Full-service-life propeller hub structure

A full-life, propeller-hub technology, applied in the field of helicopters, can solve problems such as time-consuming, labor-intensive and costly, bearing fatigue and looseness, and inability to share, and achieves the effects of simple connection structure, improved service life, and reduced maintenance and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

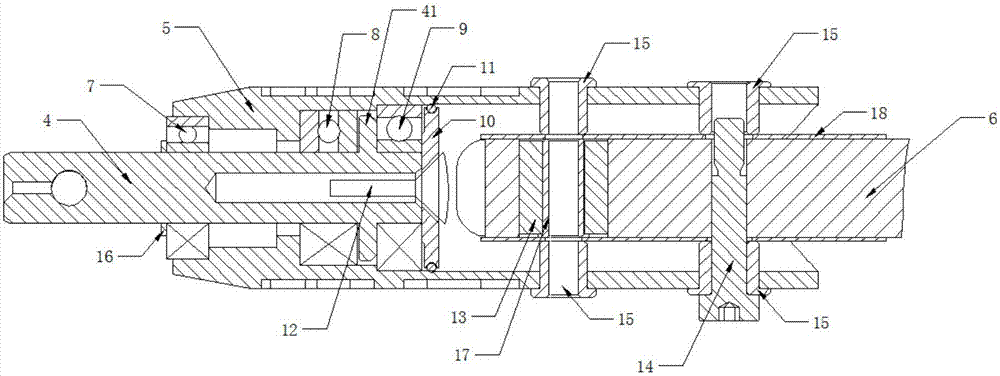

[0027] The preferred embodiments of the present invention are described below in conjunction with the drawings.

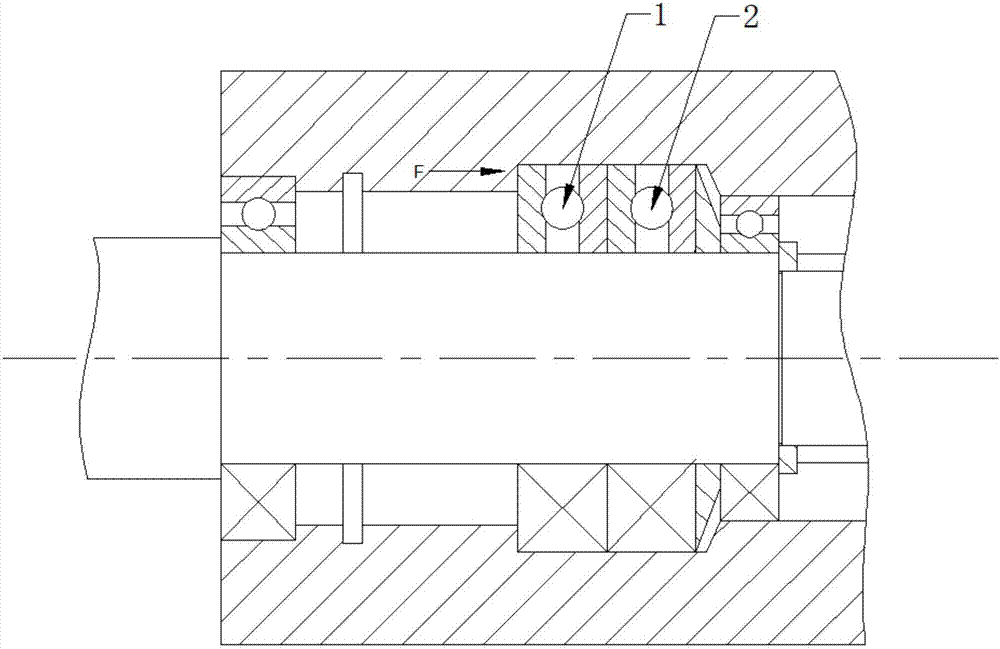

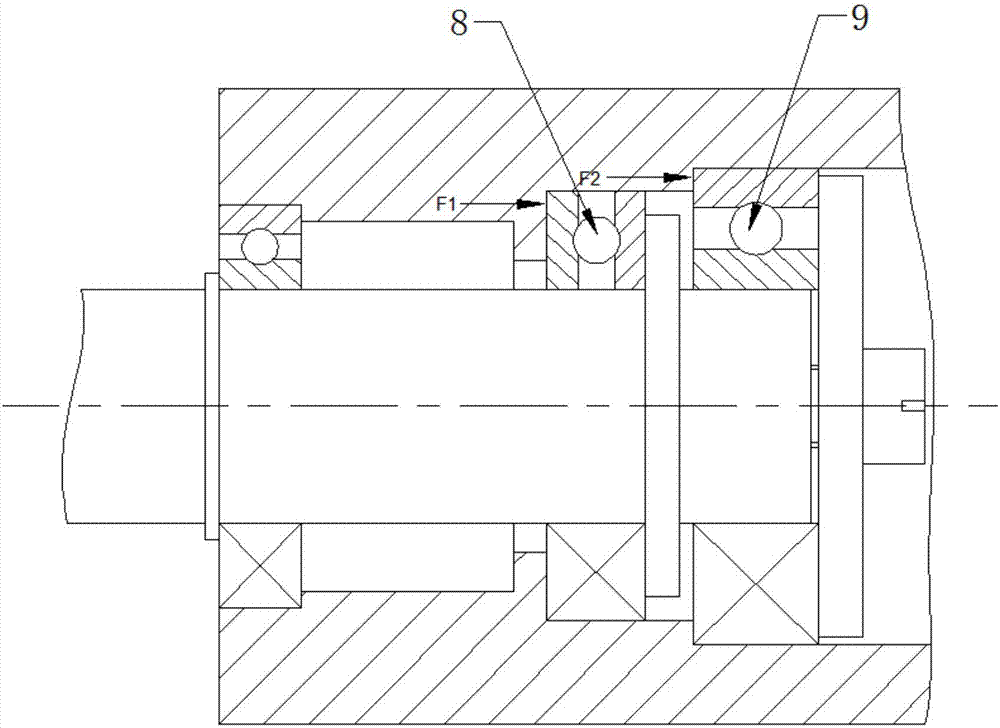

[0028] Such as Figure 2 to Figure 5 As shown, a full-life hub structure includes a hub center piece 3, a blade shaft 4, a paddle clamp 5, and a blade 6. The paddle shaft 4 is connected to the hub center piece 3 and the paddle clamp 5, and the blades 6 are arranged At the end of the blade clamp 5, the blade shaft 4 is provided with a first bearing 7, a second bearing 8 and a third bearing 9 in sequence along the direction of the end of the blade clamp 5. A step surface 41 and a second bearing 8 are provided on the blade shaft 4 The third bearing 9 and the third bearing 9 are respectively arranged on both sides of the step surface 41.

[0029] Specifically, the outer diameter of the second bearing 8 is smaller than the outer diameter of the third bearing 9, and the outer diameter of the third bearing 9 is larger than the outer diameter of the step surface 41. Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com