Patents

Literature

40results about How to "Linkage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

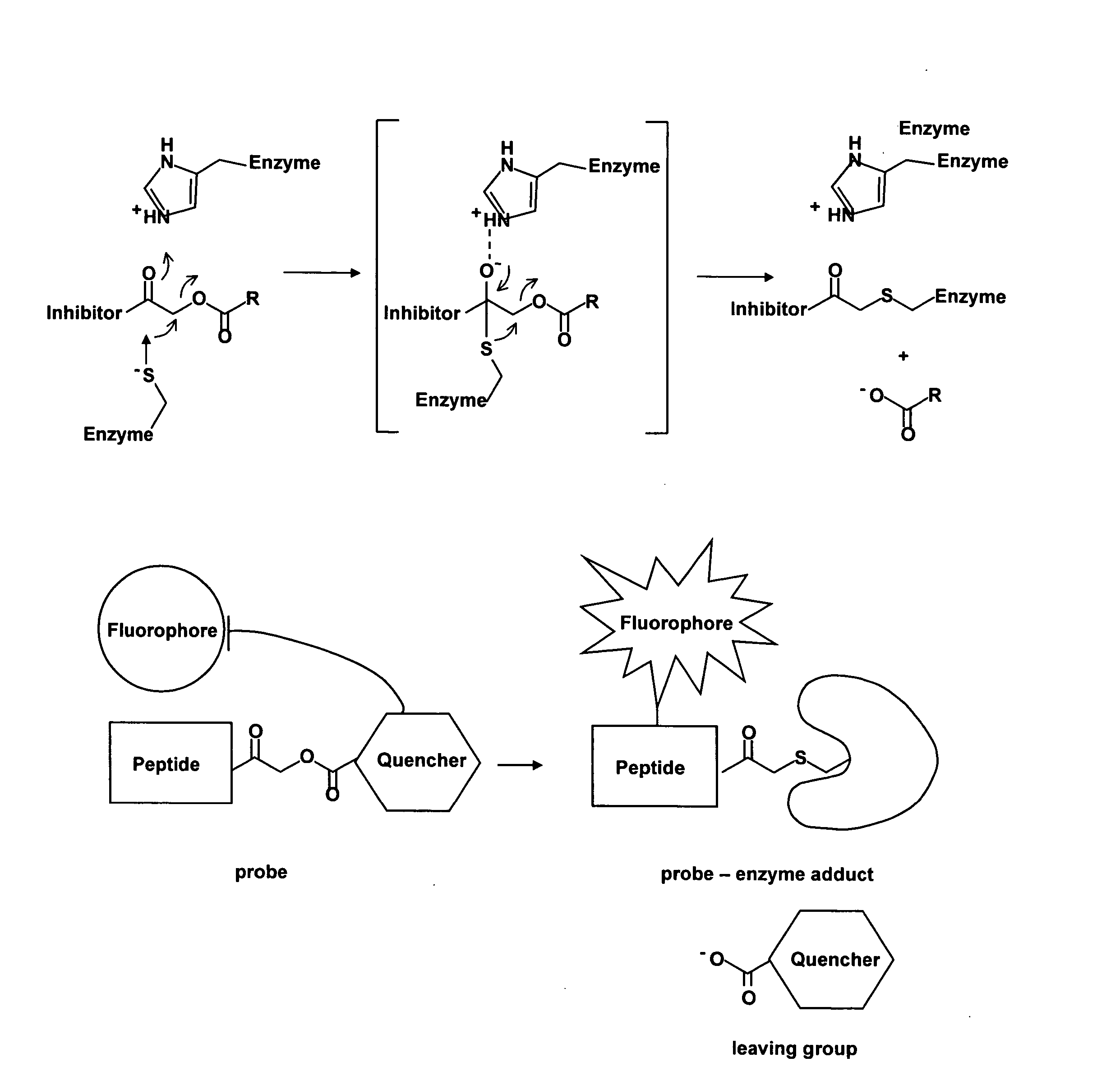

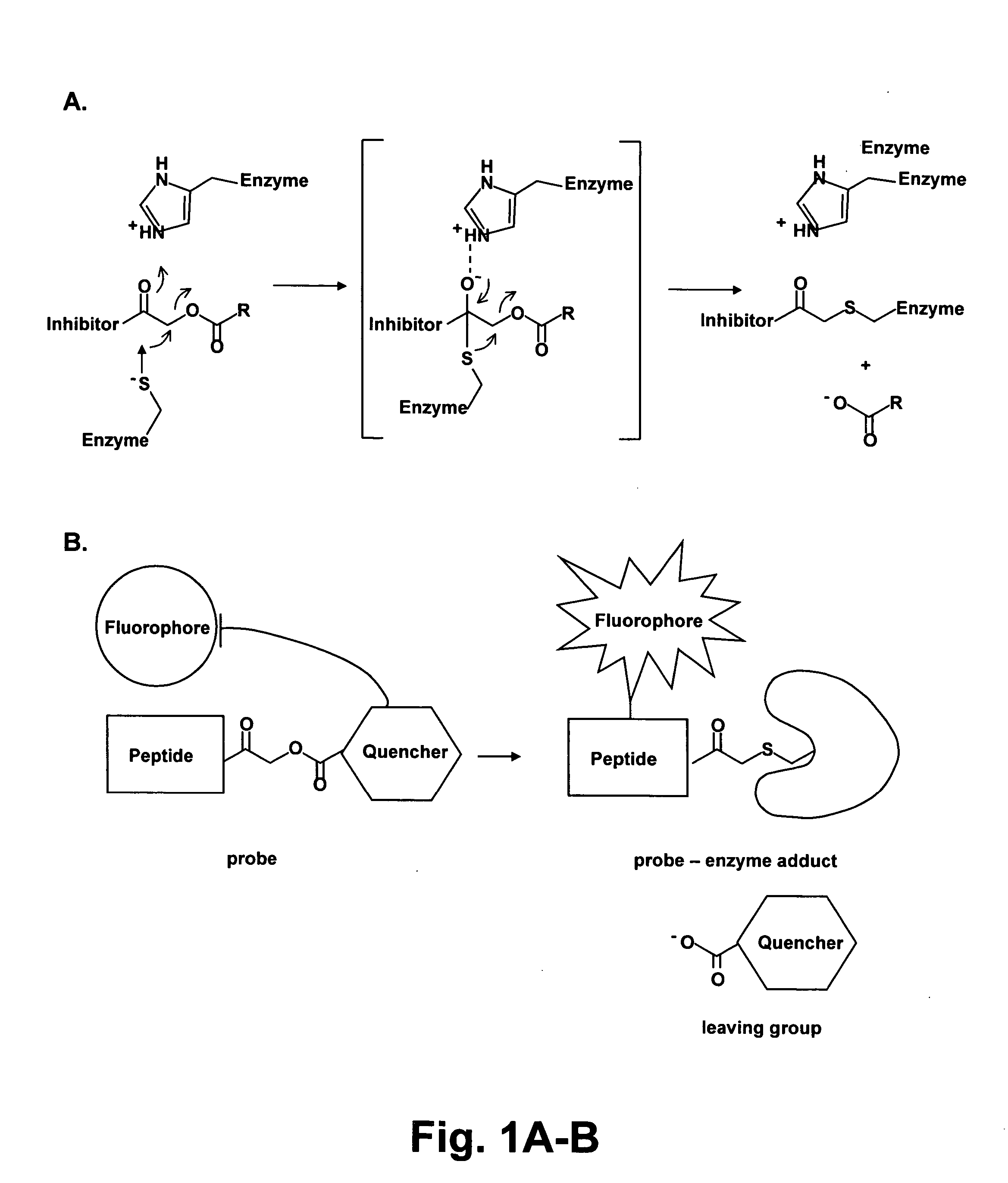

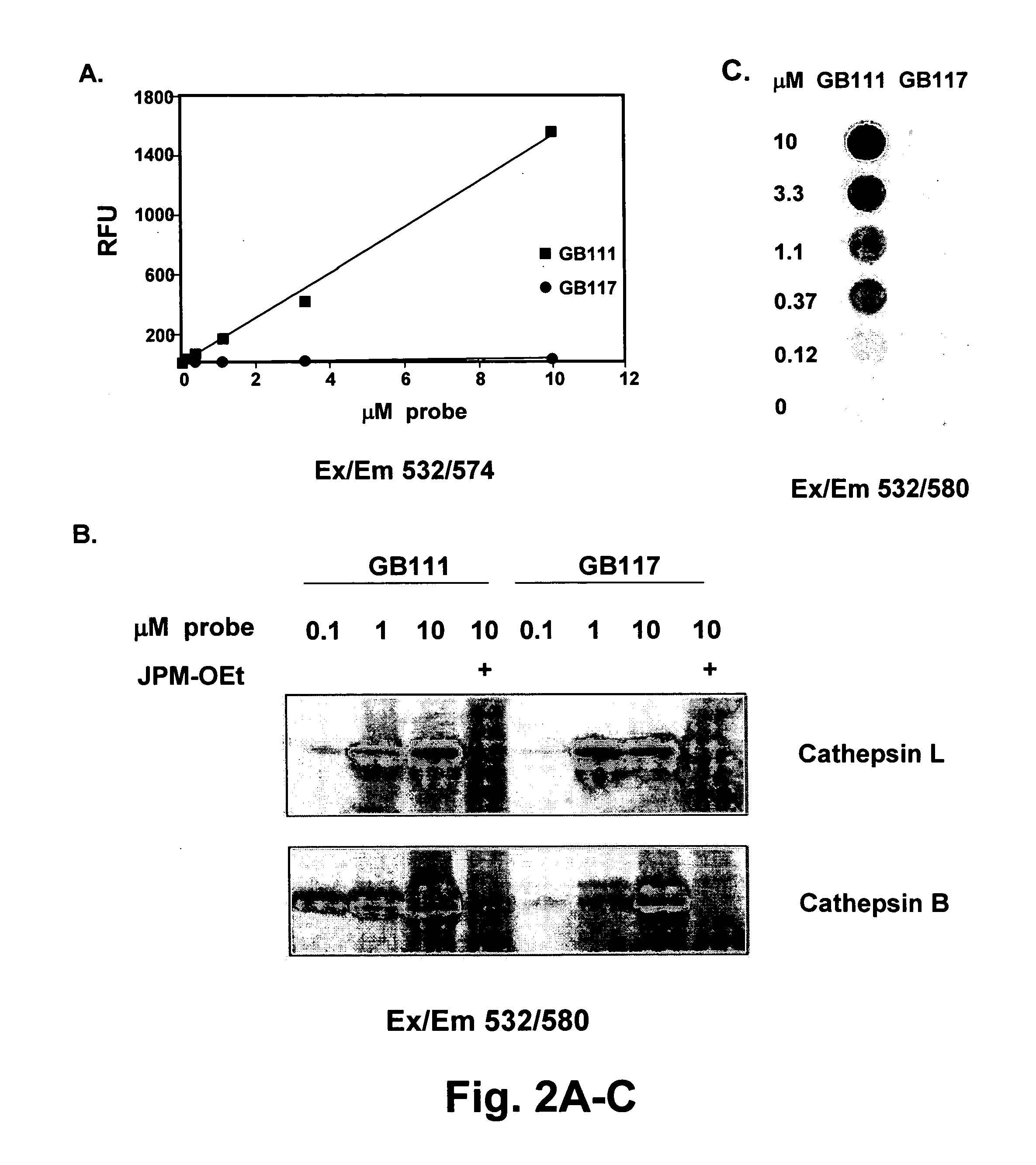

Imaging of protease activity in live cells using activity based probes

ActiveUS20070036725A1Improve resolutionHigh sensitivityUltrasonic/sonic/infrasonic diagnosticsSurgeryProteinase activityFluorophore

Methods and materials for the imaging of cells containing active proteases such as cathepsin are disclosed. The present materials include activity based probes that bind to an enzyme and are subsequently cleaved. Cleavage results in a fluorescent signal due to removal of a quenching group which, when present on the probe causes altered or no fluorescence. The probes employ an acyloxymethyl ketone reactive group, one or more amino acids for determining specificity, a fluorophore and a quencher. The probes are cell permeable and may use, for example, a QSY7 (diarylyrhodamine) quencher and a BODIPY (bora-diaza-indecene) dye.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

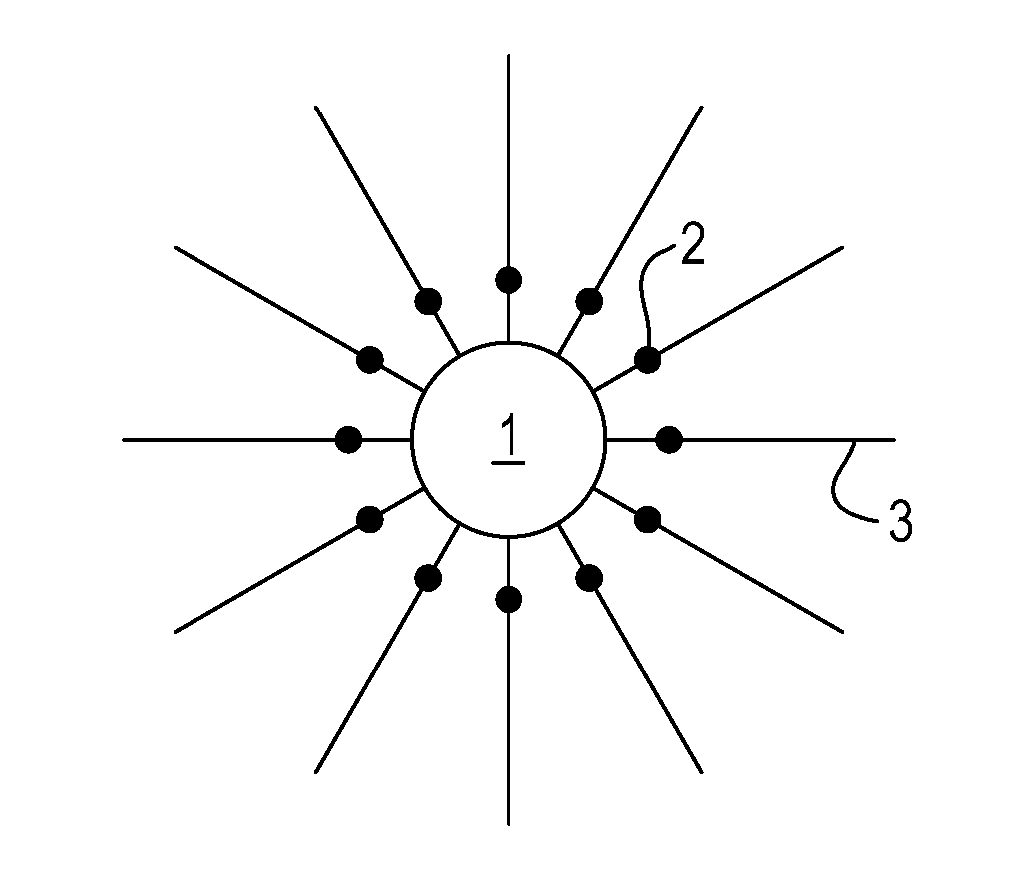

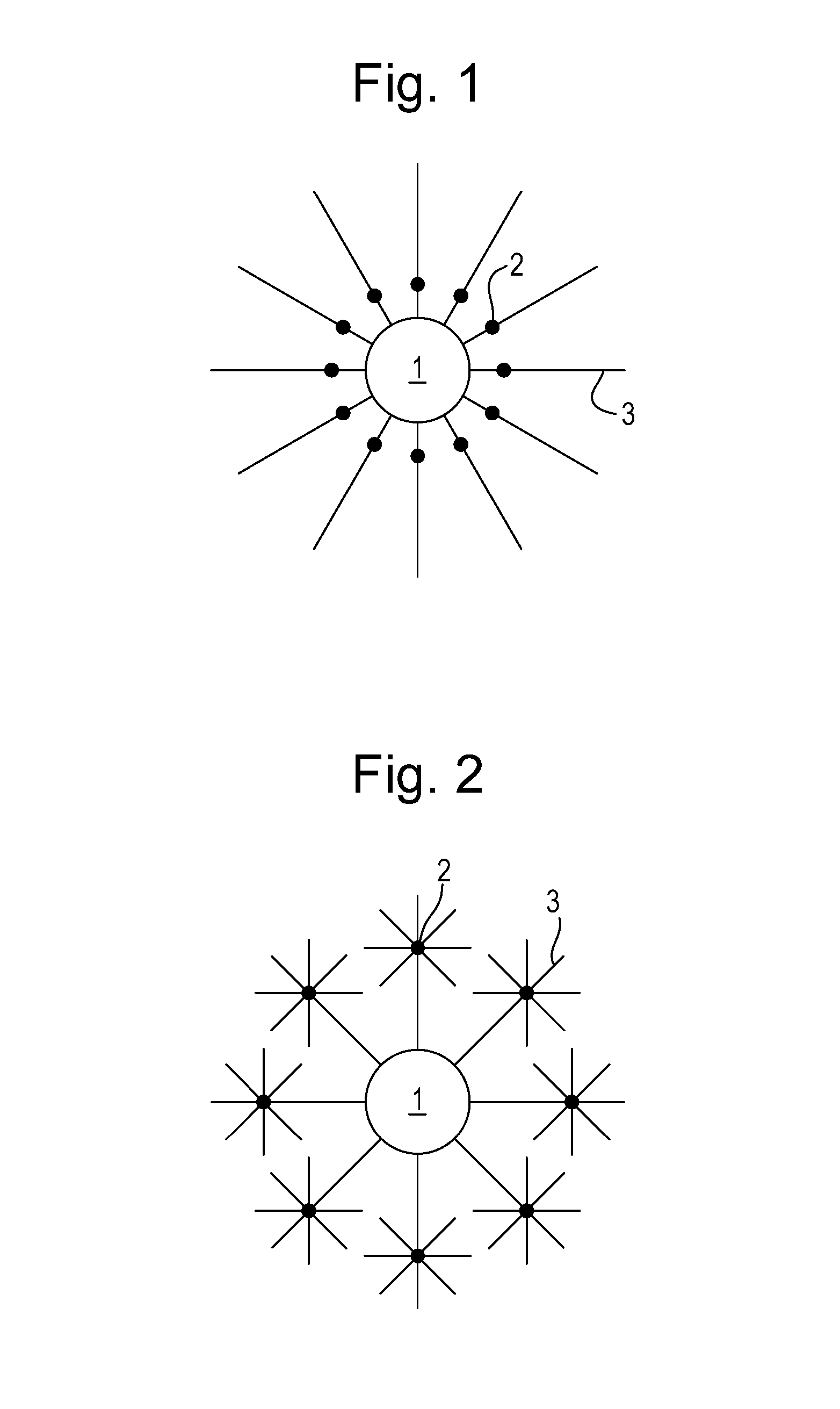

Polyrotaxane and process for producing the same

A process for producing a polyrotaxane in a high yield and at a satisfactory cost without using a large excess of a pseudopolyrotaxane and / or without using a large excess of an activated reagent. The process for polyrotaxane production comprises: an inclusion step in which a carboxylated polyethylene glycol which is a polyethylene glycol carboxylated at each end is mixed with cyclodextrin molecules to obtain a pseudopolyrotaxane which comprises cyclodextrin molecules which include the carboxylated polyethylene glycol in their cavities as if the cyclodextrin molecules are spitted with the carboxylated polyethylene glycol; and a capping step in which the pseudopolyrotaxane is reacted with capping groups having —NH2 or —OH to obtain a polyrotaxane terminated at each end by a —CO—NH-(capping group) or —CO—O-(capping group).

