Continuous variable valve lift apparatus

A valve lift, variable technology, used in valve devices, engine components, machines/engines, etc., to solve problems such as insufficient valve opening time and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

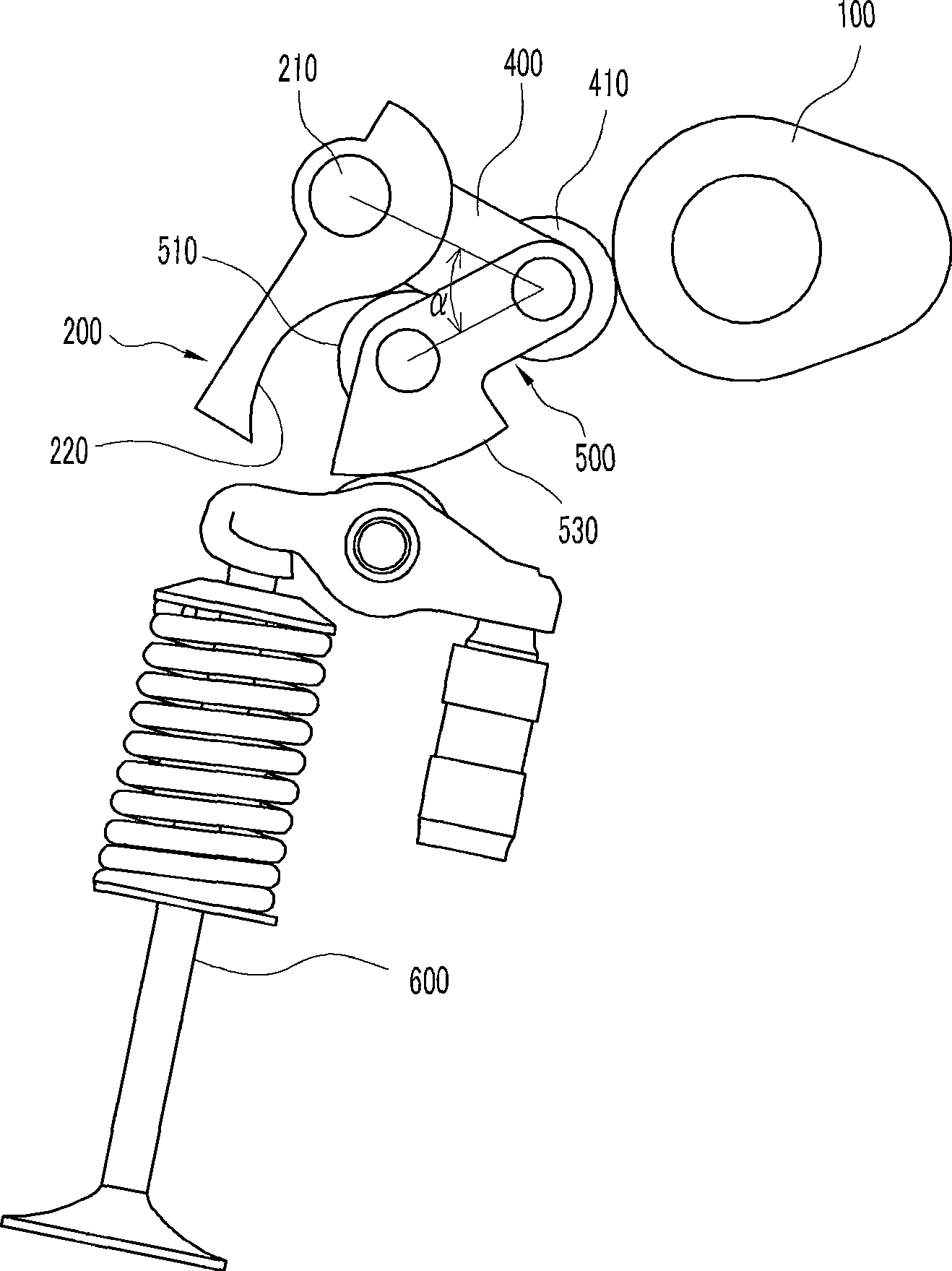

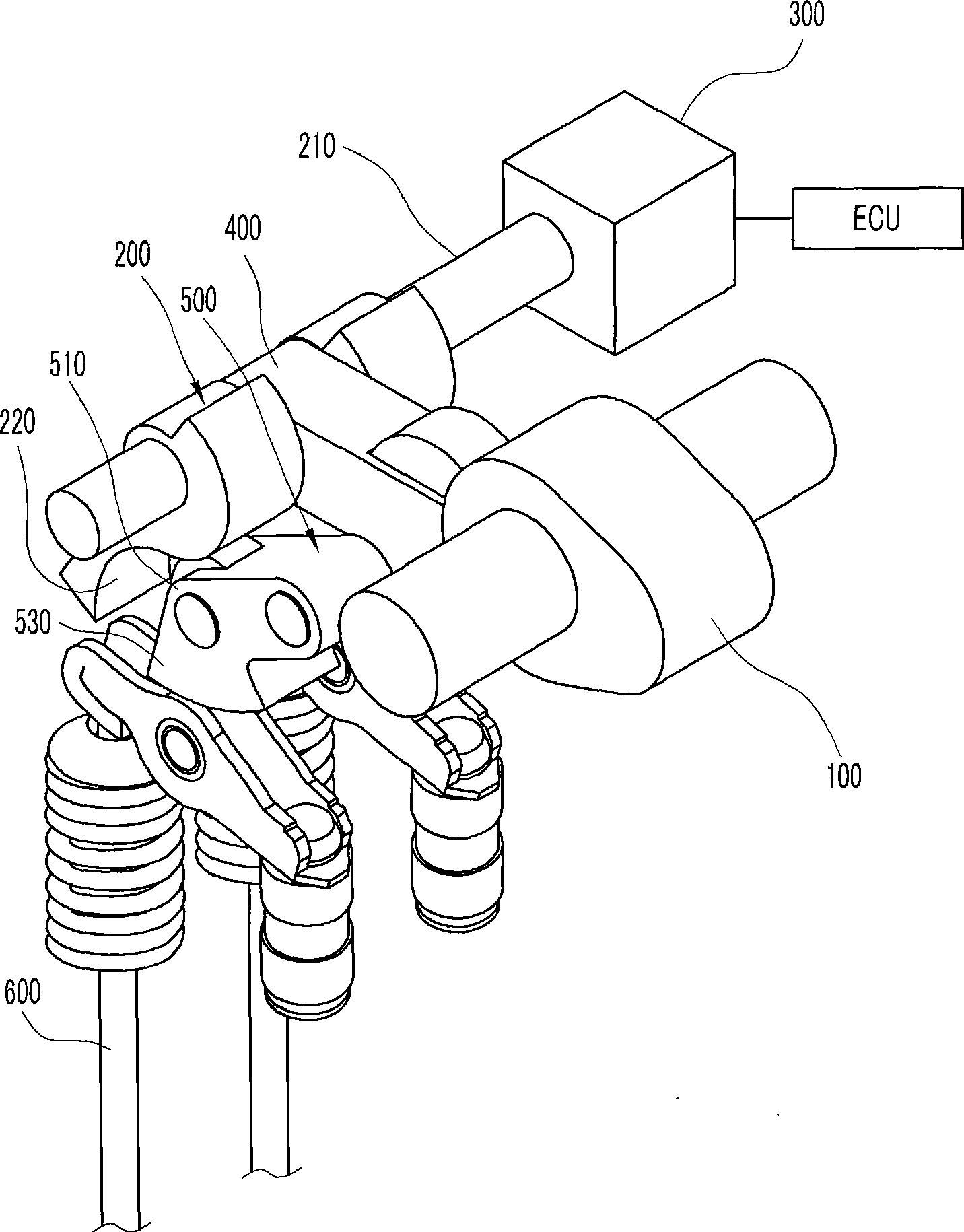

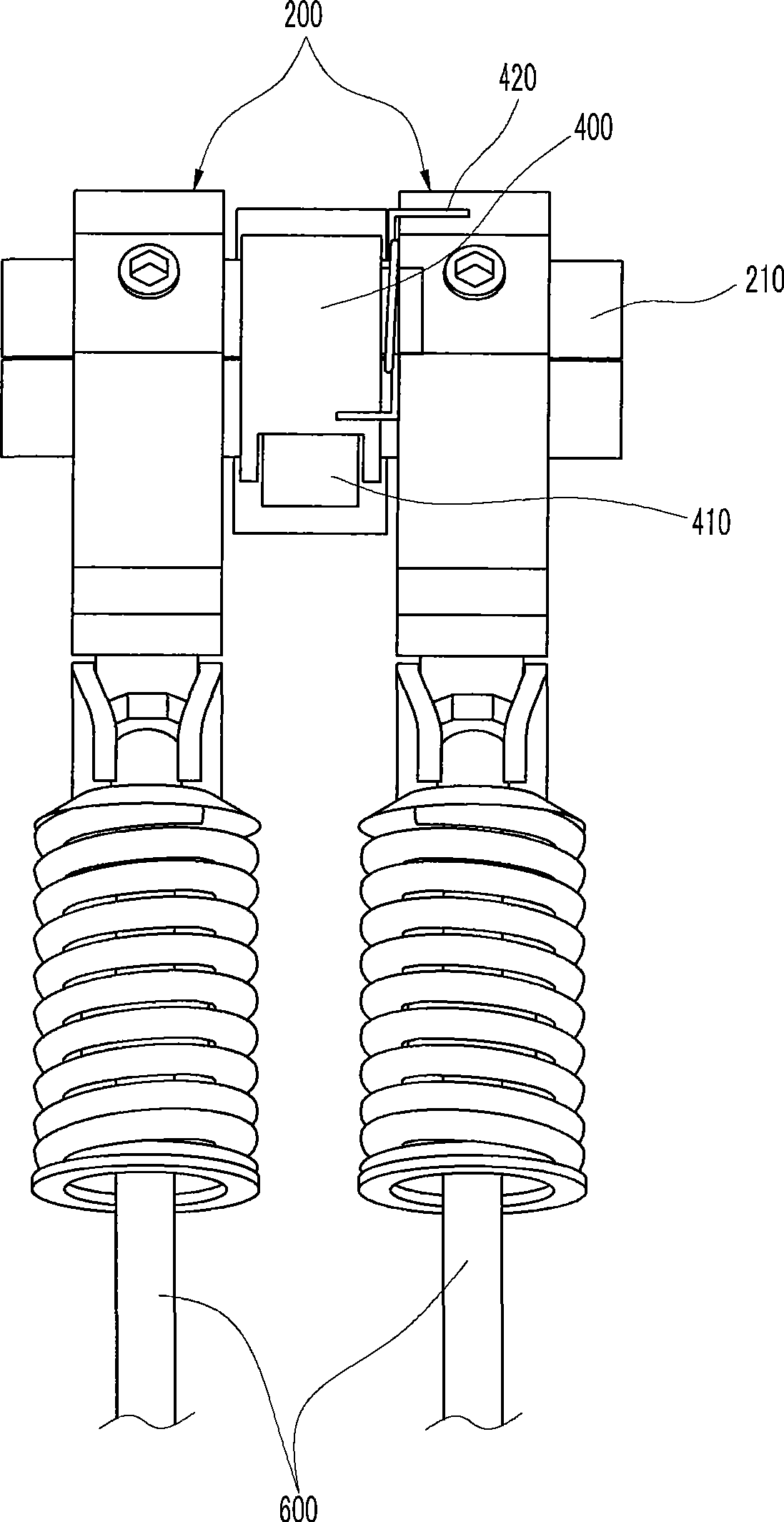

[0027] figure 1 , figure 2 with image 3 They are respectively a front view, a perspective view and a side view of a continuously variable valve lift device according to an exemplary embodiment of the present invention.

[0028] The input cam 100 is configured to impart rotation.

[0029] The lever rotation shaft 210 is connected to the control part 300 .

[0030] The lever 200 is arranged to the lever rotating shaft 210 , and the contact portion 220 is formed on the lever 200 .

[0031] The first link 400 is rotatably connected to the lever rotation shaft 210 .

[0032] The second link 500 is rotatably connected to the first link 400 and contacts the contact portion 220 .

[0033] The output cam 530 is disposed on the second link 500 to open and close the valve 600 .

[0034] The elastic portion 420 is configured to the lever rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com