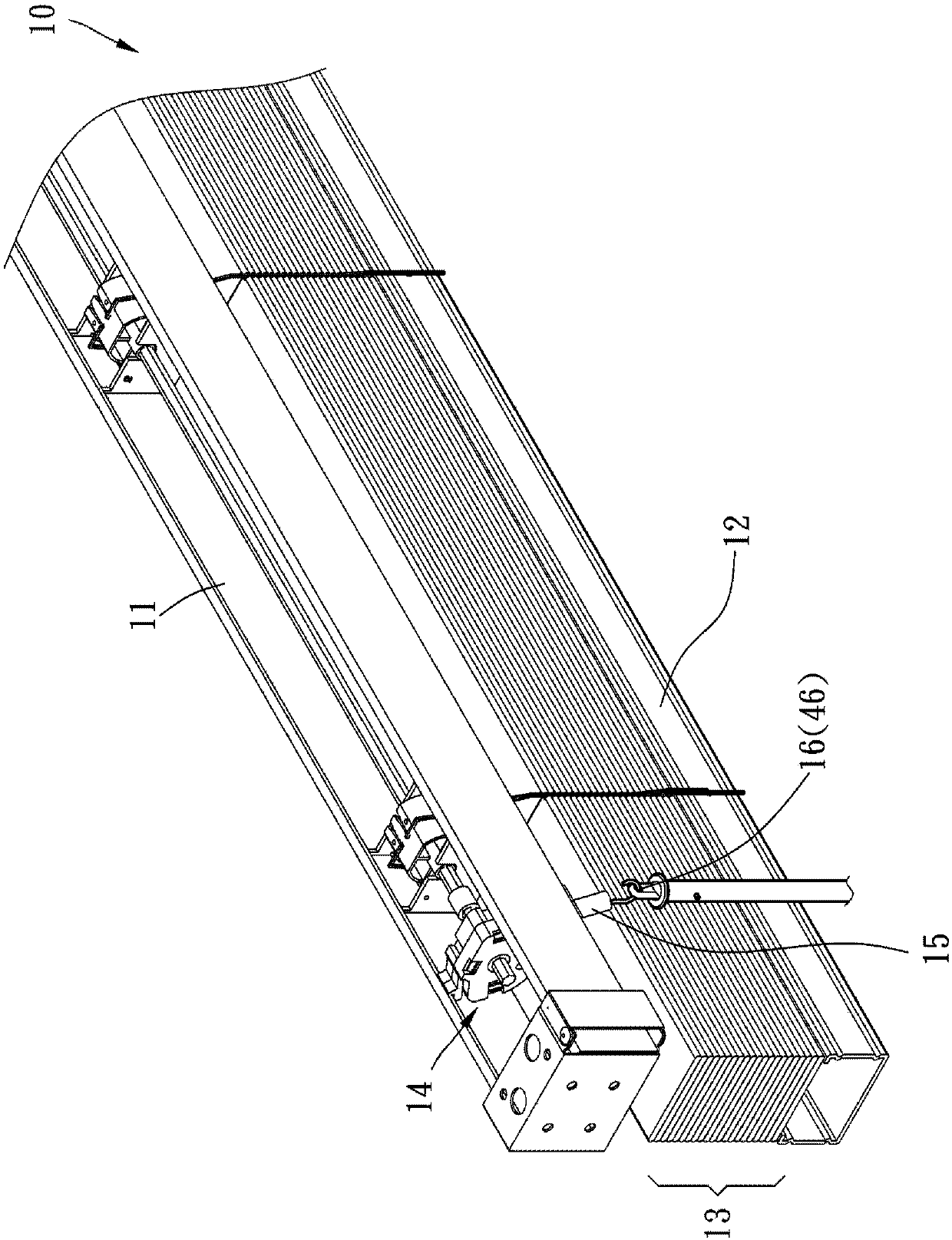

Dual-purpose rod for curtain without pulling rope and curtain blade lifting device using same

ActiveCN107939265AReach openThe action of reaching the collapseLight protection screensClamp connectionPush ups

A dual-purpose rod for a curtain without a pulling rope comprises a rod body and a rod head. The rod head is provided with a flange and a driving part. One end face of the flange is arranged at one end of the rod body. The driving part is arranged on the end face, back to the rod body, of the flange and used for being connected to a curtain blade angle adjuster in an assembled mode so that the dual-purpose rod can drive the curtain blade angle adjuster, and the curtain blade angle adjuster can adjust the angles of curtain blades further. Besides, the dual-purpose rod can apply push-up force toa lower beam through the flange directly or is in clamped connection with the lower beam and then pulls the lower beam downwards, and accordingly the opening and closing actions of the curtain bladescan be achieved.