Owner:THE UNIV OF TOKYO

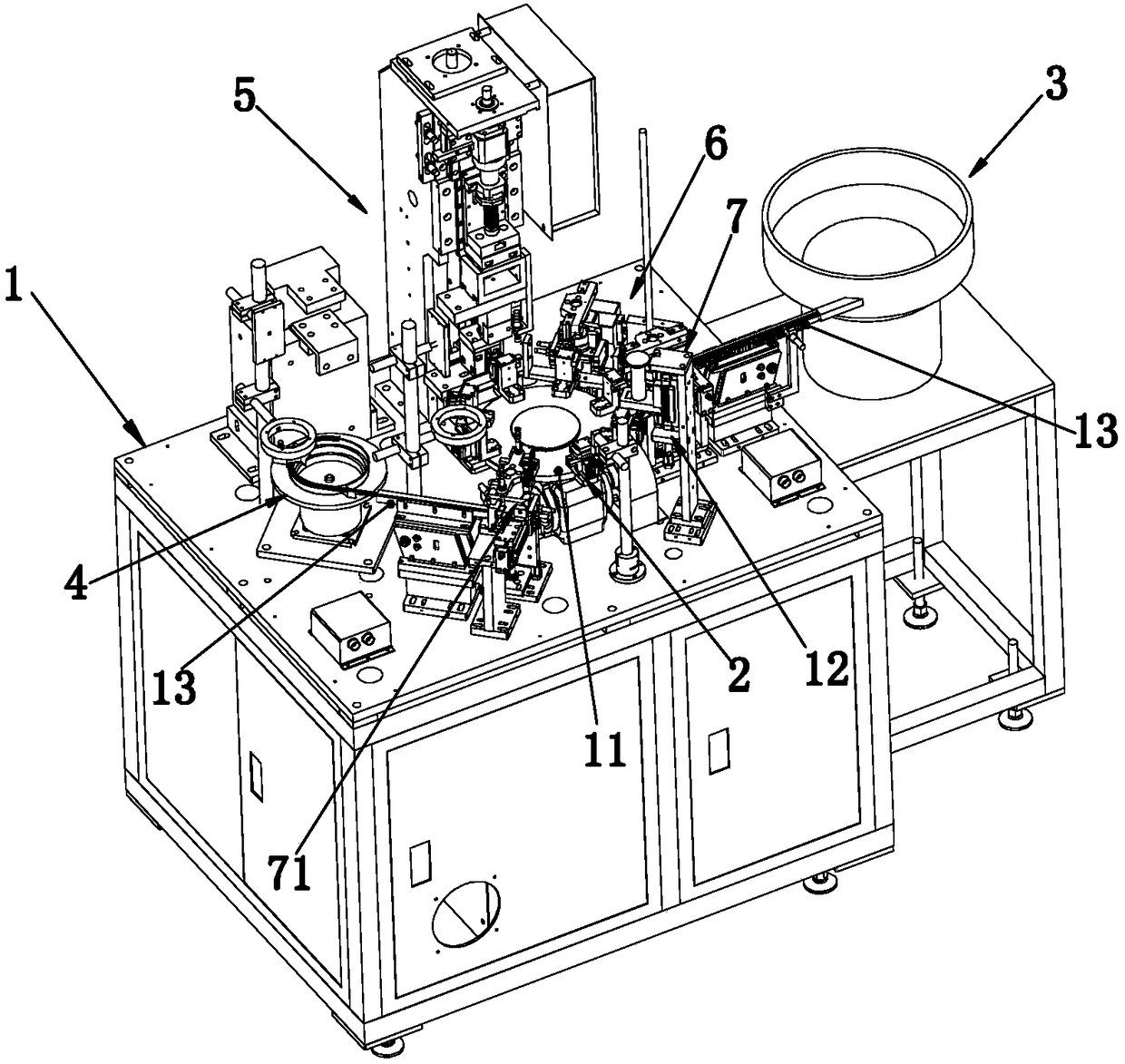

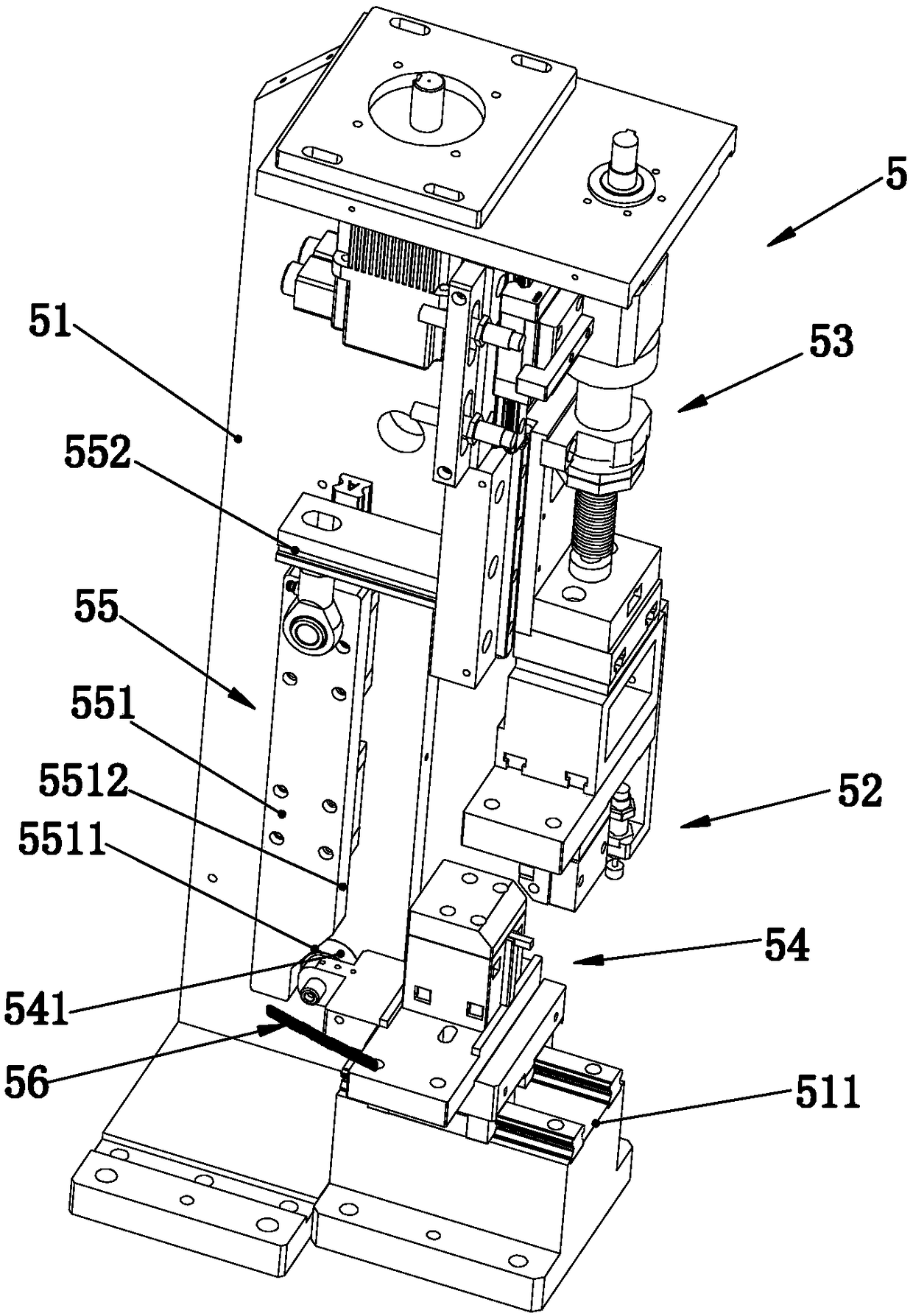

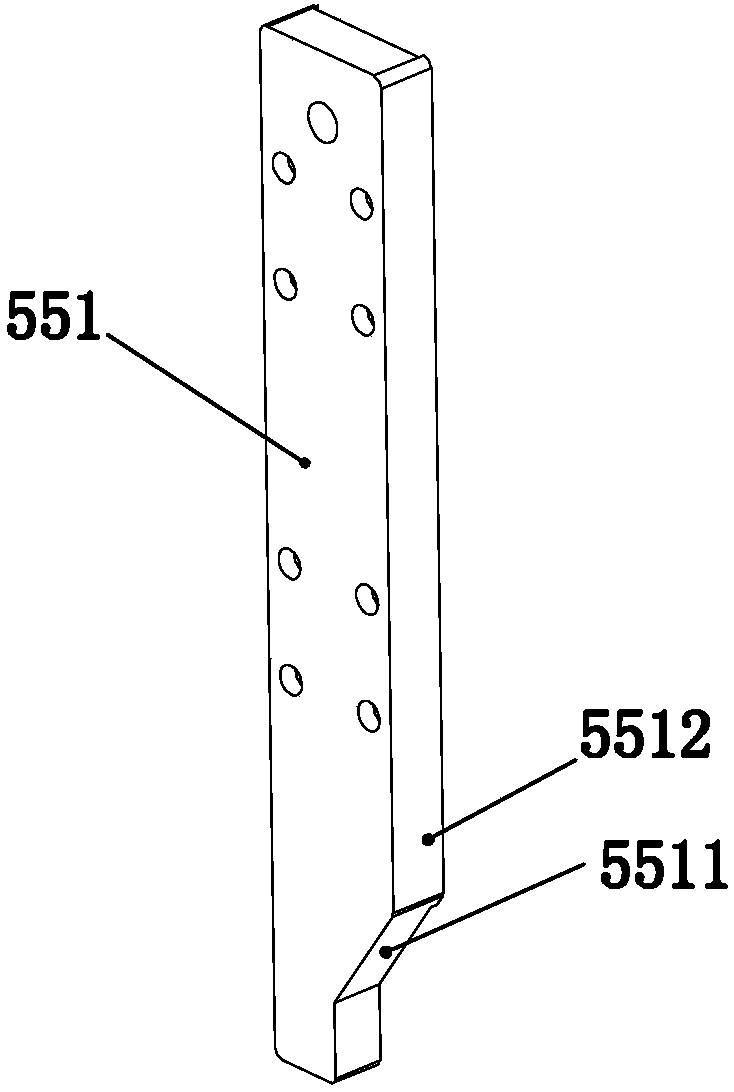

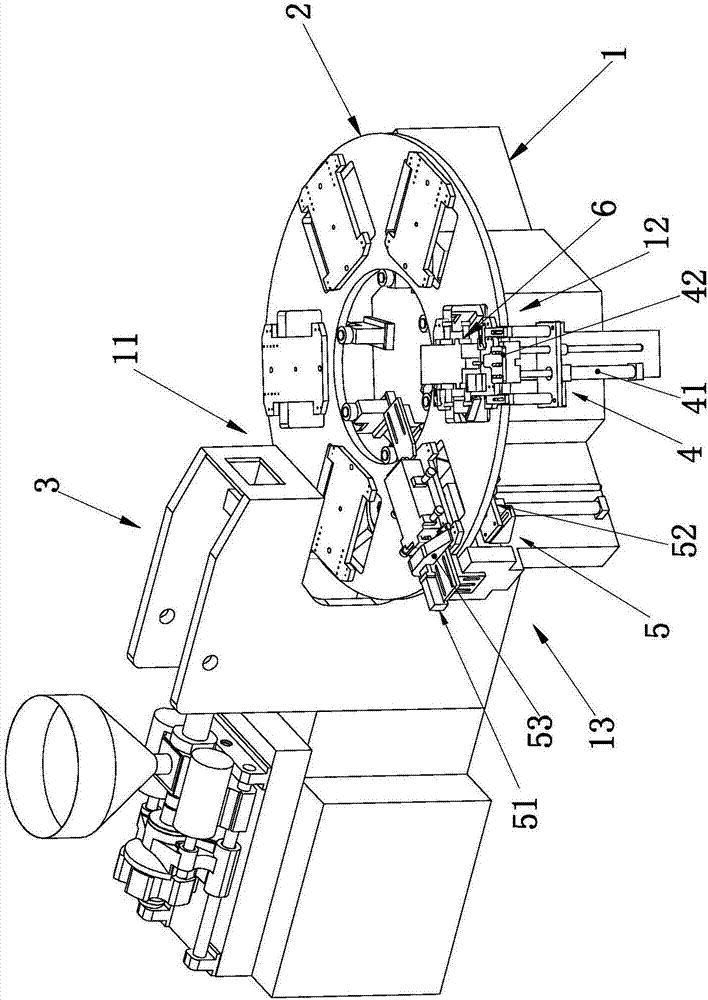

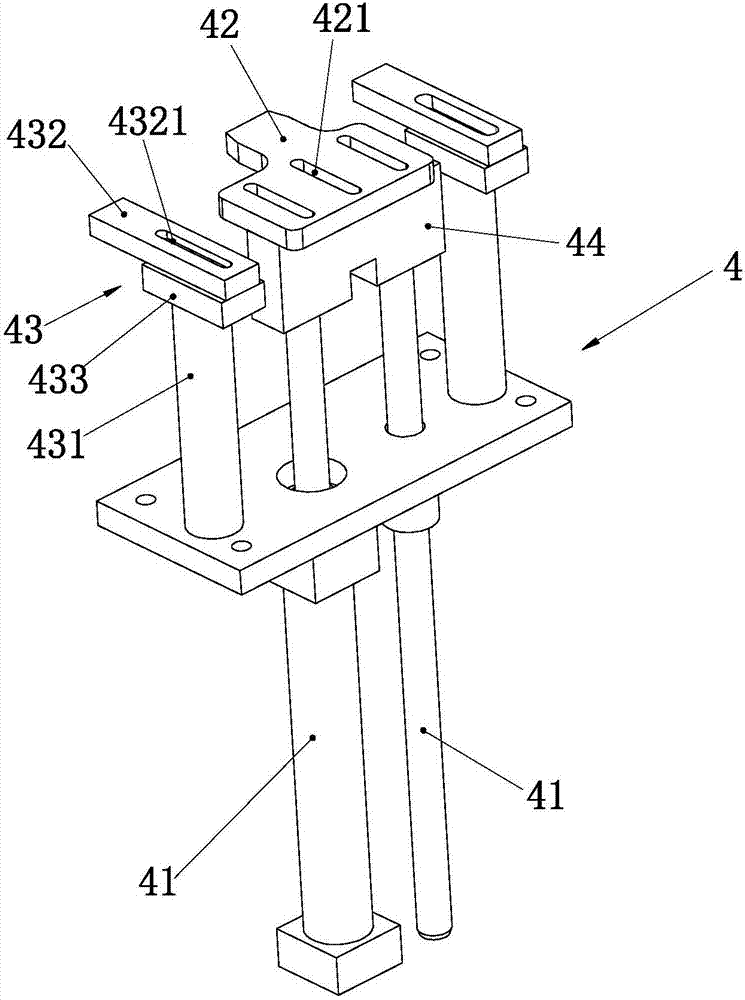

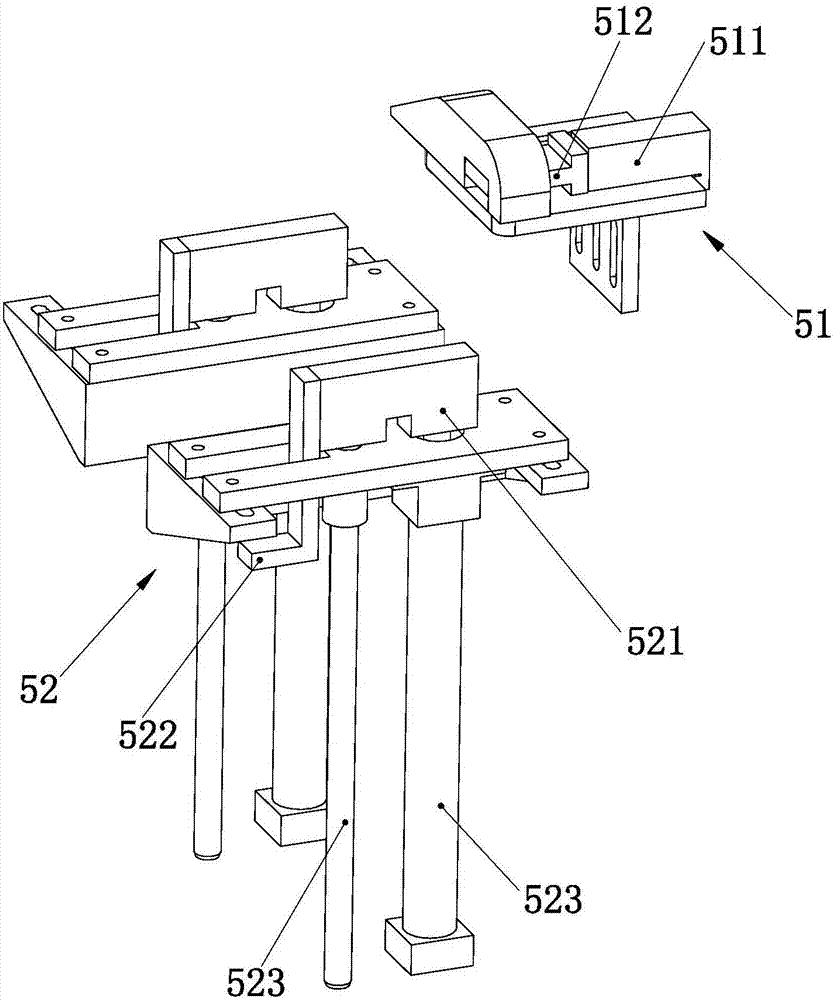

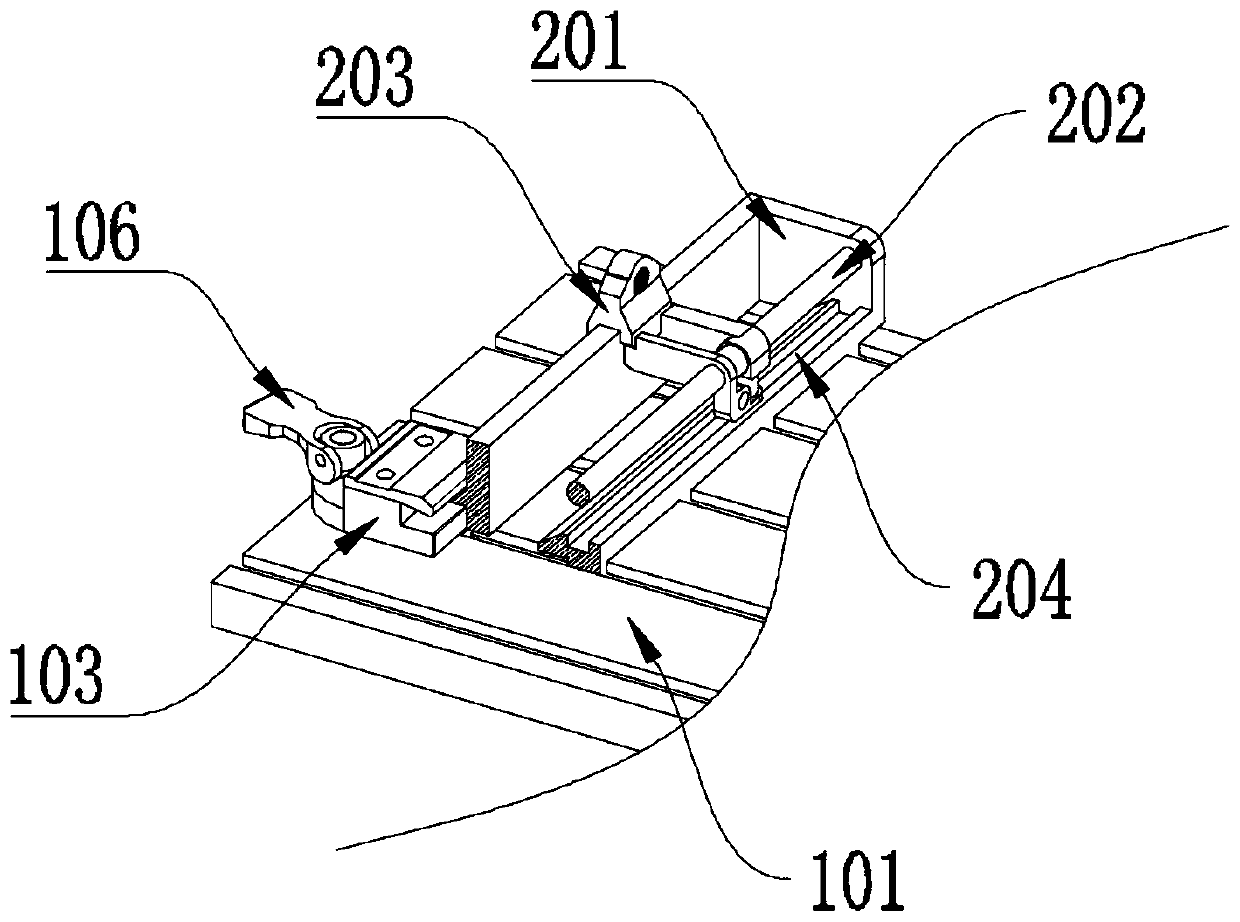

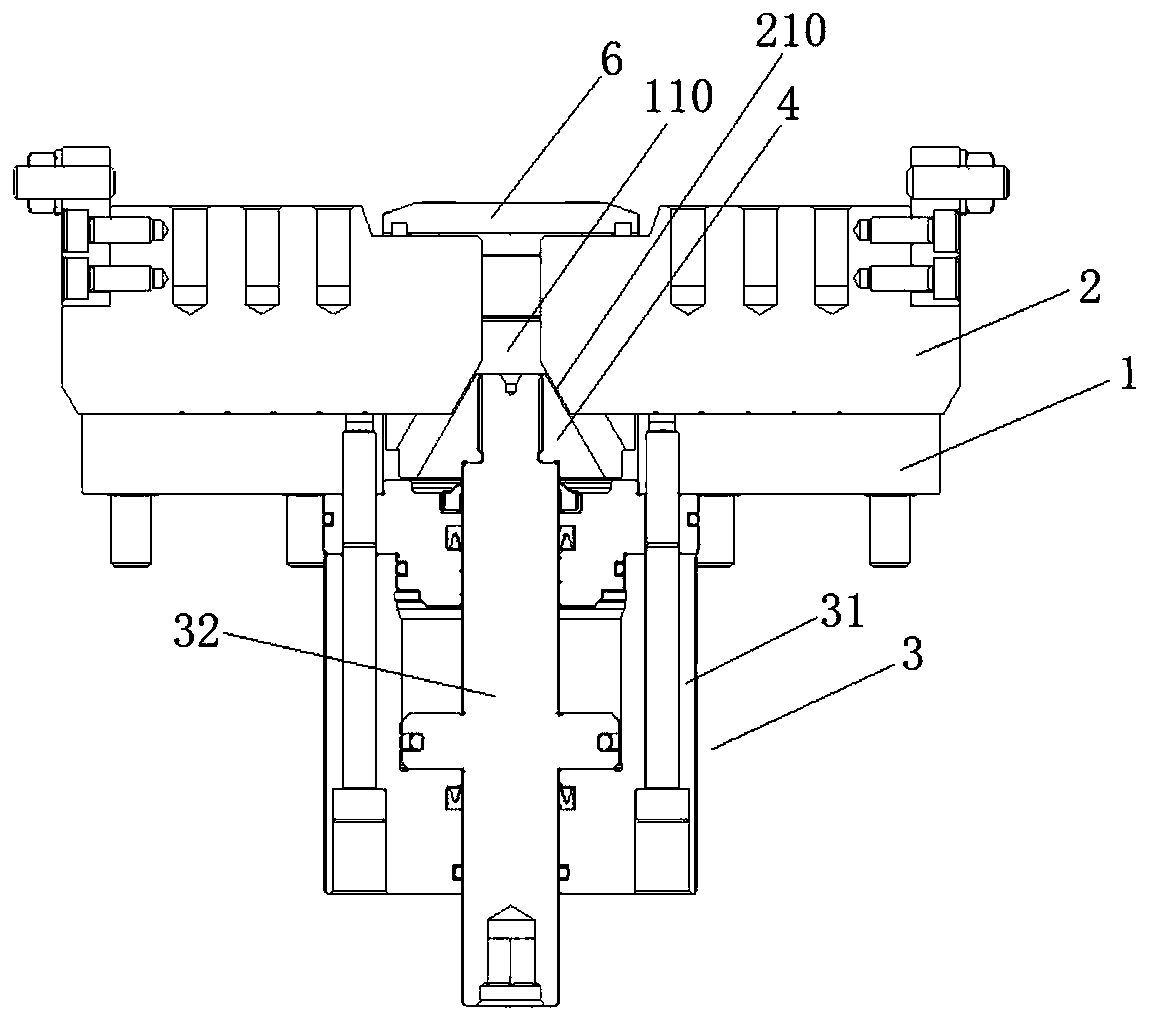

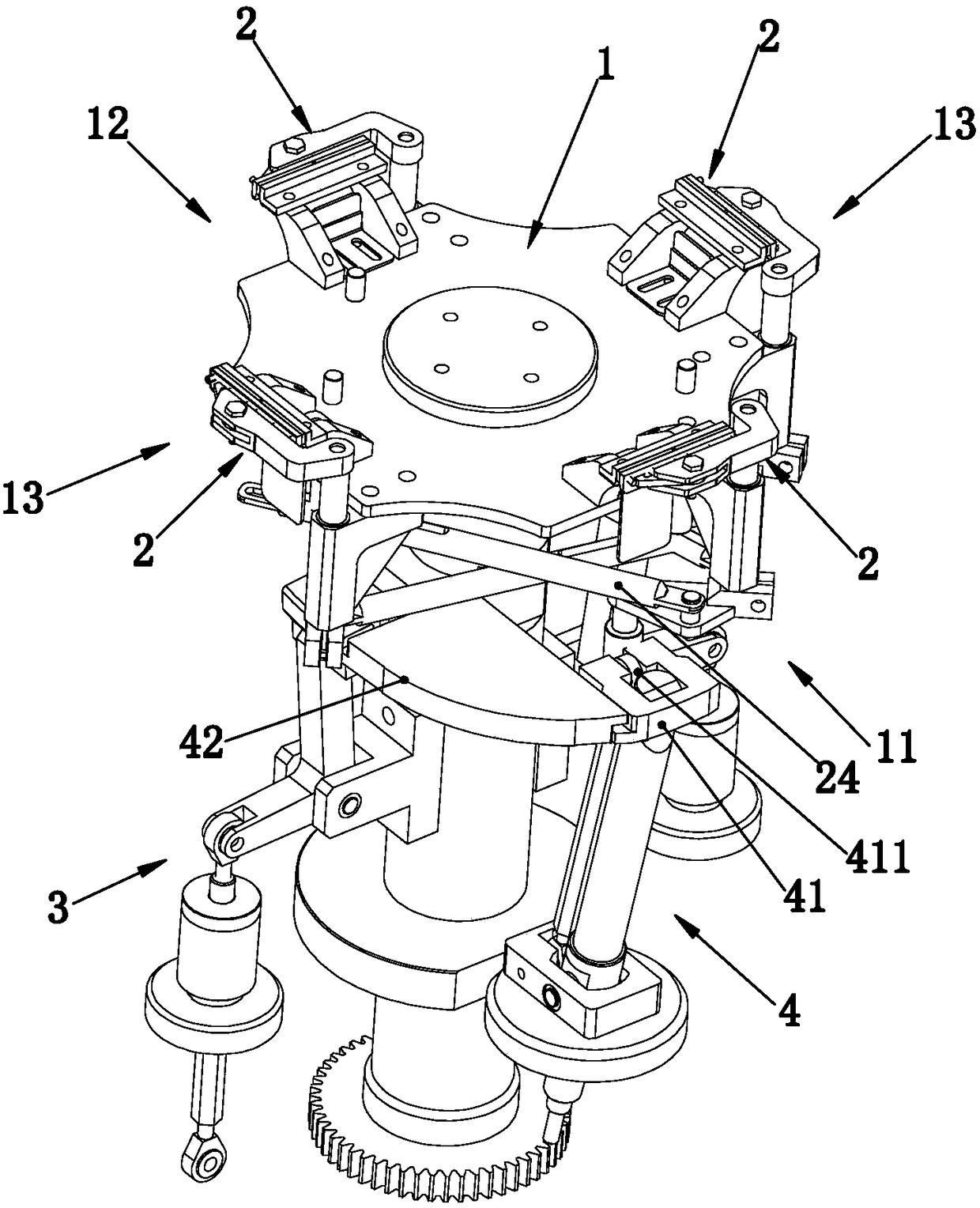

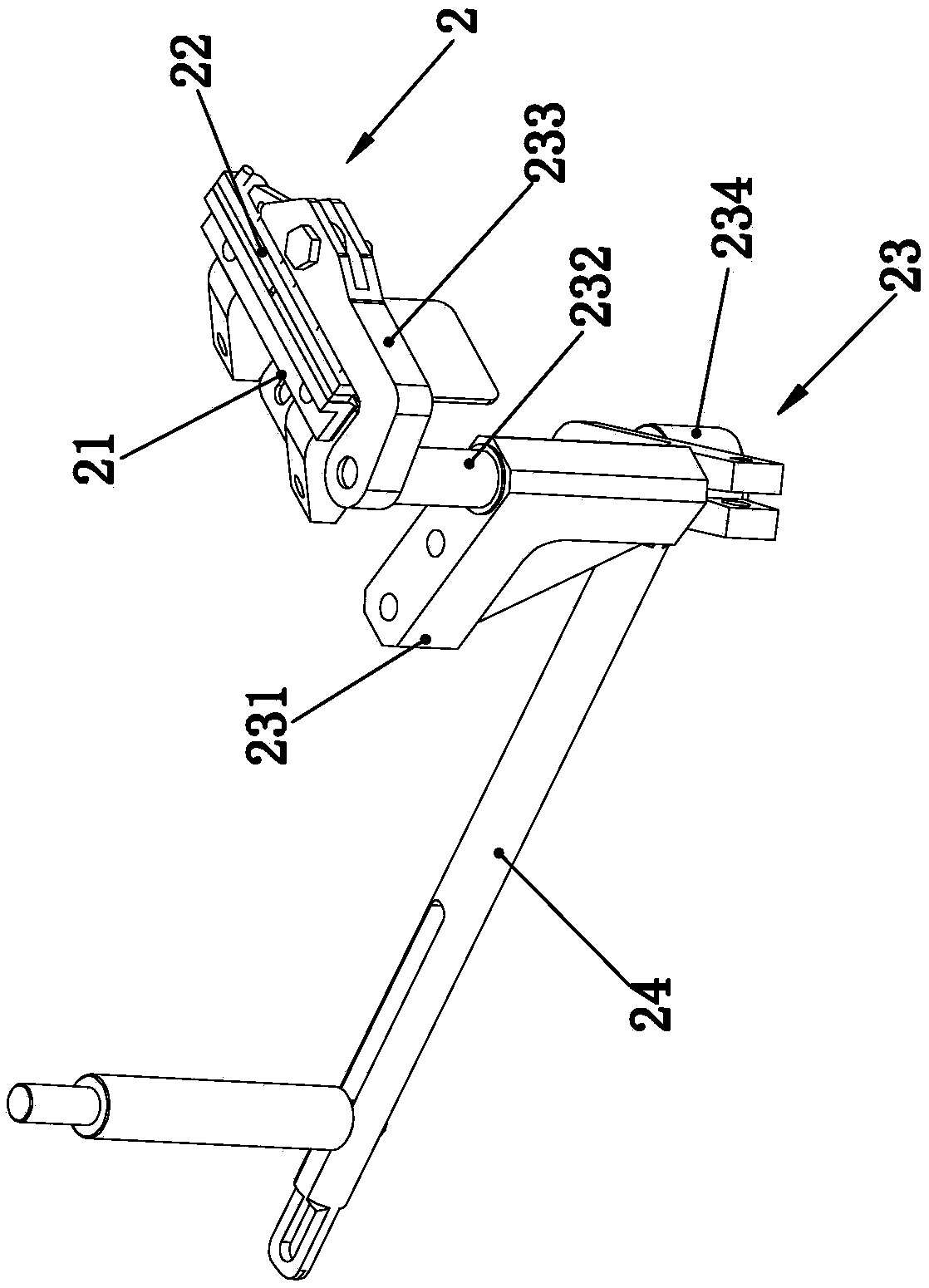

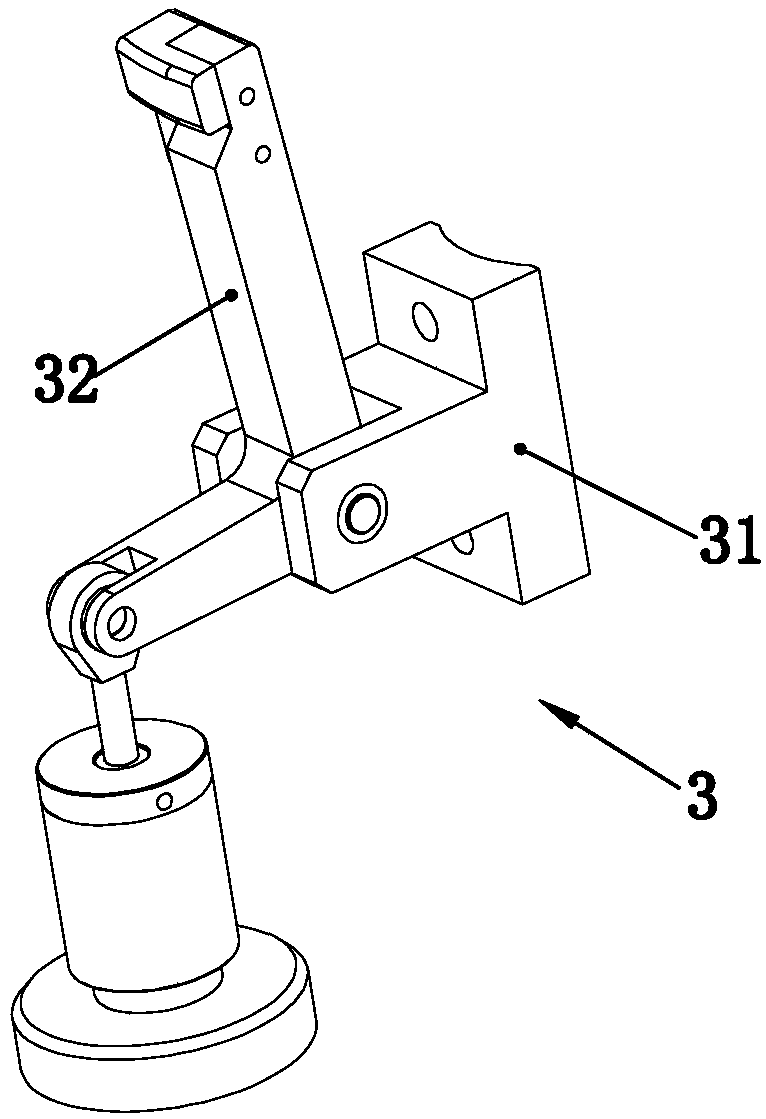

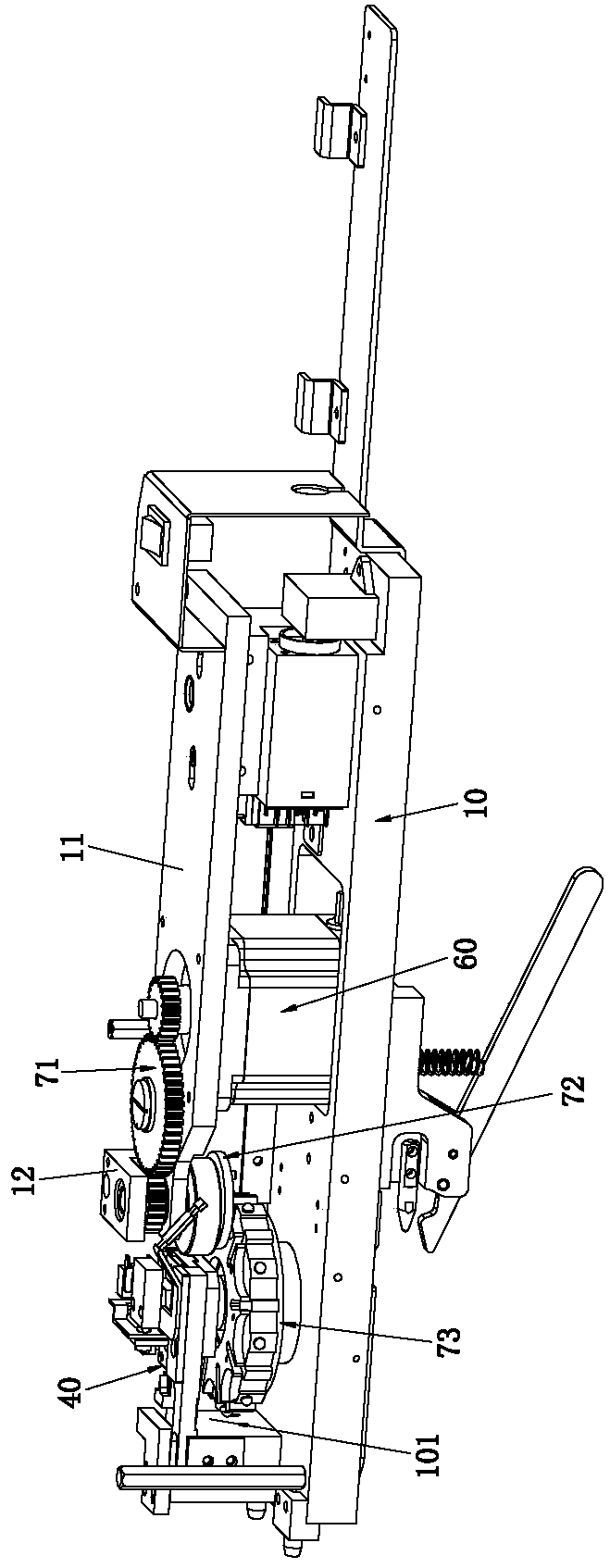

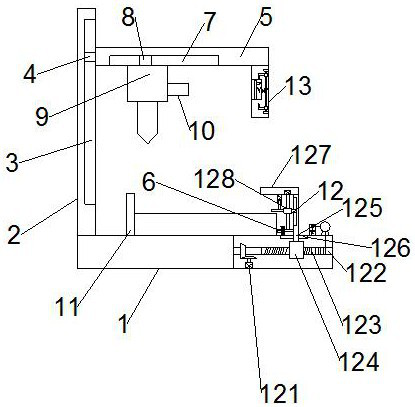

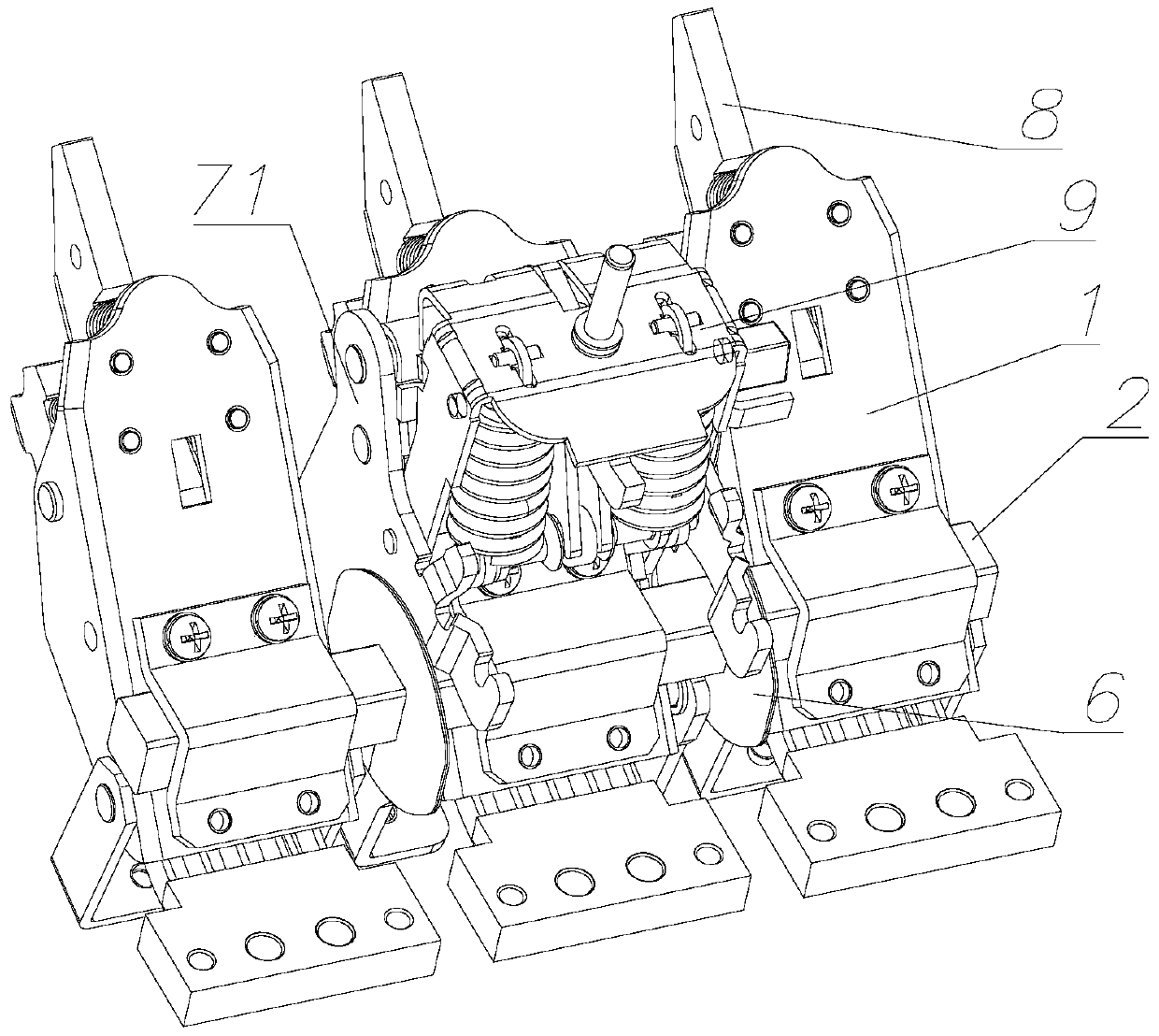

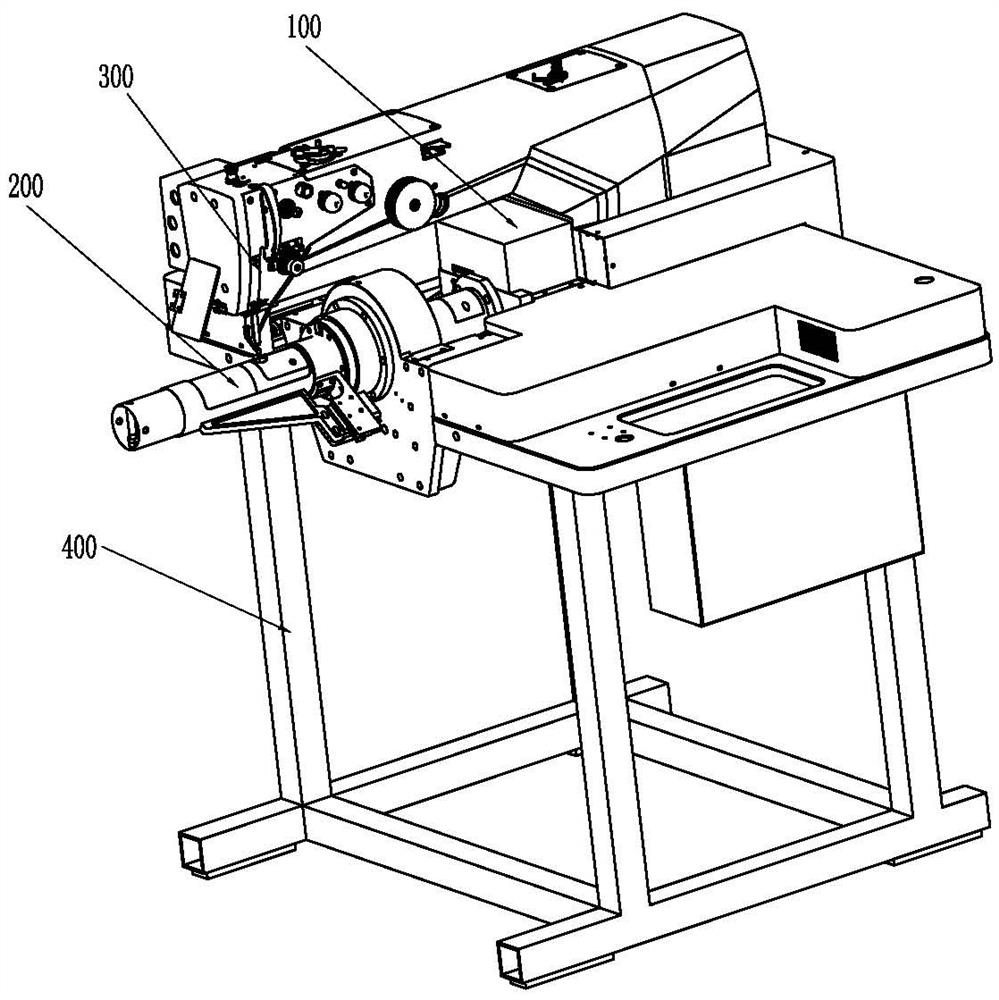

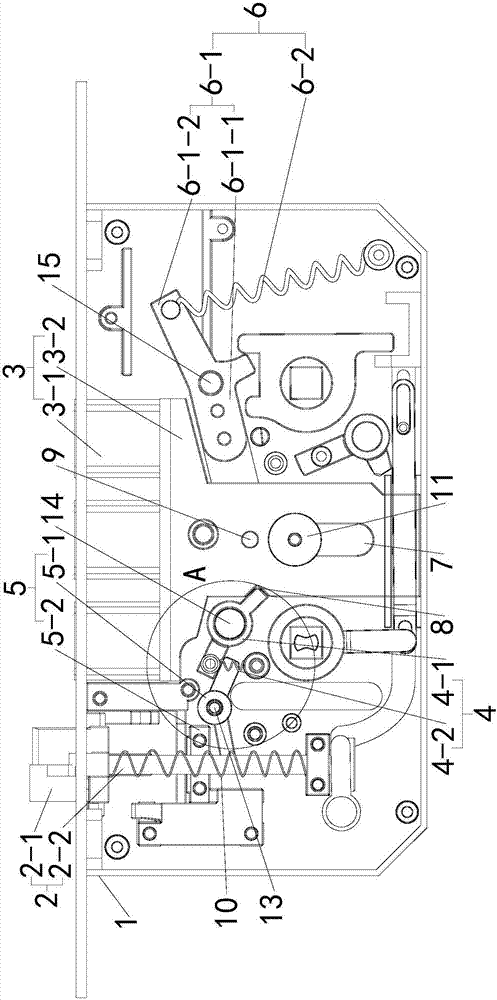

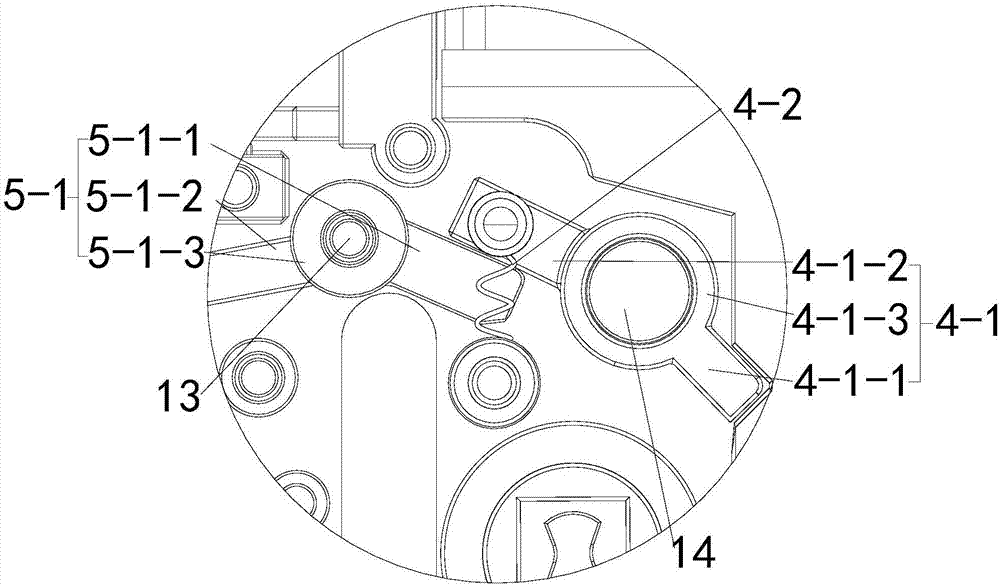

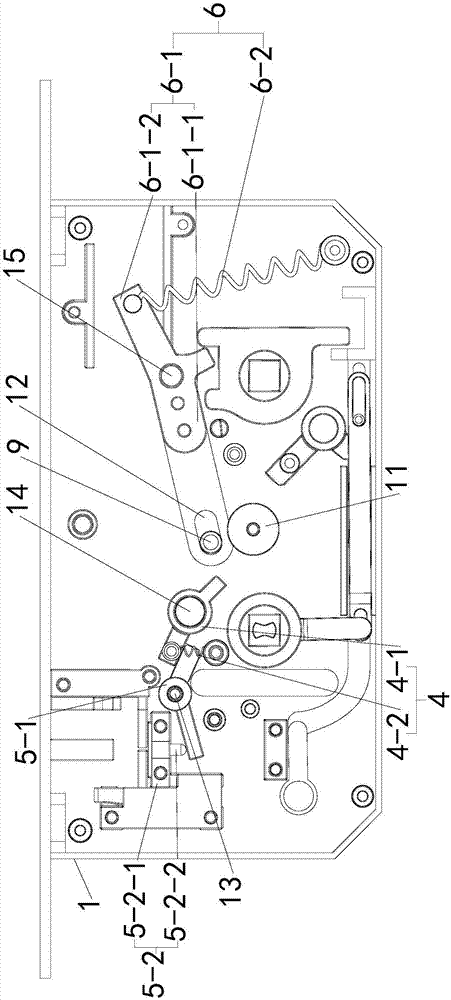

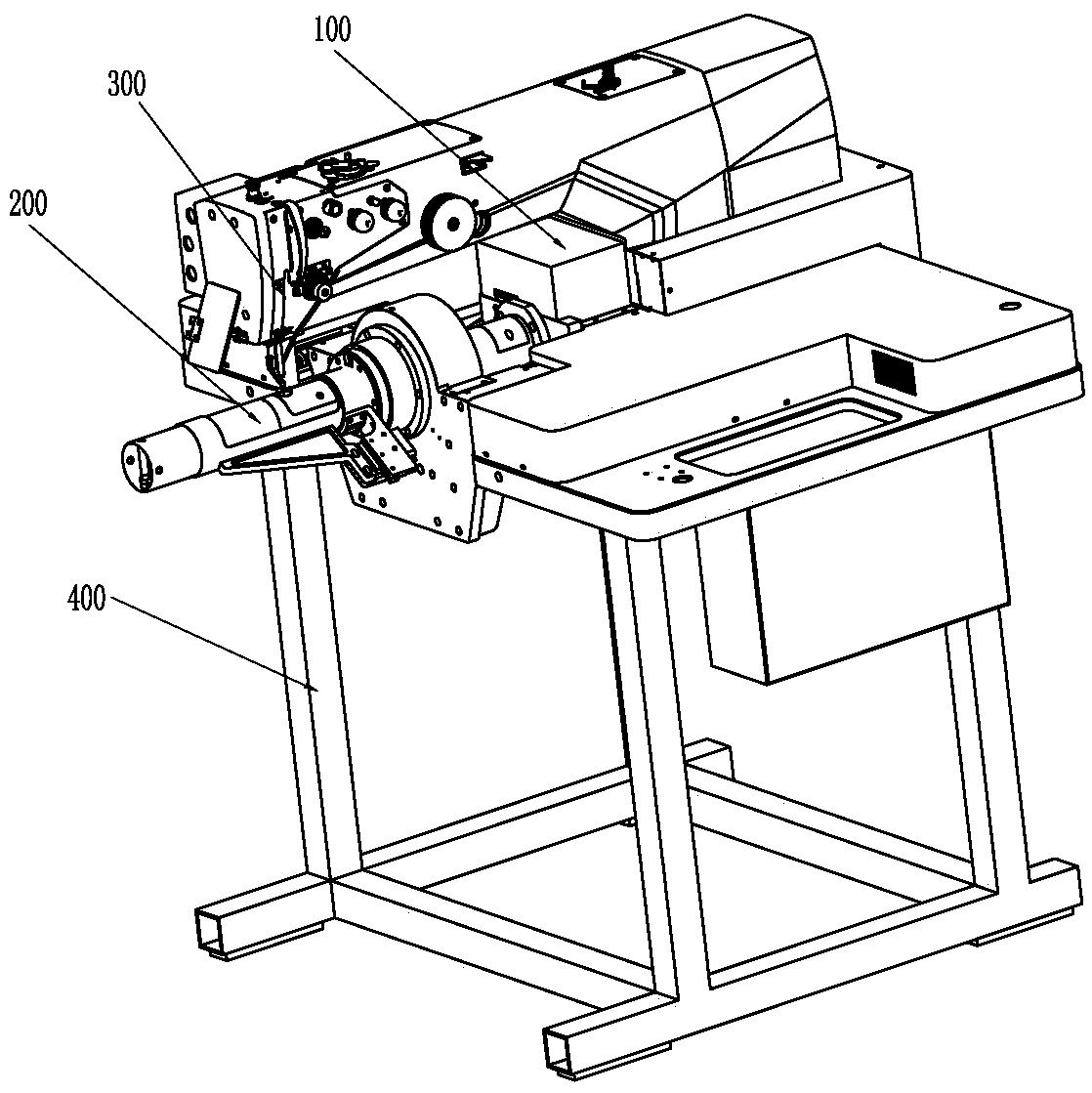

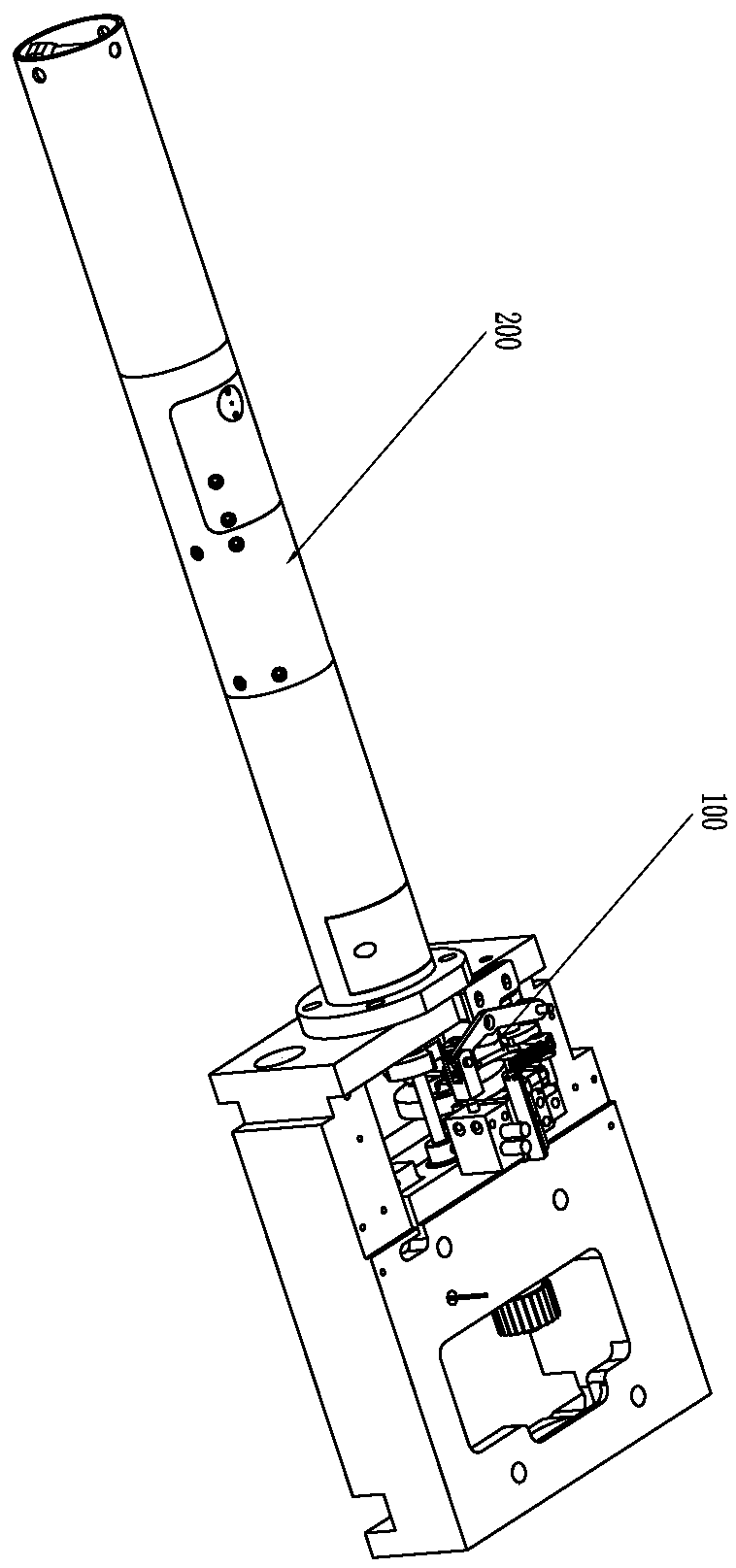

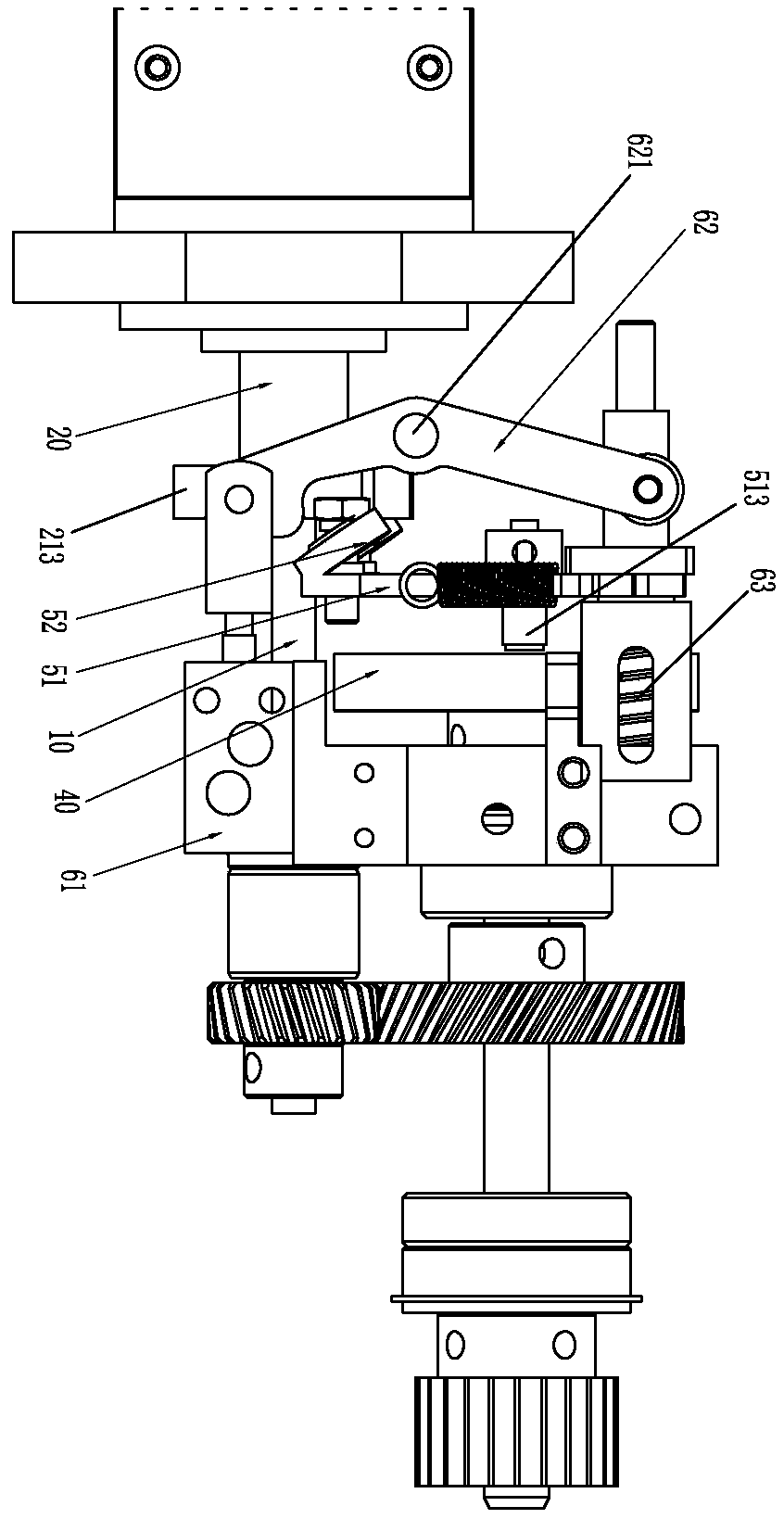

Full-automatic circuit breaker contact and silver point welding equipment

PendingCN108321037AFast transit deliveryShort transfer distanceEmergency protective device manufactureSolder feeding devicesEngineeringOutput device

The invention relates to full-automatic circuit breaker contact and silver point welding equipment. The full-automatic circuit breaker contact and silver point welding equipment comprises a machine body a rotation disc, a clamping device arranged along the edge of the rotation disc, a contact vibration charging tray, a contact drop soldering paste device, a silver point vibration charging tray, acontact and silver point welding device and a product output device. The contact vibration charging tray and the silver point vibration charging tray are connected to the clamping device through a transport channel. Conveying devices are arranged between the contact vibration charging tray and the contact drop soldering paste device and between the silver point vibration charging tray and the welding device. The welding device comprises a support seat erected on the machine body, a welding mechanism, a lifting component and a welding seat. The support seat is provided with a slide rail, wherein the welding seat carries out reciprocation slip on the slide rail. And the support seat is provided with a linkage component. In the technical scheme, the full-automatic circuit breaker contact andsilver point welding equipment is provided; and through using the equipment, welding efficiency is increased, a welding point is accurate, linkage performance is good, clamping is stable and the structure is simple.

