Automatic shoe pad production assembly line

An automatic production and assembly line technology, which is applied to footwear, other household appliances, household appliances, etc., can solve the problems of uneven mixing of raw materials, insufficient mixing force of drums, and large loss of process raw materials, so as to reduce the loss of product skin and improve production. Good stability and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

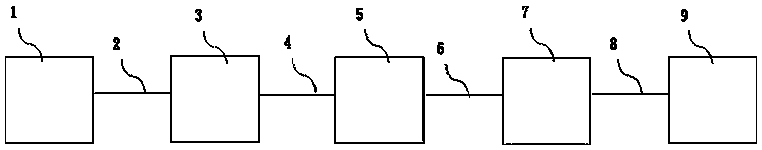

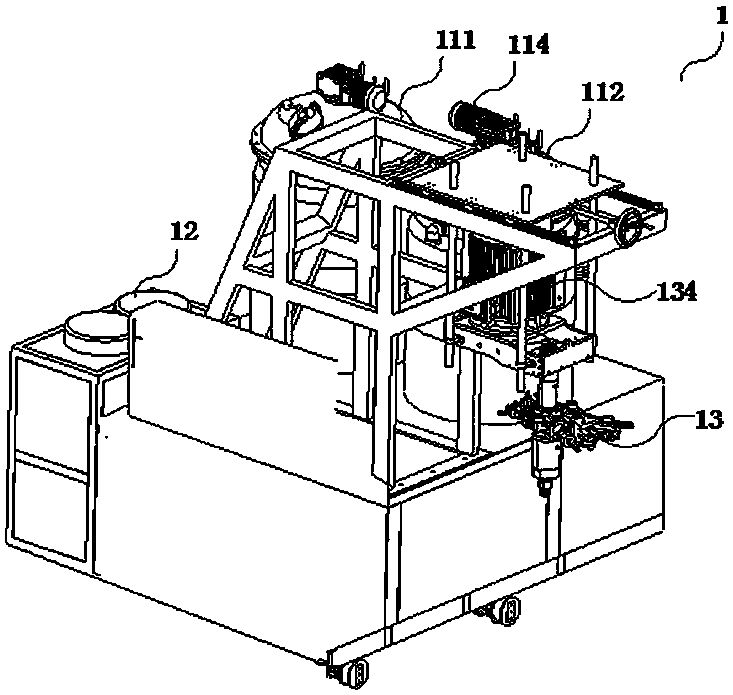

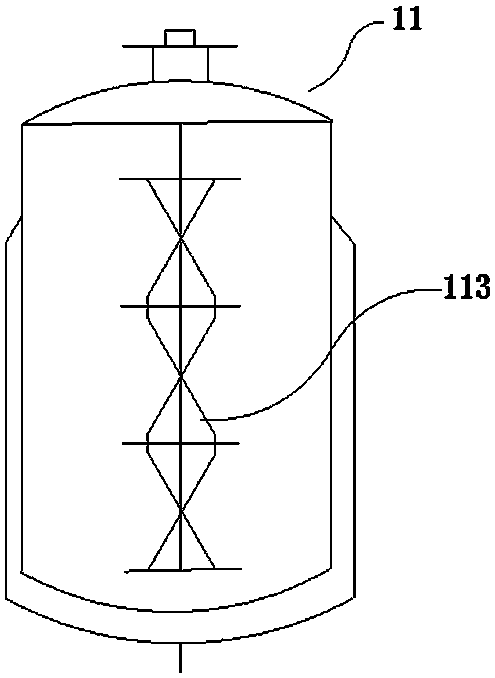

[0025] Such as figure 1 and figure 2 As shown, an automatic production line for insoles includes a filling machine 1, a foaming mold 3, a cutting machine 5, a plastic-coating machine 7 and a cloth patching machine 9, and the filling machine 1 communicates with the foaming machine 2 through the filling hose 2. The mold 3 is connected, and the foaming mold 3 is connected with the cutting machine 5 through the first conveyor belt 4, and the cutting machine 5 is connected with the plastic coating machine 7 through the second transmission belt 6, and the plastic coating Machine 7 is connected with pasting machine 9 through the 3rd transmission belt 8, and described perfusion machine 1 comprises material tank 11, refrigerator 12 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com