Hidden bracket

A hidden bracket technology, which is applied in the field of hidden brackets, can solve the problem that the pole cannot be recycled, and achieve the effect of reducing space, expanding the scope of use, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

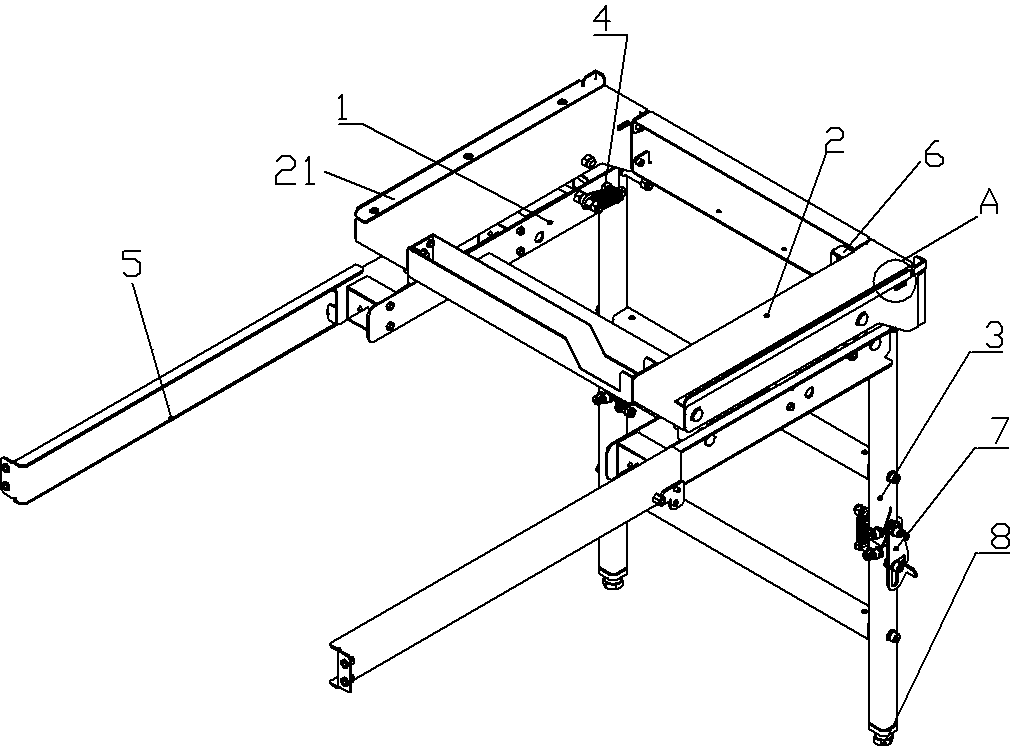

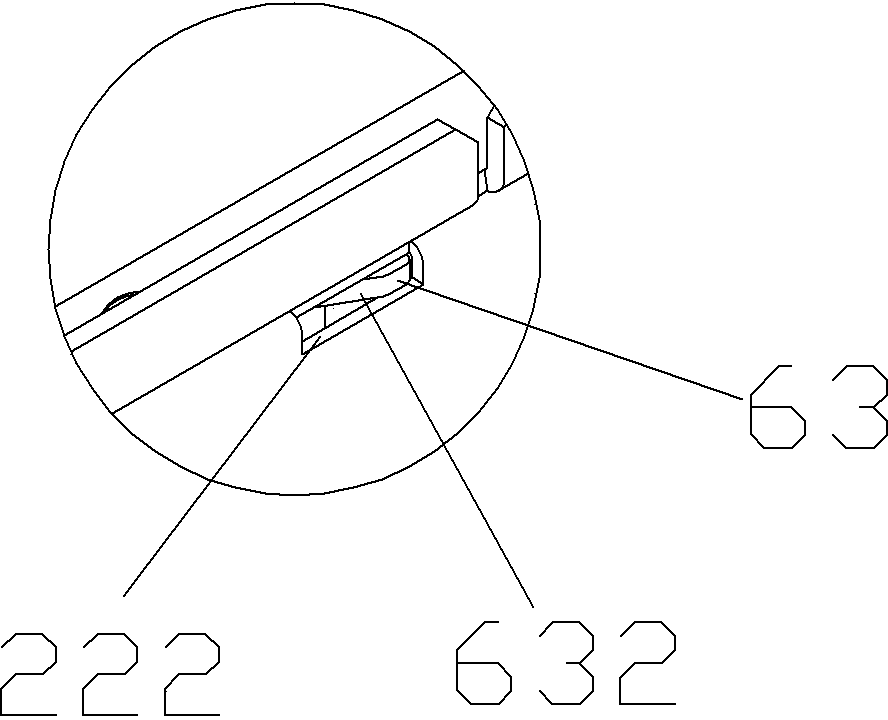

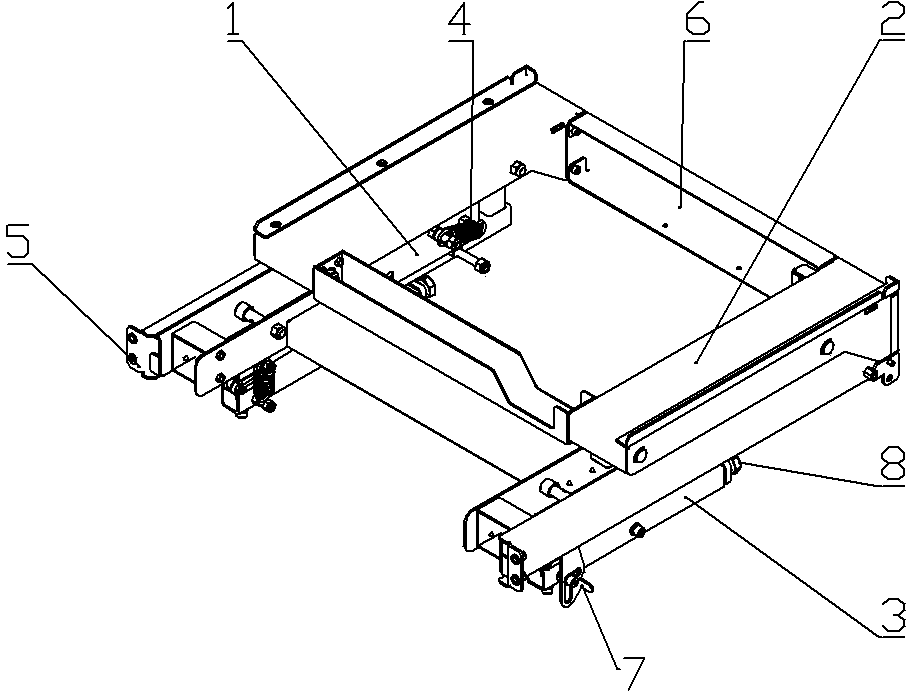

[0036] like Figures 1 to 10 As shown, an embodiment of a hidden bracket, the bracket in this embodiment includes a bottom frame 1 for sliding assembly with a guide rail 5 fixed on the cabinet body to realize the extension and concealment of the bracket, the bottom frame 1 is hinged with a bracket 3 that is used to retract when the bracket is hidden, and to expand when the bracket is stretched out. The bottom frame 1 is supported by the bracket 3 and the middle connecting frame. There is a top frame 2, and the top frame 2, the bracket 3, and the middle connection The frame and the bottom frame 1 are hinged correspondingly to form a linkage mechanism, and the hinge center axes of the hinges corresponding to the intermediate connecting frame and the bracket 3 on the top frame 2 and the bottom frame 1 are arranged in parallel, and the planes where the top frame 2 and the bottom frame 1 are located are all in line with the The chassis 1 is parallel to the sliding direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com