Anti-floating method and device for bored concrete pile reinforcement cage

A steel cage and concrete technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of pipe blockage and heavy object suppression, so as to prevent the steel cage from floating and improve the pouring efficiency and quality. , the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

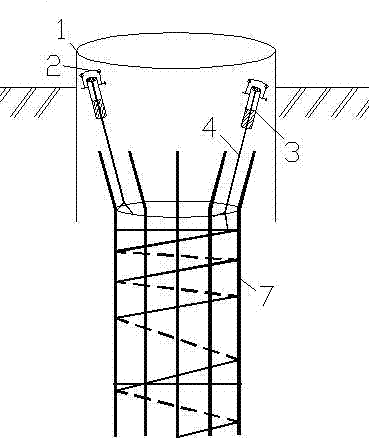

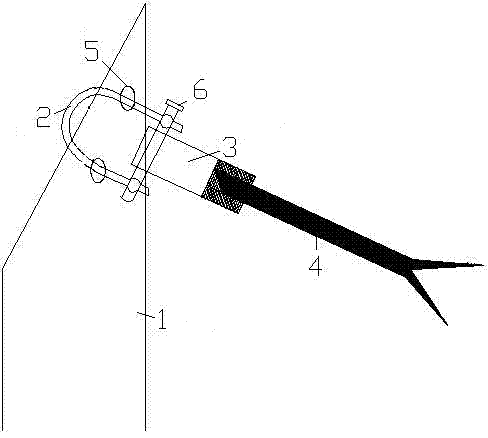

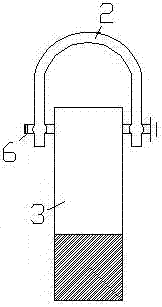

[0022] Please refer to Figure 1 to Figure 6 , the concrete cast-in-place pile reinforcement cage anti-floating method of the embodiment of the present invention, its technological process is:

[0023] Step a), before starting to drill, take the center of the pile position as the center, and determine the position of the casing on the soil according to the radius of the casing of the reinforced cage anti-floating device of the concrete pouring pile. After the casing is in place, apply pressure to move the casing The cylinder is buried in the soil, and then the drilling is started;

[0024] Step b), after the concrete pouring pile is formed into a hole, put the reinforcement cage 7 into the hole, the lock buckle passes through the installation hole 5 on the casing and connects with the connecting sleeve rod 3 through the bolt 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com