Supporting structure for mounting LED display screen

A technology of LED display screen and support structure, which is applied in the direction of supporting machines, machine tables/brackets, springs/shock absorbers, etc., which can solve the problems of display screen damage, labor cost, and display screen falling, so that it is not easy to shake and easy to use. Convenient and stable lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

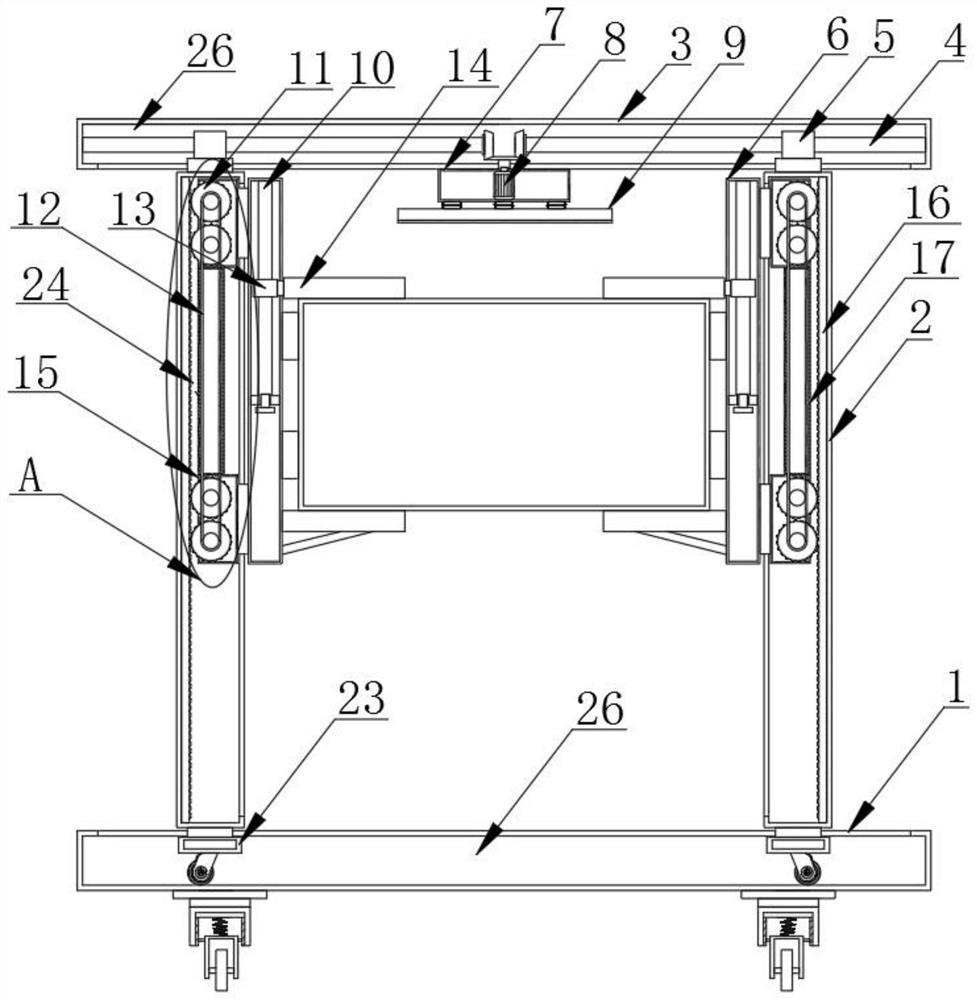

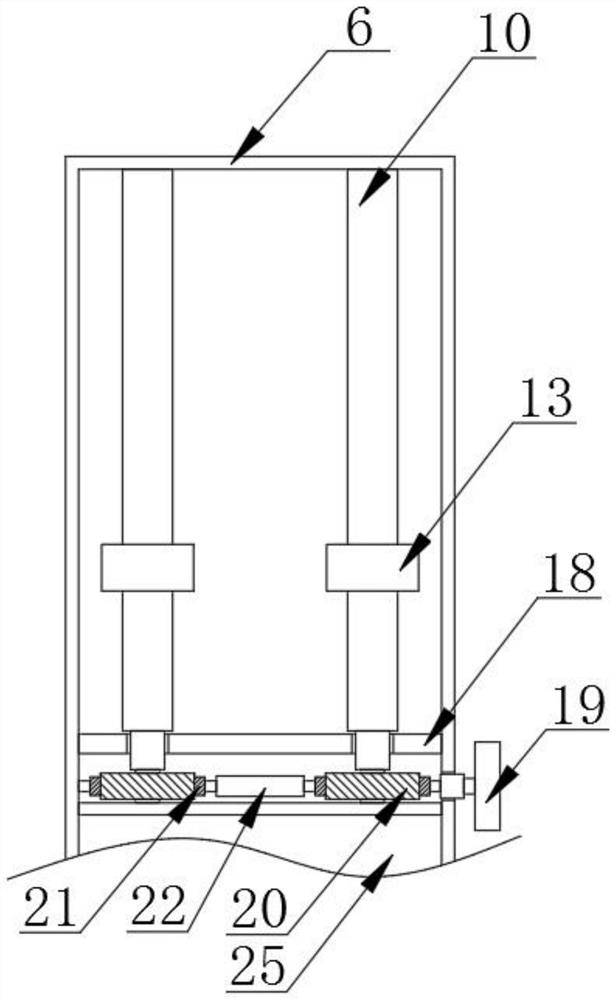

[0022] see Figure 1-4 , the present embodiment provides a support structure for LED display screen installation, including a fixed base 1, the top of the fixed base 1 is provided with a top plate 3, the inside of the top plate 3 is provided with a moving mechanism 26, between the fixed base 1 and the top plate 3 There are two support columns 2 symmetrically, and the inside of the two support columns 2 are provided with a lifting mechanism 24, and the two support columns 2 are symmetrically provided with two lifting plates 6, and the inside of the two lifting plates 6 are provided with a limit position. Institution 25.

[0023] Most of the existing supporting structures only limit and fix the LED display screen, which is inconvenient to adjust and fix it, so that it cannot be adjusted and fixed according to the LED display screens of different sizes.

