Vacuumizing transfer device of bag feeding food packing equipment

A food packaging and transfer device technology, applied in packaging and other directions, can solve problems such as inability to complete high-efficiency packaging, affecting equipment packaging speed, and low transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

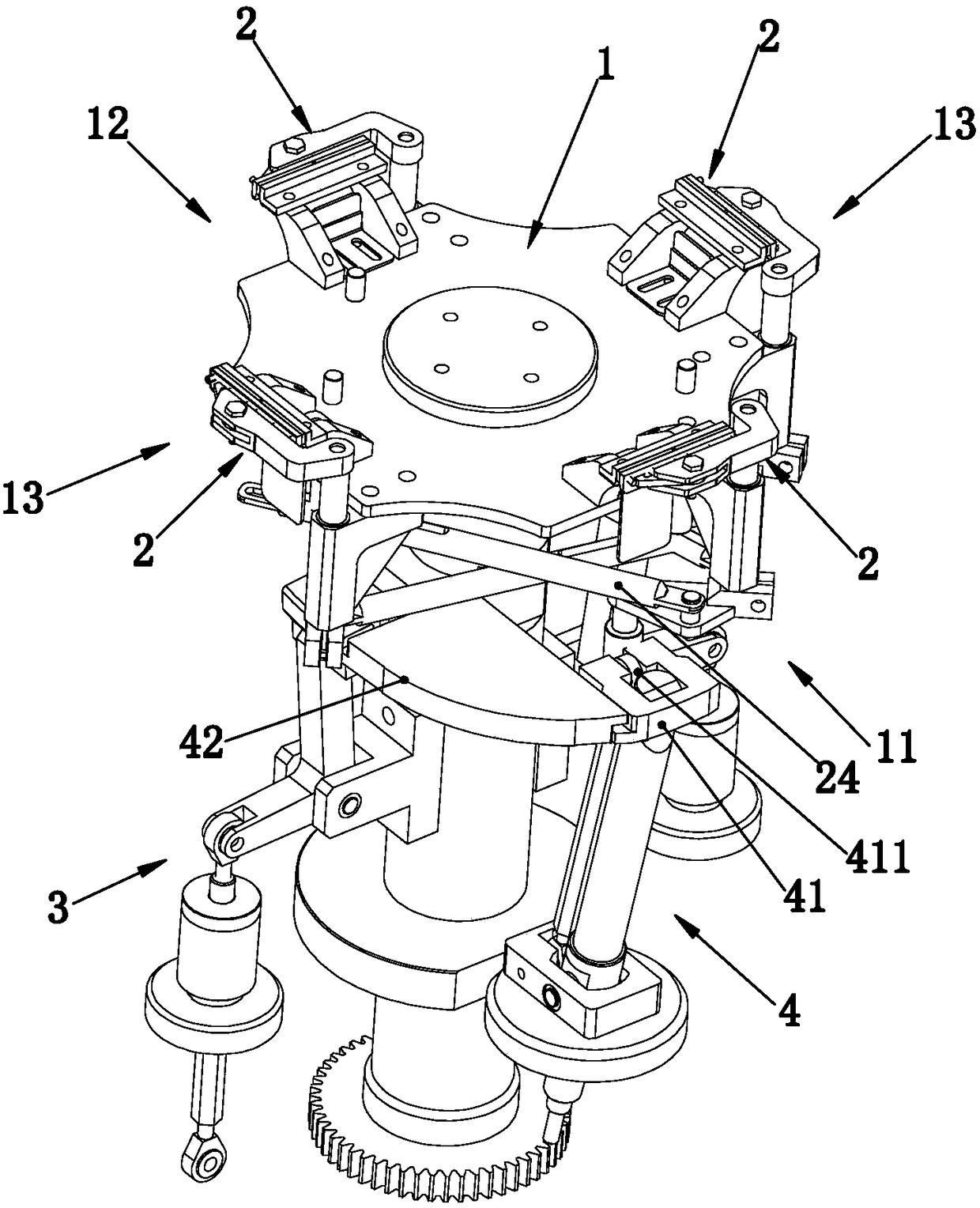

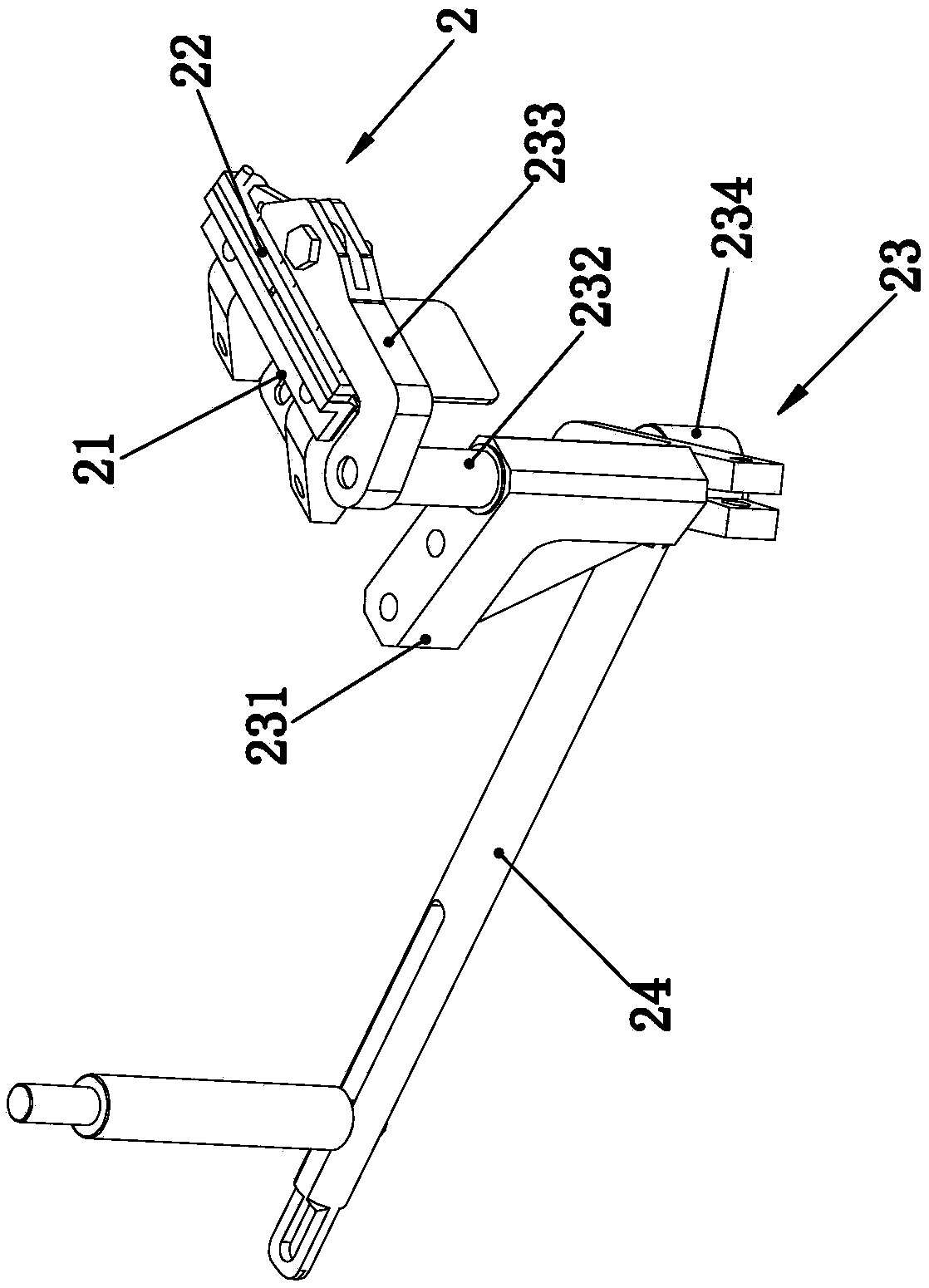

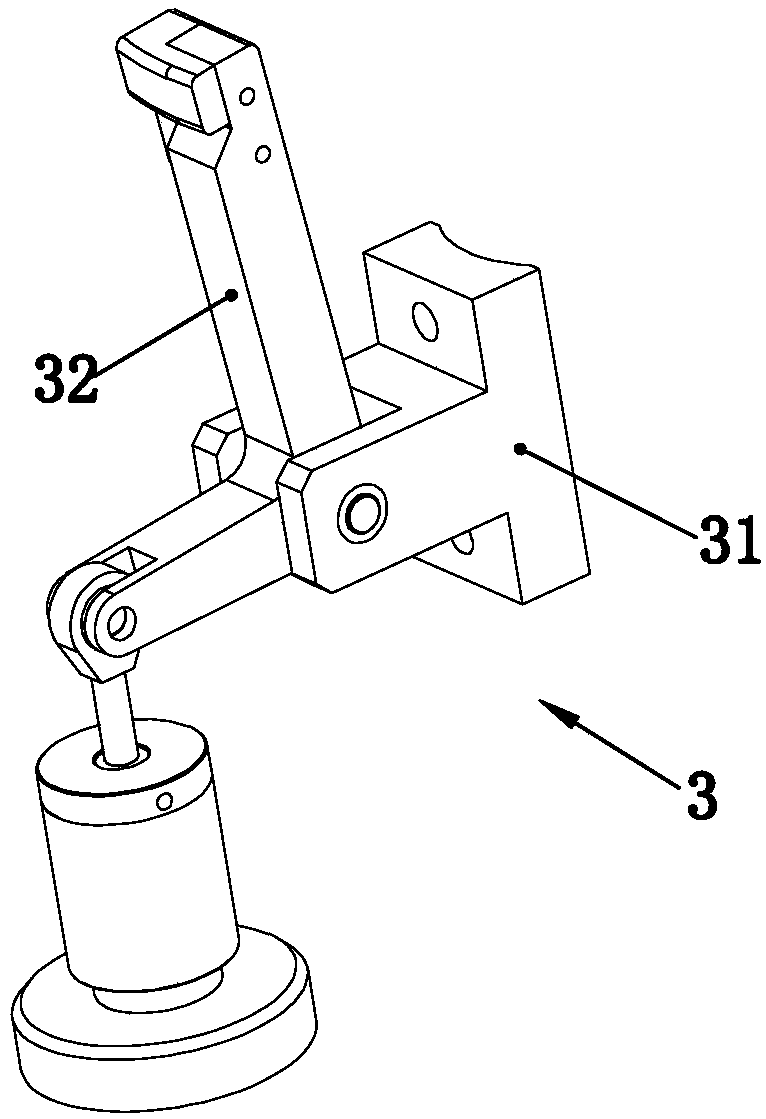

[0015] Such as figure 1 — image 3 The shown vacuum transfer device for bag-type food packaging equipment includes a rotatable turntable 1 and a number of clamping claws 2 evenly distributed on the turntable 1, and the turntable 1 includes a feeding station 11. The transfer transition station 12 corresponding to the loading station 11 and the output station 13 corresponding to each other between the feeding station 11 and the transfer transition station 12 are located at the output station 13 respectively. The opening driving mechanism 3 that urges the clamping claws 2 to open, and the clamping driving mechanism 4 that urges the clamping claws 2 to close is provided at the loading station 11 . In the above scheme, when the packaging bag to be filled with food is at the feeding station 11, the clamping claw 2 at the feeding station 11 of the turntable 1 is in an open state, and after the packaging bag enters the clamping claw 2, clamping The holding drive mechanism 4 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com