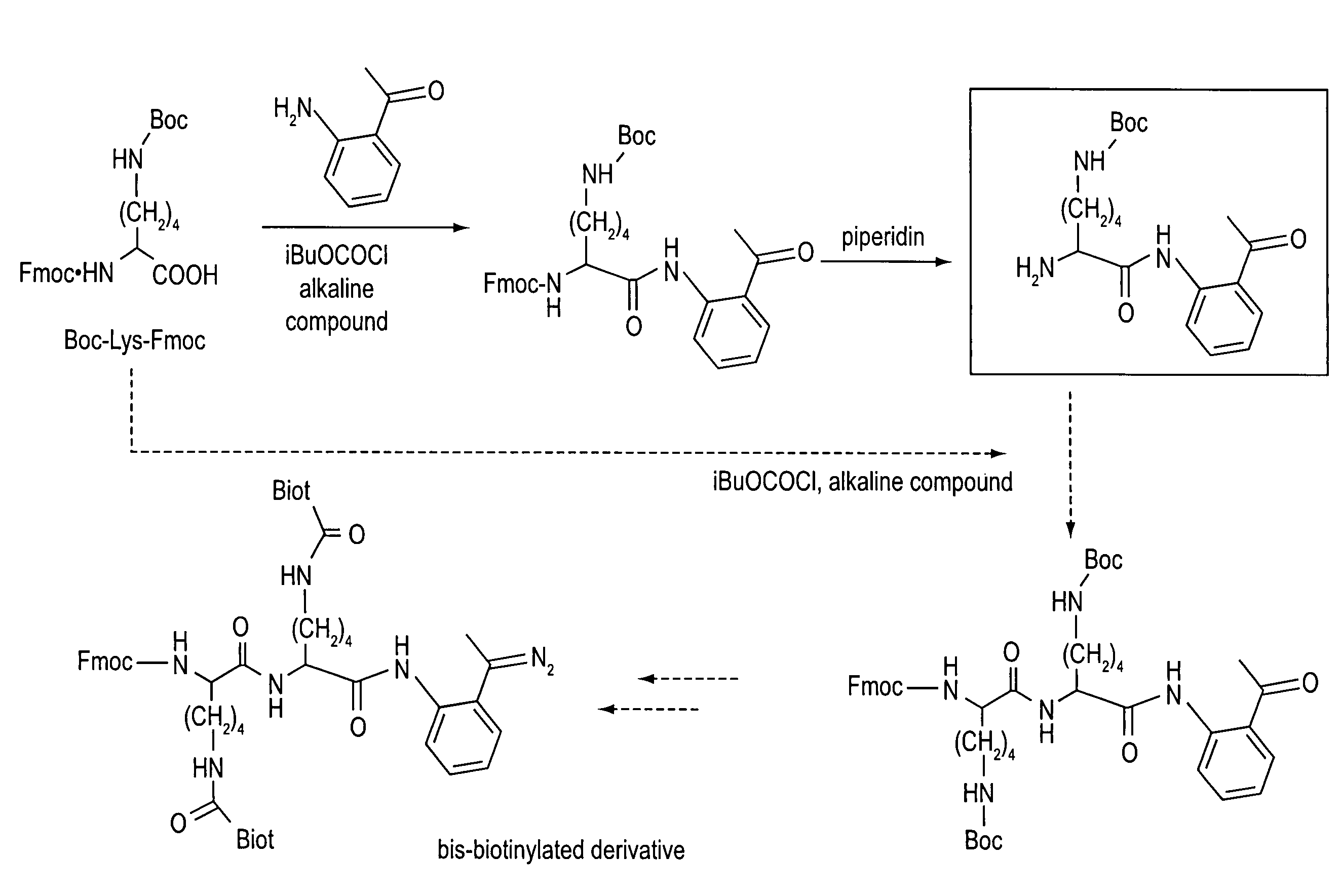

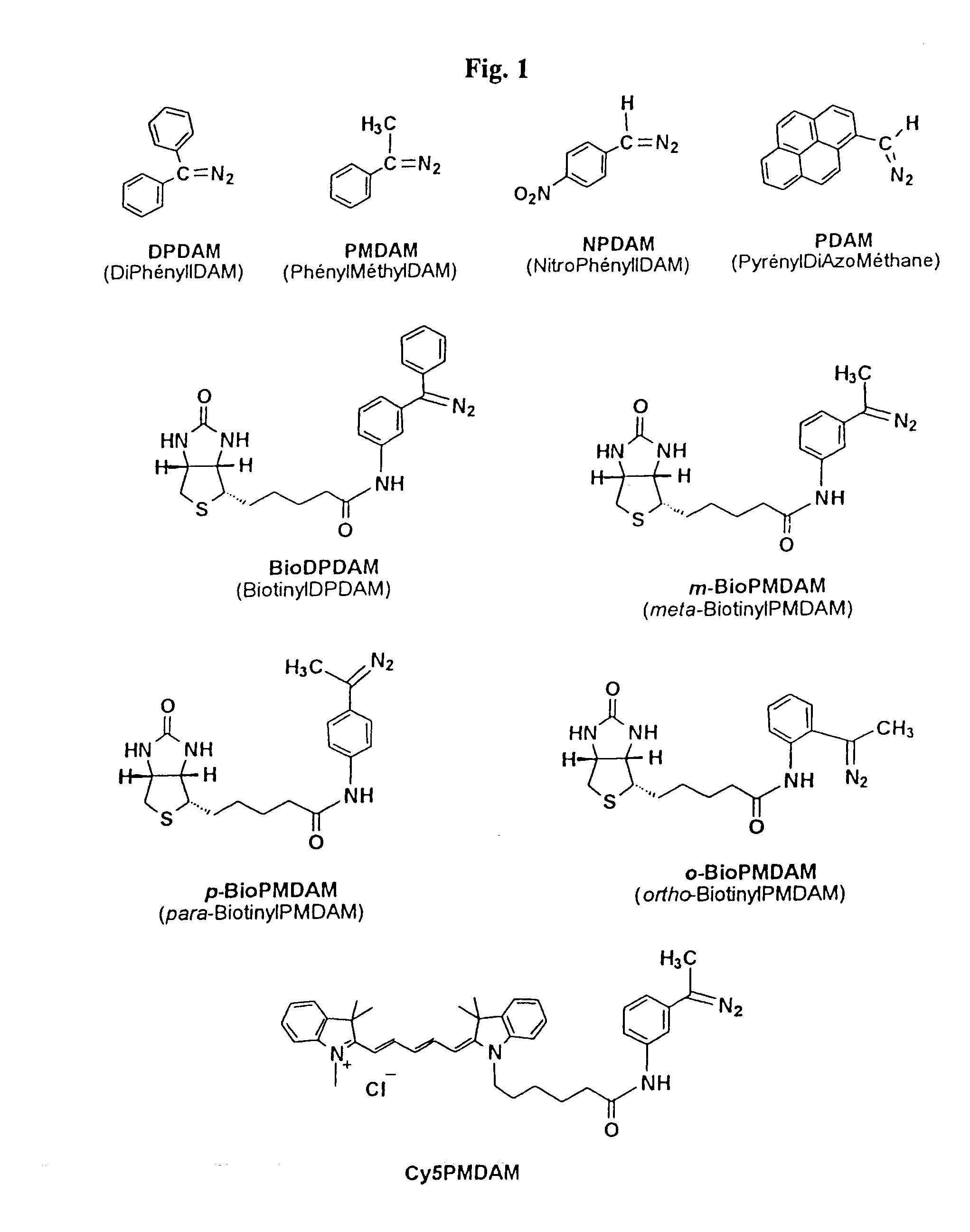

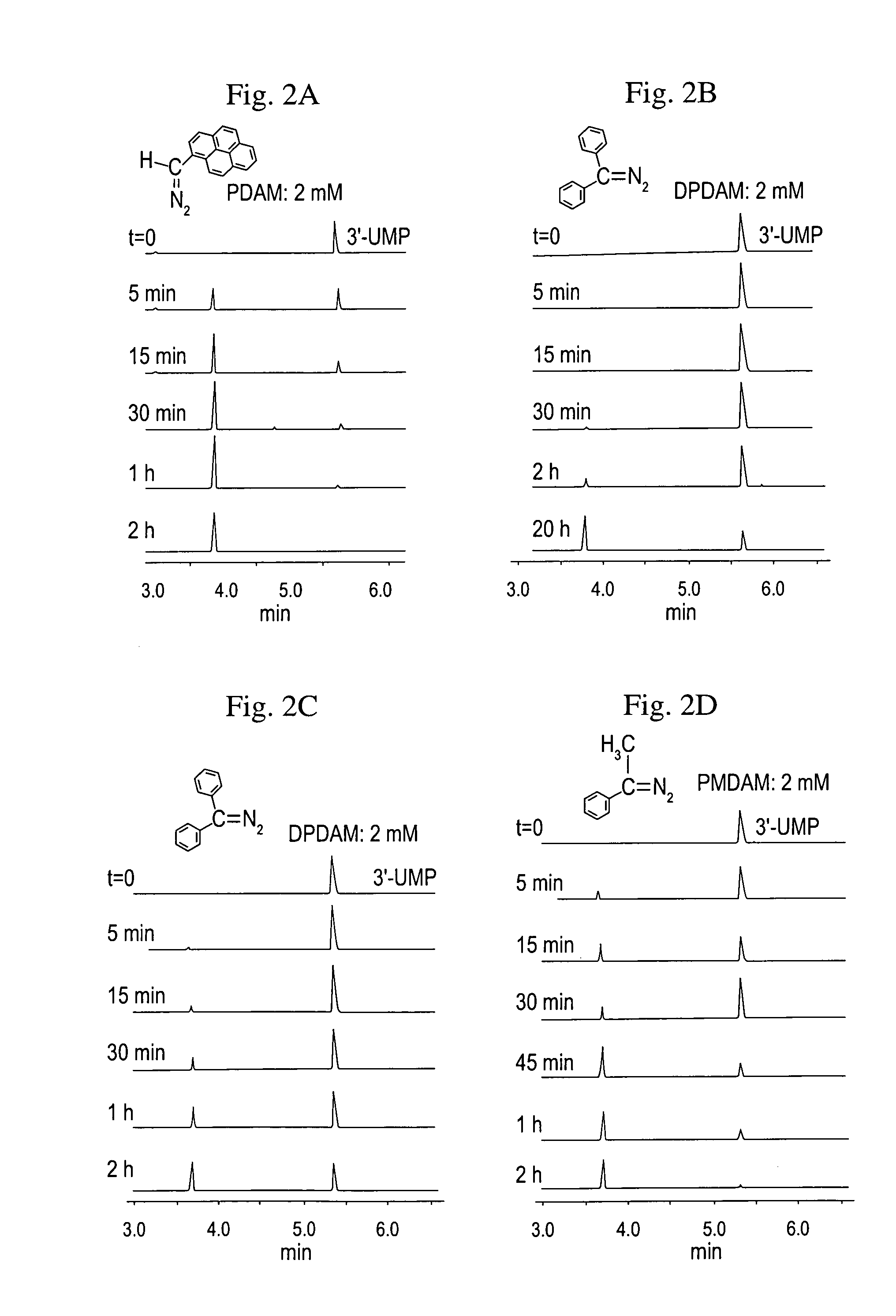

Labeling reagents, methods for synthesizing such reagents and methods for detecting biological molecules

InactiveUS7338805B2Improve solubilityGrafting is simpleSugar derivativesMicrobiological testing/measurementArylDouble bond

The present invention relates to a temperature-stable labeling reagent of formula:in whichR1 represents H or an alkyl, aryl or substituted aryl group,R2 represents a detectable marker or at least two detectable markers linked together by at least one multimeric structure,L is a linking arm containing a linear succession of at least two covalent bonds and n an integer equal to 0 or 1,R3 and R4 represent independently of each other: H, NO2, Cl, Br, F, I, R2-(L)n-Y—X—, OR, SR, NR2, R, NHCOR, CONHR, COOR with R=alkyl or aryl,A is a linking arm containing at least one covalent double bond allowing conjugation of the diazo functional group with the aromatic ring and u is an integer between 0 and 2, preferably equal to 0 or 1, and—Y—X— represents —CONH—, —NHCO—, —CH2O—, —CH2S—.The present invention also describes a method for synthesizing said markers as well as applications for labeling biological molecules, in particular nucleic acids, with a labeling reagent carrying the diazomethyl functional group.The invention finds a preferred application in the field of diagnosis.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Polyrotaxane and process for producing the same

A process for producing a polyrotaxane in a high yield and at a satisfactory cost without using a large excess of a pseudopolyrotaxane and / or without using a large excess of an activated reagent. The process for polyrotaxane production comprises: an inclusion step in which a carboxylated polyethylene glycol which is a polyethylene glycol carboxylated at each end is mixed with cyclodextrin molecules to obtain a pseudopolyrotaxane which comprises cyclodextrin molecules which include the carboxylated polyethylene glycol in their cavities as if the cyclodextrin molecules are spitted with the carboxylated polyethylene glycol; and a capping step in which the pseudopolyrotaxane is reacted with capping groups having —NH2 or —OH to obtain a polyrotaxane terminated at each end by a —CO—NH-(capping group) or —CO—O-(capping group).