Owner:陈金福

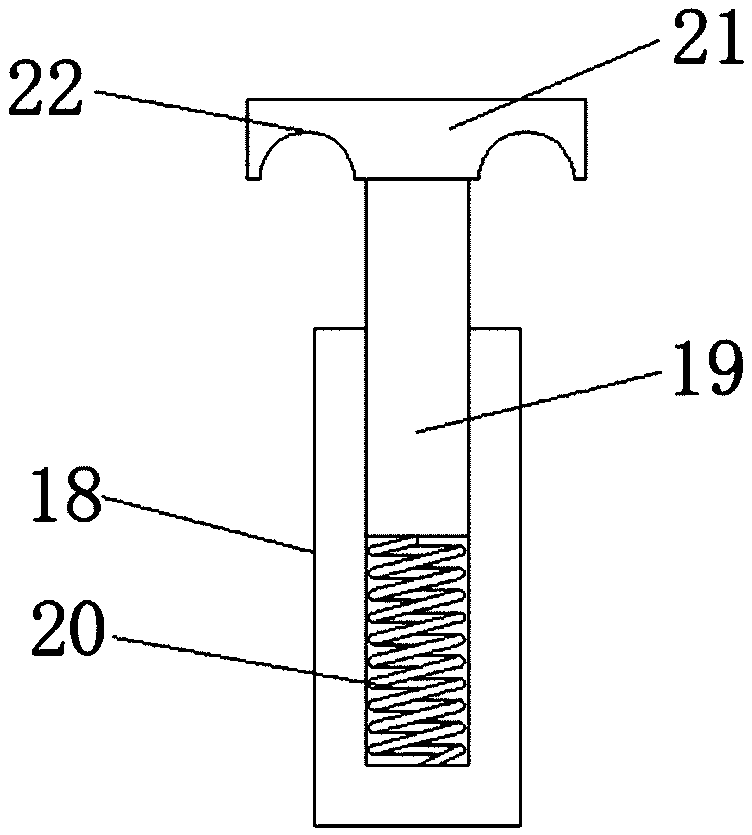

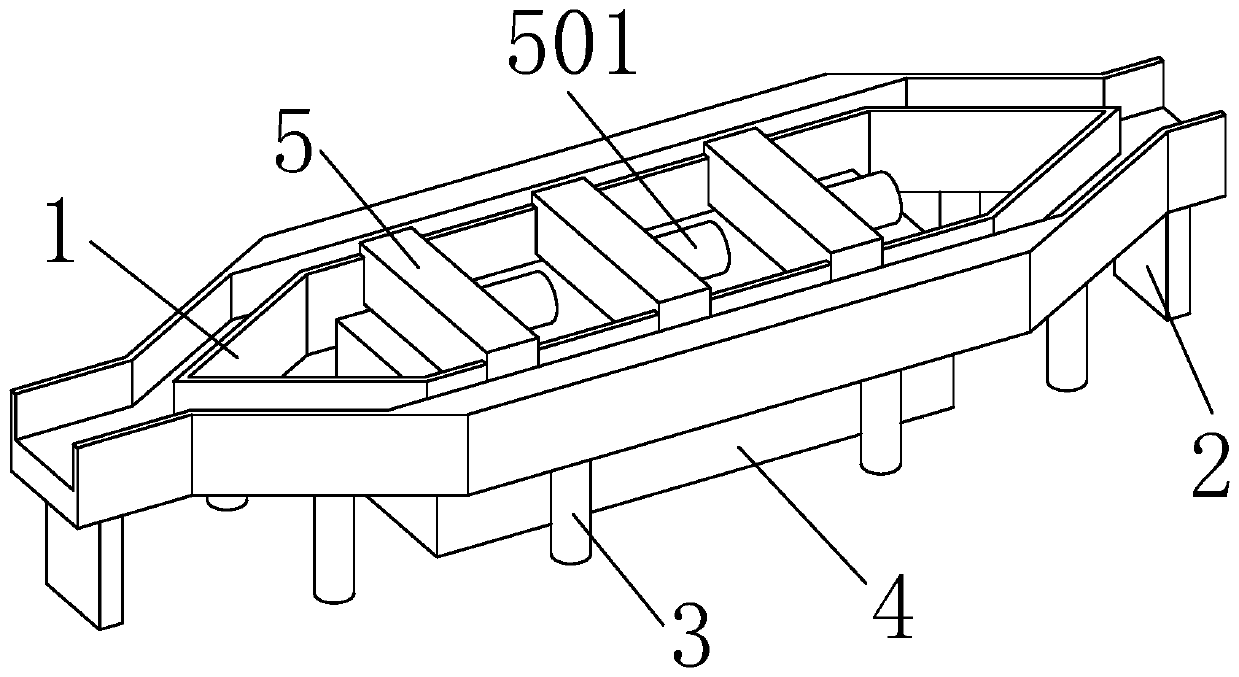

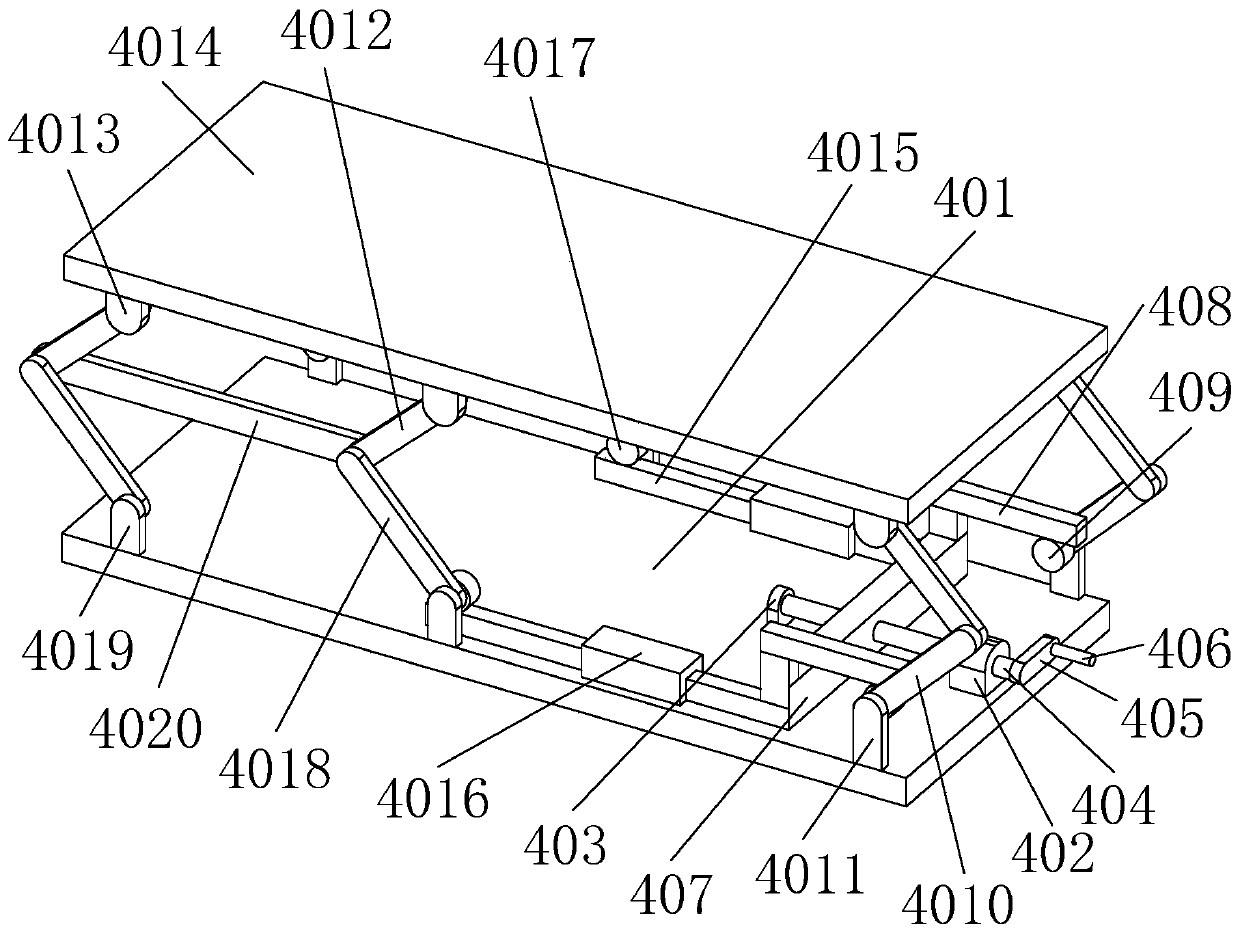

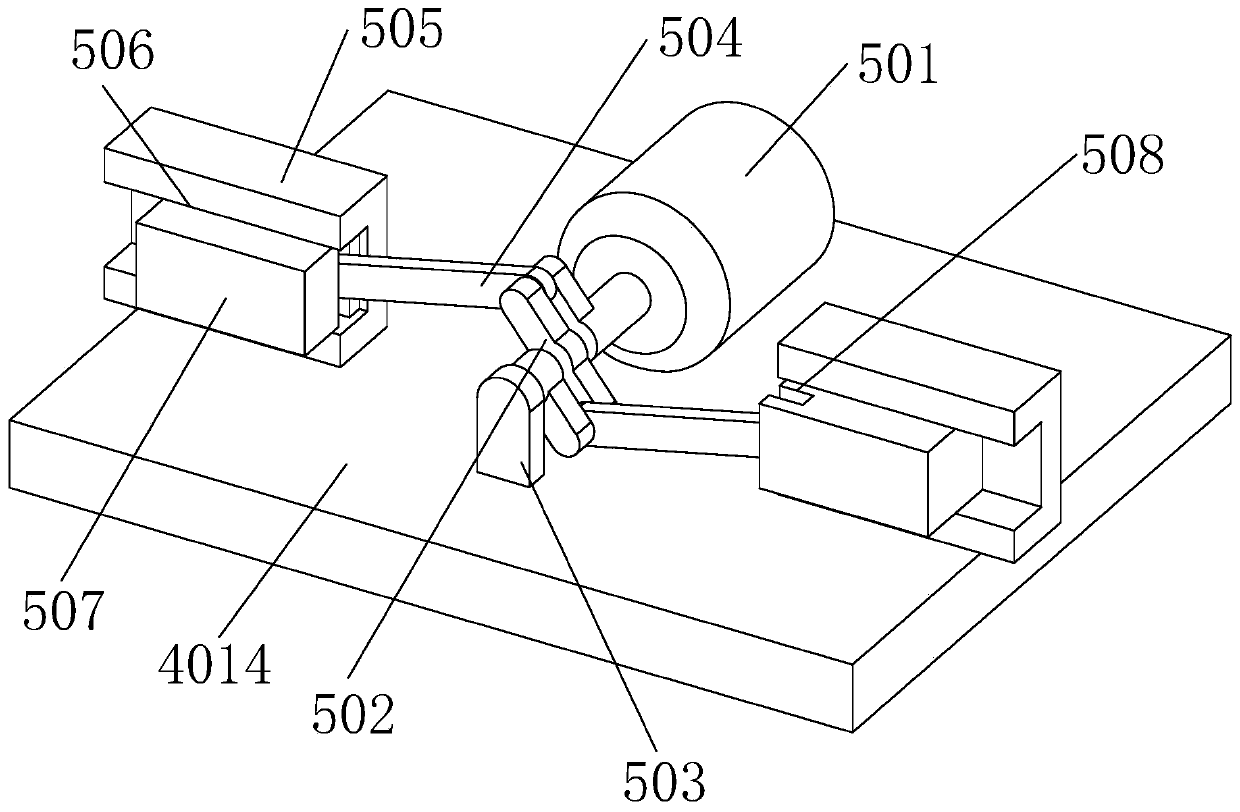

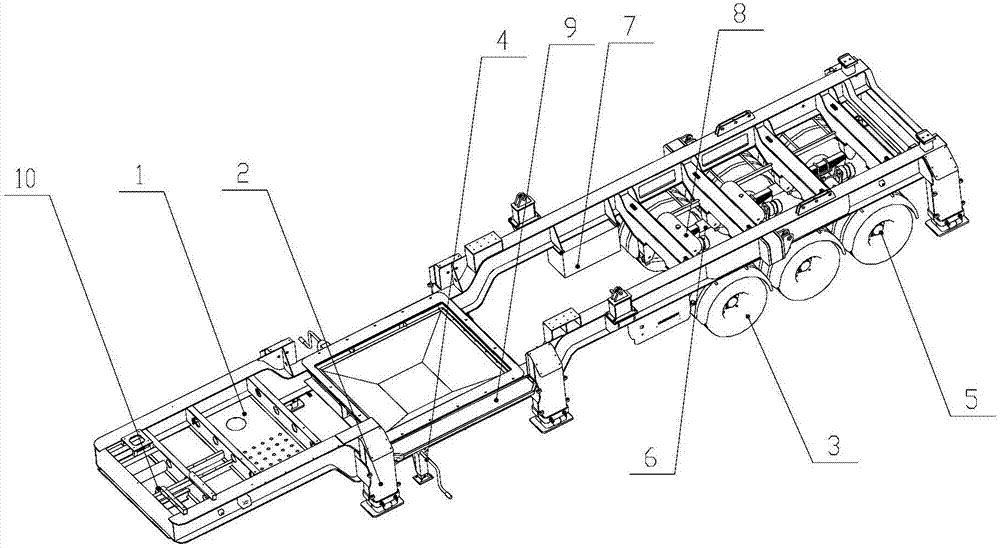

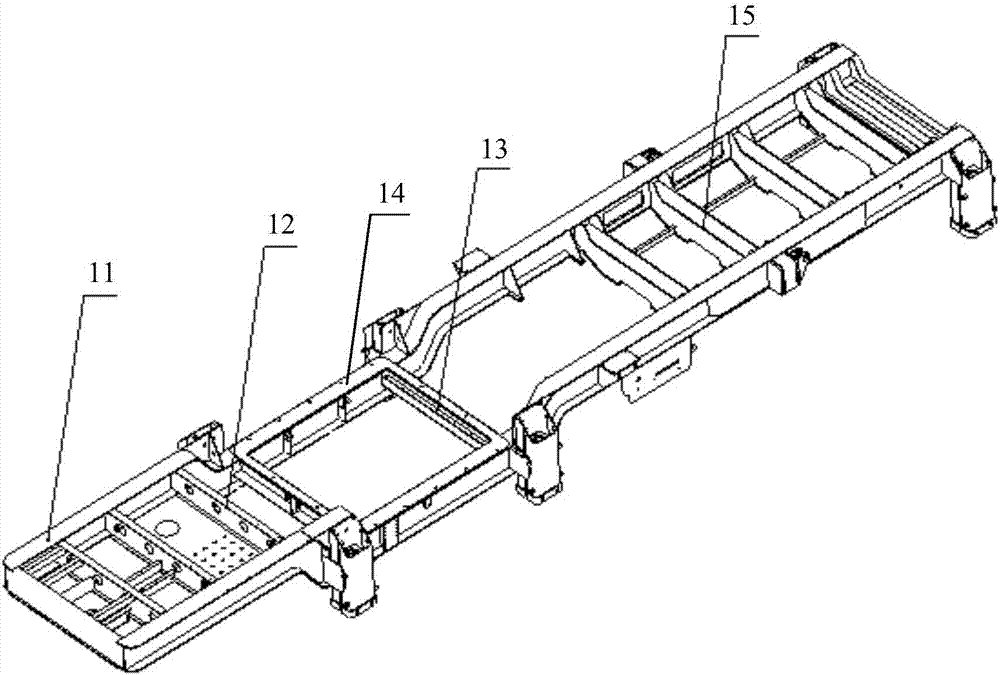

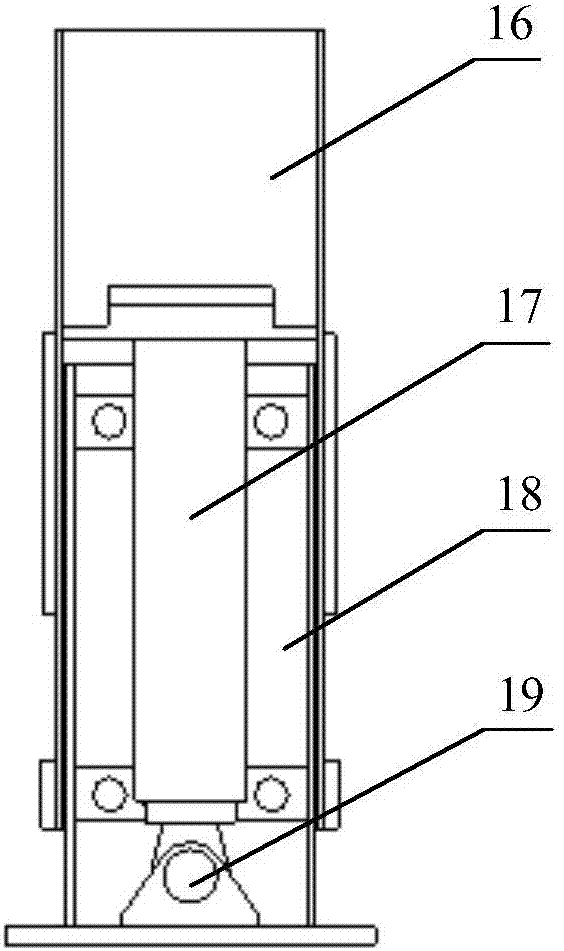

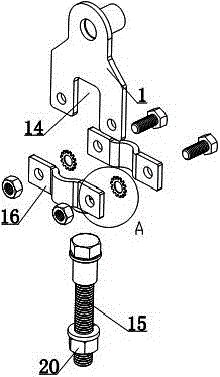

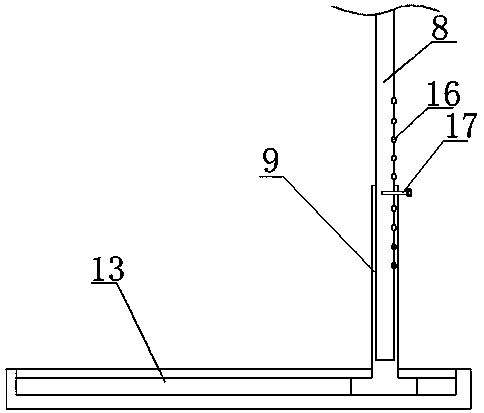

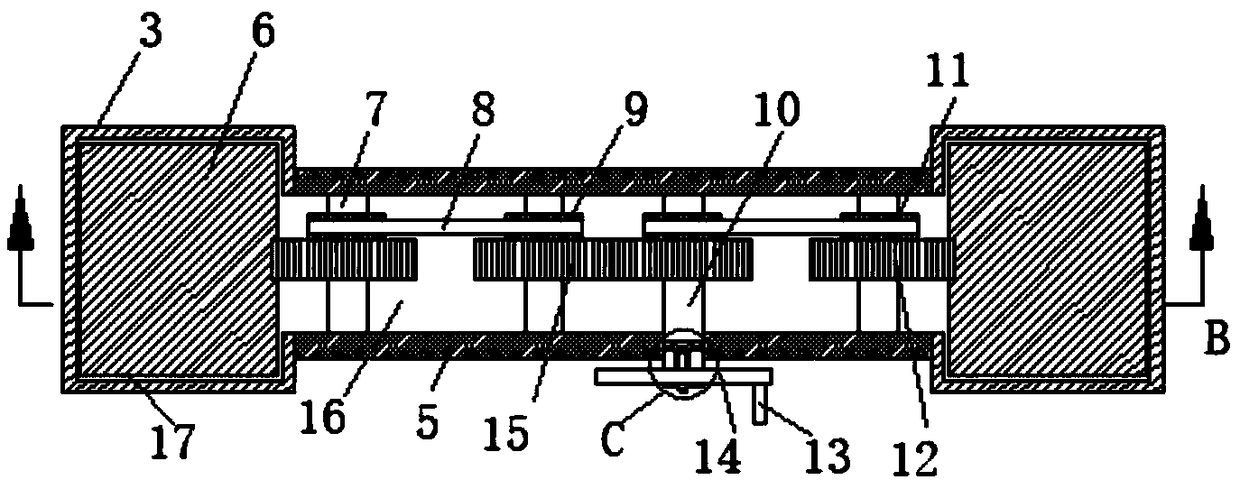

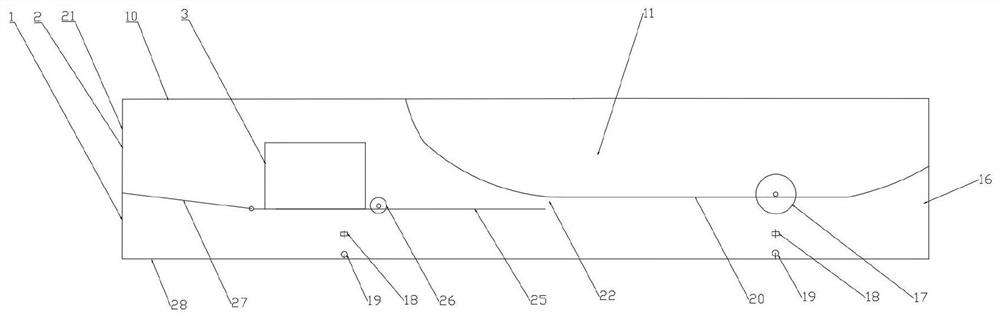

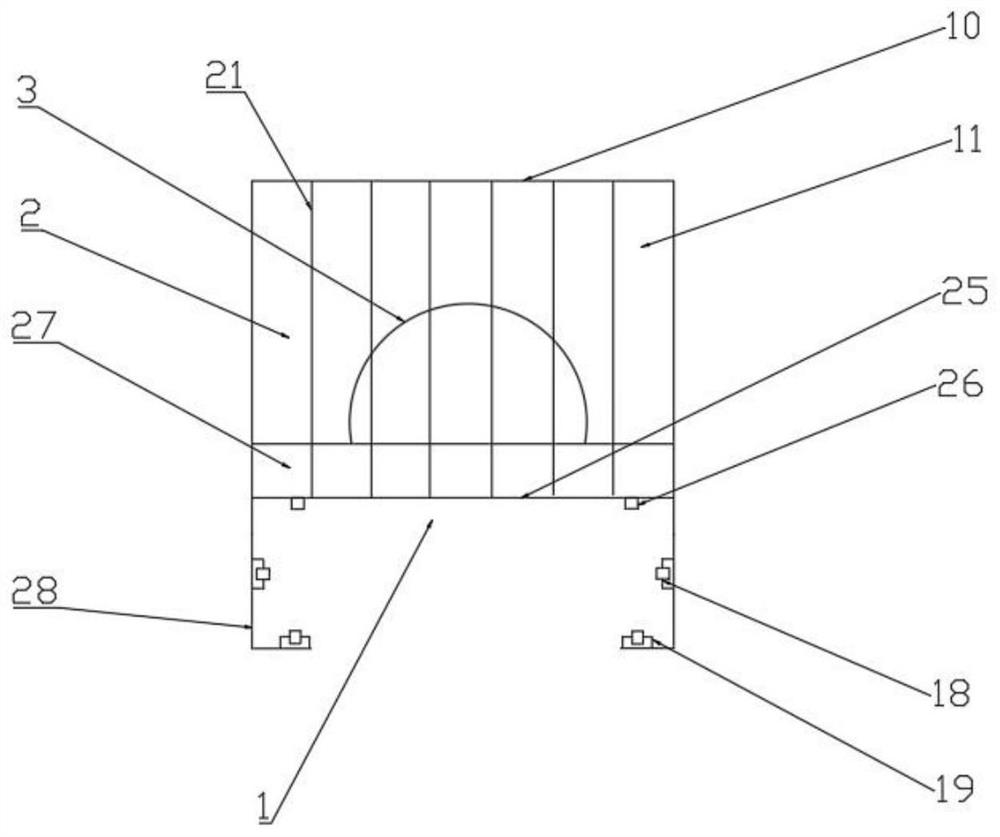

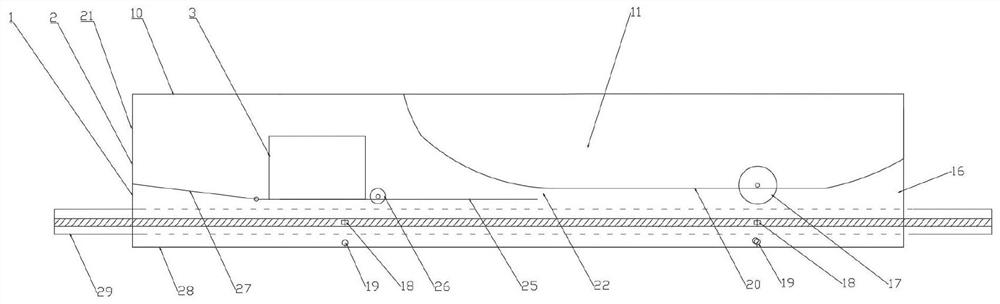

Moving crushing sieving station and semi-trailer chassis thereof

PendingCN107539368AAdjust liftAchieve fixationVehicle fittings for liftingUnderstructuresEngineeringSemi-trailer

The invention discloses a semi-trailer chassis. The semi-trailer chassis comprises a vehicle frame (1) which is capable of being connected with a tractor and a chassis supporting leg (2) fixed on a longitudinal beam (11) of the vehicle frame (1).The chassis supporting leg (2) comprises an outer sleeve (16), an inner sleeve (18) and a piston cylinder (17), wherein the inner sleeve (18) is sleeved with the outer sleeve (16) and can move along the outer sleeve (16); and a cylinder body of the piston cylinder (17) is fixed on the outer sleeve (16), and a telescopic rod of the piston cylinder (17)is connected with the bottom of the inner sleeve (18). A plurality of sets of pin holes are formed in the outer sleeve (16) and the inner sleeve (18) and used for switching and positioning the outer sleeve (16) and the inner sleeve (18). The chassis supporting leg (2) further comprises a positioning pin (20) which penetrates through one set of pin holes to position the outer sleeve (16) and the inner sleeve (18). The semi-trailer chassis effectively improves the working stability of a moving sieving station during working. The invention further discloses the moving crushing sieving station comprising the semi-trailer chassis.

