Full-automatic shoe sole forming machine

A molding machine, fully automatic technology, applied in footwear, other household appliances, household appliances, etc., can solve problems such as hidden safety hazards, inability to complete demolding of soles, and low mold opening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

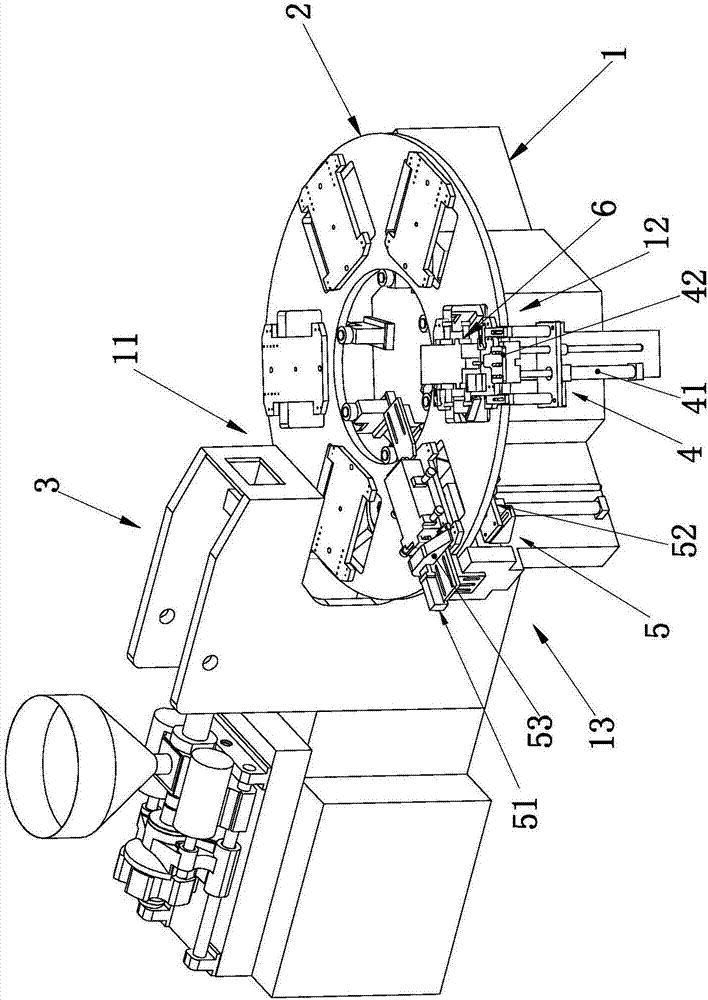

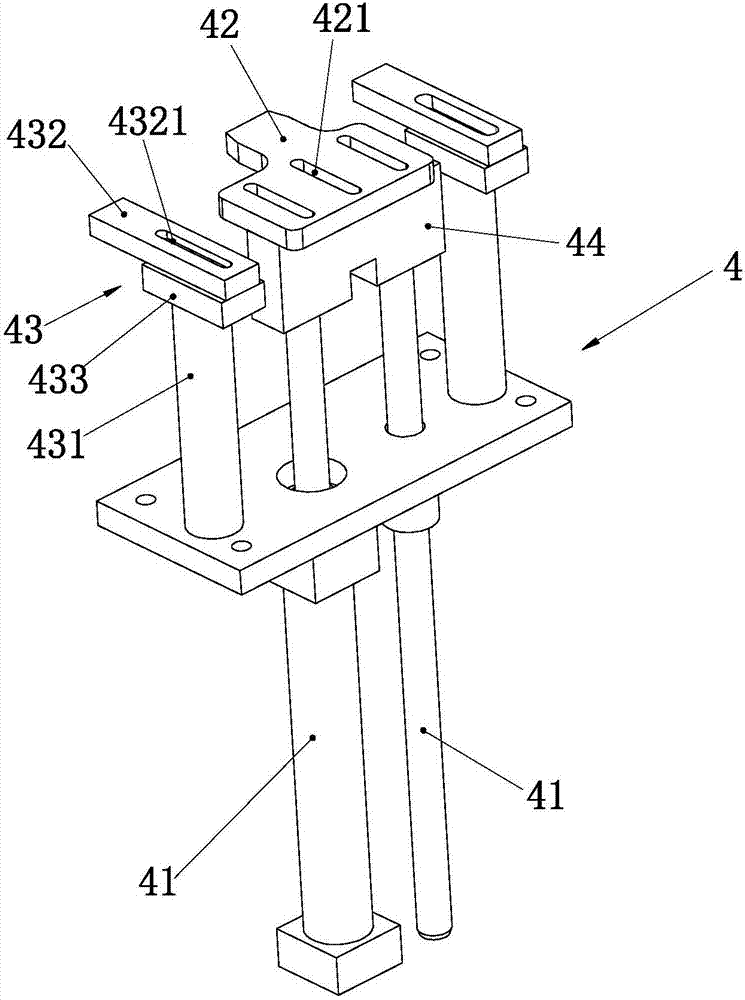

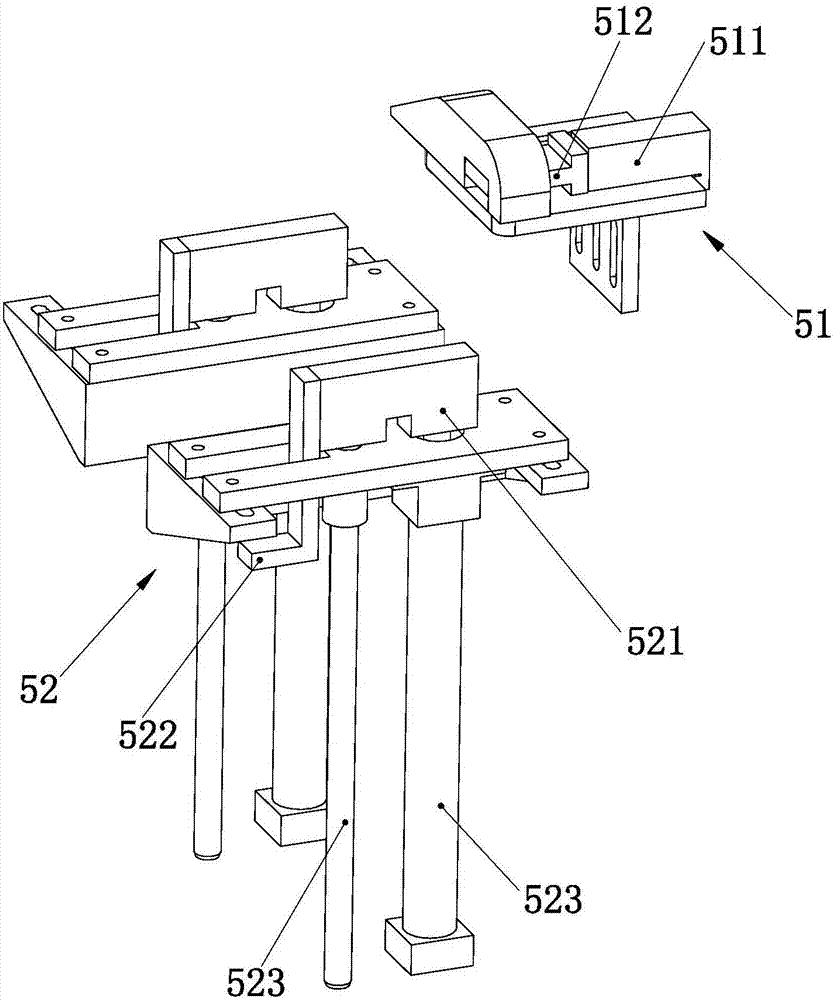

[0024] Such as figure 1 — Figure 5 A fully automatic shoe sole molding machine shown includes a body 1, a turntable 2 that is rotatable on the body 1 and has a number of sole injection molds 6 evenly distributed on it, and molding injection stations 11 that are sequentially arranged along the outer peripheral surface of the turntable 2. 12, the mold lock opening station 12 and the mold opening station 13, the molding injection station 11 is equipped with an injection head mechanism 3, the mold lock opening station 12 is equipped with an opening mold buckle mechanism 4, and the mold opening station is 13 places A mold cover opening mechanism 5 is provided, and the opening mold buckle mechanism 4 includes a drive source 41 erected on the body 1 and a top plate 42 that is linked with the drive source 41 and can be lifted and unlocked for the mold buckle of the mold cover in the sole injection mold 6 The mold opening mechanism 5 includes a relief block 53 erected on the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com