Owner:THE UNIV OF TOKYO

Full-automatic shoe sole forming machine

PendingCN107538774AReduce scrap rateQuality improvementDomestic footwearEngineeringMechanical engineering

The invention relates to shoemaking equipment, and particularly relates to a full-automatic shoe sole forming machine. The full-automatic shoe sole forming machine adopts the technical scheme that thefull-automatic shoe sole forming machine comprises a machine body, a rotary table, a forming injection molding station, a mold shackle opening station and a mold opening station, wherein the rotary table is arranged on the machine body, a plurality of shoe sole injection molds are uniformly distributed on the machine body, the forming injection molding station, the mold shackle opening station and the mold opening station are arranged on the outer circumferential surface of the rotary table in sequence, an injection head mechanism is arranged at the forming injection molding station, a mold shackle opening mechanism is arranged at the mold shackle opening station, a mold opening mechanism is arranged at the mold opening station, the mold shackle opening mechanism comprises a driving source erected on the machine body and a top plate, and the mold opening mechanism comprises an avoidance block erected at the edge of the rotary table, a pressing assembly arranged at the avoidance blockand a linked mold opening assembly which is arranged at the rotary table and is used for opening mold covers and frame bodies in shoe sole injection molds in sequence. By adopting the technical scheme, the full-automatic shoe sole forming machine which has the advantages of good mold opening linkage, no damage to products, elimination of potential safety hazards and simple structure is provided.

Owner:WENZHOU BENLONG MACHINERY

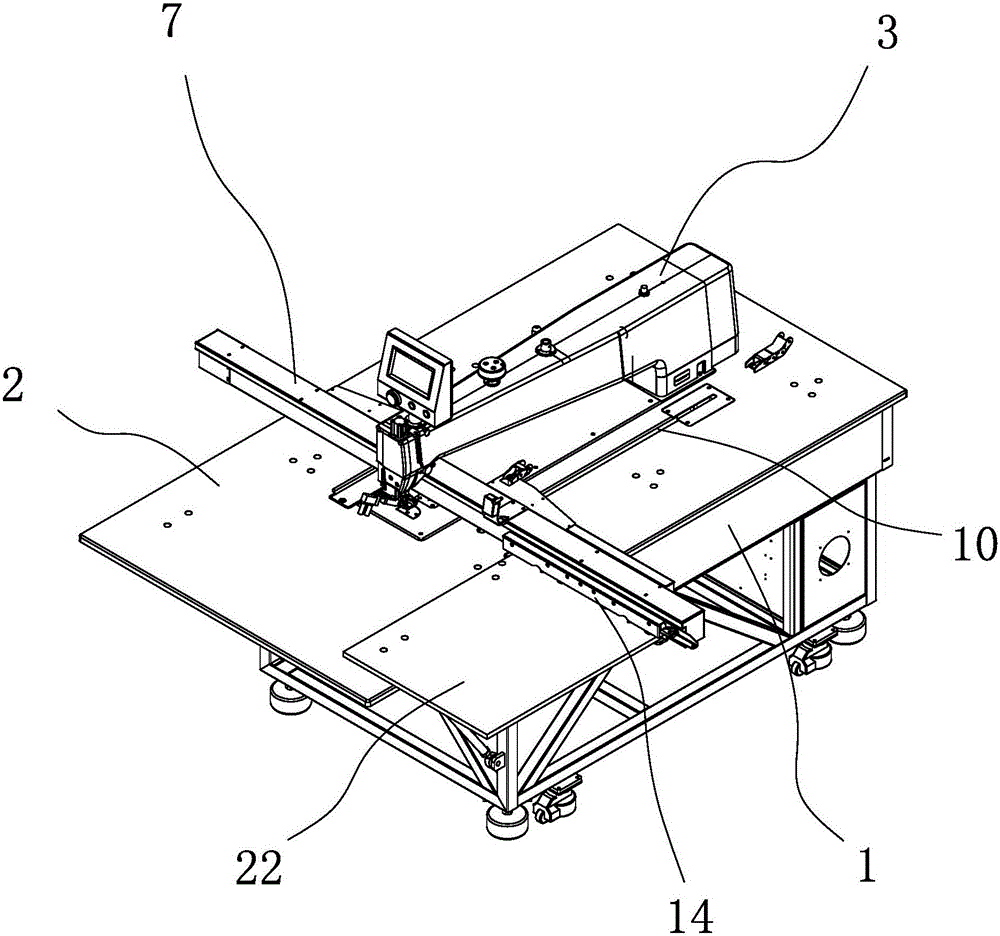

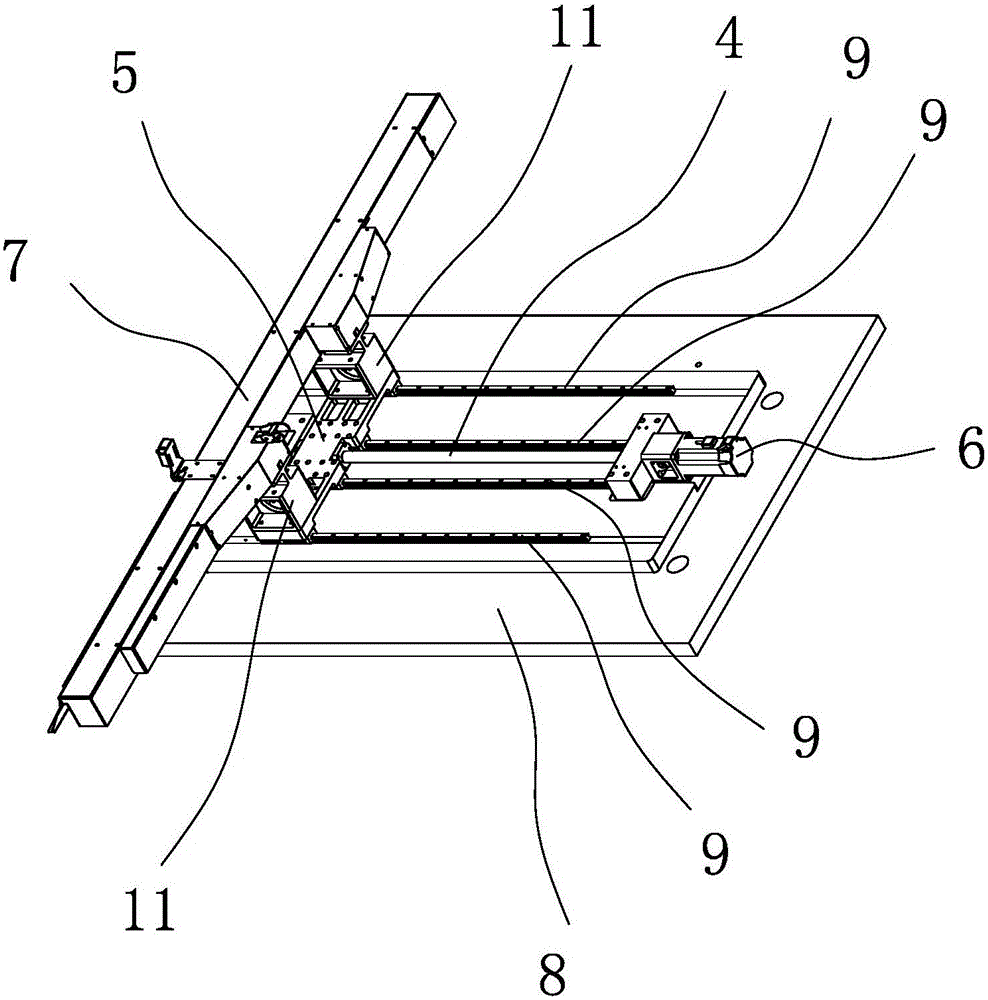

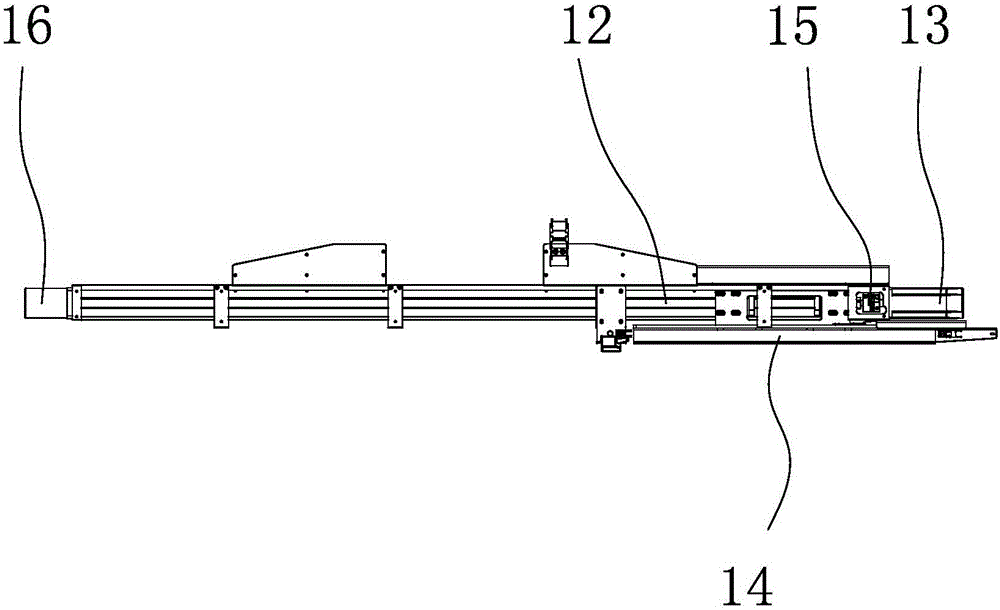

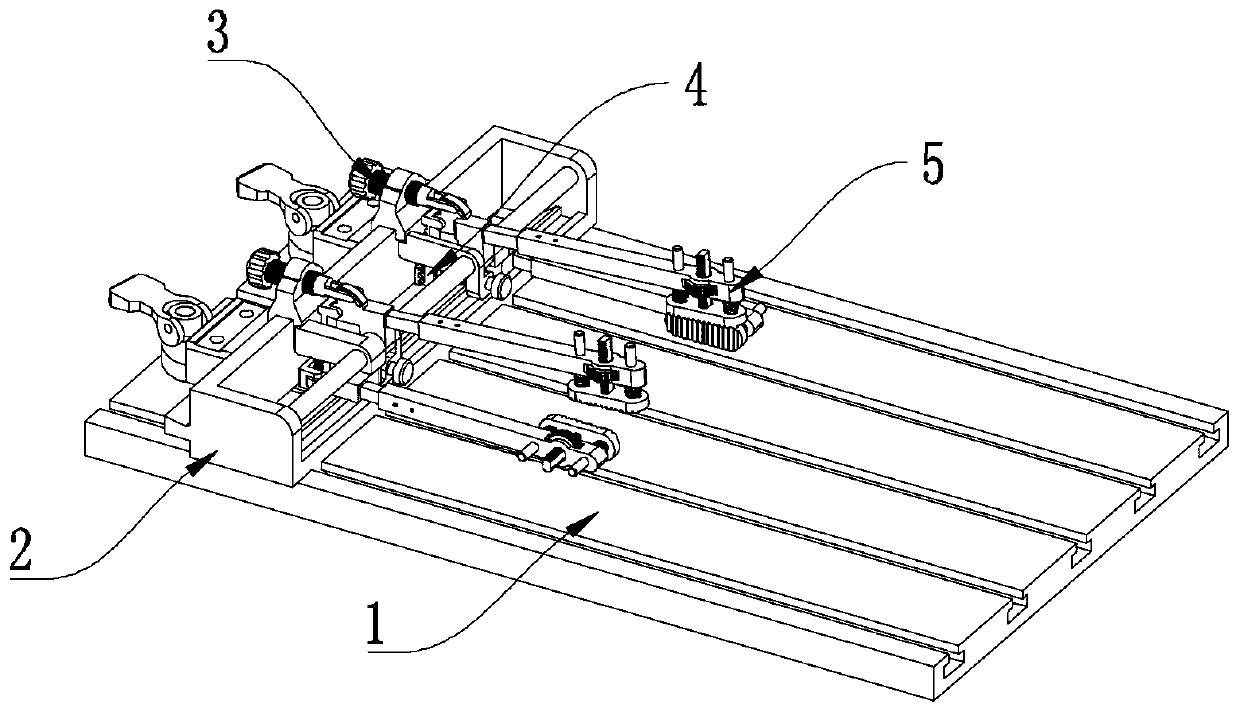

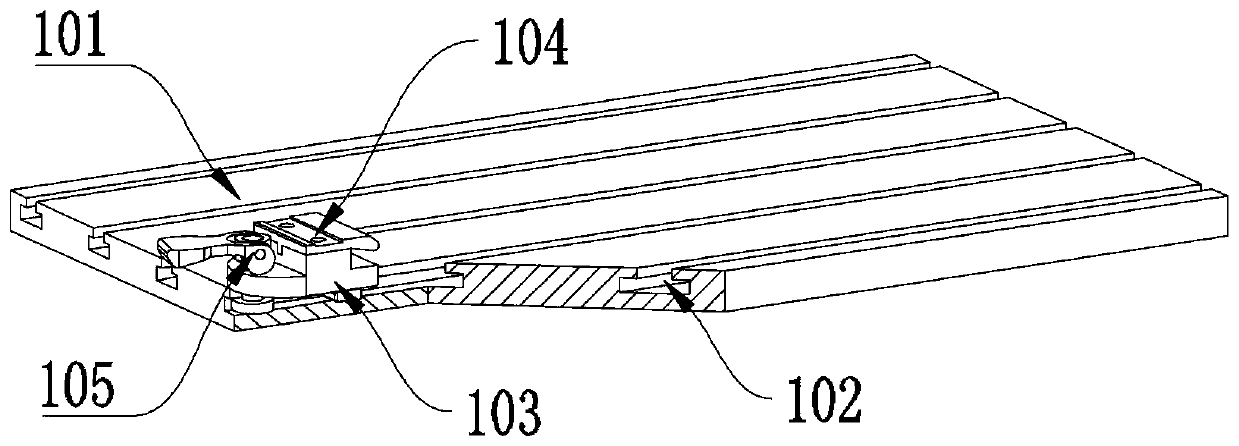

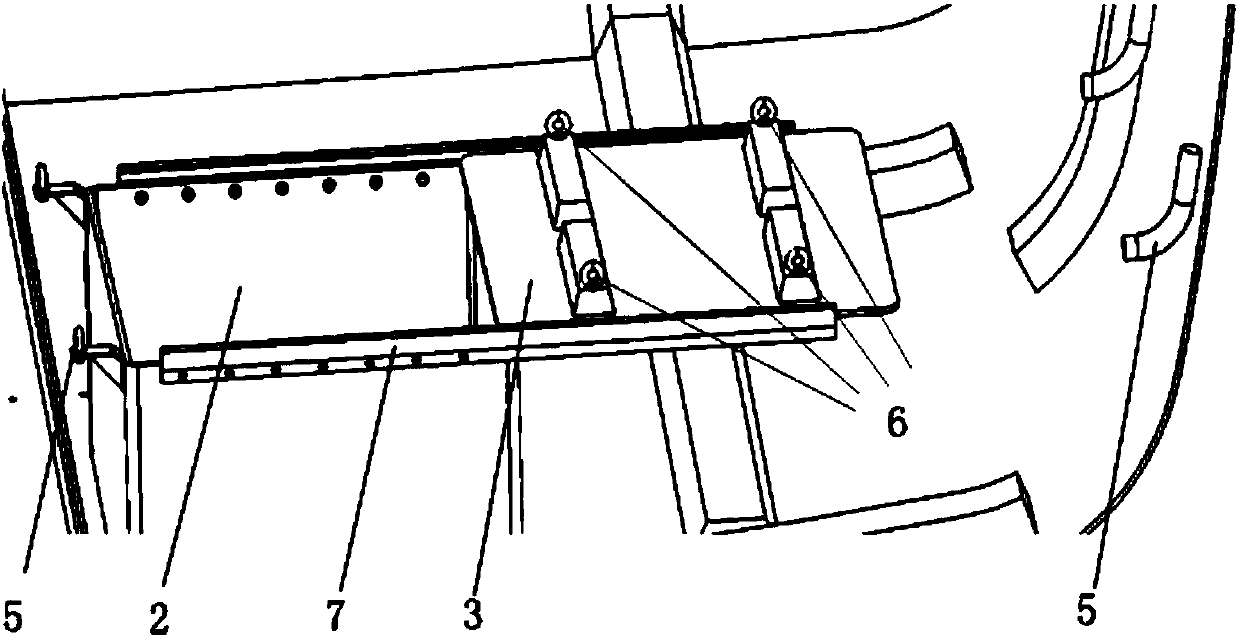

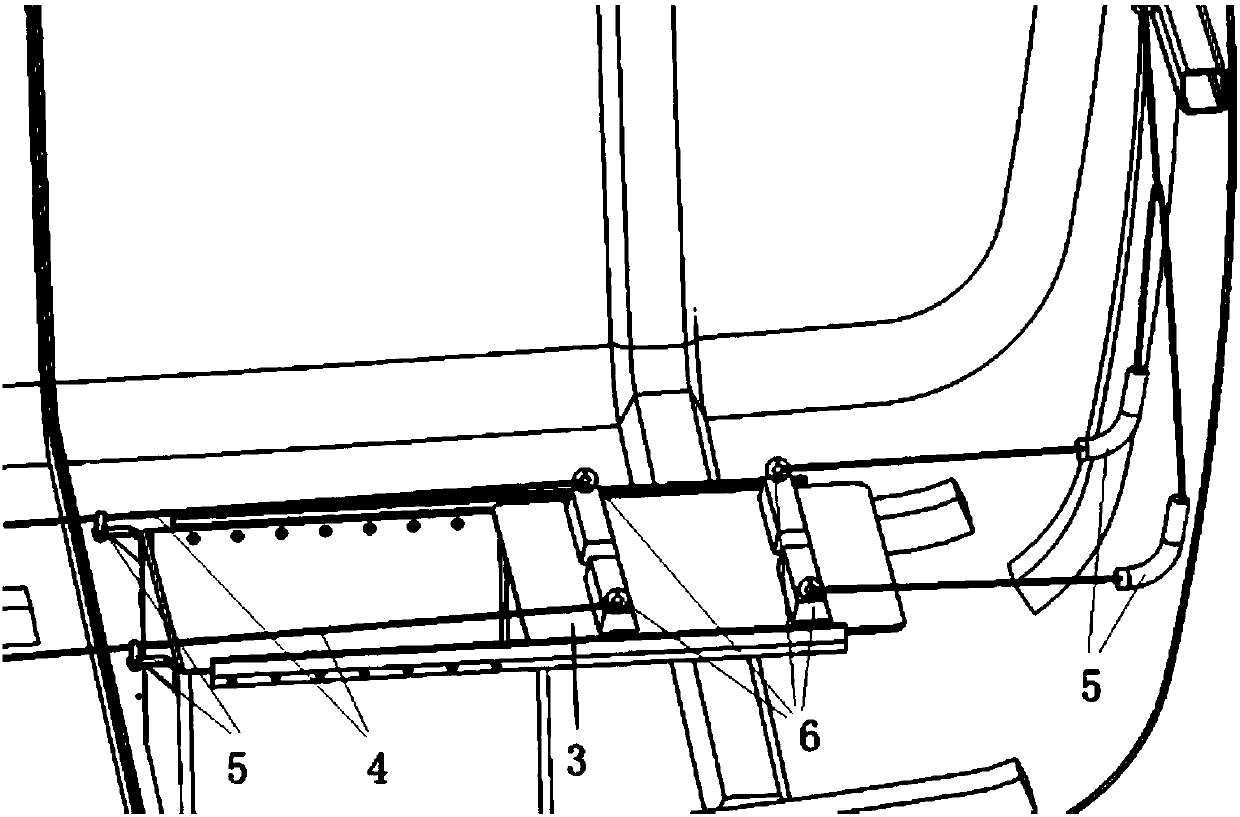

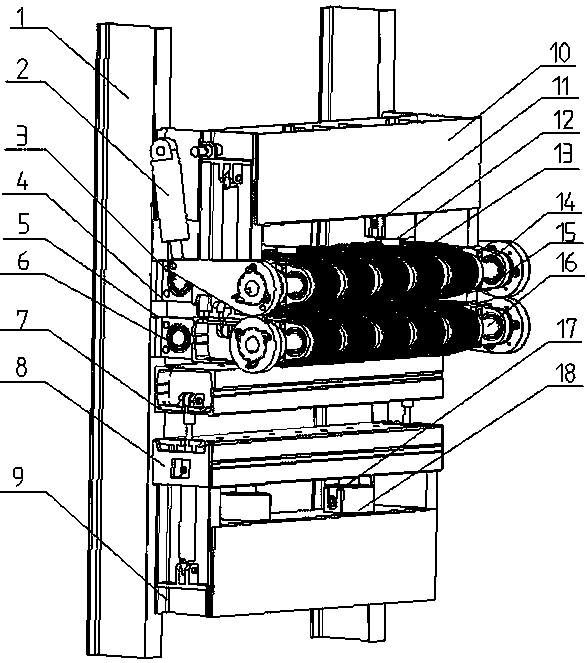

Template sewing machine

InactiveCN105862264AEasy to moveLinkage stabilityWork-feeding meansSewing-machine control devicesElectric machineryScrew joint

The invention relates to a template sewing machine, and belongs to the technical field of sewing machines. In order to solve the technical problem of how to narrow the area of a table top of the template sewing machine if required, the invention provides the template sewing machine, comprising a machine frame, a working table and a sewing machine body, wherein the working table is laid on the machine frame, and a machine head of the sewing machine body is located above the working table. The template sewing machine further comprises a transmission mechanism and a transmission rail, wherein the transmission mechanism is configured to drive a template to do back-and-forth translation along a Y direction, the transmission rail is configured to drive the template to do left-and-right translation along an X direction, the transmission mechanism is connected to the machine frame, and is located below the working table, the transmission mechanism comprises a screw rod I, a transmission bracket and a motor I, the motor I is configured to drive the screw rod I to rotate, the screw rod I is arranged along the Y direction, the transmission bracket is connected to the screw rod I in a screw joint manner, and can move in a reciprocating manner along the length direction of the screw rod I, and the transmission rail is fixedly connected to the transmission bracket, and is located above the working table. The template sewing machine according to the invention has the effects of a small table area and good stationarity.

