Full-automatic disc brake pad grinding treatment device

A disc brake pad and processing device technology, which is applied in the direction of grinding drive device, grinding frame, grinding bed, etc., can solve the problems of reducing work efficiency, inconvenient brake pad adjustment operation, brake pad shaking, etc. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

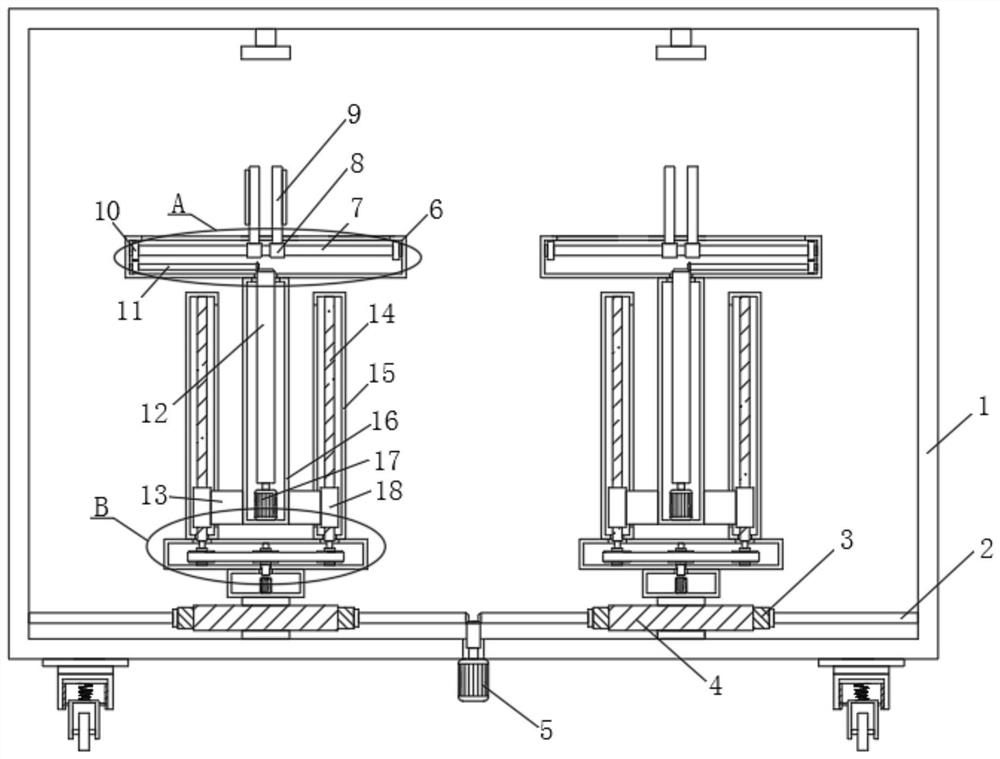

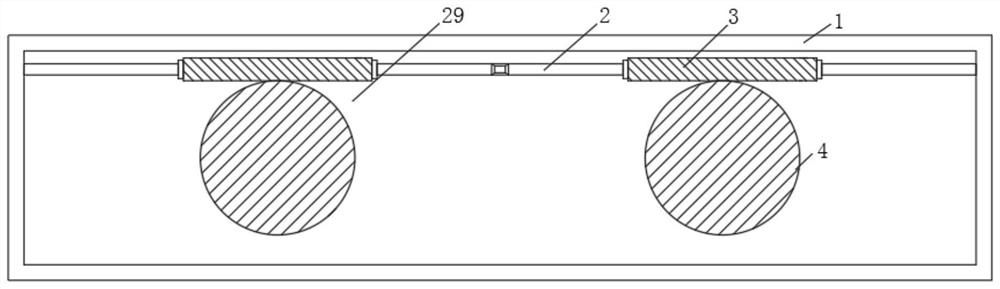

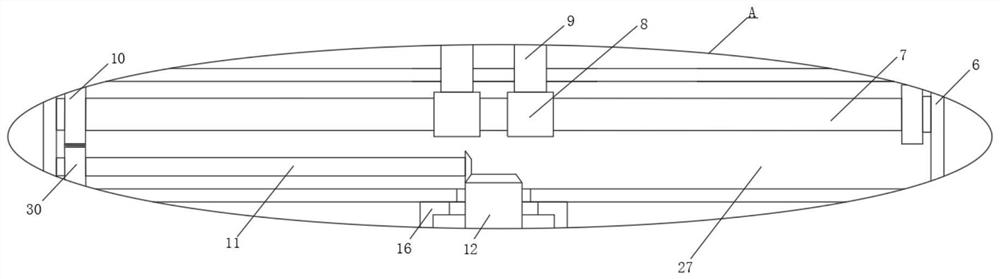

[0025] Example: such as Figure 1-5 As shown, a fully automatic disc brake pad grinding device of the present invention has two grinding heads symmetrically fixedly connected to the top surface inside the fixed box 1, including the fixed box 1, and the bottom of the fixed box 1 is provided with a first Motor 5, the output end of the first motor 5 runs through the fixed box 1 and extends to its inside, the inside of the fixed box 1 is symmetrically provided with two fixed shells 23, the bottom of the two fixed shells 23 is provided with a rotating mechanism 29, and the two fixed The top end surface of the shell 23 is fixedly connected with a second fixed plate 22, the inside of the second fixed plate 22 is provided with a rotating mechanism 28, and the end surface of the second fixed plate 22 away from the fixed shell 23 is symmetrically fixedly connected with two first fixed plates. Rod 15, the interior of two first fixed rods 15 is all provided with threaded rod 14, is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com