Paper pressing mechanism for bookbinding machines

A technology of a paper pressing mechanism and a binding machine, which is applied in the direction of binding and the like, can solve the problems of cumbersome use, easy damage to the buffer mechanism, no service life, etc., and achieves the effects of simple structure, elimination of impact force, and good paper pressing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings.

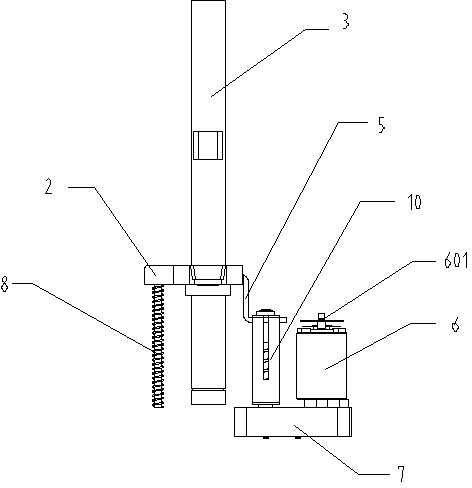

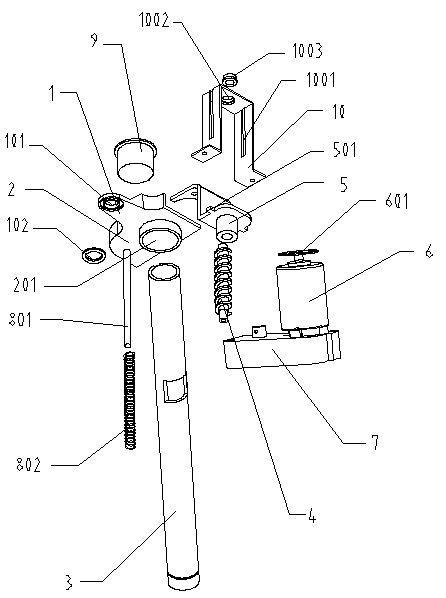

[0025] Such as Figures 1 to 2 As shown, the present embodiment includes a platen 1, a lifting bracket 2, a lifting spindle 3 for providing an action track for the lifting bracket 2, a lifting screw 4 for driving the lifting bracket 2 to move up and down, and a lifting screw 4 for fixing the lifting bracket 2. The screw guide bracket 5, the motor 6 for providing the action power of the lifting screw 4 and the gearbox 7 for adjusting the speed of the lifting screw 4; the lifting bracket 2 is socketed with the lifting main shaft 3, and the lifting bracket 2 is provided with The positioning hole 201, the lifting spindle 3 passes through the positioning hole 201 and is socketed with the lifting bracket 2, and the lifting spindle bushing 9 is arranged between the lifting spindle 3 and the lifting bracket 2. The platen 1 is fixed on the lifting bracket 2, the screw guide brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com