Owner:FEIYUE ZHONGKE TAIZHOU NUMERICAL CONTROL SYSTCO

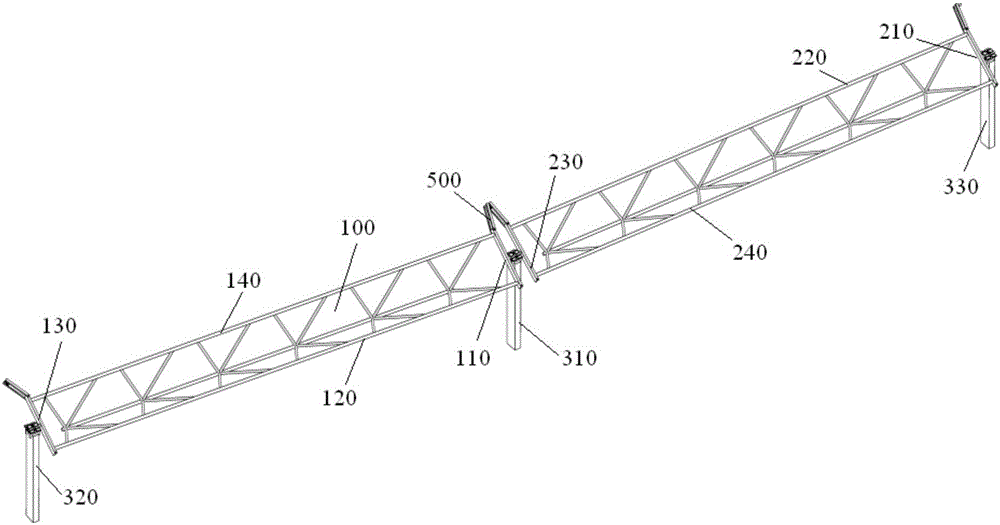

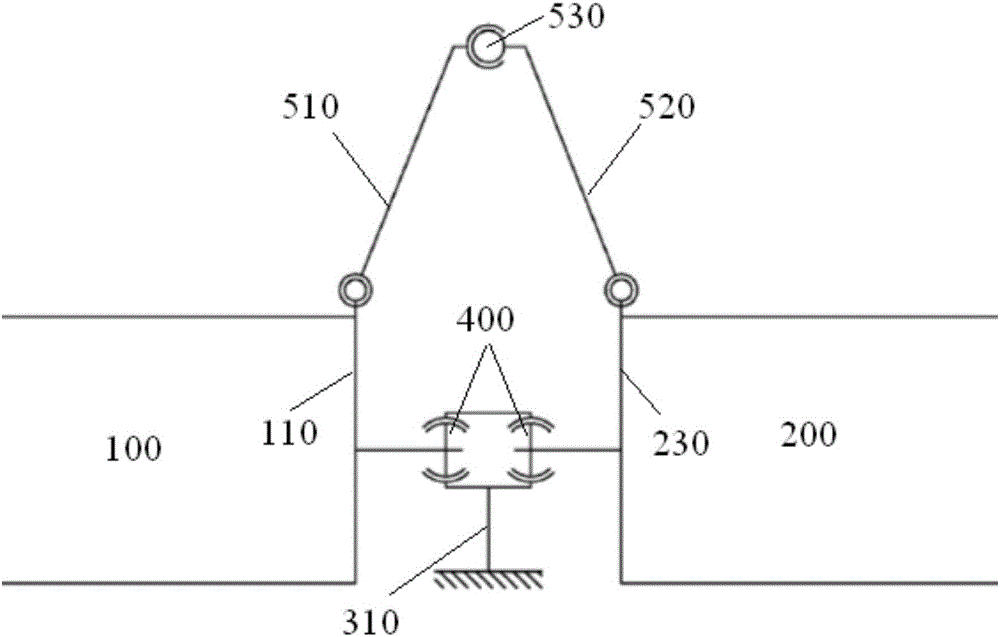

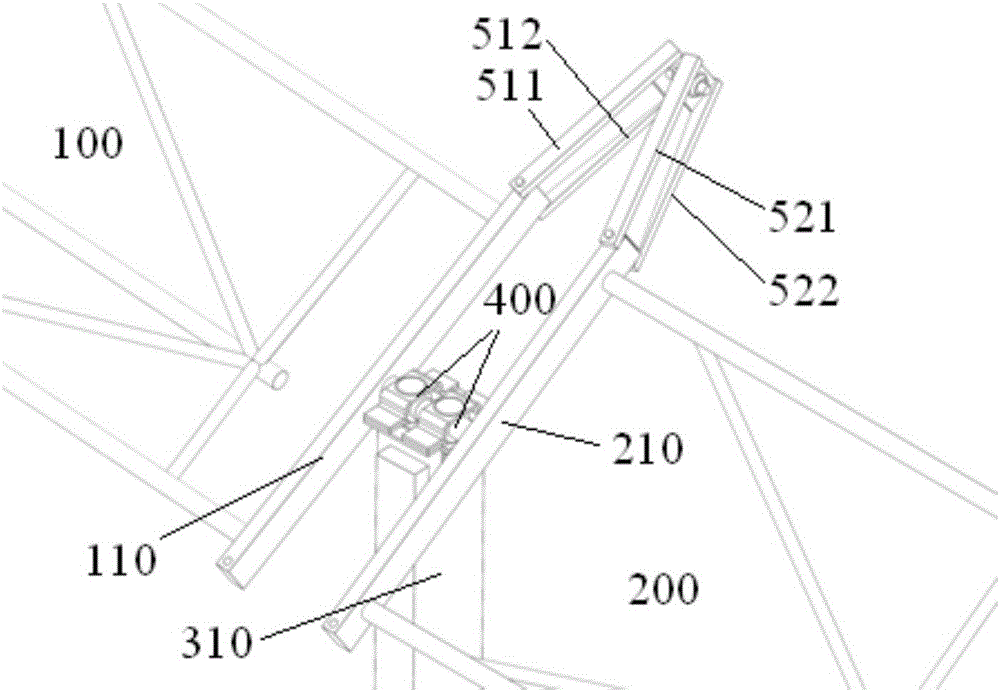

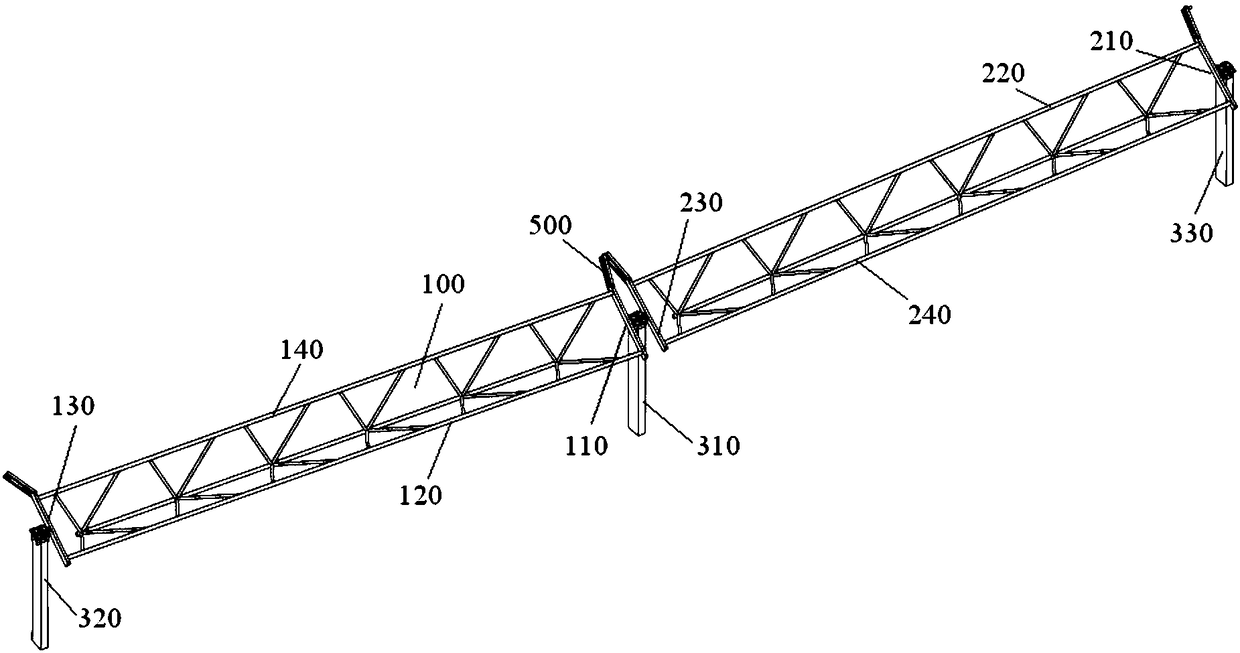

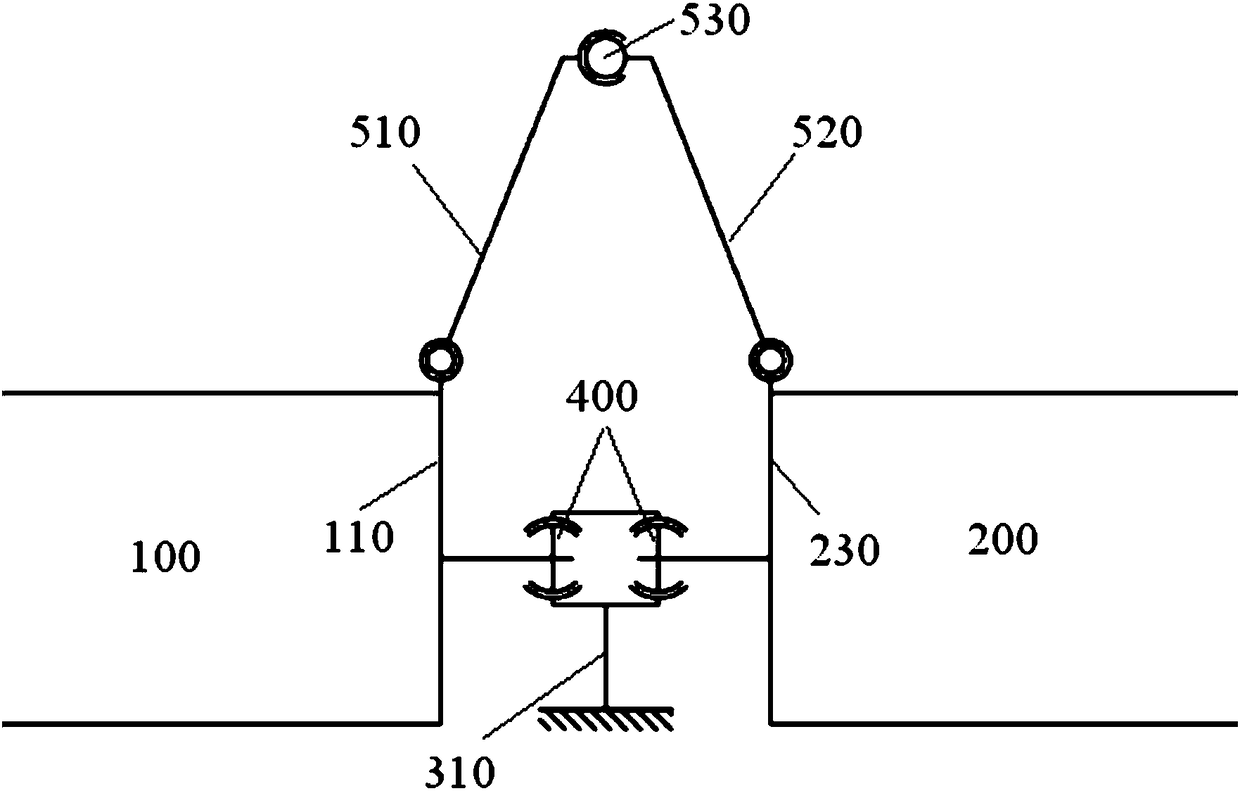

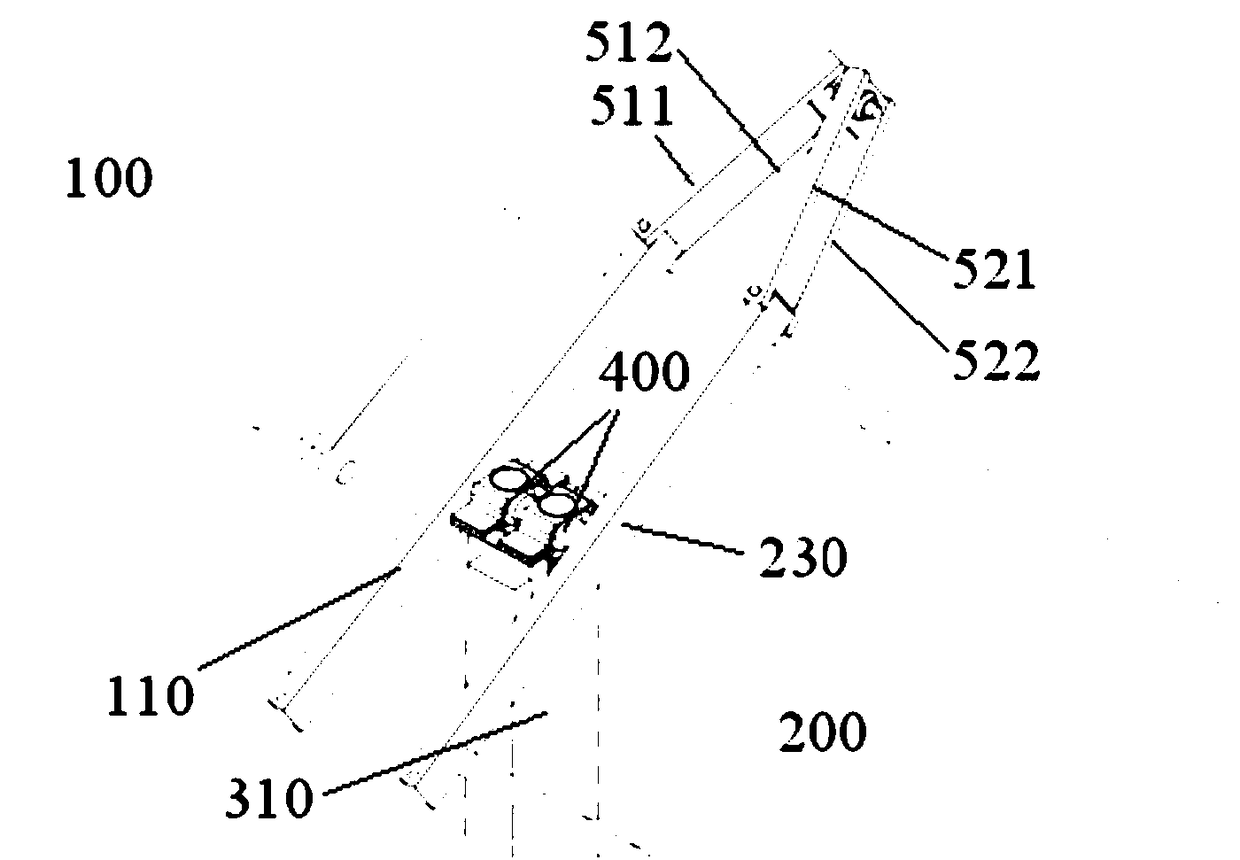

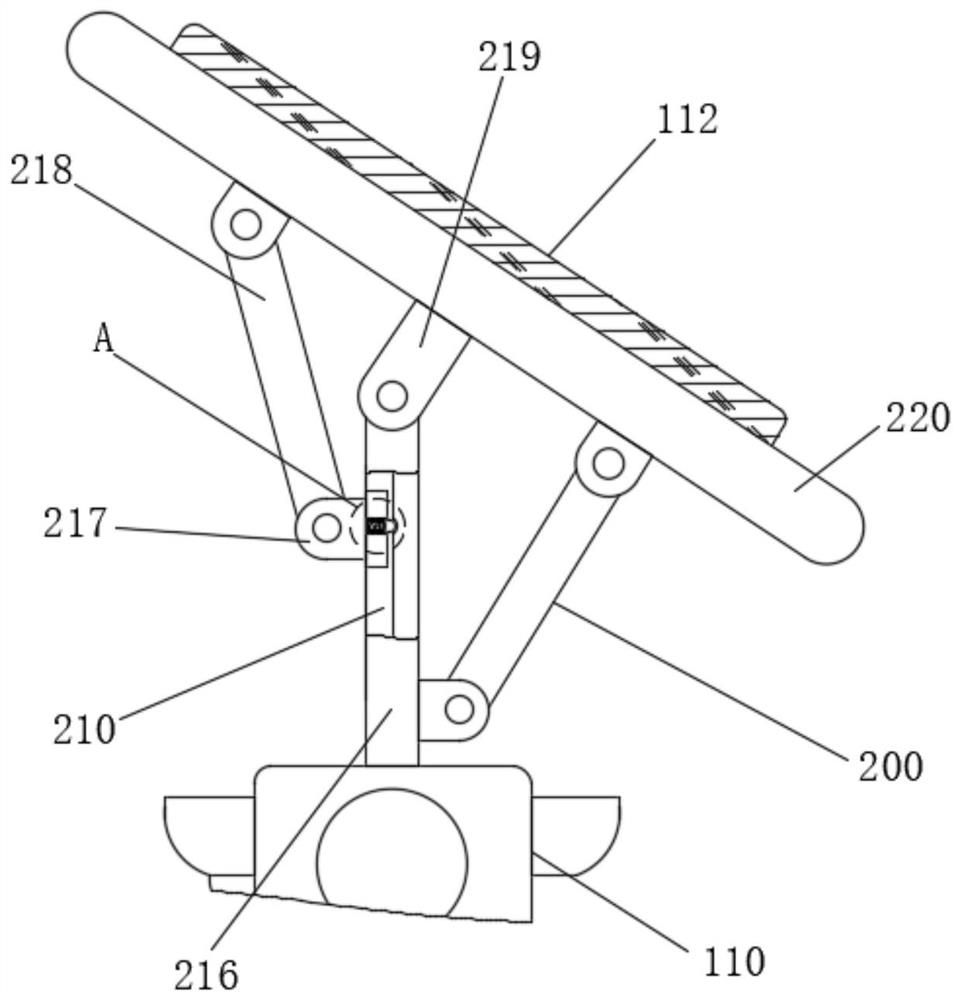

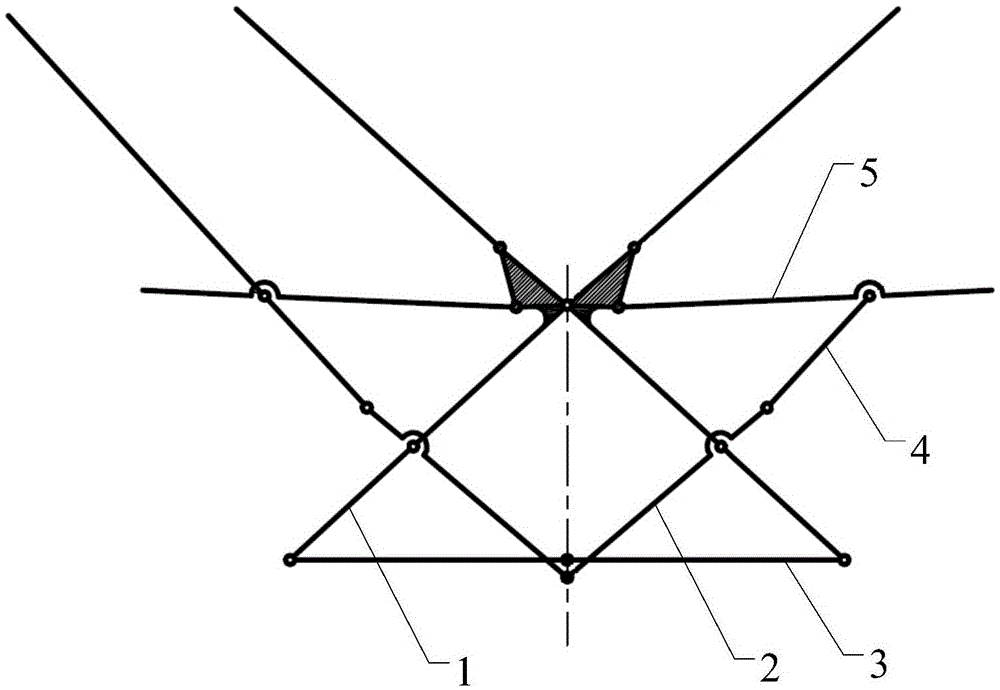

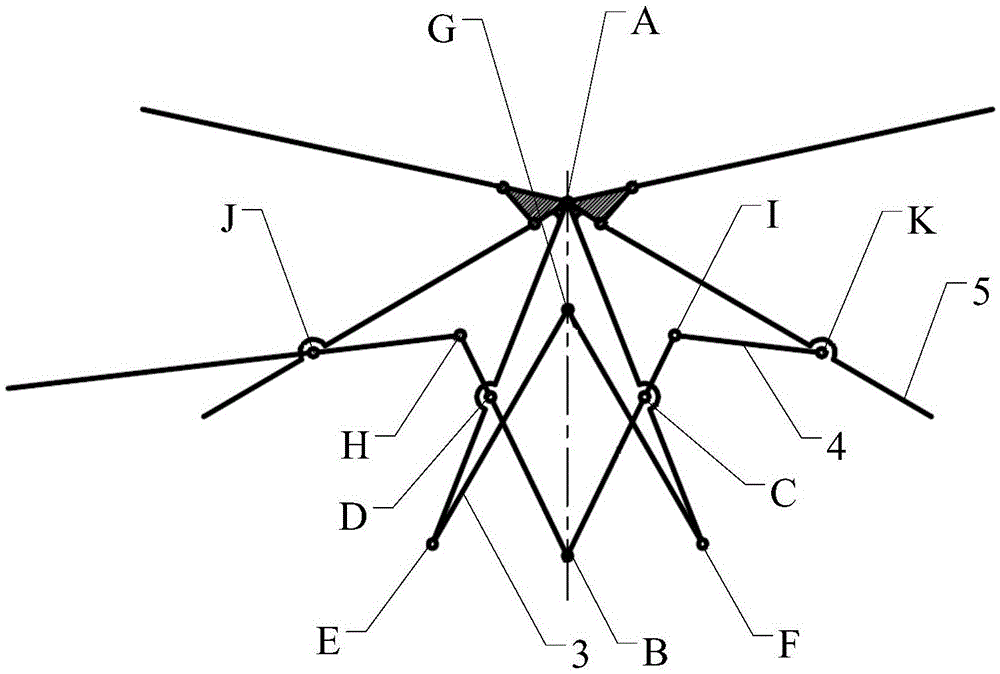

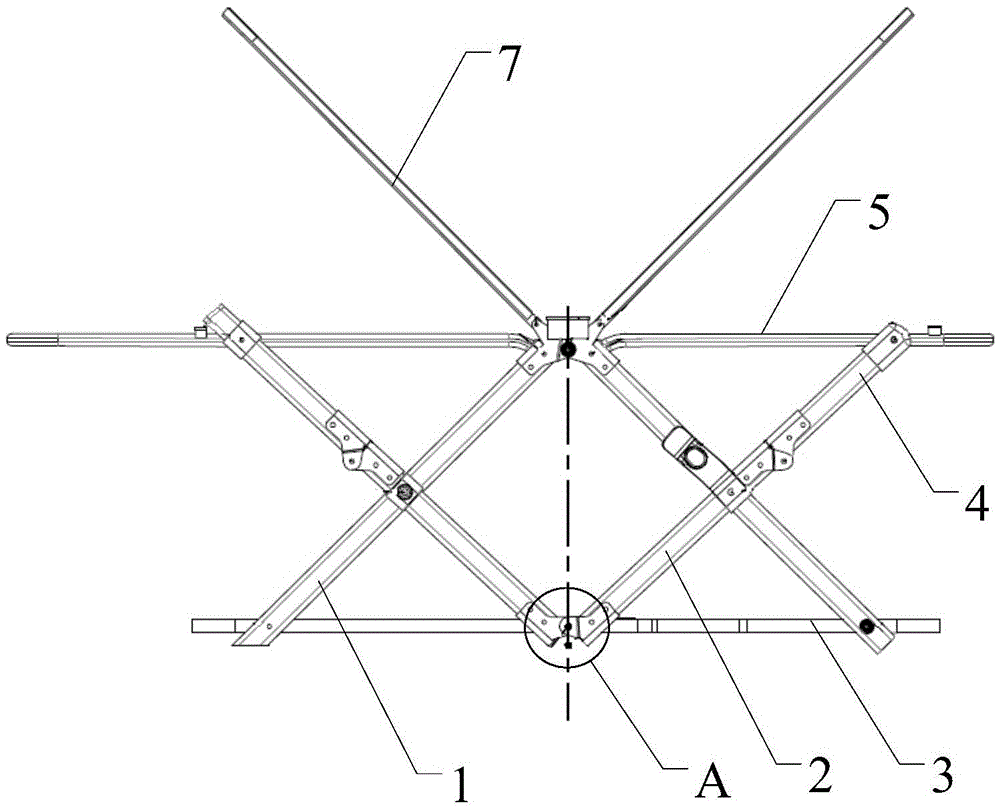

Solar tracking system

ActiveCN106788180AImplement trackingGuaranteed power generationPhotovoltaic supportsSolar heating energySolar powerSolar tracking system

The invention discloses a solar tracking system which comprises at least two main beams and a plurality of bases. The main beams are used for mounting solar photovoltaic panels, the bases are used for mounting the main beams, and two ends of each main beam are respectively connected the corresponding bases by first universal connectors; the adjacent main beams are connected with one another by connecting rod assemblies, and the connecting rod assemblies are used for transmitting rotational movement of the adjacent solar photovoltaic panels. The first universal connectors comprise first spheres and first spherical hinged supports, the first spheres are fixedly connected with the main beams, the first spherical hinged supports are fixedly arranged on the bases, and the first spheres are positioned in the first spherical hinged supports to form first spherical hinges. The solar tracking system has the advantages that the main beams can be in linkage with one another by the aid of the connecting rod assemblies even if the central axes of the adjacent main beams are not positioned on the same plane, accordingly, the multiple main beams can be driven by a driving device to rotate in uneven regions, the sun can be tracked by the solar photovoltaic panels, and the power generation of solar power generation systems can be effectively guaranteed.

Owner:ARCTECH SOLAR HLDG CO LTD

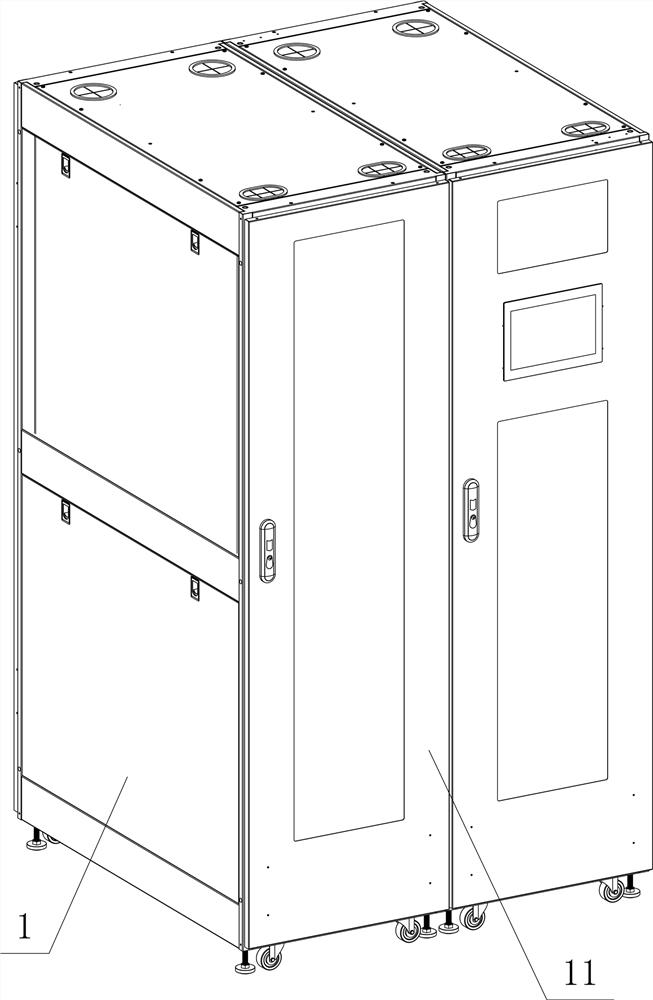

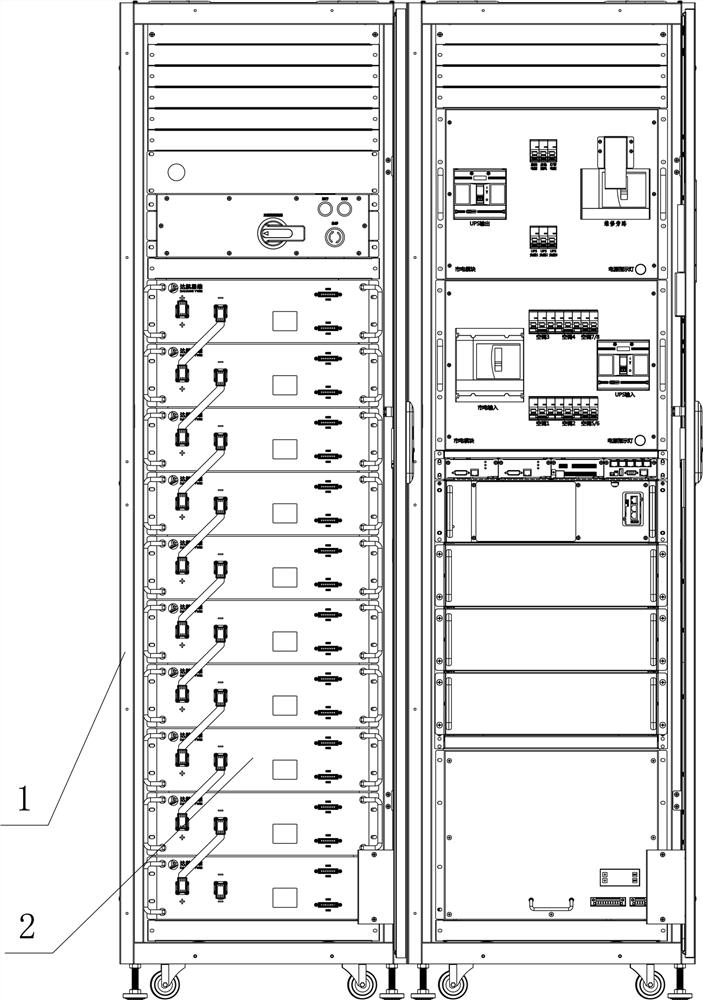

Integrated lithium battery power supply cabinet

ActiveCN114696236AImprove securityImprove the safety of useBatteries circuit arrangementsSubstation/switching arrangement cooling/ventilationElectrical batteryFire safety

The invention provides an integrated lithium battery power supply cabinet, which comprises a cabinet body, and a plurality of battery modules are arranged in the cabinet body, are connected in series and are managed and controlled through a battery management system. An independent safety assembly is arranged in each battery module and the cabinet body, the safety assemblies serve as a fire safety mechanism and are used for ensuring the overall stability and the electrical safety of the cabinet body, and when the safety assemblies detect that continuous sudden temperature rise, smoking or fire breaks out in the battery modules, mechanical triggering is achieved, and the safety of the cabinet body is ensured. After being triggered, the fire extinguishing agent is communicated with a tank body filled with a fire extinguishing agent, so that the fire extinguishing agent enters the battery module through a pipeline, is uniformly dispersed into the battery module from the top of the battery module, is quickly gasified and absorbs heat after entering the battery module, extrudes internal excess air, prevents a fire point from being in contact with the air, and realizes quick and effective fire extinguishing and fire point spreading prevention; the safety coefficient is high. The integrated lithium battery power supply cabinet is stable and reliable to use, has a mechanical active fire extinguishing mechanism, and is high in safety.

Owner:浙江达航数据技术有限公司

A solar tracking system

ActiveCN106788180BImplement trackingGuaranteed power generationPhotovoltaic supportsSolar heating energyEngineeringSolar power

The invention discloses a solar tracking system which comprises at least two main beams and a plurality of bases. The main beams are used for mounting solar photovoltaic panels, the bases are used for mounting the main beams, and two ends of each main beam are respectively connected the corresponding bases by first universal connectors; the adjacent main beams are connected with one another by connecting rod assemblies, and the connecting rod assemblies are used for transmitting rotational movement of the adjacent solar photovoltaic panels. The first universal connectors comprise first spheres and first spherical hinged supports, the first spheres are fixedly connected with the main beams, the first spherical hinged supports are fixedly arranged on the bases, and the first spheres are positioned in the first spherical hinged supports to form first spherical hinges. The solar tracking system has the advantages that the main beams can be in linkage with one another by the aid of the connecting rod assemblies even if the central axes of the adjacent main beams are not positioned on the same plane, accordingly, the multiple main beams can be driven by a driving device to rotate in uneven regions, the sun can be tracked by the solar photovoltaic panels, and the power generation of solar power generation systems can be effectively guaranteed.

Owner:ARCTECH SOLAR HLDG CO LTD

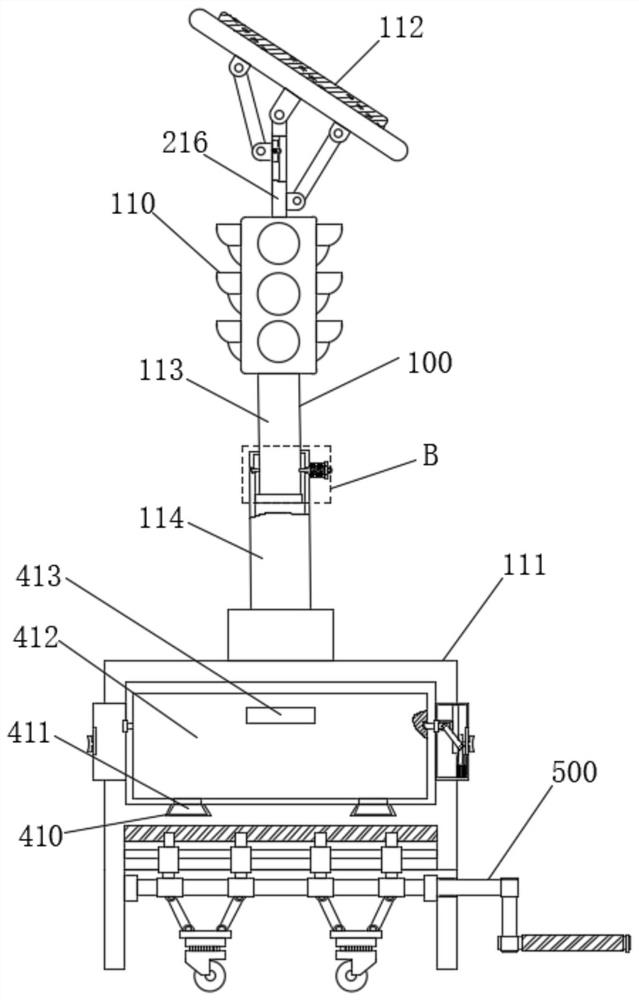

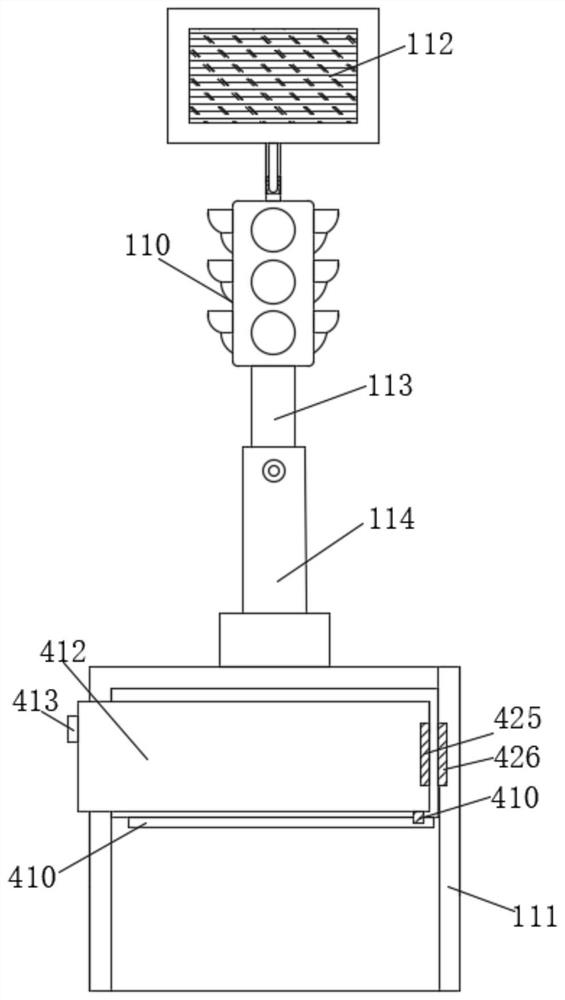

Smart city traffic signal lamp convenient to charge

InactiveCN112489471AImprove convenienceImprove efficiencyBatteries circuit arrangementsRoad vehicles traffic controlTraffic signalEngineering

A smart city traffic signal lamp convenient to charge disclosed by the present invention comprises a device main body, the device main body comprises a signal lamp main body, a pedestal, a photovoltaic panel and a first connecting rod, one side of the signal lamp main body is fixedly connected with the first connecting rod, and one end of the first connecting rod is connected with a storage rod through sleeving. One end of the storage rod is fixedly connected with the pedestal, and an adjusting mechanism is arranged on one side of the signal lamp main body. By arranging a first sliding block,a mounting groove, a first sliding groove, a first spring, a top ball and an arc-shaped groove, the first sliding block slides in the first sliding groove, so that the photovoltaic panel is adjusted,the device is fixed in the adjusting process through mutual clamping between the top ball and the arc-shaped groove, the device does not deviate any more, and the device can be correspondingly adjusted according to actual sunshine irradiation, so that the high efficiency of the device during use is further improved, the use efficiency of the device is improved, and the utilization rate of the device is greatly increased.