Owner:CHINA RAILWAY CONSTR HEAVY IND

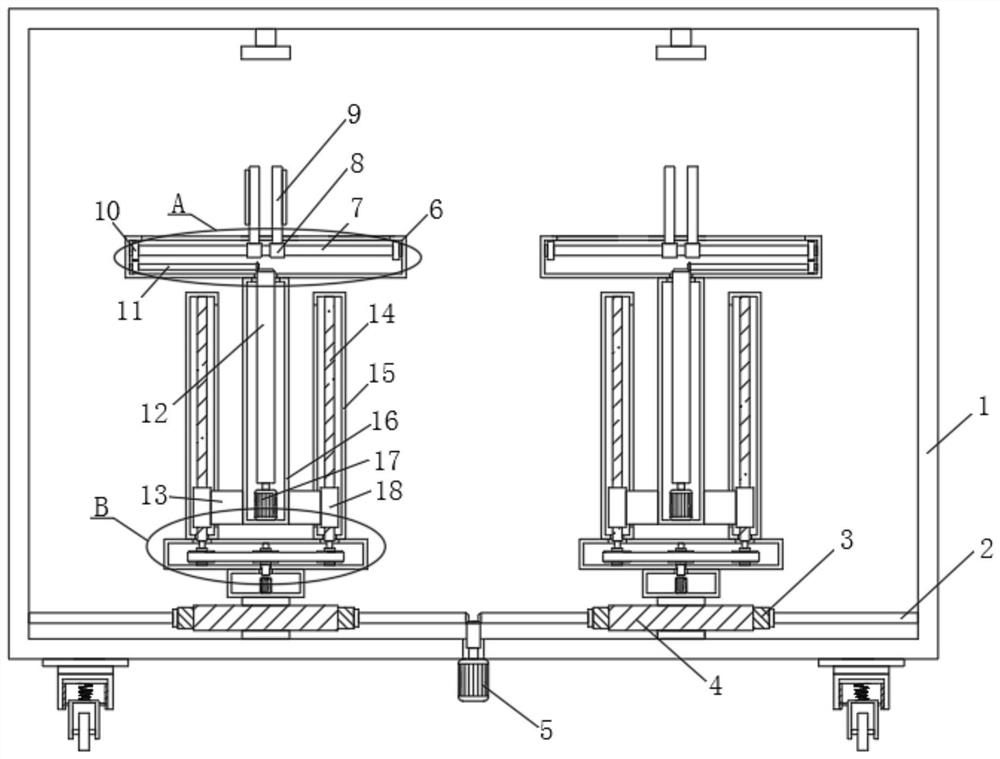

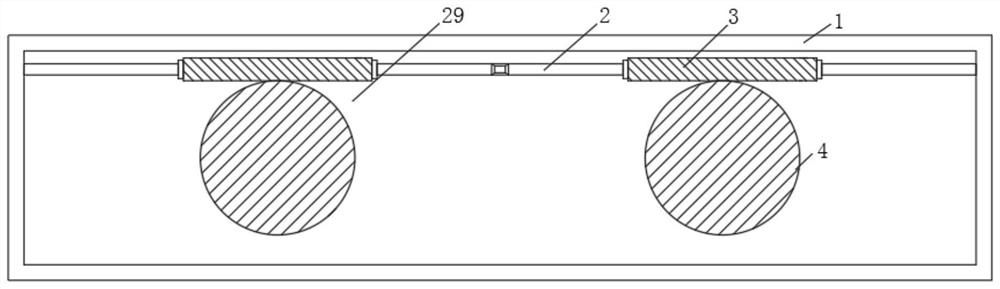

Two-rotary-wheel type unreeling wheel

InactiveCN106144697AEasy to installConvenience to workWebs handlingEngineeringMechanical engineering

Owner:陈沛

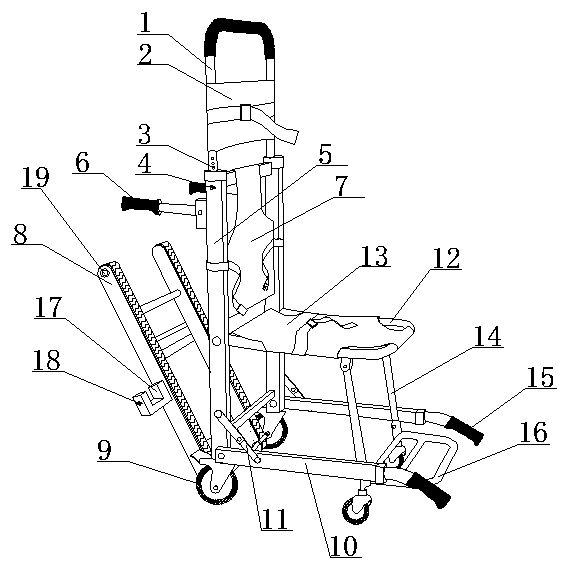

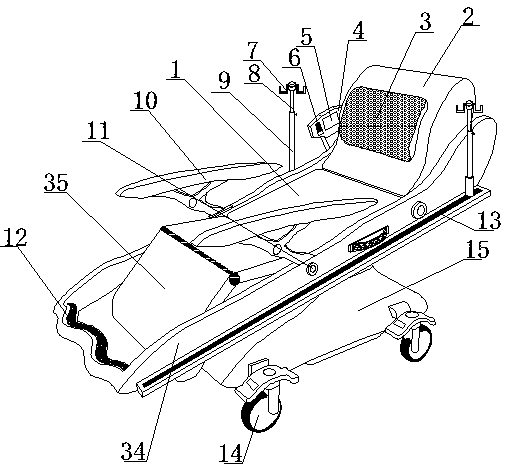

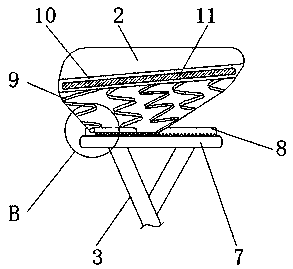

Stair stretcher used for emergency treatment

The invention belongs to the technical field of medical devices, and discloses a stair stretcher used for emergency treatment. The stair stretcher comprises a carrying trestle, a main body frame, a transmission device, an accessory body frame, a base and a supporting frame, wherein bearing cloth A is fixedly arranged in the middle of the carrying trestle, and the two ends of the bottom of the carrying trestle are inserted into the main body frame. By arranging a pin bolt at the upper end of the main body frame, and forming pin bolt holes in the carrying trestle, when the pin bolt is inserted into different pin bolt holes, ascending and descending of the carrying trestle can be adjusted, so that the height of the bearing cloth A is adjusted; by arranging fixing belts on the bearing cloth A,bearing cloth B and bearing cloth C respectively, the body of a patient can be fixed; by arranging the transmission device on the back of the main body frame, it can be achieved that the stretcher ispushed on a stair; connection between the main body frame and the base, connection between the main body frame and the accessory body frame, connection between the accessory body frame and the supporting frame and connection between the supporting frame and the base are achieved through rotary shafts respectively, and telescoping rods are arranged at the corners between the main body frame and the accessory body frame so that the bending degree of the stretcher can be adjusted to meet requirements of the patient.

