Rocker arm type auxiliary clamping device for numerical control machining

A clamping device and rocker-type technology, which is applied in the field of rocker-type auxiliary clamping devices, can solve the problems of easy shaking, single function of rocker-type clamps, and inability to adjust the clamping force of workpieces, etc., and achieve quick adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

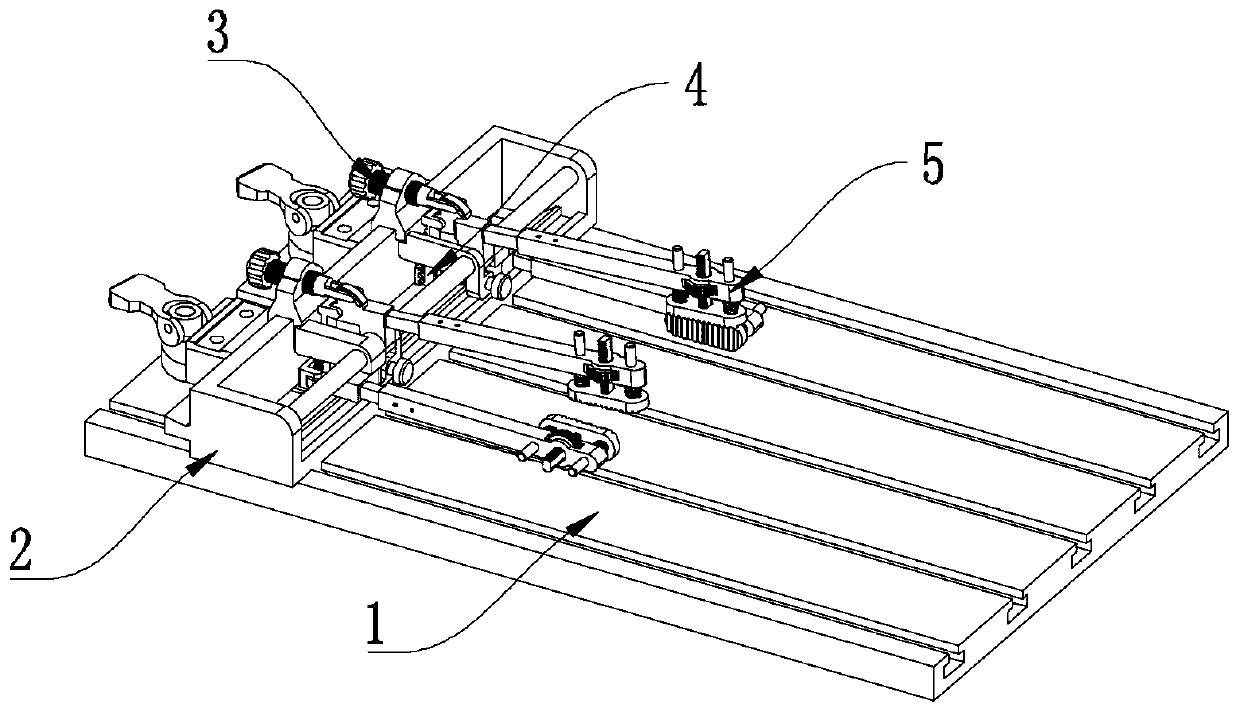

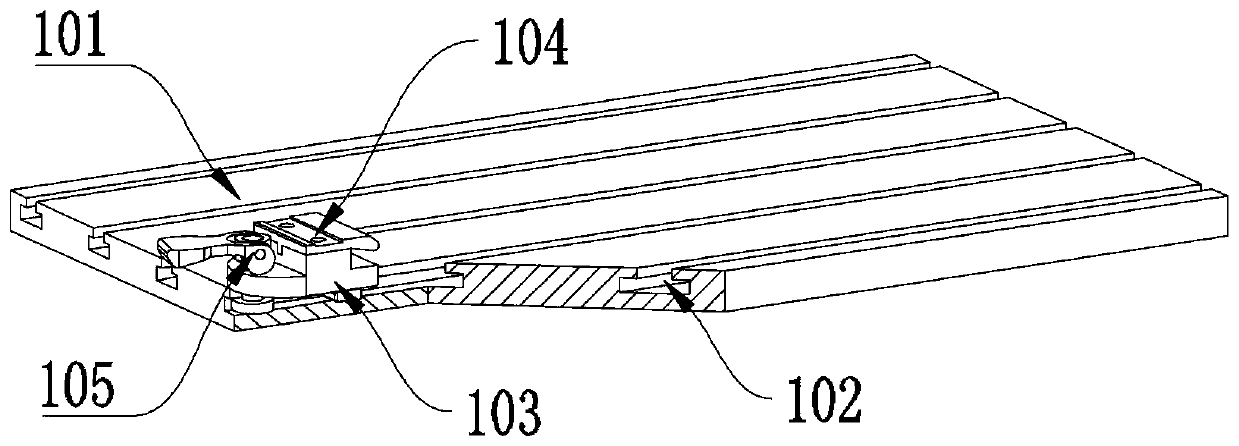

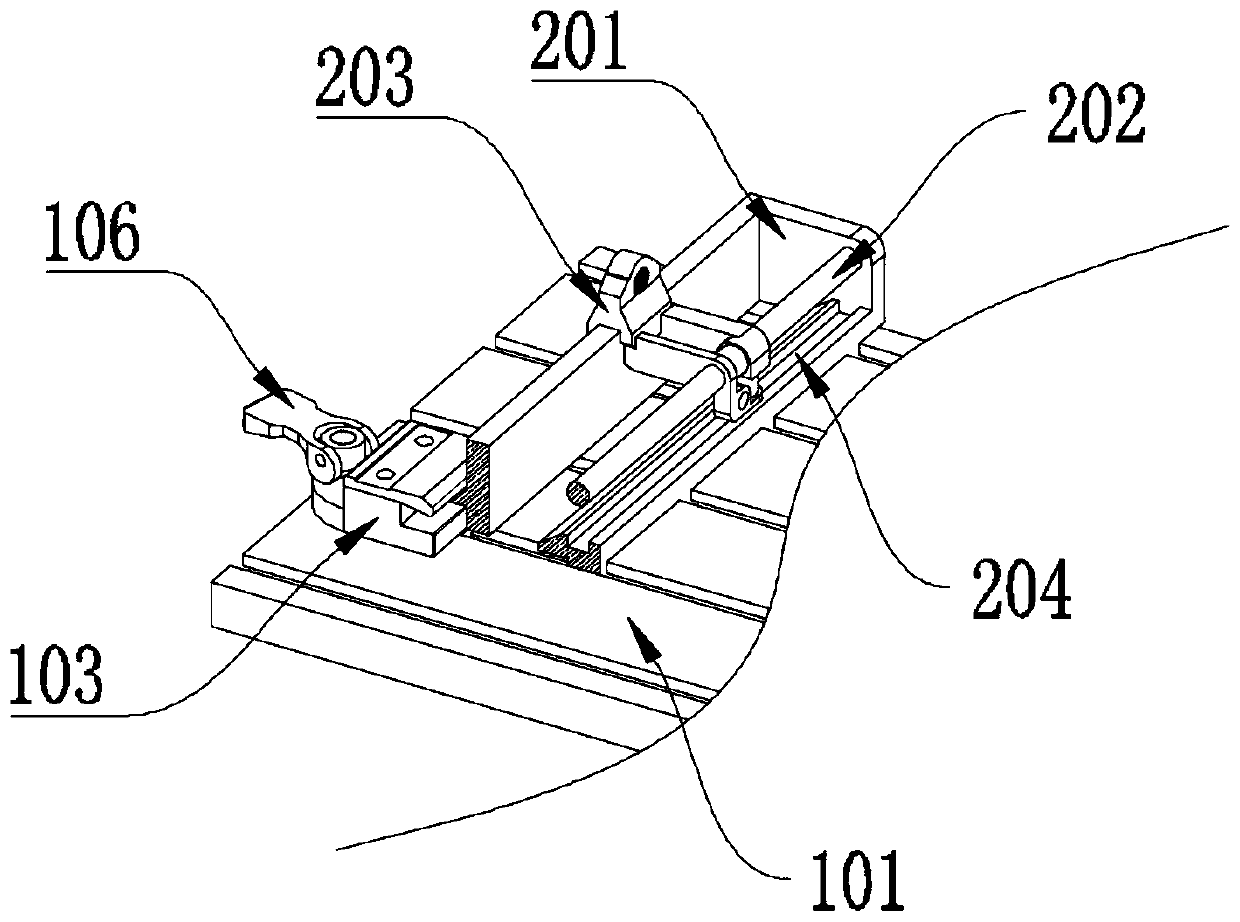

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a rocker-type auxiliary clamping device for numerical control machining, which includes a fixed structure 1; a sliding structure 2 is slidably installed on the upper end surface of the fixed structure 1, and the whole adjustment structure 3 is vertically slid and fixed on the sliding structure 2; the adjustment structure 3 is connected to the root of the rocker arm structure 4, and the clamping structure 5 is sleeved and installed at the end of the rocker arm structure 4, and the guide column at the middle position of the fastening plate 502 is provided with threads as a whole , and the fixed knob 503 is installed on the threaded guide column on the telescopic rod 501, and the threaded engagement between the fixed knob 503 and the guide column is fixed, and the two ends of the threaded guide column are vertically cut off, and Simultaneously, the inner warp of the fixed knob 503 cuts off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com