Owner:席朝

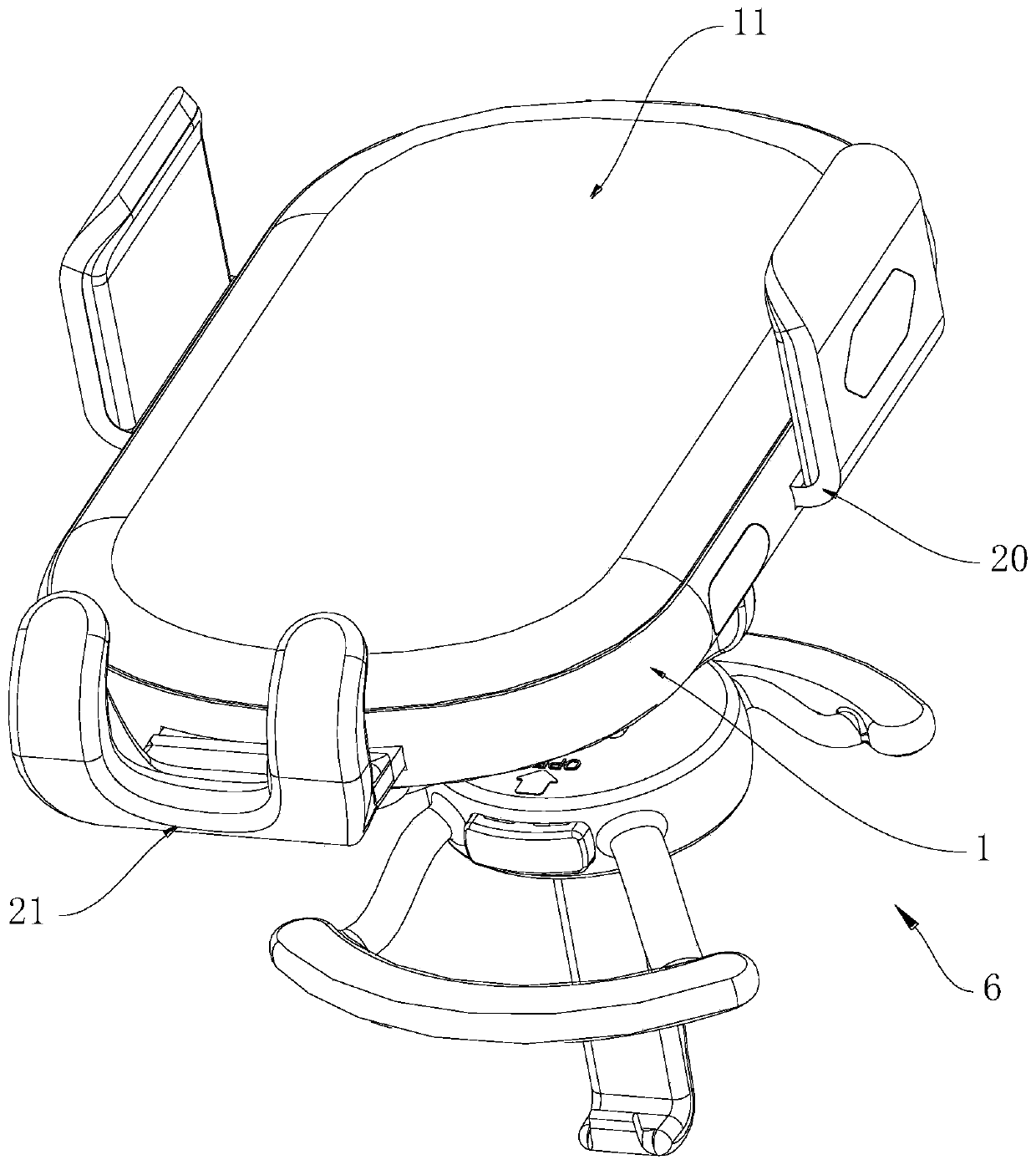

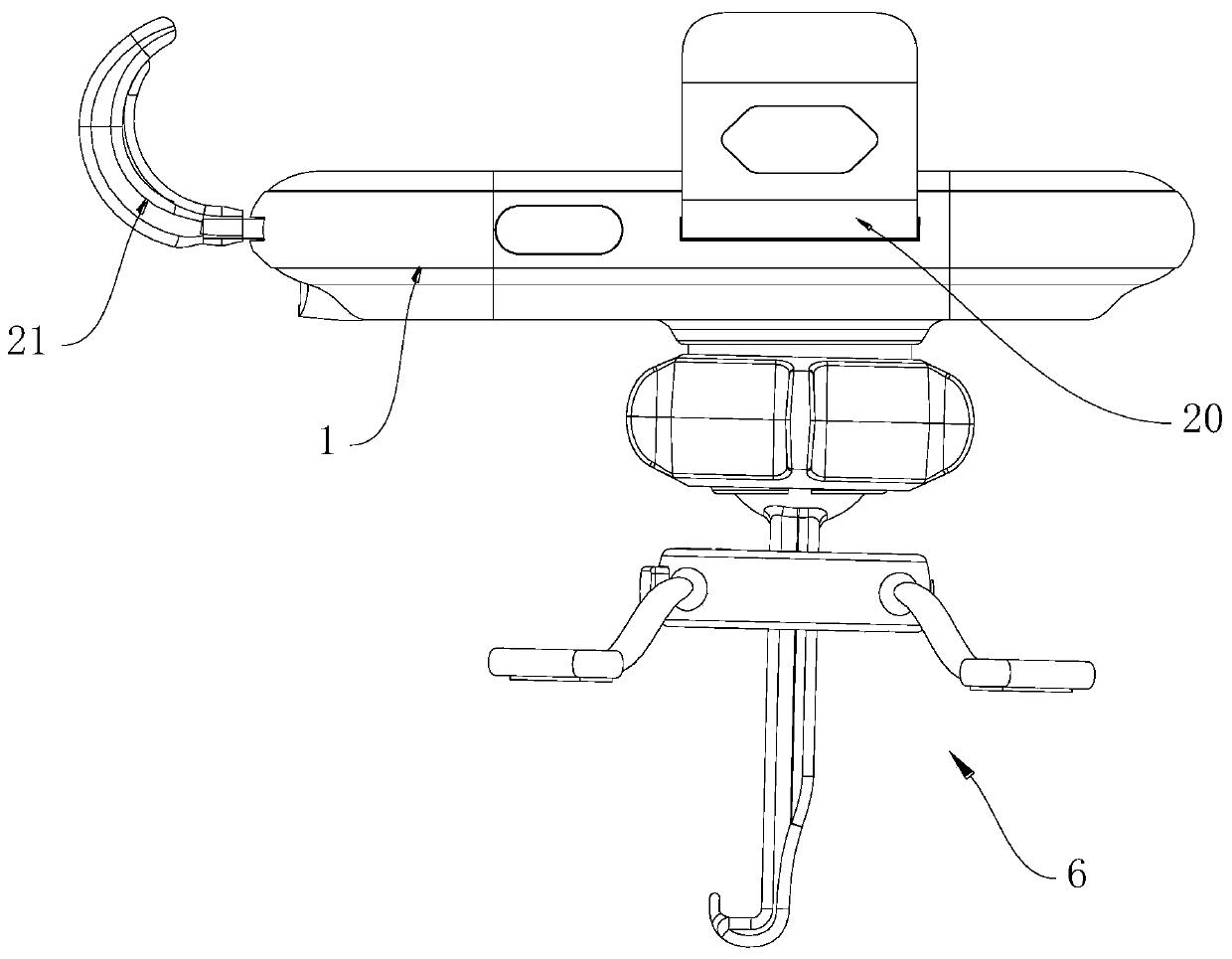

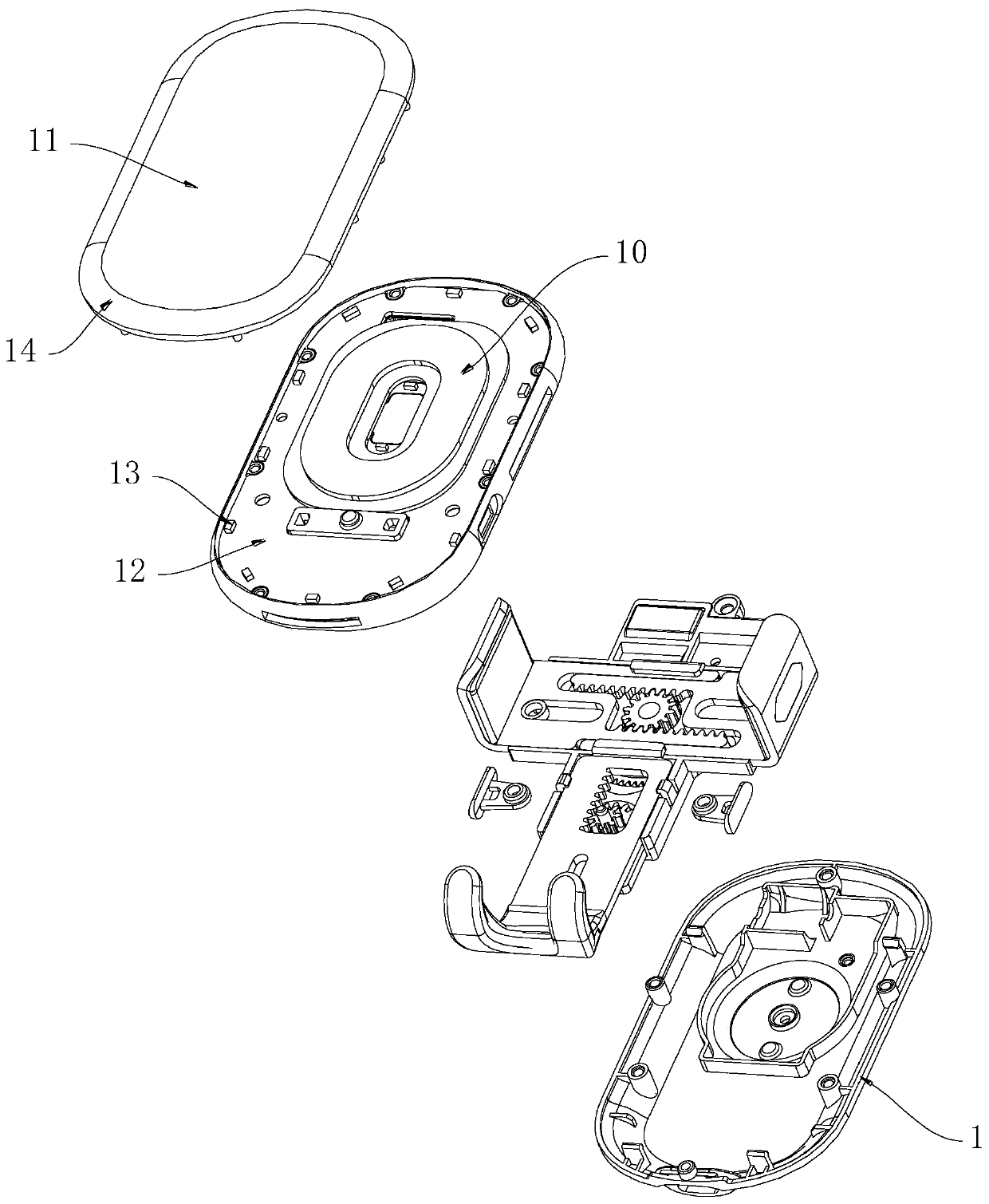

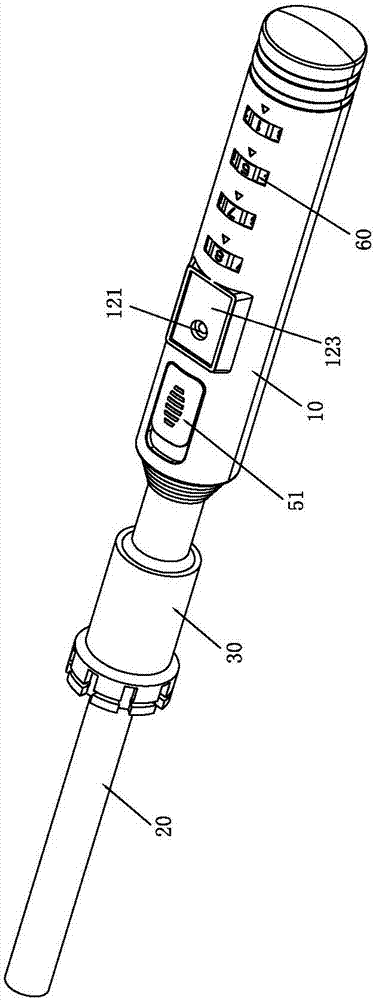

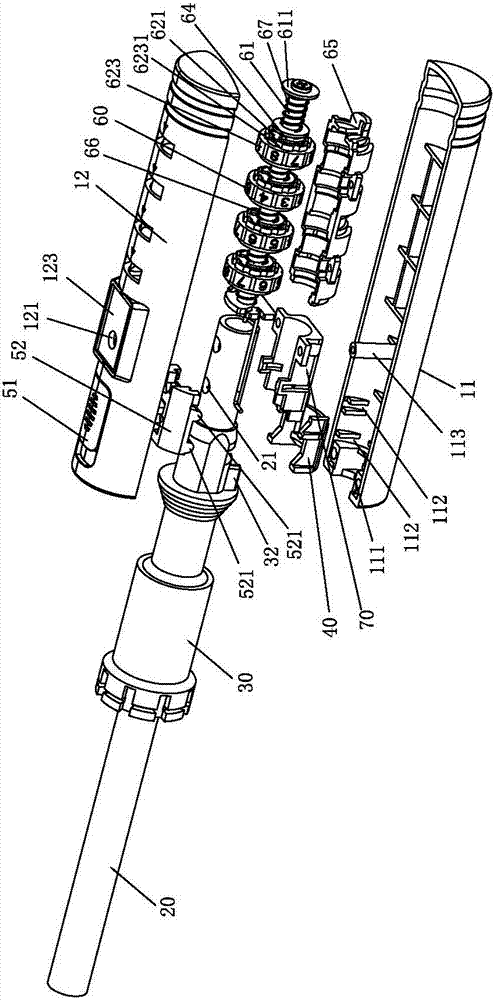

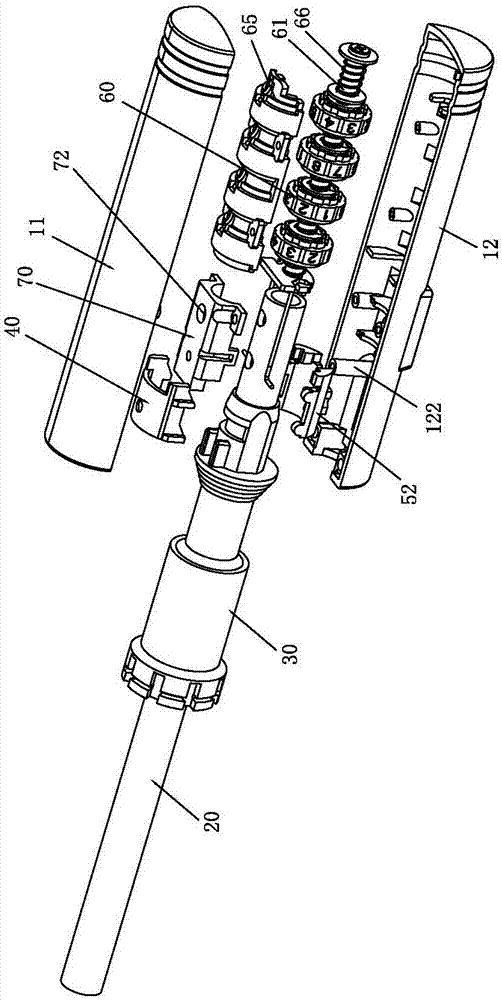

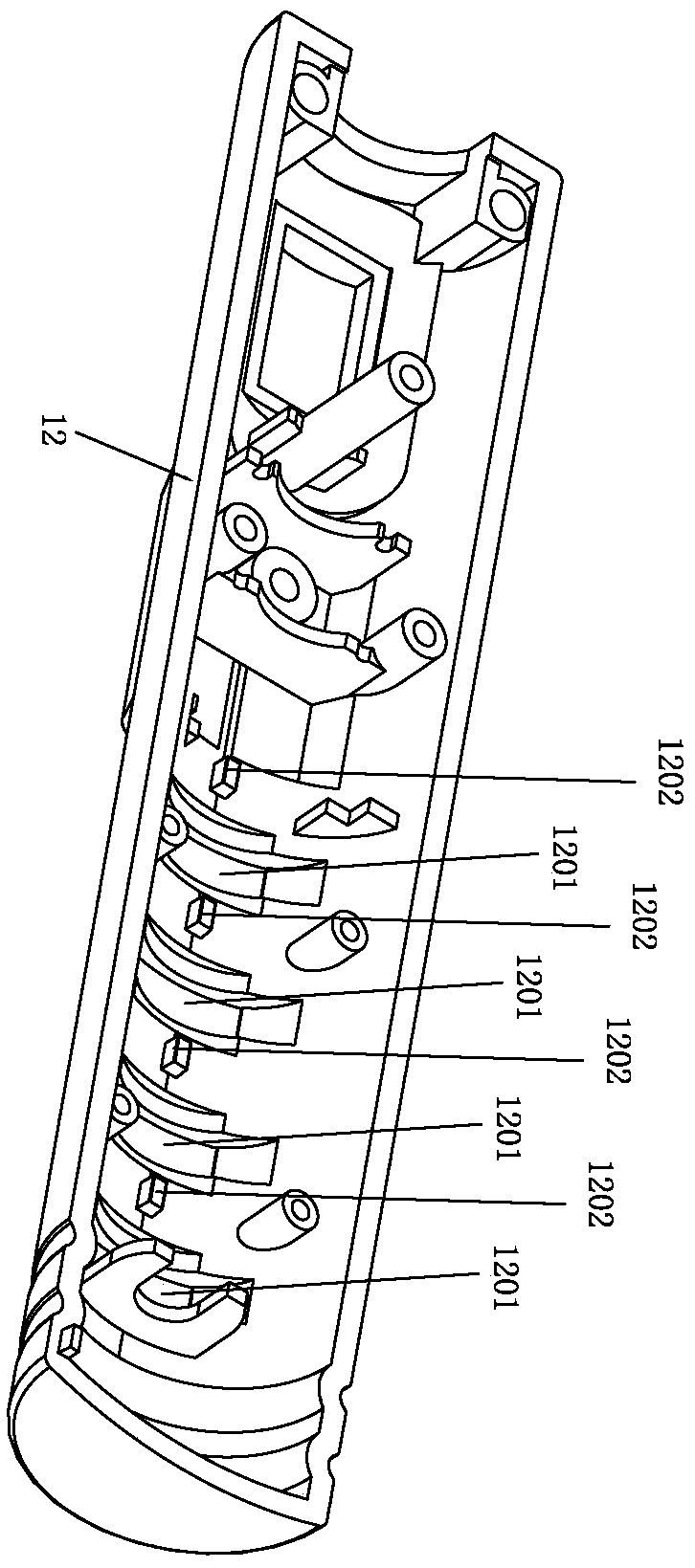

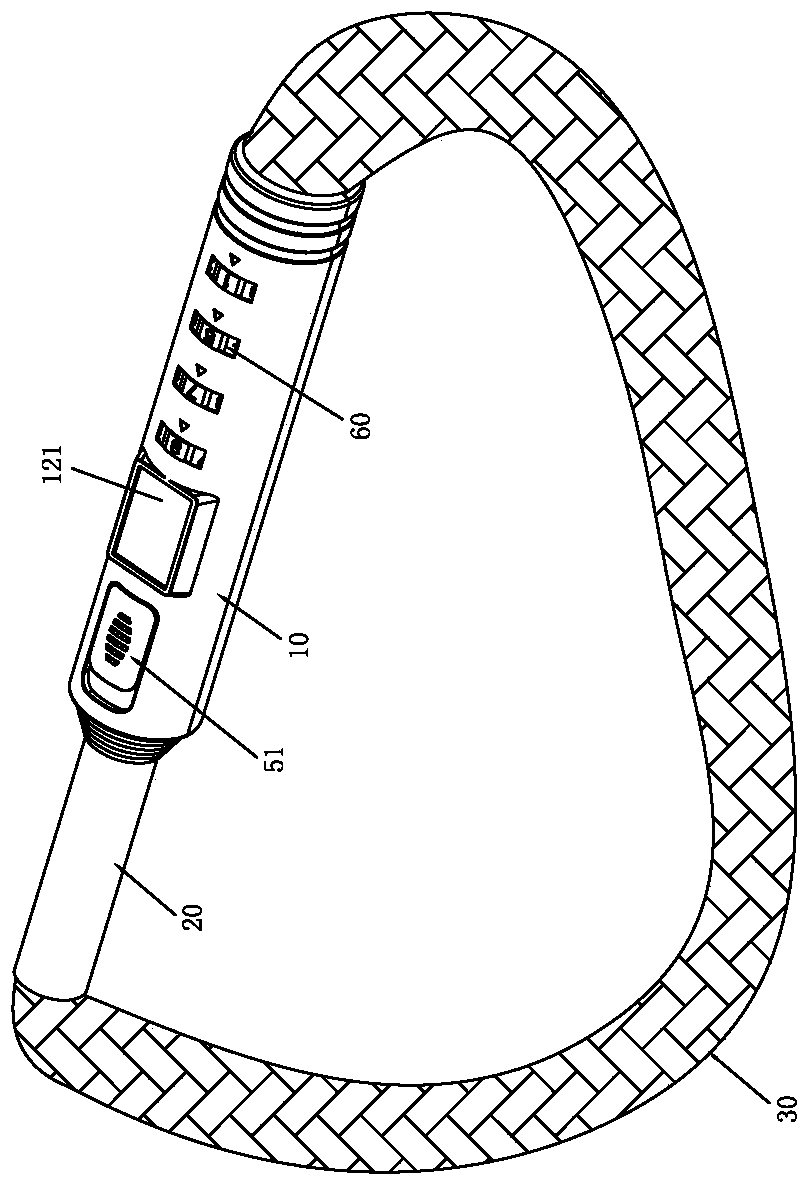

Speed reduction linkage type clamping mechanism and mobile phone support

PendingCN110958340AShorten the sliding strokeLinkage stabilityTelephone set constructionsGear wheelMobile phone

The invention discloses a speed reduction linkage type clamping mechanism. The speed reduction linkage type clamping mechanism comprises a bracket, wherein two transverse clamping jaws and a longitudinal clamping jaw are arranged on the bracket; the transverse clamping jaw comprises a transverse support arm; a transverse spur rack is formed at the end part of the transverse support arm; the two transverse spur racks are arranged in a staggered mode, and a driving gear is clamped between the two transverse spur racks. The two transverse spur racks are meshed with the driving gear; the longitudinal clamping jaw comprises a longitudinal support arm; a longitudinal spur rack is arranged above or below the longitudinal support arm; a reduction gear capable of rotating is arranged on the bracket; longitudinal teeth are formed on the longitudinal support arm; the longitudinal teeth are meshed with an output wheel of the reduction gear. When the driving gear rotates forwards or reversely, thetwo transverse clamping jaws are driven to be away from each other or close to each other, and the longitudinal clamping jaws are driven to slide in the longitudinal direction in a speed reduction mode through cooperation of the driving gear, the longitudinal support arm and the reduction gear. According to the speed reduction linkage type clamping mechanism, a mobile phone can be supported, the supporting action can be executed in a decelerating mode in the clamping process, and then stable and reliable linkage is achieved.

Owner:深圳市智高翔科技发展有限公司

Rocker arm type auxiliary clamping device for numerical control machining

ActiveCN111468968AEasy to adjustSmooth slidingPositioning apparatusMetal-working holdersNumerical controlControl theory

The invention provides a rocker arm type auxiliary clamping device for numerical control machining. The device comprises a fixing structure. The upper end face of the fixing structure is slidably provided with a sliding structure. An adjusting structure is integrally vertically and slidably fixed to the sliding structure. The adjusting structure is connected with the root of a rocker arm structure, and the tail end of the rocker arm structure is sleeved with a clamping structure. An adjusting rotary knob is installed on the adjusting structure through threads, and the position distance of theadjusting rotary knob can be adjusted through the threads, an adjusting block installed at the tail end of the adjusting rotary knob is in a rotatable state integrally, the adjusting block cannot rotate along with adjustment and rotation of the adjusting rotary knob, and meanwhile the tail end of the adjusting block is slidably installed inside an inclined sliding groove. When the adjusting blockmoves along with rotation of the adjusting rotary knob, the adjusting block can be driven to move backwards, and therefore the adjusting block can lift the whole rocker arm along the trajectory of theinclined sliding groove, and the purpose of adjusting and opening a rocking lever is achieved.

Owner:扬州轩业电热电器有限公司

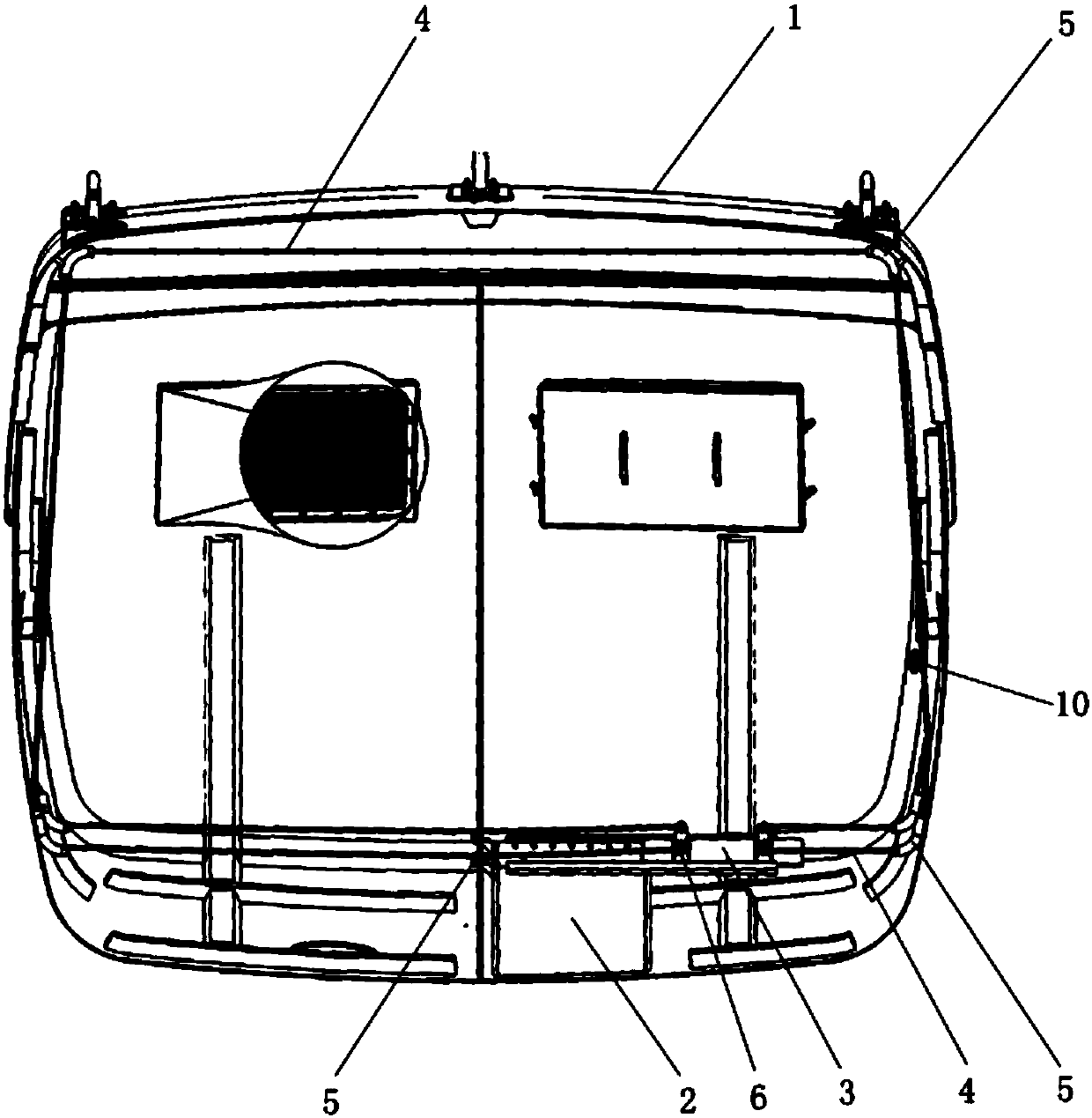

Four-connecting-rod locking mechanism and foldable trolley using same

ActiveCN106476874AQuick foldExpand quicklyCarriage/perambulator with multiple axesHand cartsVehicle frameLocking mechanism

The invention provides a four-connecting-rod locking mechanism and a foldable trolley using the same. The locking mechanism comprises a two-connecting-rod component and middle four-connecting-rod components. The trolley comprises a foldable frame and wheels, wherein the foldable frame is formed by two symmetrical four-connecting-rod mechanisms connected by support rods; the unfolded foldable frame forms a trolley bin capable of containing objects, and a trolley top cover for protecting the objects in the trolley bin is arranged at the top of the trolley bin. The four-connecting-rod locking mechanism has the advantages that the three four-connecting-rod components are locked through one two-connecting-rod component to form a stable truss structure, full linkage among rods can be achieved by the mechanism, and fast folding and unfolding of the locking mechanism can be achieved effectively. In addition, the trolley has the advantages that the trolley can be pushed by hands and is small in floor space after folding, convenient to use, capable of achieving linkage, light and handy, stable and high in practicality.

Owner:陈昭胜 +1

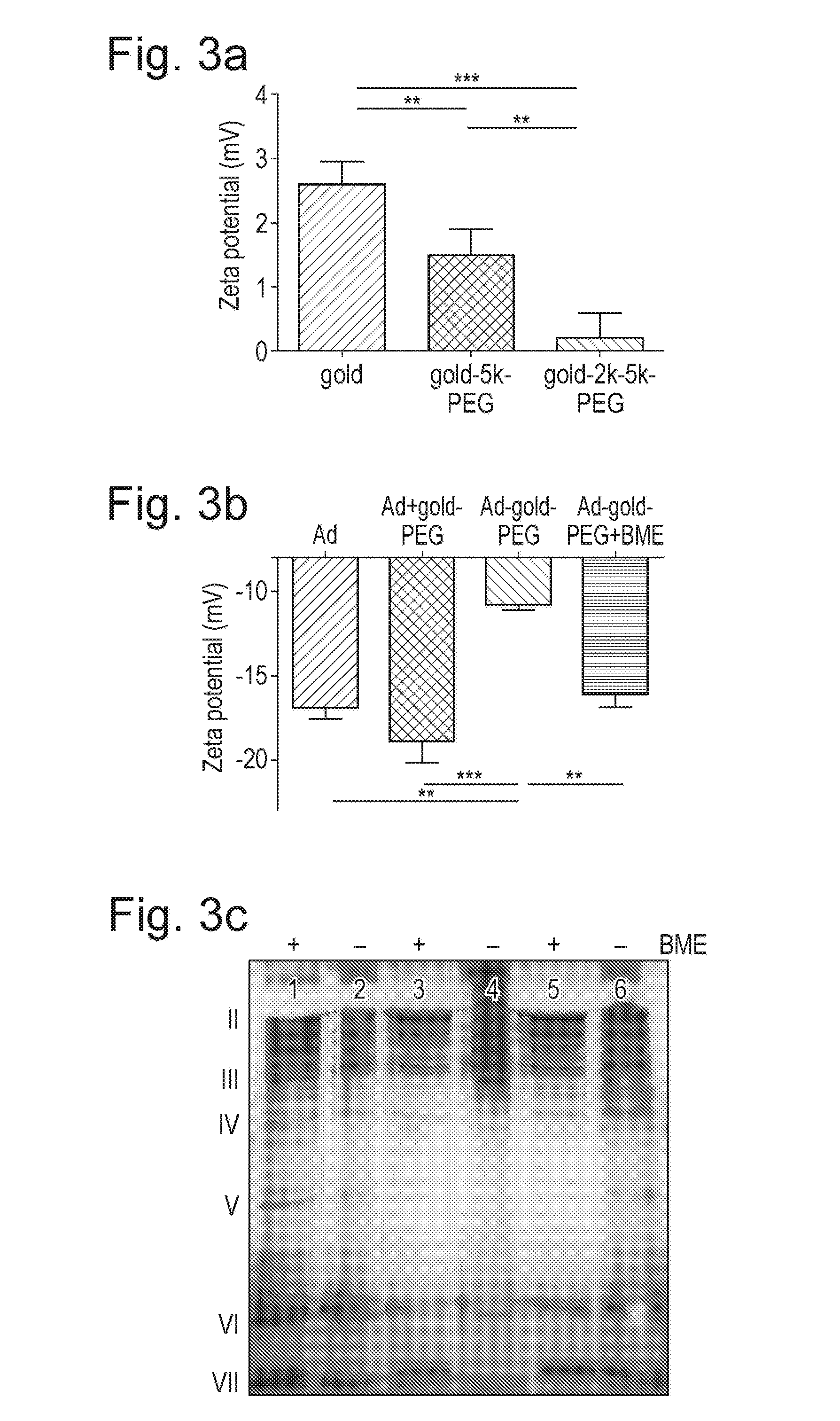

Shielded biologic therapeutic

InactiveUS20160250352A1Good biocompatibilityLow biocompatibilitySonopheresisPowder deliveryChemistryBiotherapeutic agent

The present invention provides a shielded biologic therapeutic comprising a biologic therapeutic which is covalently and cleavably bound to one or more nanoparticle, with a plurality of polymer chains bound to the or each nanoparticle.