Owner:周楚楚

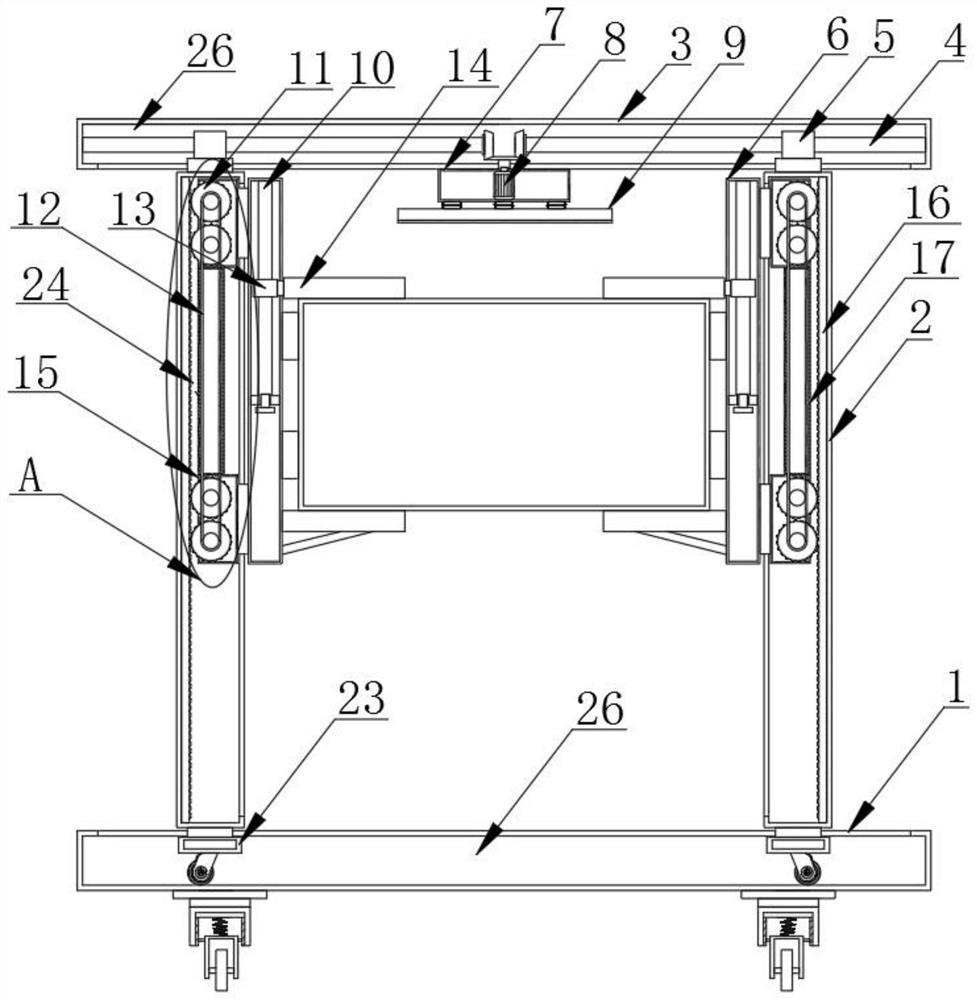

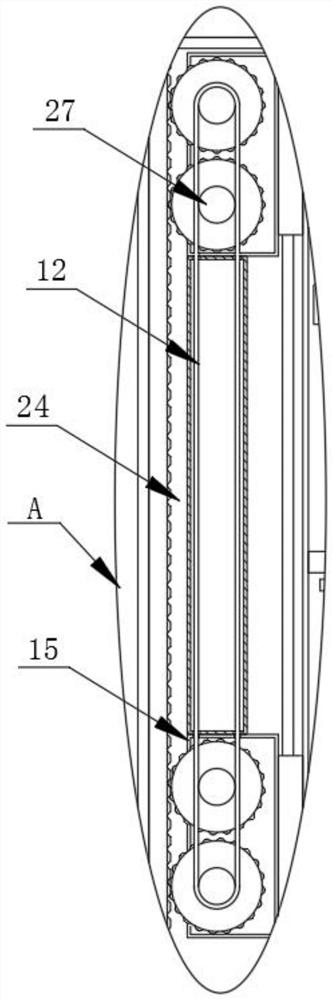

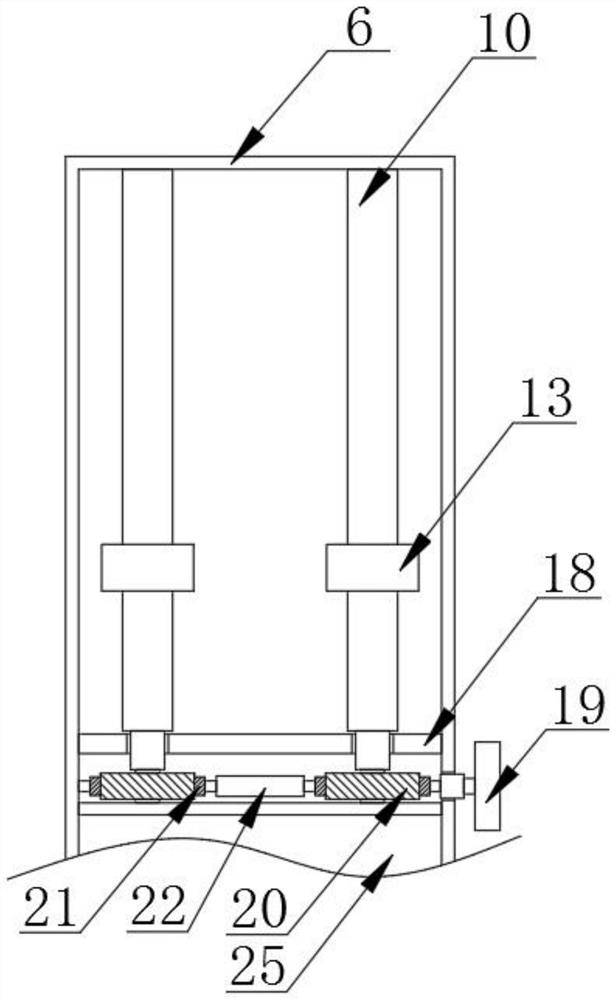

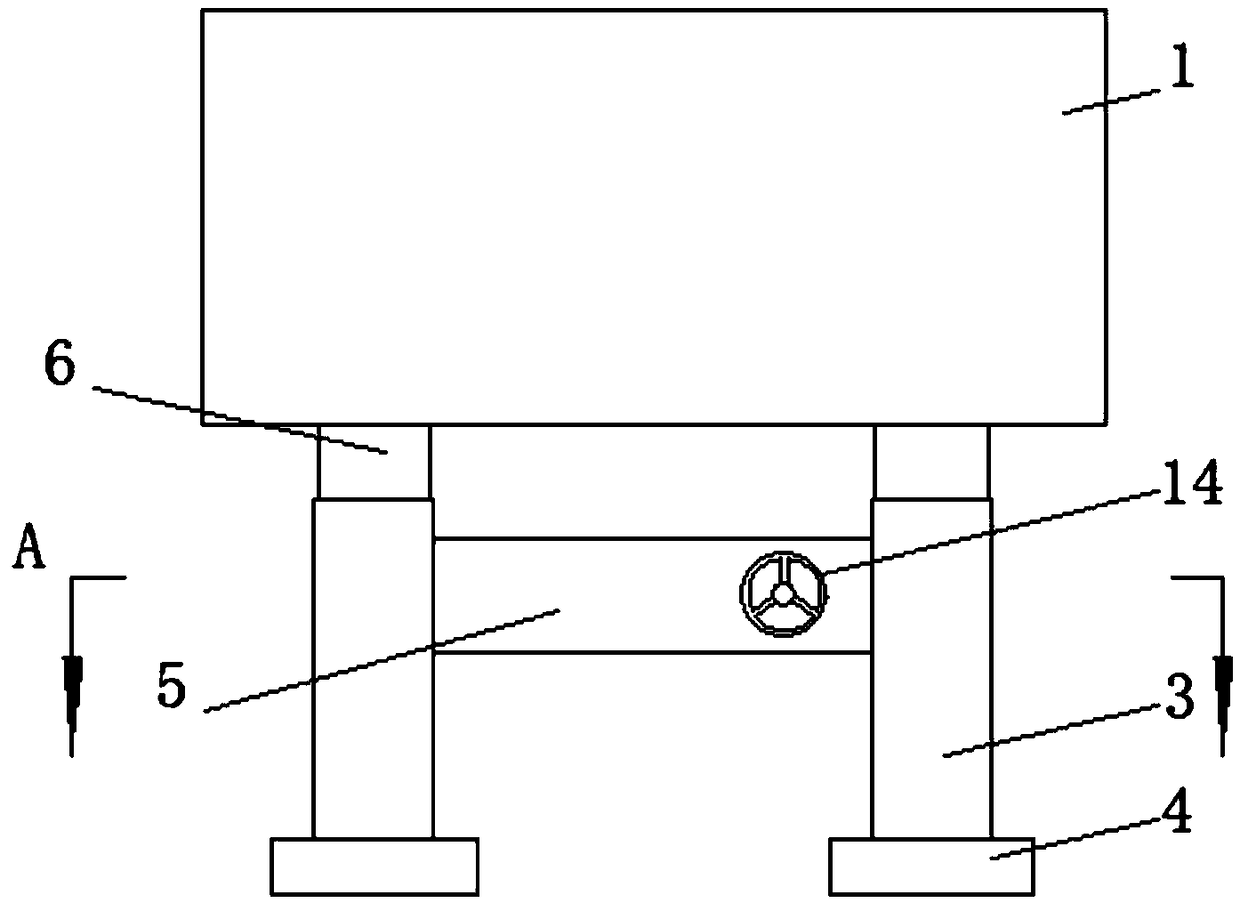

Supporting structure for mounting LED display screen

PendingCN113833959AEasy to useAdjust liftStands/trestlesVibration suppression adjustmentsPhysicsEngineering

The invention discloses a supporting structure for mounting a LED display screen, and relates to the technical field of building template conveying, the supporting structure comprises a fixed base, wherein a top plate is arranged at the top of the fixed base, moving mechanisms are arranged in the top plate, two supporting columns are symmetrically arranged between the fixed base and the top plate, and lifting mechanisms are arranged in the two supporting columns; two lifting plates are symmetrically arranged between the two supporting columns, and limiting mechanisms are arranged in the two lifting plates. The supporting structure for mounting the LED display screen has the advantages that the LED display screen can be conveniently mounted and operated, the purpose of limiting and fixing can be achieved only by rotating a rotating disc during use; and meanwhile, the LED display screens of different models and sizes can be limited and operated, and therefore, the situation that only the LED display screens of the same model can be mounted is avoided; and the LED display screens can be conveniently adjusted and lifted, and therefore, different mounting operation requirements are met.

Owner:江苏润江智汇显示科技有限公司

Nursing bed for nursing in obstetrics and gynecology department

InactiveCN108542642AFixed reachReach high and lowNursing bedsAmbulance serviceObstetric historyEngineering

Owner:林迺建

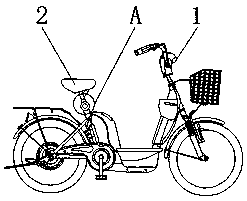

Electric bicycle with horizontally-movable seat cushion

The invention discloses an electric vehicle capable of horizontally moving a cushion, comprising a vehicle body and a connecting shaft, the vehicle body is connected with a support rod, and the support rod is provided with a second chute, and the outer end of the connection shaft penetrates through the The second chute is connected with the adjustment knob, and the outer side of the connecting shaft is connected with a supporting device, and the upper and lower ends of the supporting device are respectively connected with the connecting rod and the supporting rod, and the upper end of the connecting rod is equipped with a supporting plate, And the upper end of the support plate is provided with a splint. The electric vehicle that can move the seat cushion horizontally can facilitate the user to adjust the lifting of the connecting rod, and can reduce the effort that the user spends when adjusting the height of the seat cushion, so that it is convenient for the user to use and can improve the safety of the user when using the electric vehicle in winter. Comfortable, and can reduce the probability of accidents, can make the seat cushion slide horizontally, and can fix the horizontal position of the seat cushion to avoid horizontal sliding due to the inertia of the user when riding, thereby increasing the safety factor of the electric vehicle .

