Coaxial linkage type braiding feeder

A linkage type, braided technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of unstable overall transmission, increased production cost, complex transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

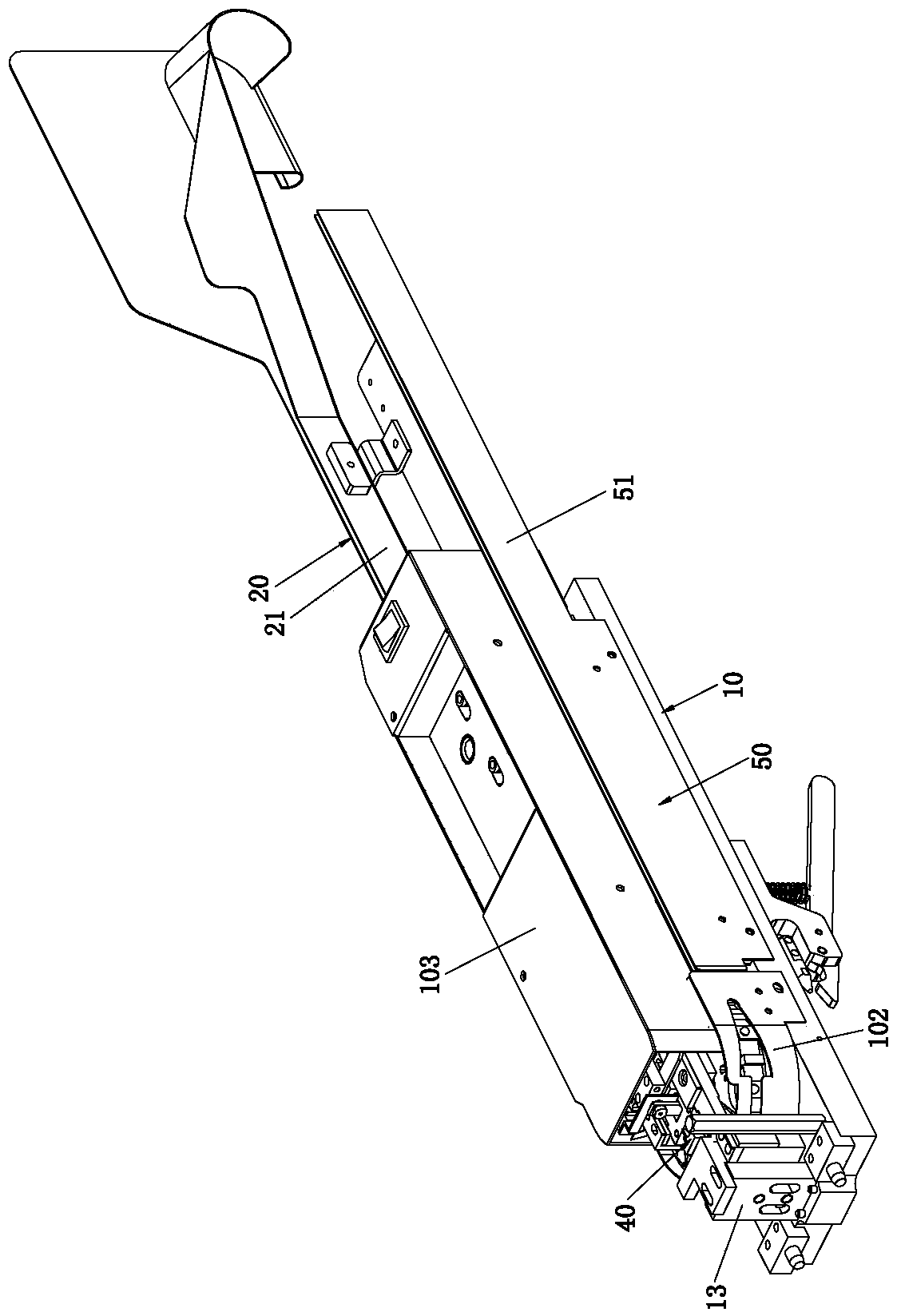

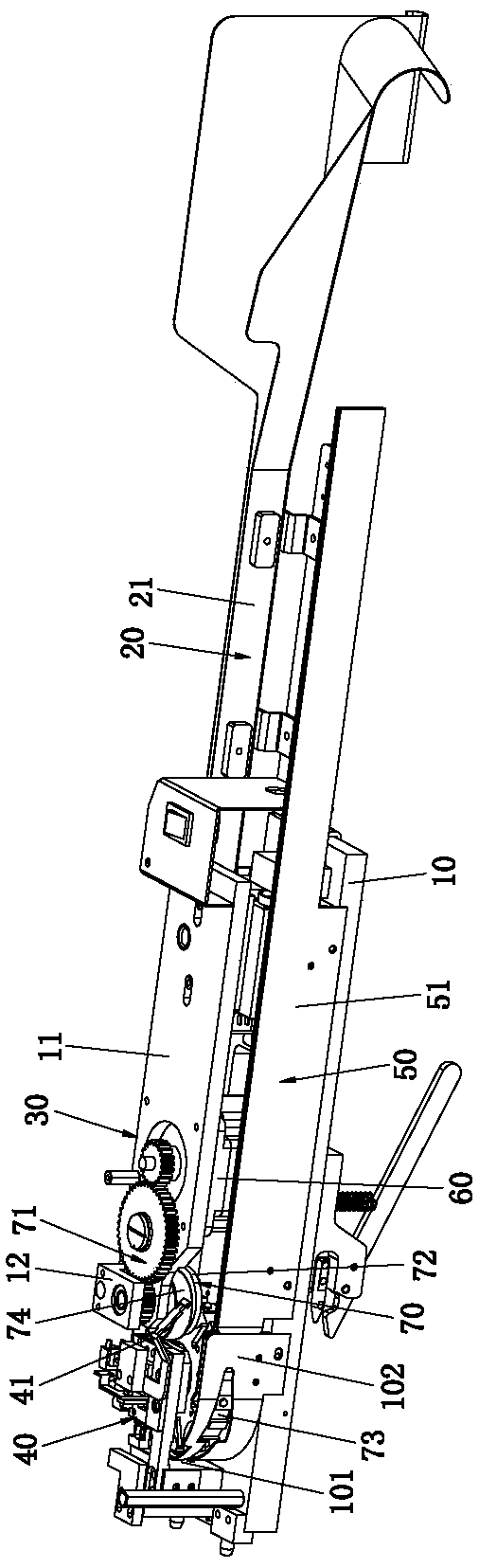

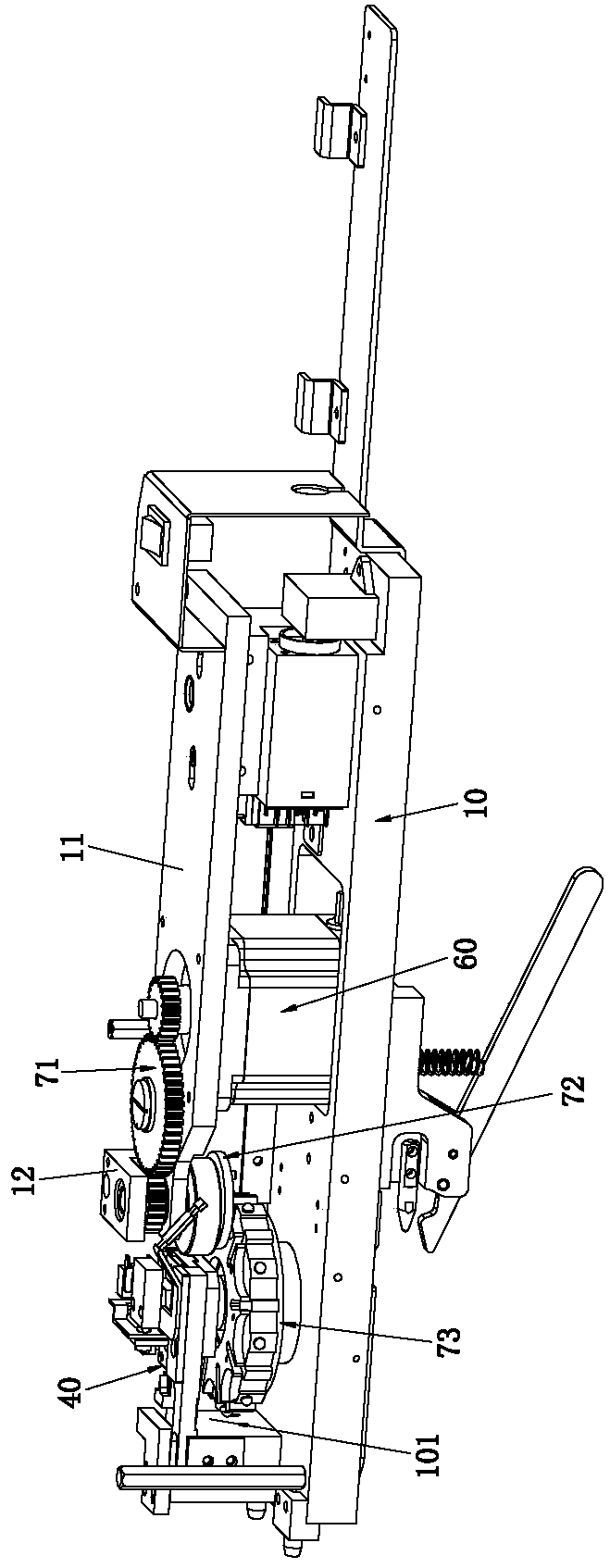

[0062] Please refer to Figure 1 to Figure 14As shown, it shows the specific structure of the embodiment of the present invention.

[0063] The coaxial linkage braiding feeder includes a base 10 and a loading mechanism 20, a feeding mechanism 30, a cutting mechanism 40, and a feeding mechanism 50 installed on the base 10; the feeding mechanism 30 includes a driving device 60 And the linkage 70; one end of the linkage 70 is connected to the driving device 60, and the other end is connected to the feeding mechanism 20, the cutting mechanism 40, and the blanking mechanism 50; the linkage 70 includes a transmission gear set 71, an eccentric wheel 72, The braiding wheel 73 that is used to drive the tape to move for feeding; one end of the transmission gear set 71 is connected to the driving device 60, and the other end is connected to one end of the eccentric wheel 72; the other end of the eccentric wheel 72 is intermittently connected to the Braiding wheel 73, this braiding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com