Rapid ratchet spanners

A ratchet wrench, a fast technology, applied in the directions of wrenches, manufacturing tools, wrenches, etc., can solve the problems of hindering the popularization and popularization of the quick ratchet wrench, high manufacturing cost, complicated structure, etc., and achieves low production cost, simple structure improvement, and obvious effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

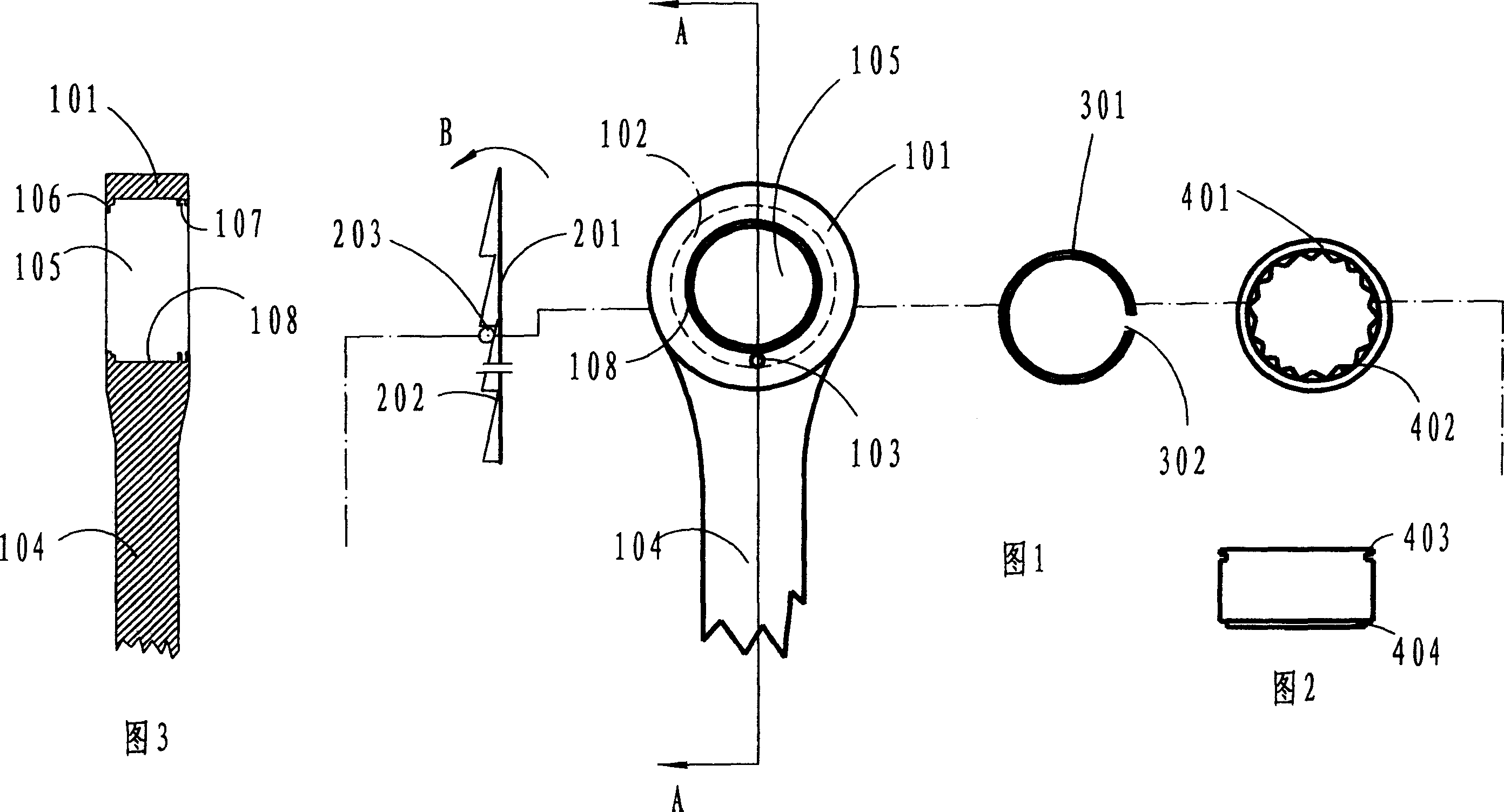

[0012] The serial numbers in the figure respectively indicate: head 101, annular groove 102, positioning pin hole 103, handle 104; through hole 105, shrinking platform 106, circlip groove 107, inner edge wall 108; multi-stage slope spring ring 201 , slope 202, needle roller 203; circlip 301, circlip opening 302;

[0013] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

[0014] Referring to Figures 1-3, Figure 1 shows an exploded view of the present invention. It includes a wrench body and a working twist plate 401. The wrench body consists of a head 101 and a handle 104. A through hole 105 that can receive the working twist plate 401 is formed on the head 101. The through hole 105 is circular. An annular groove 102 is formed on the inner wall 108 of the through hole 105 of the head 101 . The shape and size of the annular groove 102 should match the multi-stage slope spring ring 201, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com