Four-connecting-rod locking mechanism and foldable trolley using same

A locking mechanism, four-bar linkage technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

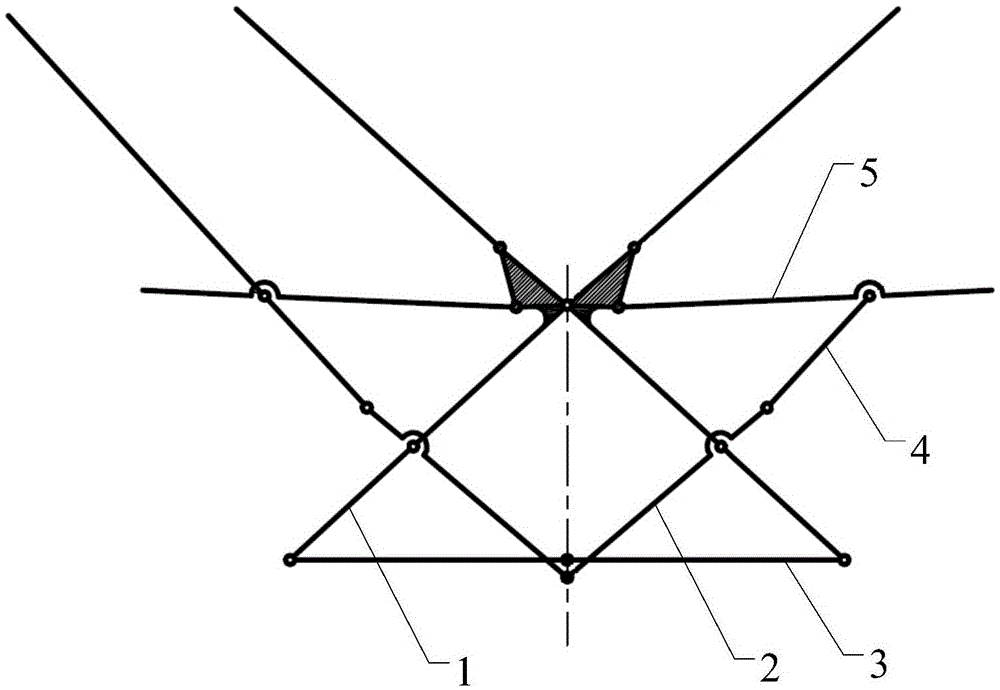

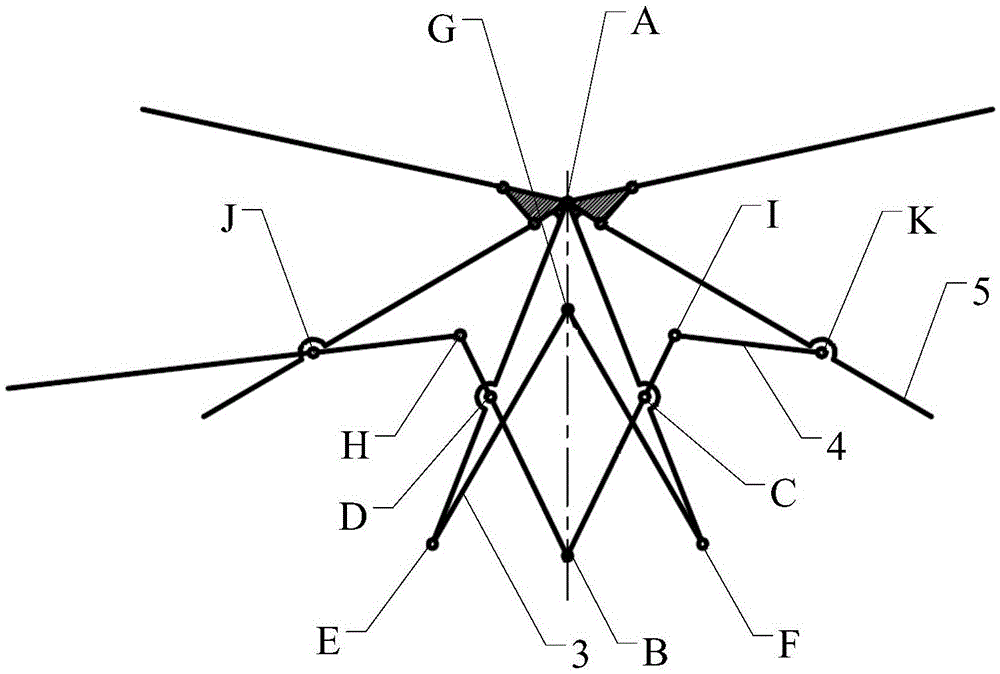

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention provides a four-link locking mechanism, which is mainly used to describe the use of a set of two-link assembly mechanisms in this technical solution to lock three sets of four-link assemblies mechanism, thereby forming a truss assembly that can be folded and opened in linkage.