Owner:OXSONICS LTD

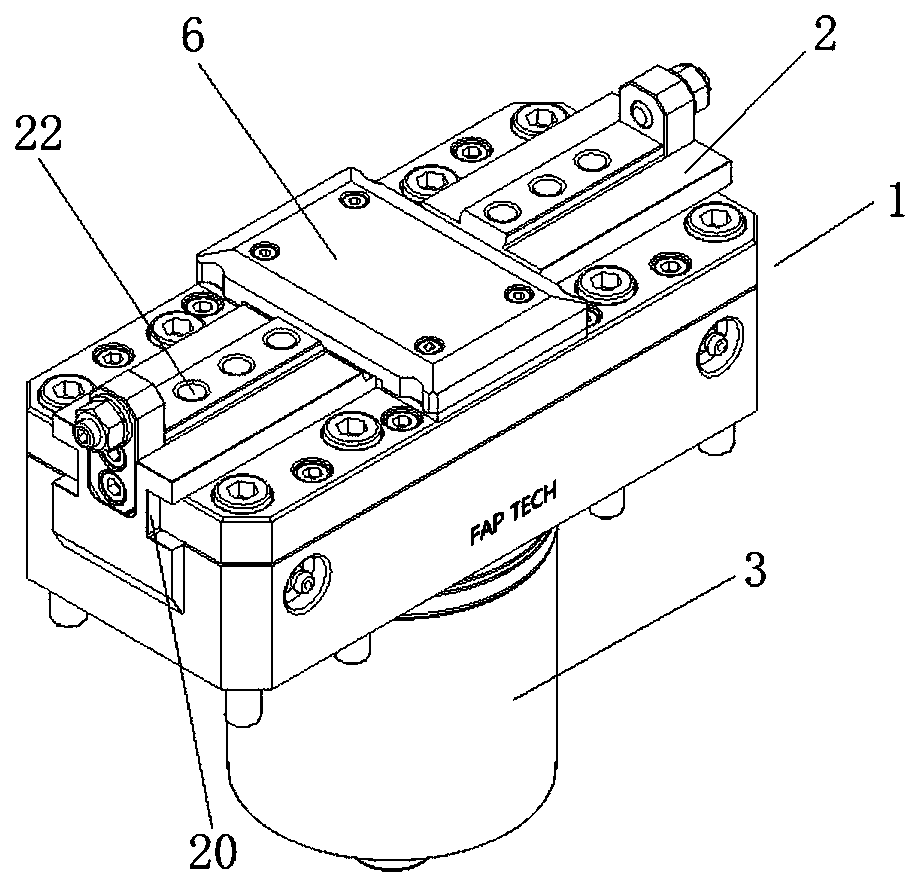

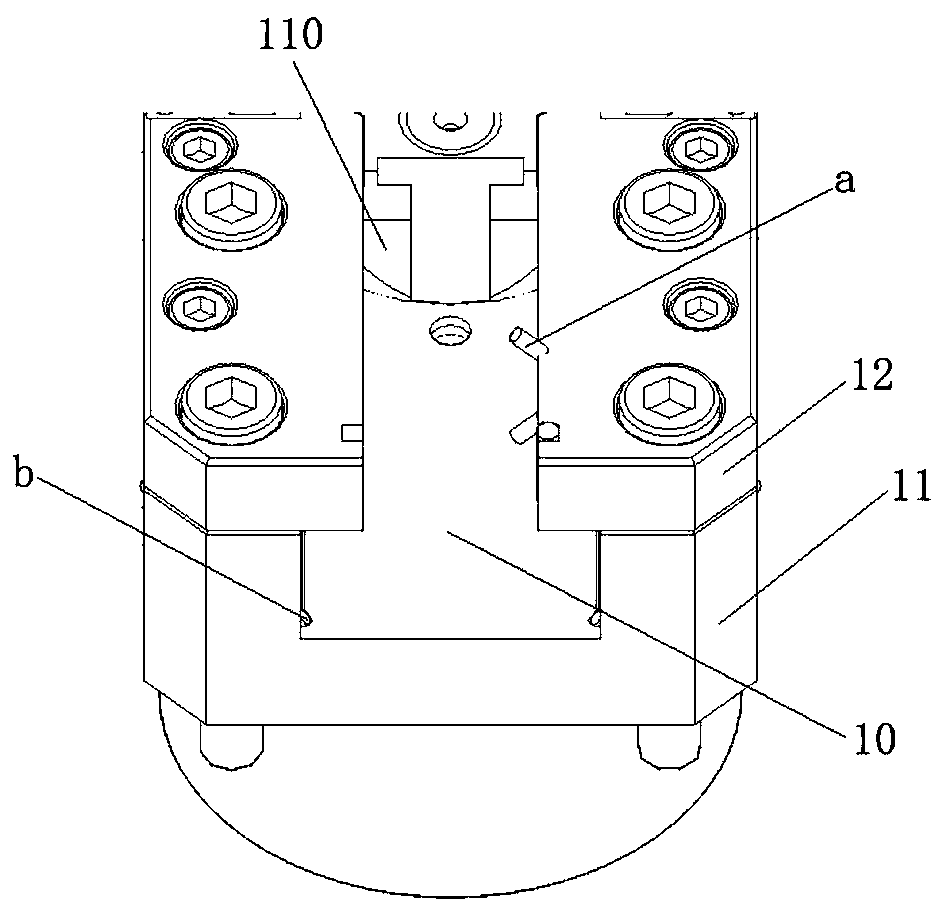

Wedge block type synchronous fixture

PendingCN110328544AImprove stabilityLinkage stabilityWork clamping meansPositioning apparatusCylinder blockMechanical engineering

The invention relates to a wedge block type synchronous fixture. The wedge block type synchronous fixture comprises a base, a driving piece mounted on the base, a wedge block driven by the driving piece, and two clamp bases linked with the wedge block; chutes extending in the length direction of the base are symmetrically formed in the two sides of the top of the base; the clamp bases are slidingly matched in the corresponding chutes; a vertical through hole is formed in the middle part of the base, is positioned between the two chutes, and communicates with the chutes; the driving piece comprises a cylinder block mounted at the bottom of the base, and a piston rod in vertical moving fit in the cylinder block; a driving end of the piston rod extends into the vertical through hole; the wedge block is mounted at the driving end of the piston rod, so that the wedge block is positioned between the two clamp bases; two vertical inclined grooves are oppositely and symmetrically arranged on the sides, towards the wedge block, of the clamp bases; and correspondingly, two vertical inclined buckles matched with the two vertical inclined grooves are arranged on the side, towards the clamp bases, of the wedge block, so that the wedge block is linked with the clamp bases on two sides for approaching or leaving. The wedge block type synchronous fixture is higher in stability and excellent inrigidity.

Owner:朗快智能科技(杭州)有限公司

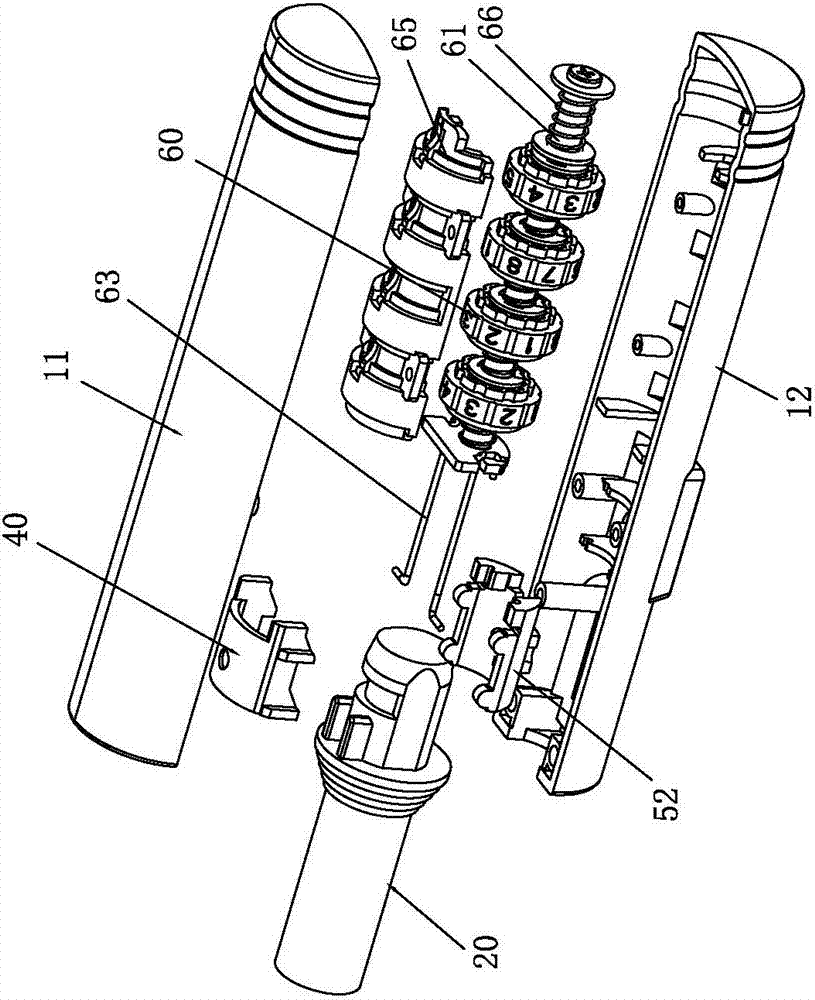

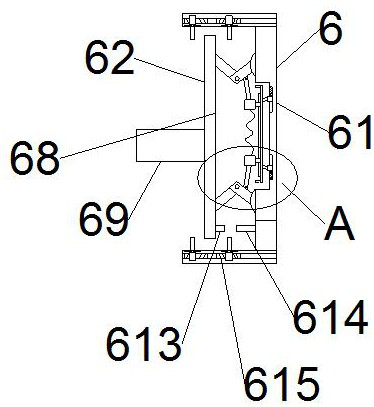

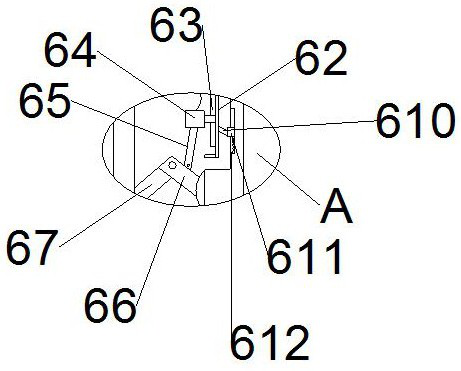

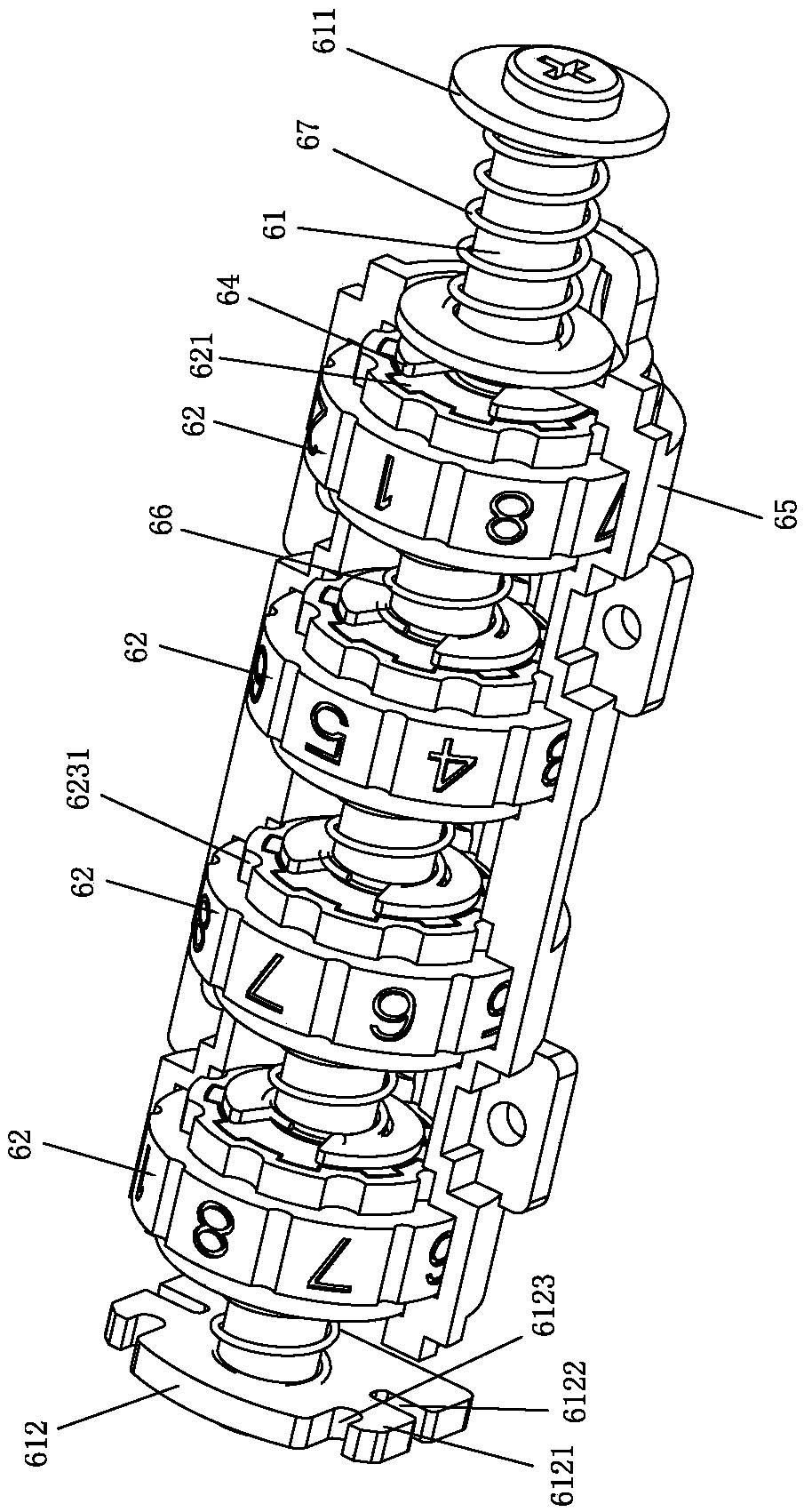

Mechanical password changing vehicle lock as well as unlocking control system and method thereof

ActiveCN107246187AEasy maintenance and managementReduce consumptionPuzzle locksIndividual entry/exit registersControl systemPassword

The invention discloses a mechanical password changing vehicle lock as well as an unlocking control system and method thereof. The mechanical password changing vehicle lock comprises a ring-shaped lock main body, wherein the ring-shaped lock main body is provided with a first end and a second end which can be opened and closed; in a locking state, the first end and the second end of the ring-shaped lock main body are fixed with each other through a lock catch; in an unlocking state, the first end and the second end are separated from each other in a released mode; the first end is provided with a splicing rod part; one end of the splicing rod part is provided with a first buckle part; the second end is provided with a lock case; the lock case is provided with a hollow part; a pushing button, a locking block and a locking block return elastic element, which are sequentially arranged from top to bottom, are arranged on a position, which corresponds to the hollow part, on the lock shell; and the pushing button is connected with a password type lock cylinder structure which is used for controlling the pushing button to not freely push. Through the delicate design of the password type lock cylinder structure, the password can be automatically, mechanically and regularly changed after a password wheel group is unlocked, so that bad phenomenon such as vehicle loss and theft caused by password fixing are avoided, and vehicle management and maintenance is convenient. Meanwhile, the mechanical password changing vehicle lock is delicate and reasonable in structural design, is stable in linkage and is good in using reliability.

Owner:深圳罗丰新材料科技有限公司

Vacuumizing transfer device of bag feeding food packing equipment

The invention relates to food packing equipment, in particular to a vacuumizing transfer device of bag feeding food packing equipment. The vacuumizing transfer device of the bag feeding food packing equipment comprises a turntable capable of rotating, and multiple clamping jaws uniformly distributed on the turntable and capable of being opened and closed; the turntable comprises a loading station,a transfer transition station corresponding to the loading station, and output stations positioned between the loading station and the transfer transition station and corresponding pairwise; openingdriving mechanisms for urging opening of the clamping jaws are arranged in the output stations; and the loading station is provided with a clamping driving mechanism for urging closing of the clampingjaws. The vacuumizing transfer device of the bag feeding food packing equipment improves the transfer efficiency, and is simple in structure.

Owner:WENZHOU READOR MACHINERY

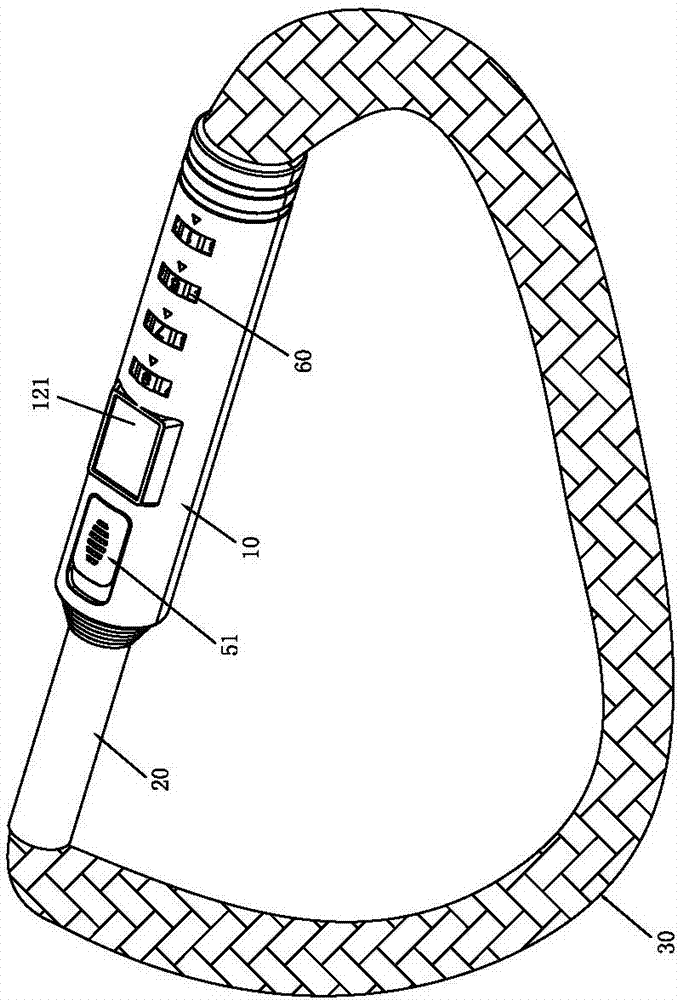

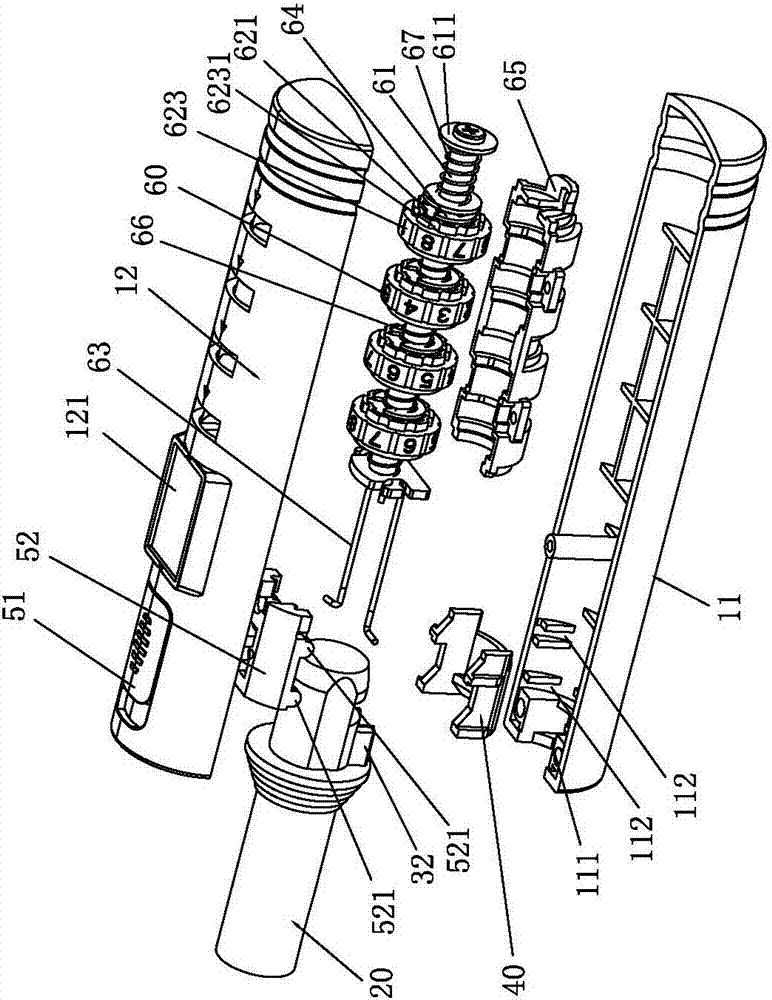

Automatic password transformation type anti-theft umbrella and unlocking control system and method thereof

ActiveCN107269137AAvoid lossAvoid misappropriation and other bad phenomenaLocks for portable objectsPuzzle locksControl systemPassword

The invention discloses an automatic password transformation type anti-theft umbrella and an unlocking control system and method thereof. The automatic password transformation type anti-theft umbrella comprises an umbrella handle, an umbrella shaft and an umbrella support; a first buckle part is arranged at one end of the umbrella support; the umbrella handle is provided with a hollow part, and a push button, an umbrella support buckling block and an umbrella support buckling block reset elastic element are sequentially installed on the umbrella handle from top to bottom in a manner of corresponding to the hollow part; the push button is connected with a password type lock cylinder structure used for controlling the push button to be free of pushing at will; the password type lock cylinder structure comprises a movable shaft and one or more password wheel sets installed on the movable shaft; when the umbrella needs to be opened, right passwords are obtained through pulling, password wheels are linked with rotating wheels to rotate until unlocking grooves of the rotating wheels right face unlocking stopping blocks; through the ingenious design of the password type lock cylinder structure, automatic and mechanical regularization password changing after the umbrella is opened through the password wheel set is achieved, poor phenomena such as umbrella losing and embezzling caused by fixed passwords are avoided, and umbrella management and maintenance are facilitated; and meanwhile, the umbrella opening and closing push button sliding control structure is ingenious and reasonable in design, linkage is stable, and the using reliability is good.

Owner:深圳罗丰新材料科技有限公司

Pull-rope-type wind turbine generator engine cabin object-craning hole lid

The invention provides a pull-rope-type wind turbine generator engine cabin object-craning hole lid. The pull-rope-type wind turbine generator engine cabin object-craning hole lid comprises a push-pull lid, a flexible rope and a guiding part, the push-pull lid is slidably connected to an object-craning hole, the end, close to the object-craning hole, of the guiding part is annularly arranged fromthe inner side of an engine cabin to the other end close to the object-craning hole, the flexible rope is arranged along the guiding part, the two ends of the flexible rope are both connected with thepush-pull lid, and by pulling the flexible rope, the push-pull lid is driven to slide to open or close the object-craning hole. The pull-rope-type wind turbine generator engine cabin object-craning hole lid is simple in structure and low in cost, maintenance personnel who use the pull-rope-type wind turbine generator engine cabin object-craning hole lid can conveniently and quickly open or closethe wind turbine generator engine cabin object-craning hole simply by standing on a rack pedal to pull the flexible rope without climbing to the bottom of the engine cabin, and the pull-rope-type windturbine generator engine cabin object-craning hole lid is convenient to use, safe and reliable.

Owner:GUODIAN UNITED POWER TECH

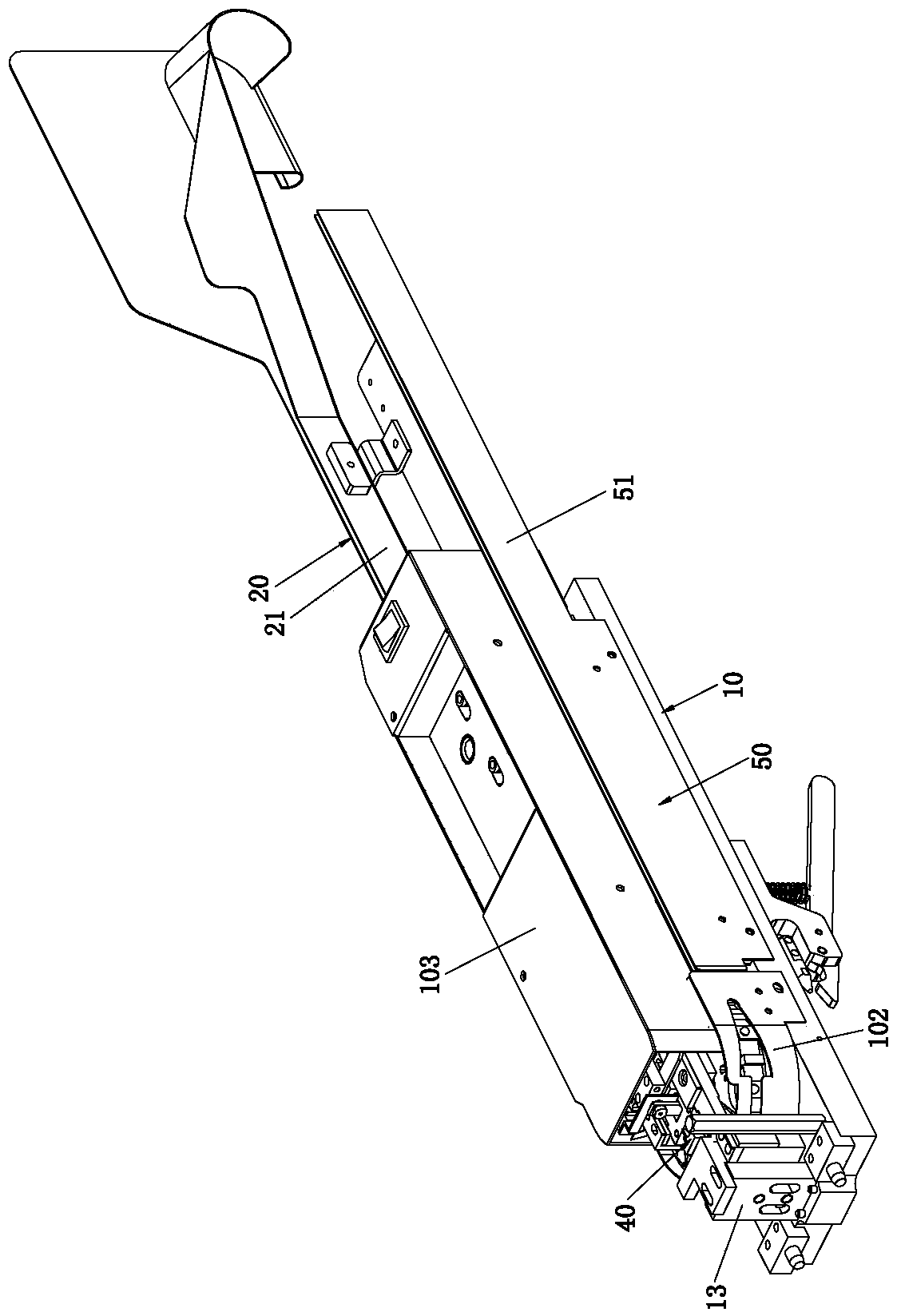

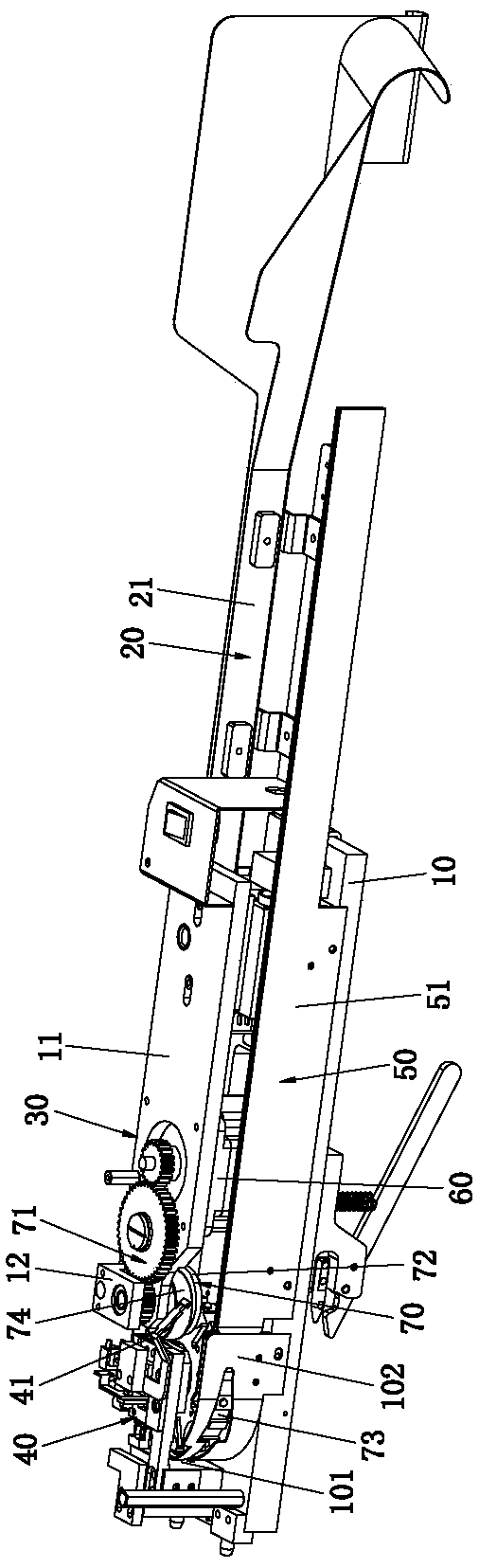

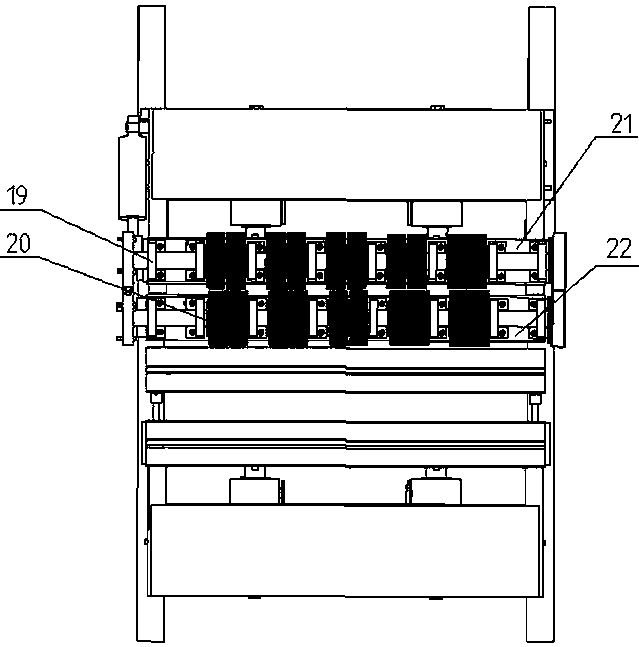

Coaxial linkage type braiding feeder

PendingCN109287115ALinkage stabilitySmooth linkageElectrical componentsEngineeringMechanical engineering

The invention discloses a coaxial linkage type braiding feeder, which comprises a machine base, a loading mechanism, a material conveying mechanism, a material cutting mechanism and an unloading mechanism, wherein the feeding conveying mechanism comprises a driving device and a linkage device; the linkage device comprises an eccentric wheel a braiding wheel; one end of the eccentric wheel is in intermittent linkage connection with the braiding wheel, the braiding wheel is rotatably mounted on the machine base, and the side wall of the outer circle of the braiding wheel is connected with an output end of the loading mechanism and an input end of the unloading mechanism; and the material cutting mechanism comprises a linkage block and a first cutter in linkage connection with the linkage block, a transmission member is connected onto the eccentric wheel, the transmission member is in intermittent linkage connection with the linkage block, a material cutting region is formed in the outputend of the loading mechanism and the input end of the unloading mechanism, and the first cutter reciprocates in the cutting region. Thereby, the coaxial linkage type braiding feeder realizes the transmission manner that single drive is linked with a plurality of motions, the overall layout is smart and reasonable, the linkage between the transmission structures is more stable and smooth, and themanufacturing cost is reduced.