Owner:NANJING LENIAS PHOTOELECTRIC EQUIP

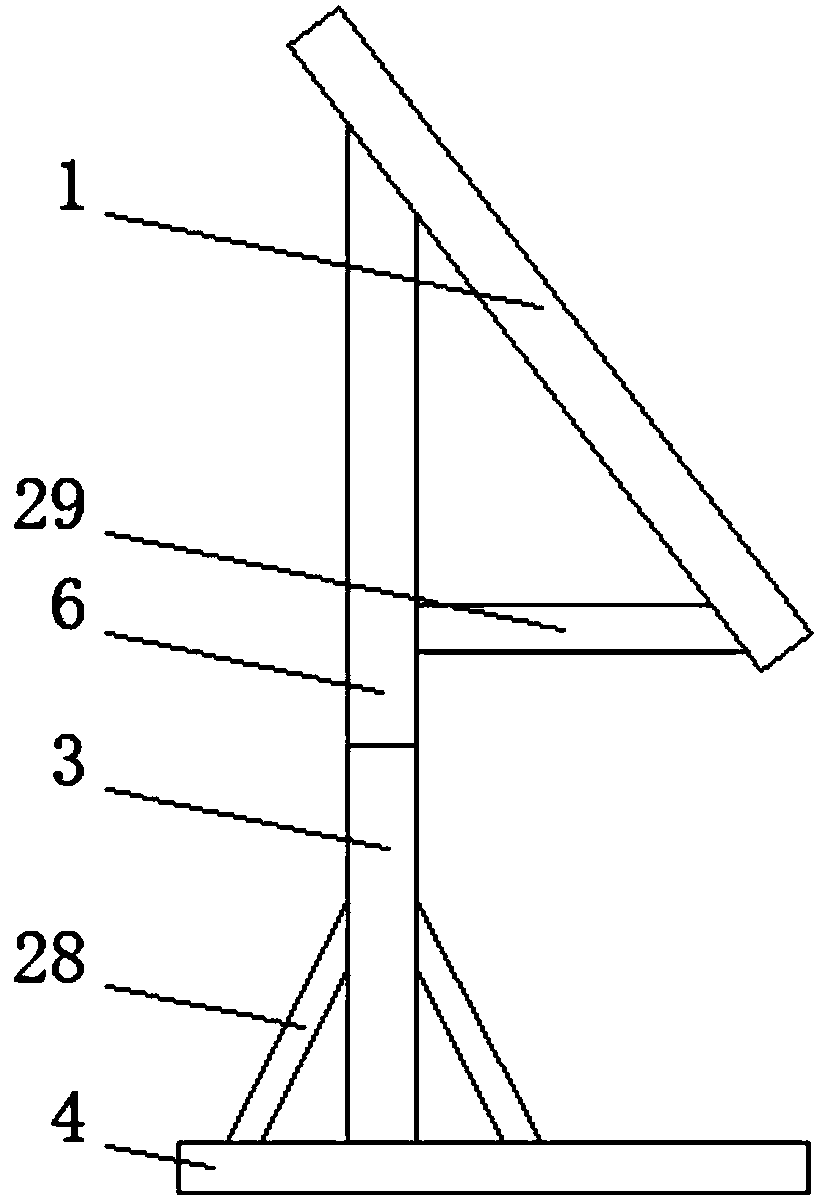

Designing major hand-operated drawing board

ActiveCN109017131AAchieve scaleEffectively fixedOther artistic work equipmentsFixed frameDrawing board

The invention discloses a designing major hand-operated drawing board. The designing major hand-operated drawing board comprises a drawing board body. First fixing frames are symmetrically distributedat the upper end of the back face of the drawing board body. Second fixing frames are movably connected with the first fixing frames through telescopic grooves. A fixedly connected connecting rod isarranged between the second fixing frames. An adjusting groove is formed in the connecting rod. Two first adjusting shafts are arranged in the middle of the adjusting groove. Each first adjusting shaft is provided with a first driving gear and a second driving gear. The first driving gears are engaged with each other. Second driven gears are connected with the adjacent second driving gears throughchains. The inner sides of the first fixing frames are provided with a rack engaged with the second driven gears. The connecting rod is provided with a fixing hole. The outer sides of the first adjusting shafts are provided with a rotary plate. A handle bar is arranged on the outer side of the rotary plate, an operator can directly rotate the rotary plate, the drawing board is adjusted to go up and down, and adjustment is quite convenient and quick.

Owner:MAANSHAN TEACHERS COLLEGE

High-speed rail transit device

ActiveCN113879340AWon't derailNo frictionRailway tunnelsRailway componentsMarine engineeringRail transit

The invention relates to a high-speed rail transit device which comprises a power cavity, a rail-holding suspension cavity and a passenger and cargo compartment, and is characterized in that the passenger and cargo compartment is of a compartment body structure; the power cavity is arranged between the passenger and cargo compartment and the rail-holding suspension cavity and is defined by a power cavity bottom plate, a passenger and cargo compartment bottom plate, a rail-holding windward plate and a shell, a power cavity air inlet is formed by an opening in the front end of the power cavity, a power cavity lower nozzle is formed by an opening in the rear end of the power cavity, the power cavity lower nozzle is reserved between the power cavity bottom plate and the passenger and cargo compartment bottom plate, the power cavity air inlet is further provided with a protective grating, and the area of the power cavity air inlet is larger than that of the power cavity lower nozzle. According to the high-speed rail transit device, the front end of a jet sucks air from the air inlet of the power cavity and then jets high-pressure air from the lower nozzle of the power cavity, the high-pressure air flows between the passenger and cargo compartment and the rail device, and an air cushion is formed between the passenger and cargo compartment and the rail device due to exhaust limitation and high air pressure to generate lift force and advancing power.

Owner:王全文

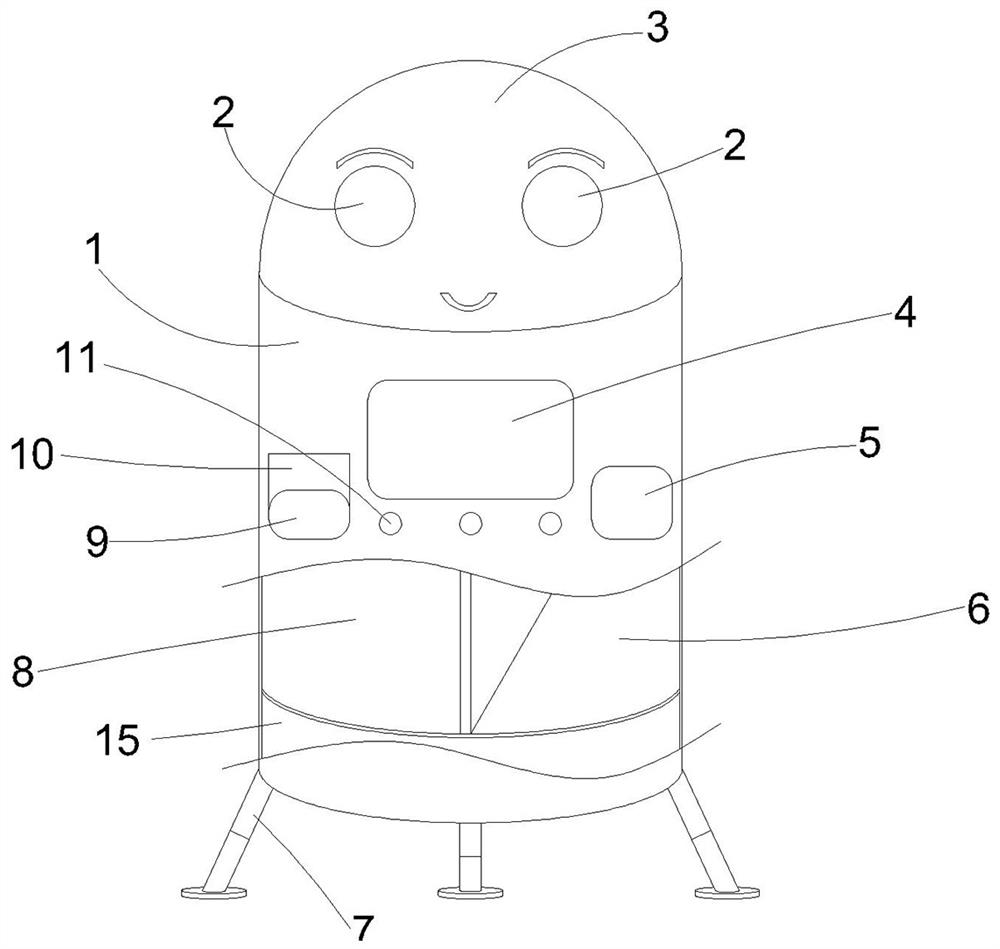

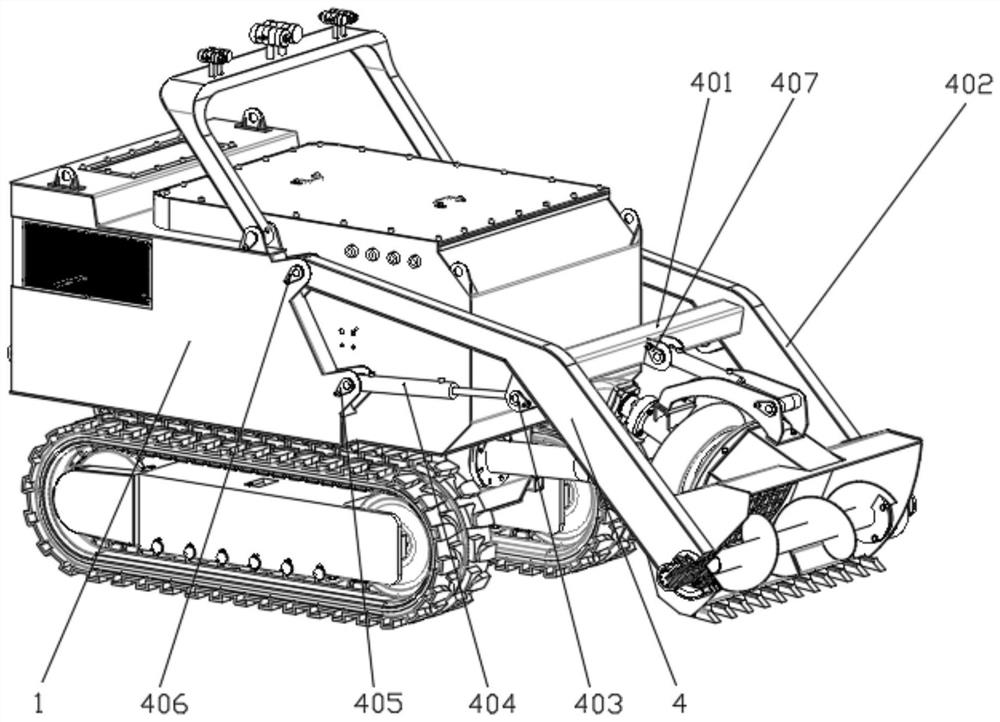

Intelligent robot for stoma patients

ActiveCN113059580ARealize the purpose of adjustmentEasy to rotate connectionManipulatorNursing accommodationRechargeable cellRechargeable battery pack

The invention belongs to the technical field of advanced manufacturing and automation, and particularly discloses an intelligent robot for stoma patients. The intelligent robot comprises a robot shell, a movement mechanism is arranged at the bottom end of the robot shell, a collection cavity, a supply cavity and a control mechanism are arranged in the robot shell, an ostomy bag collection mechanism is arranged in the collection cavity, and an ostomy bag supply mechanism is arranged in the supply cavity. The control mechanism comprises a panoramic camera, a recognition camera, a laser radar, a distance sensor, a control processor arranged in the robot shell and a rechargeable battery pack electrically connected with the control processor, wherein the panoramic camera, the recognition camera, the laser radar and the distance sensor are arranged at the top end of the robot shell, a timing module is arranged on a controller, and the control processor is electrically connected with a touch display screen and a sound alarm which are arranged on the robot shell. A control button electrically connected with the control processor is arranged on the robot shell.