[0036] The four-link locking mechanism includes a two-link assembly and a middle four-link assembly;

[0037] The middle four-link assembly is a rhombus structure composed of two symmetrically arranged first connecting rods 1 and two symmetrically arranged second connecting rods 2. The top ends of the two first connecting rods 1 and The bottom ends of the two second connecting rods 2 are hinged by hinges; the two connecting rod assemblies are composed of two equal-length third connecting rods 3 hinged; the two equal-length connecting rod assemblies are composed of two equal-length The third connecting rod 3 is formed, and when tw...

Embodiment 2

[0045] Such as image 3 or 4, the embodiment of the present invention provides a four-link locking mechanism, and this embodiment 2 further defines the structure of the four-link locking mechanism on the basis of embodiment 1, improving the four-link The stability and safety of the locking mechanism connection.

[0046] Such as Figure 4 As shown, the position of the hinge point in the middle of the two connecting rod assemblies is lower than the position of the hinge point with the first connecting rod 1, and the bottom of one of the second connecting rods 2 is connected with a limit rod 6, and the two The hinge point in the middle of the connecting rod assembly abuts against the limiting rod 6 .

[0047] The two-link assembly has three rotation centers, and the rotation center in the middle is lower than the rotation centers on both sides, so when the four-link locking mechanism is folded, the component force on the two-link assembly must be horizontal, Therefore, it is n...

Embodiment 3

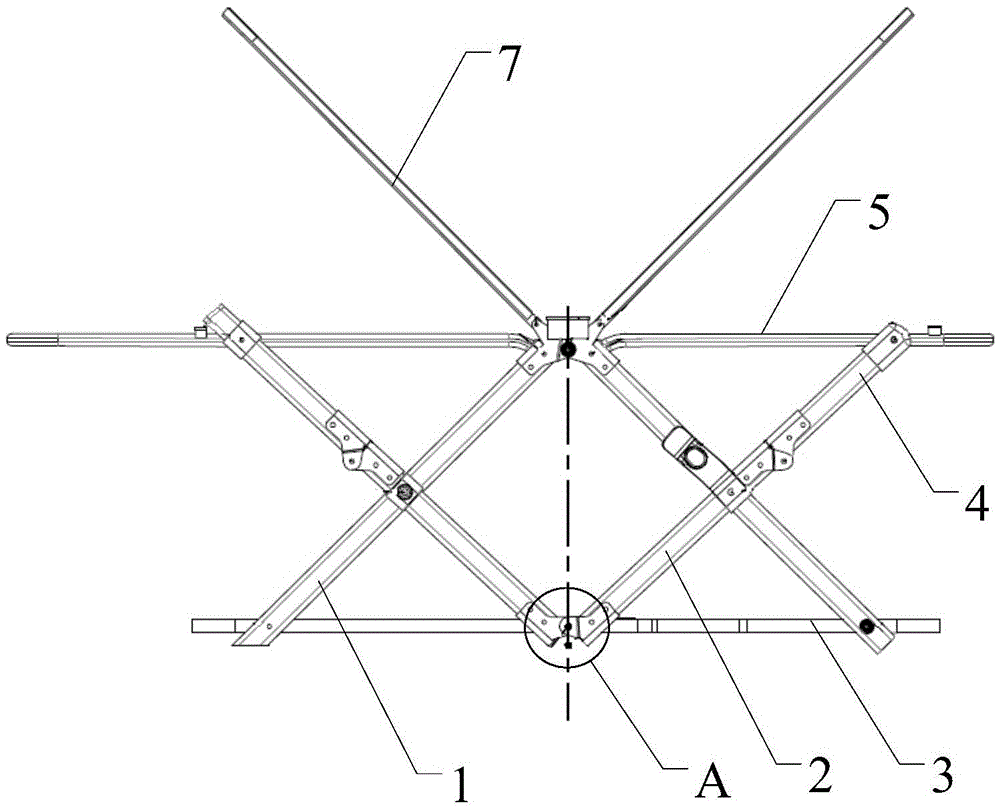

[0050] Such as Figure 5 As shown, in order to overcome the defects existing in trolleys or handcarts in the prior art, the present invention provides a folding trolley using the four-link locking mechanism. The full linkage between the rods can be realized, and the trolley has wide application and high safety.

[0051] This handcart comprises car body 8, and described car body 8 comprises the folding vehicle frame 9 that can unfold or folds and the wheel 10 that is arranged at the bottom of described folding vehicle frame 9, and described wheel 10 comprises front wheel and rear wheel, and described folding The vehicle frame 9 is composed of two symmetrically arranged four-bar linkage locking mechanisms connected by struts 11, and the two-link assembly in the two four-bar linkage locking mechanisms is connected by struts 11 to form a double-folded chassis 12 , the ends of the first crossbar 5 in the two four-bar linkage locking mechanisms are connected by the struts 11 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com