Owner:东莞市南部佳永电子有限公司

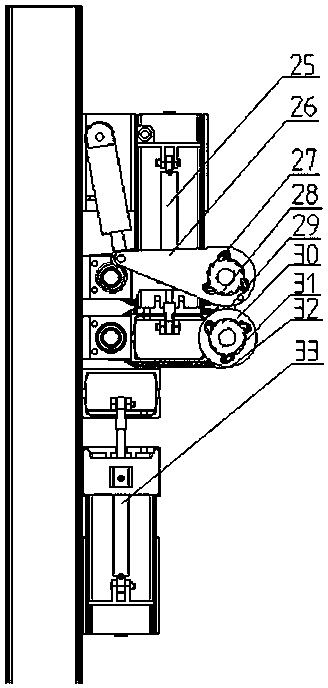

Electrohydraulic control clamping and belt loosening linkage device for maintenance of inclined belt conveyor

The invention provides an electrohydraulic control clamping and belt loosening linkage device for maintenance of an inclined belt conveyor. According to the device, in the normal operation and maintenance working condition process of the belt conveyor, an upper clamping body mechanism and a lower clamping body mechanism are designed, so that synchronous clamping of an upper rubber belt and a lowerrubber belt is achieved; lifting cylinders on the two sides, an upper sliding beam and a lower sliding beam are designed, and the different working condition positions of the upper sliding beam and the lower sliding beam are controlled, so that free switching of the device between the normal operation working condition and the maintenance working condition is achieved, the adaptability is higher,and the manufacturing cost and the workload are reduced; a driving oil cylinder is designed to drive a ratchet wheel housing and a tooth-shaped chain wheel to deflect, so that the clamping and belt pulling functions of tooth-shaped chains on the upper rubber belt in the working process are achieved; and the multiple tooth-shaped chains are designed to clamp the rubber belts, so that the pressuredistribution of the multi-point pressurized rubber belts is uniform, the extra direction pressure generated by deformation and clamping of the rubber belts is avoided, the service life of the device is prolonged, and the rubber belts can be clamped more stably, safely and reliably.

Owner:TAIYUAN UNIV OF TECH +1

Needling production line for textiles

The invention relates to a needling production line for textiles. The needling production line comprises a central control unit, an opening and picking unit, a cotton storing and feeding unit, a carding machine unit, a lapping machine unit and a needling machine unit, wherein the central control unit is respectively connected with the opening and picking unit, the cotton storing and feeding unit, the carding machine unit, the lapping machine unit and the needling machine unit through signal wires; the cotton storing and feeding unit is positioned between the opening and picking unit and the carding machine unit; the lapping machine unit is positioned between the carding machine unit and the needing machine unit. The needling production line realizes integrated control, saves the space occupied by an equipment control unit, further saves the labor cost, also improves the production efficiency of equipment, and thus ensures that the linkage of the whole production line is more stable. The problems that interlocking signals are easily interfered and the like during equipment linkage are solved.

Owner:杨配媛

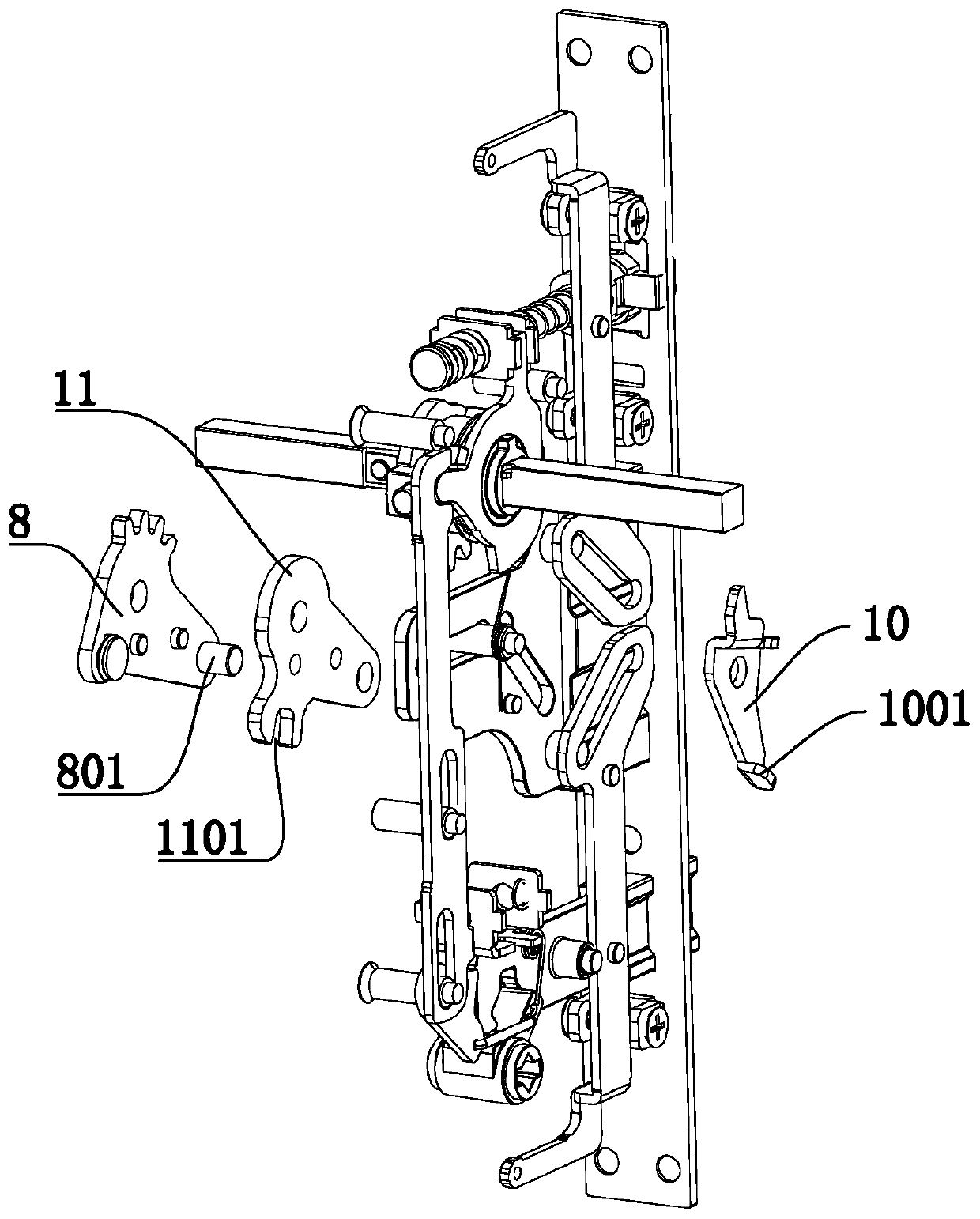

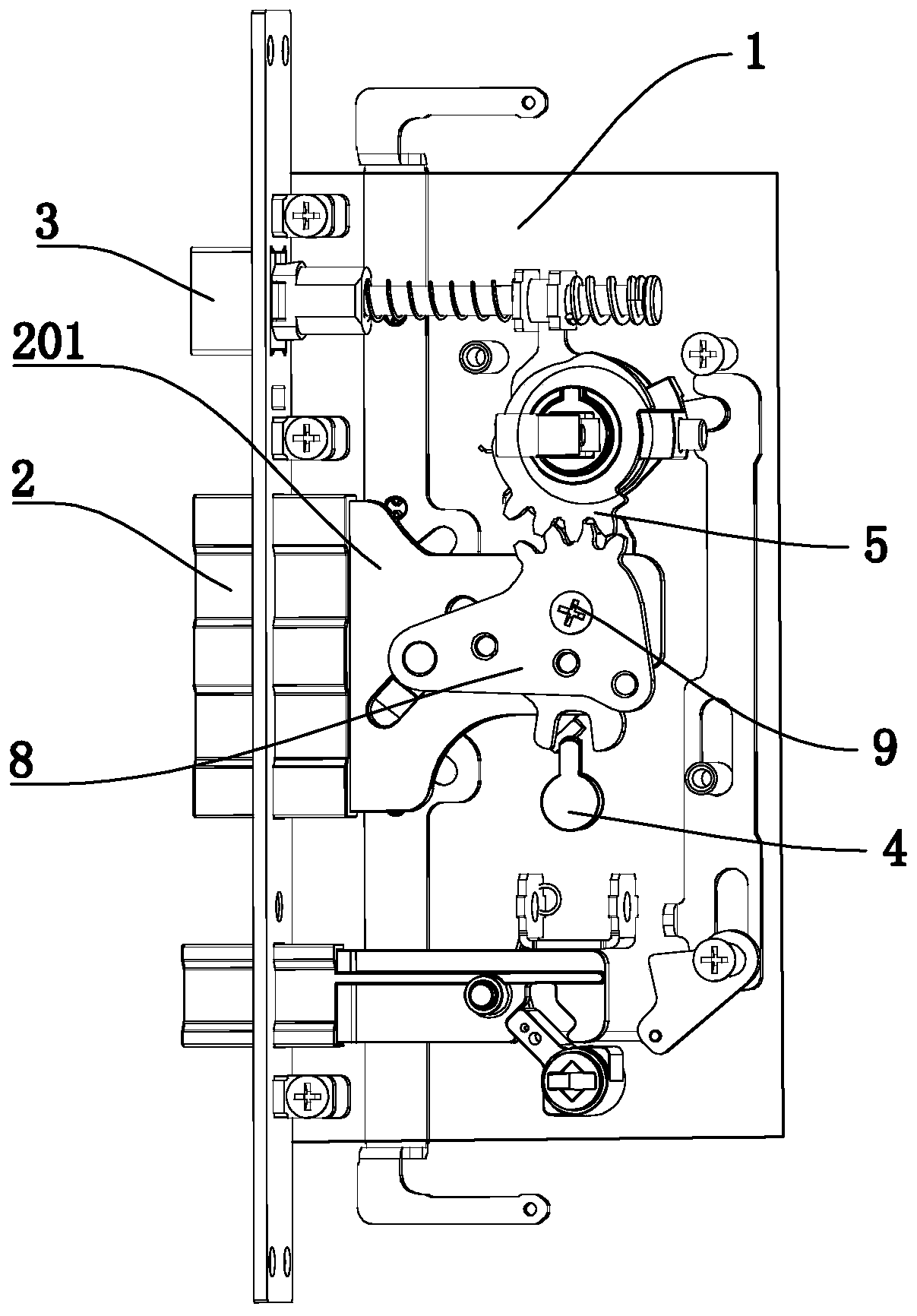

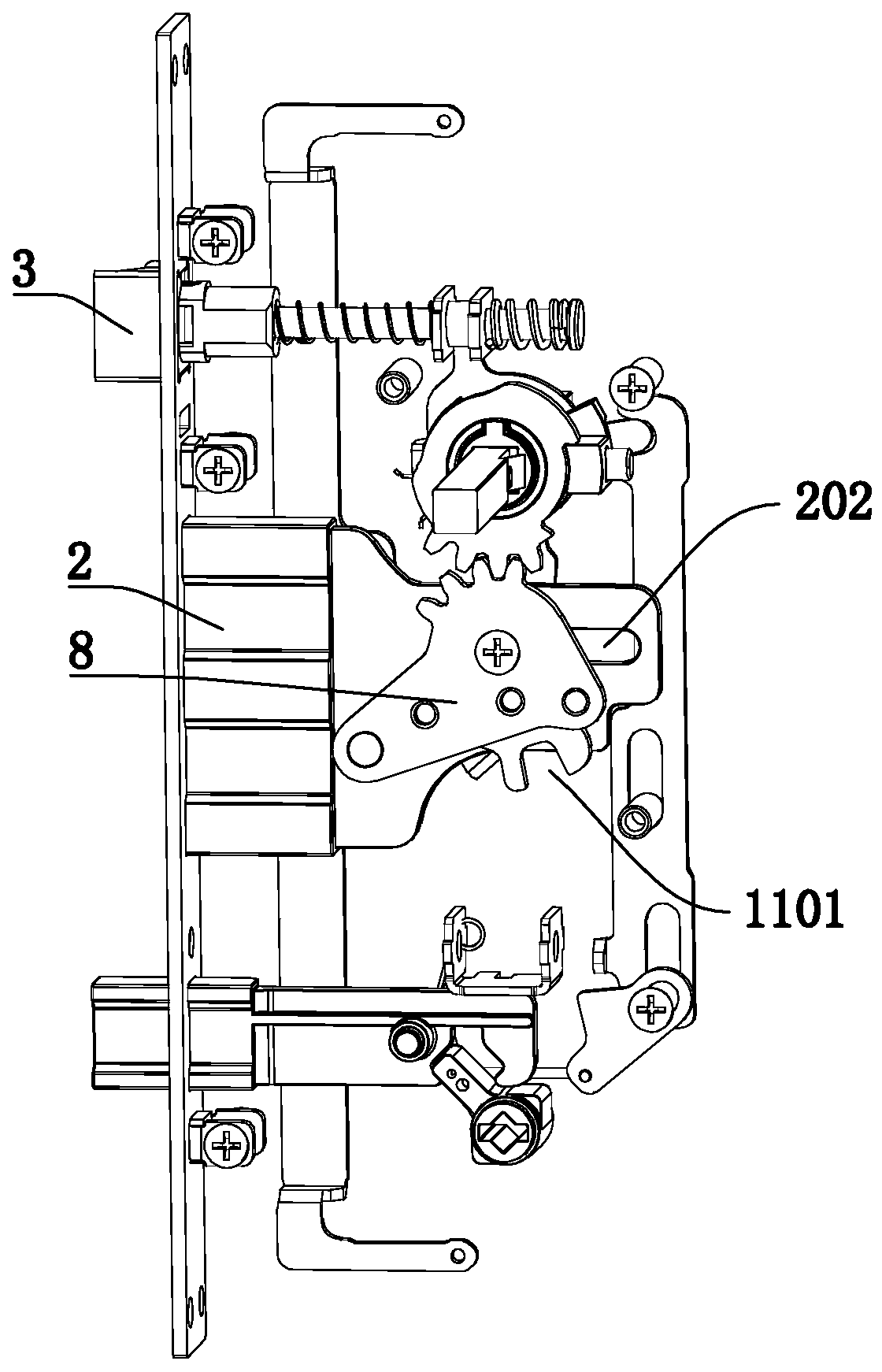

Mechanical key unlocking mechanism

Owner:浙江天宇安防科技有限公司

A welding equipment for pcba motherboard processing

ActiveCN114043134BEasy to movePlay a buffering effectWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a welding equipment for processing a PCBA main board, which comprises a welding base, a welding vertical column is arranged on the upper part of the welding base, an electric sliding rail is arranged on the welding column, and an electric sliding block is arranged in the electric sliding rail for sliding. There is a lifting seat on the block, the lower part of the lifting seat is provided with a horizontal sliding rail, a sliding seat is provided in the electric sliding rail in the horizontal sliding rail, the lower part of the sliding seat is provided with a welding head, and the side of the sliding seat is provided with a touch block, and the touch block Set in contact with the trigger assembly. The invention starts the limit motor, the driving bevel gear and the driven bevel gear mesh with the limit rotation shaft, and the limit rotation shaft rotates to realize the rotation of the limit screw area, and then realize the movement of the limit screw block, and pass through the welding base through the limit through column. The limit through groove of the locator is matched with the upper seat, so as to realize the movement of the anti-position component.

Owner:深圳市日月辉电子有限公司

Mechanical password-changing vehicle lock and its unlocking control system and method

ActiveCN107246187BEasy maintenance and managementReduce consumptionPuzzle locksIndividual entry/exit registersPasswordControl system

The invention discloses a mechanical password changing vehicle lock as well as an unlocking control system and method thereof. The mechanical password changing vehicle lock comprises a ring-shaped lock main body, wherein the ring-shaped lock main body is provided with a first end and a second end which can be opened and closed; in a locking state, the first end and the second end of the ring-shaped lock main body are fixed with each other through a lock catch; in an unlocking state, the first end and the second end are separated from each other in a released mode; the first end is provided with a splicing rod part; one end of the splicing rod part is provided with a first buckle part; the second end is provided with a lock case; the lock case is provided with a hollow part; a pushing button, a locking block and a locking block return elastic element, which are sequentially arranged from top to bottom, are arranged on a position, which corresponds to the hollow part, on the lock shell; and the pushing button is connected with a password type lock cylinder structure which is used for controlling the pushing button to not freely push. Through the delicate design of the password type lock cylinder structure, the password can be automatically, mechanically and regularly changed after a password wheel group is unlocked, so that bad phenomenon such as vehicle loss and theft caused by password fixing are avoided, and vehicle management and maintenance is convenient. Meanwhile, the mechanical password changing vehicle lock is delicate and reasonable in structural design, is stable in linkage and is good in using reliability.

Owner:深圳罗丰新材料科技有限公司

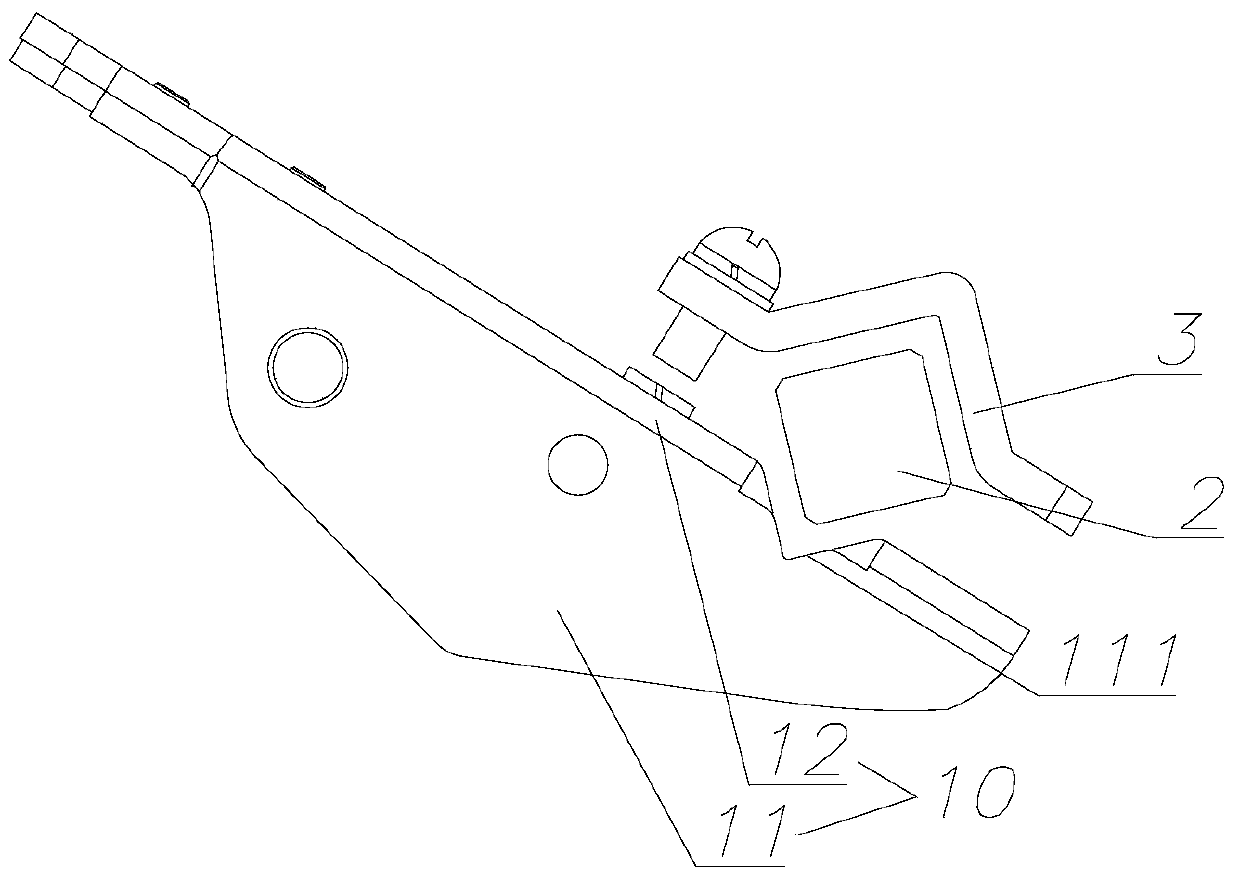

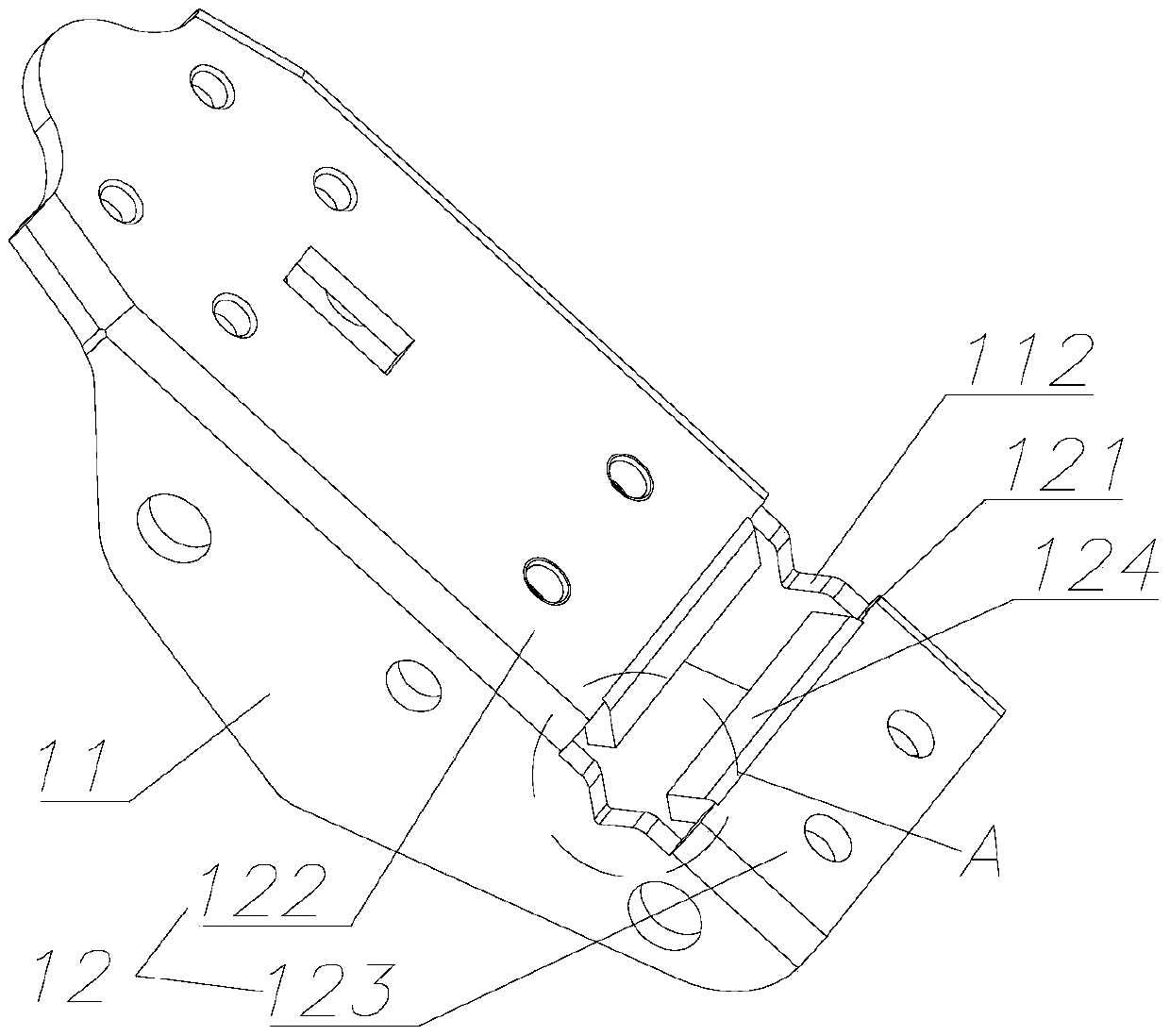

Rotary shaft device of circuit breaker

ActiveCN107170651BLinkage stabilityContactsProtective switch operating/release mechanismsCardboardCircuit breaker

A rotating shaft device for a circuit breaker, which includes a plurality of contact supports installed with moving contacts and a rotating shaft for linking the plurality of contact supports. The contact and separation of the contacts realize the closing and breaking of the circuit breaker; the radial section of the rotating shaft is a parallelogram, the contact support is provided with a shaft groove with a V-shaped structure for installing the rotating shaft, and the rotating shaft device also includes a V-shaped The card plate of the fixed groove of the structure, the fixed groove of the V-shaped structure is set corresponding to the shaft groove of the V-shaped structure, the contact support is fixedly connected with the card plate, and the rotating shaft is fixed in the space enclosed between the shaft groove and the fixed groove , the shaft groove cooperates with two adjacent sides of the rotating shaft, and the fixed groove cooperates with the other two adjacent sides of the rotating shaft, so that multiple contacts can be supported through the rotating shaft for stable and firm linkage.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

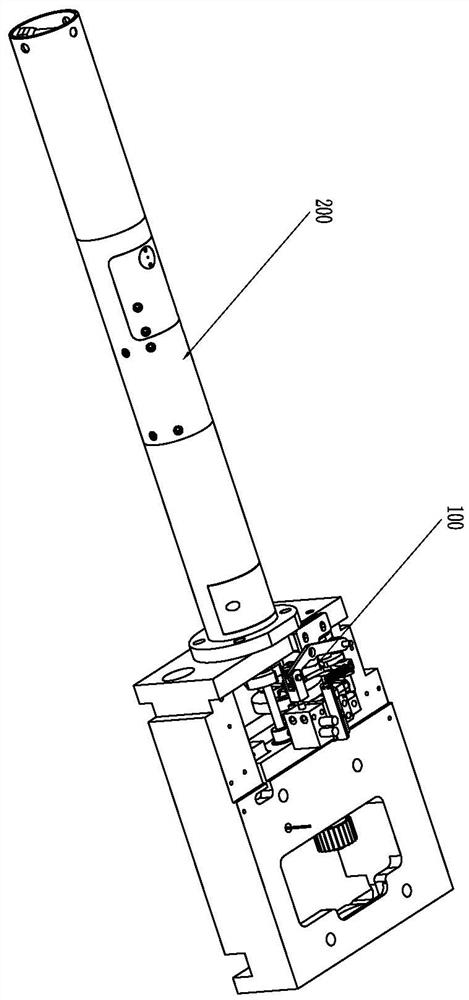

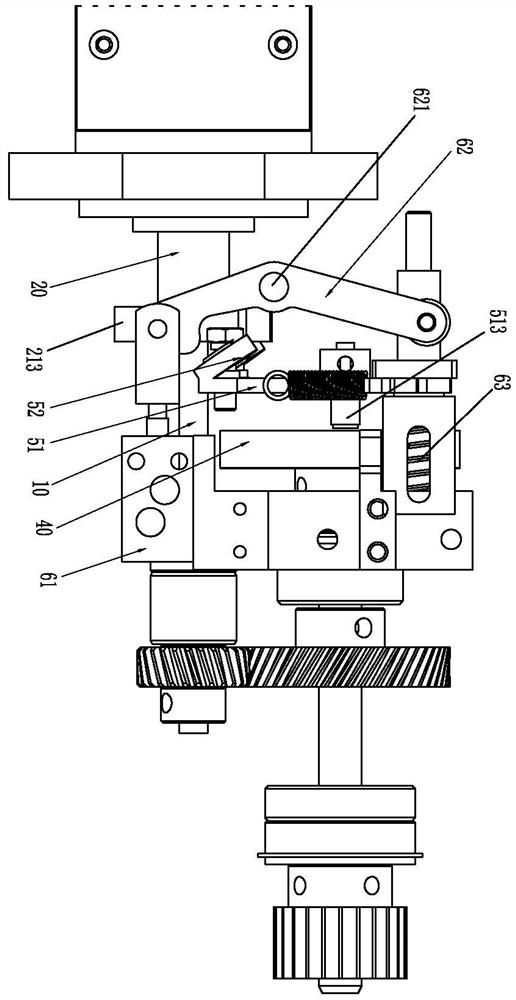

Small Diameter Cylindrical Sewing Machine

ActiveCN109537193BConducive to miniaturization designCompact designNeedle severing devicesLoop takersClutch controlCrank

The invention discloses a small-diameter cylindrical sewing machine, which comprises a frame, a machine head arranged on the frame, and a cylinder located below the machine head; an eccentric installation through hole located above the axis of the cylinder is arranged in the cylinder, The eccentric installation through hole is equipped with a movable knife shaft cylinder, and the movable knife shaft cylinder is equipped with a rotary hook shaft; the movable knife shaft cylinder and the rotary hook shaft share a driving motor as power; the motor is connected to a transmission shaft, which is respectively connected to There are cam base and transmission assembly; the cam base is linked to a crank connecting rod assembly, and the crank connecting rod assembly is linked to the movable knife shaft; the transmission assembly is linked to the hook shaft; the clutch control assembly is used to control the clutch of the crank connecting rod assembly and the cam base , to realize intermittent thread trimming; in this way, through the structural design of the cylinder, moving knife shaft barrel, and hook shaft, and the moving knife shaft barrel and hook shaft share a driving motor as power, thereby effectively saving design space , which is conducive to the miniaturization design of the cylinder to meet the needs of small objects or small area processing and trimming.

Owner:GUANGDONG JIN YUE LAI AUTOMATION EQUIP CO LTD

A cipher lock

The invention provides a cipher lock comprising a shell, an inclined tongue component, a square tongue component, a restraining component capable of restraining extension movement of a square tongue, a transmission component which can operate in linkage with an inclined tongue synchronization member to release the restraint of the restraining component on the movement of a square tongue synchronization member, and a power component capable of providing power for movement of the square tongue synchronization member. The restraining component is supported on the shell and is in pressing joint with the square tongue synchronization member to restrain movement of the square tongue synchronization member; one end of the transmission component is connected with the inclined tongue synchronization member and the other end is connected with the restraining component to transmit movement of the inclined tongue synchronization member to the restraining component; one end of the power component is connected with the square tongue synchronization member and the other end of the power component is fixedly connected with the shell. The cipher lock has the advantages of high stability, long service life, simple structure and low cost.

Owner:青岛韩昌物联智能控制有限公司

Small-diameter cylinder sewing machine

ActiveCN109537193AConducive to miniaturization designCompact designNeedle severing devicesLoop takersClutch controlDrive shaft

The invention discloses a small-diameter cylinder sewing machine. The machine comprises a rack, a head arranged on the rack and a cylinder located below the head, wherein an eccentric mounting throughhole located above the axis of the cylinder is formed in the cylinder, a moving cutter shaft barrel is mounted in the eccentric mounting through hole, and a rotating hook shaft is mounted in the moving cutter shaft barrel; the moving cutter shaft barrel and the rotating hook shaft share one drive motor as power; the motor is connected with a drive shaft, and a cam seat and a drive assembly are connected onto the drive shaft; the cam seat is linked with a crank connecting rod assembly linked with the moving cutter shaft barrel; the drive assembly is linked with the rotating hook shaft; a clutch control assembly is used for controlling separation and combination of the crank connecting rod assembly and the cam seat to realize intermittent thread trimming. Thus, structural design of the cylinder, the moving cutter shaft barrel and the rotating hook shaft is used, the moving cutter shaft barrel and the rotating hook shaft share one drive motor as power, so that the design space is effectively saved, miniaturization design of the cylinder is facilitated, and the thread trimming demand of small object or small area processing is met.

Owner:GUANGDONG JIN YUE LAI AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com