Owner:HENAN CANCER HOSPITAL

An intelligent teaching lifting platform sliding adjustment rod

Owner:山东业达网络科技股份有限公司

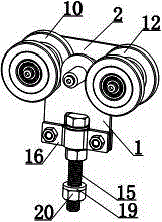

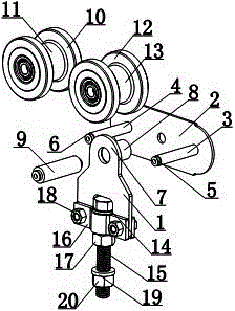

A split smart plunger with a pulley mechanism

InactiveCN109723408BReal-time control of motion speedAvoid damageFlexible member pumpsFluid removalButterfly valveControl theory

The invention relates to the field of gas well drainage and gas recovery, in particular to a split-type intelligent plunger with a pulley mechanism. It is characterized in that: the intelligent plunger includes the plunger body and the pulley mechanism at its lower end, the plunger sleeve and its built-in spring slips, the opening butterfly valve with locking device, the upper and lower buffers and the self-adaptive valve mechanism built in the lower buffer And the pressure, temperature, and speed sensors and microprocessor attached to the plunger body and the plunger sleeve control the speed of the plunger body and the plunger sleeve in the upward or downward process by controlling the action of the pulley mechanism. Compared with the existing technology, it has the following advantages: It solves the defect that the speed of the plunger used for drainage is uncontrollable in the continuous production operation without shutting down the well, and thus effectively avoids the plunger body and the plunger sleeve in the upward or downward process. In the process, severe collision occurs, causing downhole or wellhead accidents.

Owner:SOUTHWEST PETROLEUM UNIV

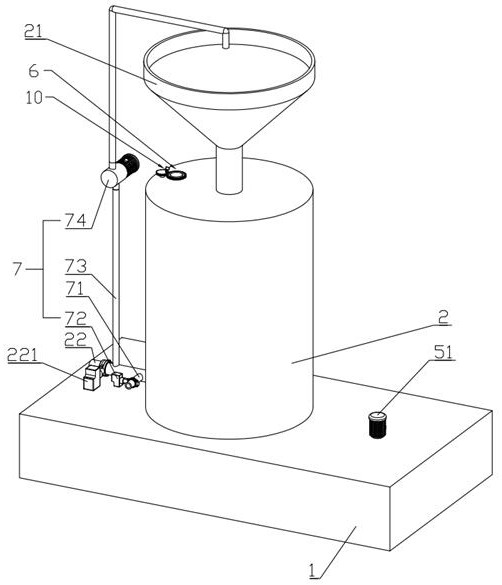

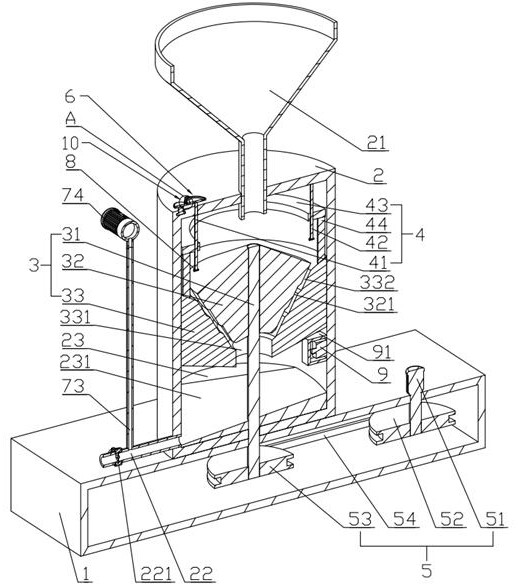

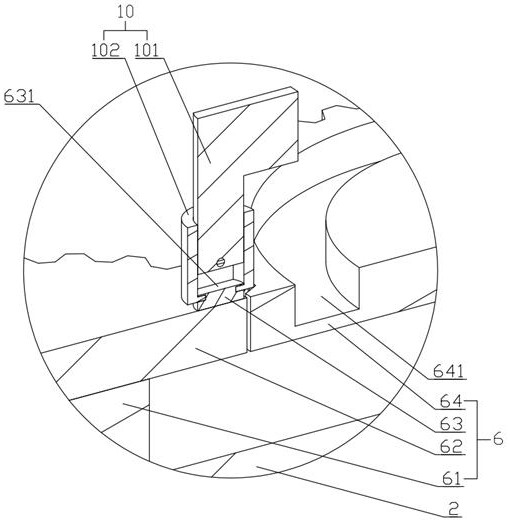

A high-efficiency colloid mill for dairy processing

The invention discloses a high-efficiency colloid mill for processing dairy products, comprising a box body, a feeding hopper fixed with the top of the box body, a grinding component installed in the box body, and a position fixed to the side wall of the box body near the bottom of the box body The discharge pipe is connected with each other, and the grinding assembly includes a rotating rod rotatably installed on the bottom wall of the box body, a rotating tooth fixedly sleeved on the rotating rod, and a fixed tooth installed in the box and matched with the rotating tooth. The bottom of the fixed tooth is provided with There is a blanking opening, and an adjusting component for adjusting the distance between the fixed teeth and the rotating teeth and a lower driving component for driving the rotating rod to rotate are installed on the box body. In this solution, when products with different finenesses need to be obtained, the staff only needs to adjust the distance between the fixed teeth and the rotating teeth by adjusting the components, until the fineness of the processed products is stable and meets the production requirements, stop The adjustment of the distance between the fixed teeth and the rotating teeth is beneficial for the staff to process corresponding products according to different fineness requirements.

Owner:山东亚奥特乳业有限公司

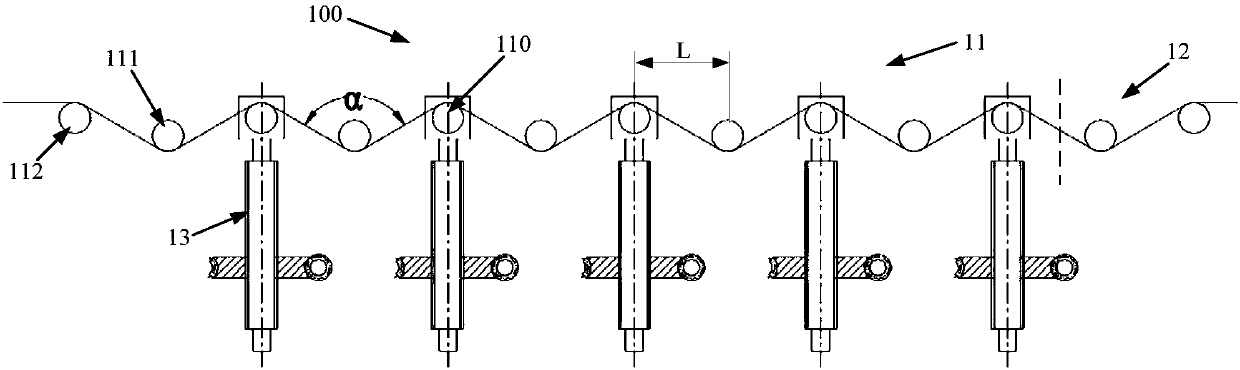

carbon fiber extension

The present invention provides a carbon fiber expanding device. The carbon fiber expanding device includes an expanding roller set, and the expanding roller set includes N expanding rollers, wherein, N is an odd number greater than or equal to 3, and the outer surface of the expanding roller is along the axial direction. At least one guide groove is evenly arranged, and the N expanding rollers include upper rollers and lower rollers, and the upper rollers and the lower rollers are arranged alternately above and below the carbon fiber bundles, and wherein the upper rollers are distributed on the same In the horizontal plane, the lower rollers are distributed in the same horizontal plane. According to the carbon fiber expansion device of the present invention, the structure is simple and easy to use. During the expansion process of the carbon fiber bundle passing through the upper roller and the lower roller alternately, it continuously widens and becomes thinner, so that the width and thickness of the carbon fiber bundle after expansion are uniform and moderate; and the carbon fiber bundle of the present invention The carbon fiber expansion device can adjust the lifting of the expansion roller, so that the expansion tension can be adjusted as required to meet the expansion requirements of different carbon fiber bundles.