[0024] In order to achieve the effect of adjusting LED display screens of different lengths, the moving mechanism 26 includes...

Embodiment 2

[0029] see Figure 1-2 , further improvements have been made on the basis of Example 1:

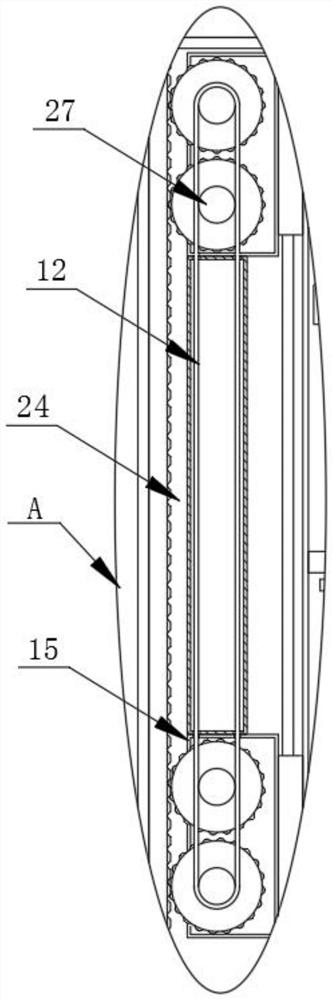

[0030] In order to achieve different installation work requirements, the lifting mechanism 24 includes two gear boxes 15, and the opposite ends of the two gear boxes 15 are welded through the connecting shell 17. Two gears 11 are arranged in the two gear boxes 15, and the two gears 11 A rotating block 27 is fixedly connected to one end of the rotating block 27, and the other end of the rotating block 27 is rotationally connected to the inner wall of the gear box 15. A belt 12 is arranged inside the connecting case 17, and both ends of the belt 12 run through the gear box 15 and are connected to the rotating block 27. , the outside of the support column 2 is provided with a drive motor, and the output end of the drive motor passes through the support column 2 and extends into the gear box 15, and one of the gears 11 is welded to the output end of the drive motor.

[0031]In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com