Small Diameter Cylindrical Sewing Machine

A sewing machine and small-diameter technology, applied in the field of sewing machines, can solve the problems of complex structure, high production cost, difficult automatic sewing and thread trimming, etc., and achieve the effects of simple and reasonable structural design, improved processing quality, and omission of thread trimming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

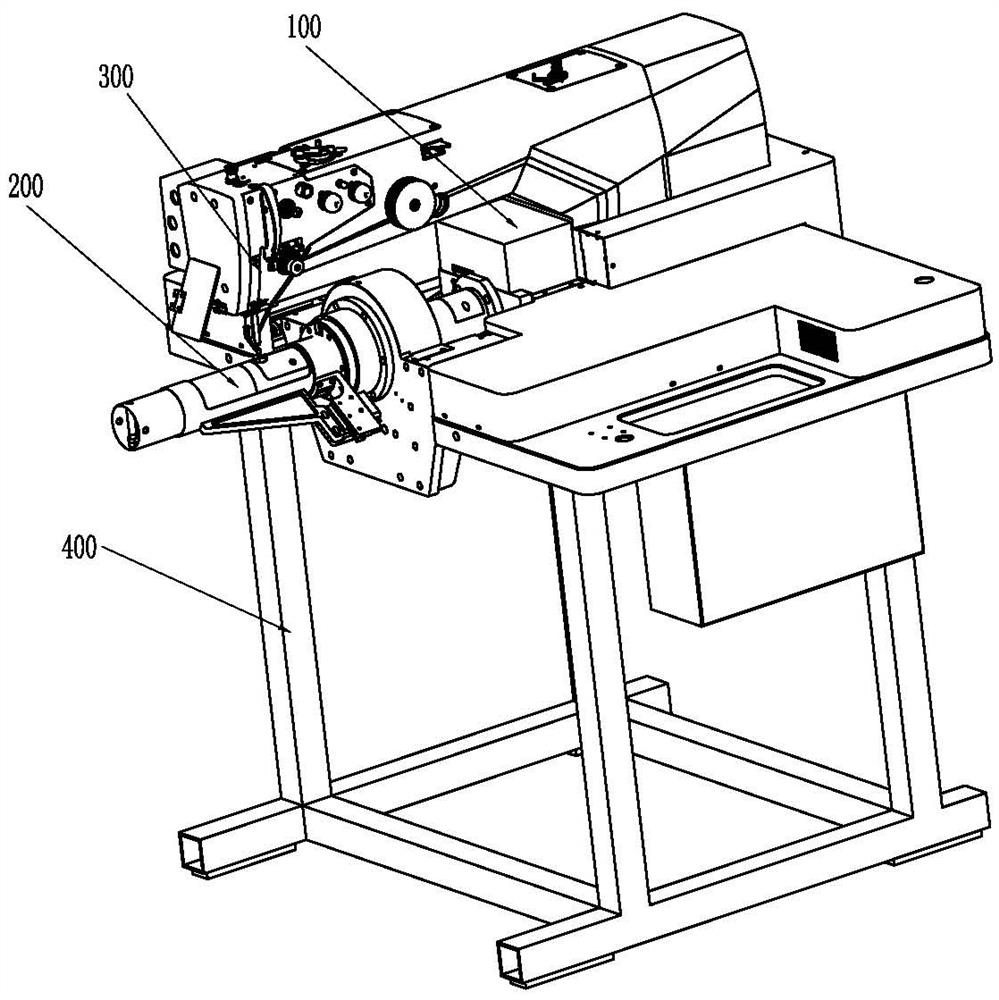

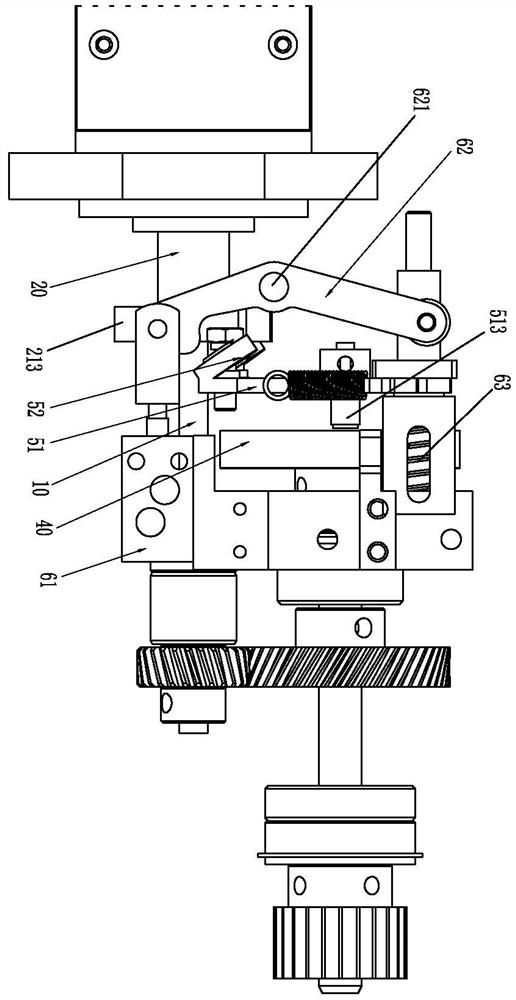

[0058] Please refer to Figure 1 to Figure 13 As shown, it shows the specific structure of the embodiment of the present invention.

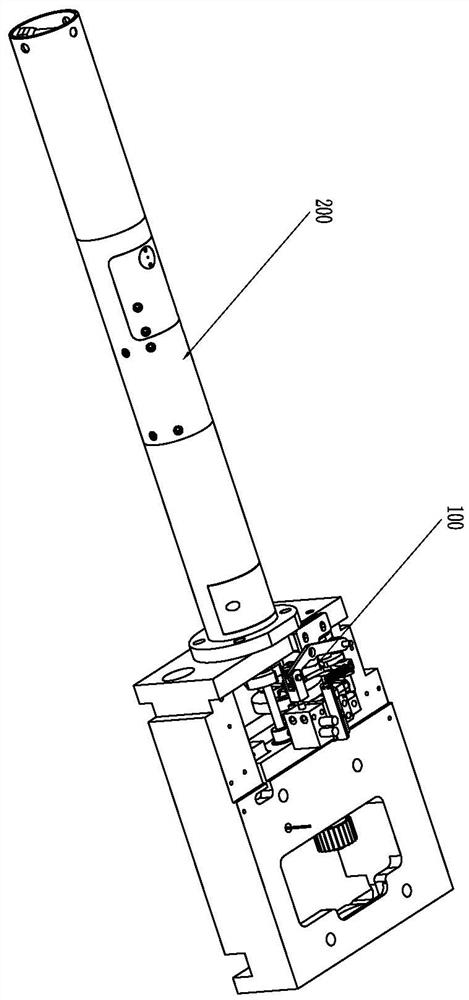

[0059] Such as figure 1 As shown, it shows a small-diameter cylinder sewing machine, which has a frame 400, a machine head 300 arranged on the frame 400, a cylinder 200 located below the machine head 300, and an automatic thread trimmer 100; The invention focuses on the automatic thread trimmer 100. In this paper, the cylinder 200 and the automatic thread trimmer 100 are introduced to realize the small diameter design of the cylinder part:

[0060] The top of the cylinder 200 is an arc-shaped processing table. The cylinder 200 is provided with an eccentric installation through hole 201 located above the axis of the cylinder and extending in the same direction as the cylinder. The eccentric installation through hole 201 is installed There is a moving knife shaft tube 202, the rotary hook shaft 10 is installed in the said moving knife shaft tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com