Owner:BEIJING ONLYTOP HIGH TECH MATERIALS

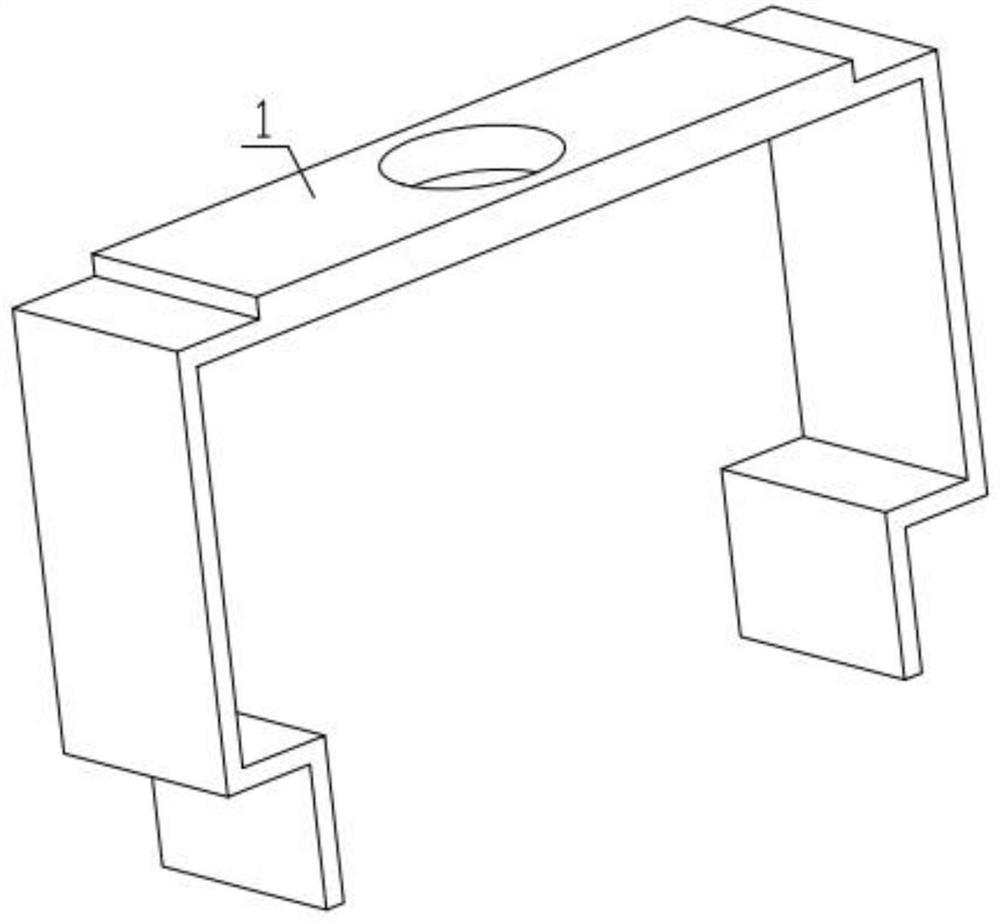

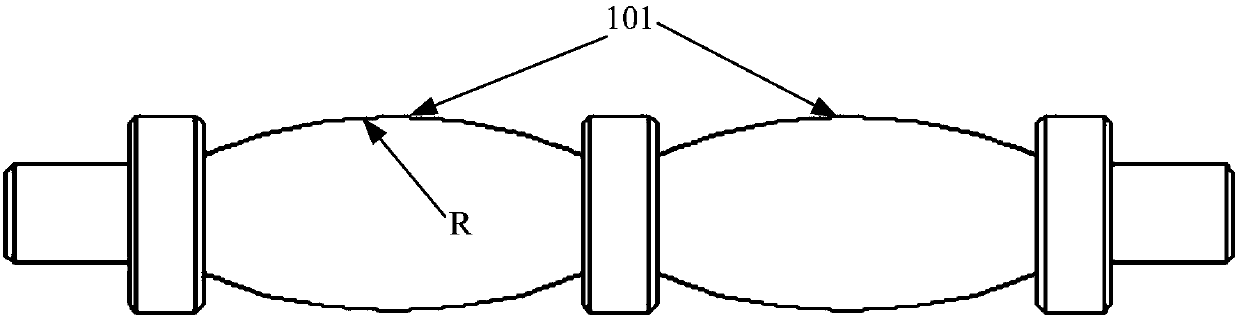

Adjusting mechanism for thin film packaging machine and longitudinal sealing force arm

The invention discloses an adjusting mechanism for a thin film packaging machine and a longitudinal sealing force arm. The adjusting mechanism is arranged between a packaging machine body and the longitudinal sealing force arm. The adjusting mechanism comprises a fixing base, an adjusting block, a screw rod and nuts matched with the screw rod. The fixing base and the adjusting block are fixed to the packaging machine body and the longitudinal sealing force arm respectively. The fixing base and the adjusting block are each correspondingly provided with an outward-vertical U-shaped through groove. The screw rod is vertically arranged inside the U-shaped through grooves in the fixing base and the adjusting block. The upper end of the fixing base, the lower end of the adjusting block and the portion, between the fixing base and the adjusting block, of the screw rod are each provided with a nut. The adjusting mechanism has the beneficial effects that stress applied to the adjusting mechanism when longitudinal sealing force arm is inclined can be effectively released, and deformation of the screw rod is avoided; and the longitudinal sealing force arm can be conveniently adjusted to ascend and descend by rotating the nuts. The adjusting mechanism is simple in structure and convenient to use and has the good practicability.

Owner:锦麒生物科技(安徽)有限公司

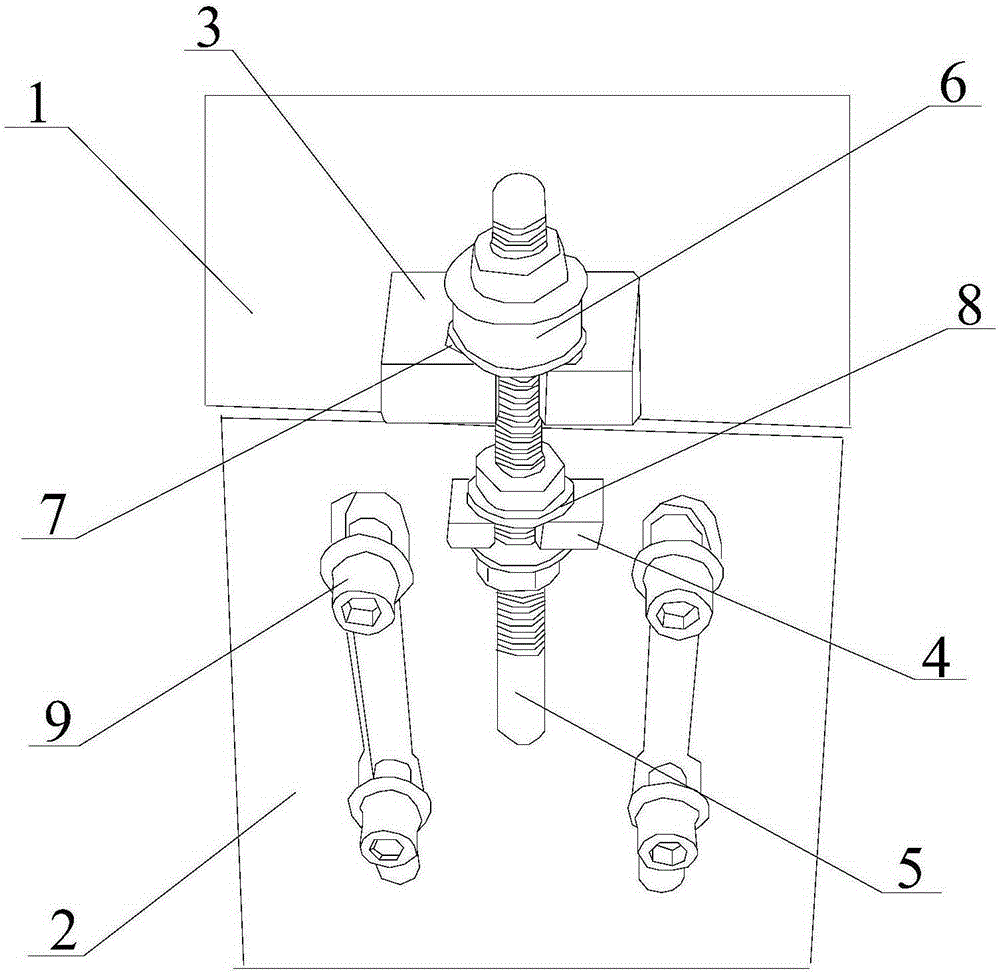

Big arm mechanism

PendingCN112593621ASupport and Adjust AngleSupport and height adjustmentSewer cleaningGudgeon pinCylinder block

The invention discloses a big arm mechanism. The big arm mechanism is installed on a vehicle body of a desilting robot and comprises a connecting square pipe and big arms arranged on the two sides ofthe connecting square pipe, wherein the two ends of the connecting square pipe are welded to the two big arms, the positions, close to the square pipe, of the bottom faces of the big arms are rotationally connected with piston ends of big arm lifting oil cylinders through lifting oil cylinder piston pin shafts, cylinder body ends of the big arm lifting oil cylinders are located on the lower sidesof the big arms and rotationally connected to the vehicle body through lifting oil cylinder body pin shafts, and the large-arm lifting oil cylinders are used for driving the large arms to move up anddown on the vehicle body. According to the big arm mechanism, aiming at the defects of the existing equipment, the large arms and the large arm lifting oil cylinders are designed to be symmetrically arranged, so that the balance moment is favorably obtained, and the operation is more reliable; and the height of a trailing suction screw is adjusted, the working efficiency is greatly improved underthe condition that the dredging effect is guaranteed, the risk of hydraulic oil leakage is avoided, the using effect is good, and the market prospect is wide.

Owner:POWERCHINA XIBEI ENG +1

Full-automatic disc brake pad grinding treatment device

InactiveCN112792691AAdjust the size of the spacingAdjust liftGrinding carriagesGrinding drivesDisc brakeElectric machinery

The invention discloses a full-automatic disc brake pad grinding treatment device. The full-automatic disc brake pad grinding treatment device comprises a fixing box, wherein a first motor is arranged at the bottom of the fixing box; the output end of the first motor penetrates through the fixing box and extends into the fixing box; two fixing shells are symmetrically arranged in the fixing box; rotating mechanisms are arranged at the bottoms of the two fixing shells; second fixing plates are fixedly connected to top end faces of two fixing shells; and rotating mechanisms are arranged in the second fixing plates. The full-automatic disc brake pad grinding treatment device has the beneficial effects that a brake pad can be limited and fixed, and meanwhile the protection effect is achieved; the brake pad is prevented from being fixed in a clamping mode, so that the phenomenon of clamping deformation of the brake pad is not prone to occurring; meanwhile, the brake pad can be lifted, so that operation of different grinding thicknesses can be met; and the rotating effect is achieved, and the grinding efficiency can be improved through cooperation of a grinding assembly.

Owner:深圳市中科华工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com