Quantitative filling device and quantitative filling method

A filling device and filling pipe technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of large quantitative filling accuracy error, inability to meet quantitative filling, flowmeter measurement error, etc., and achieve filling accuracy High, the perfusion process is uniform and stable, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention are described in detail below:

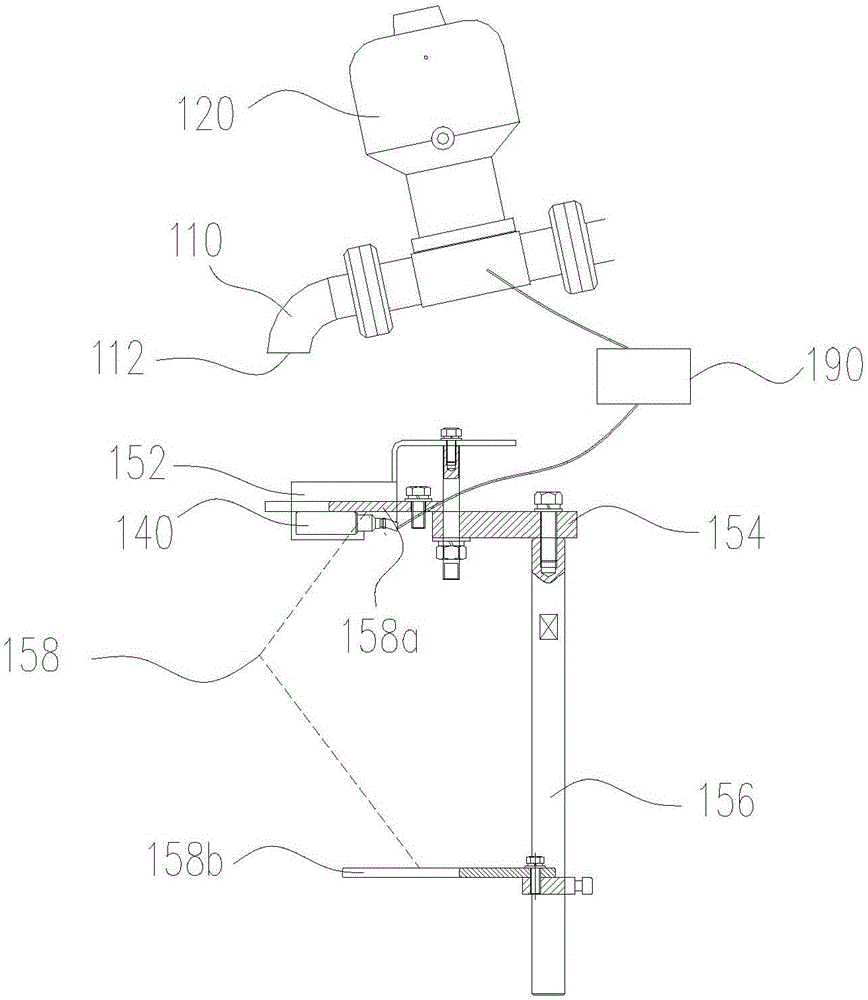

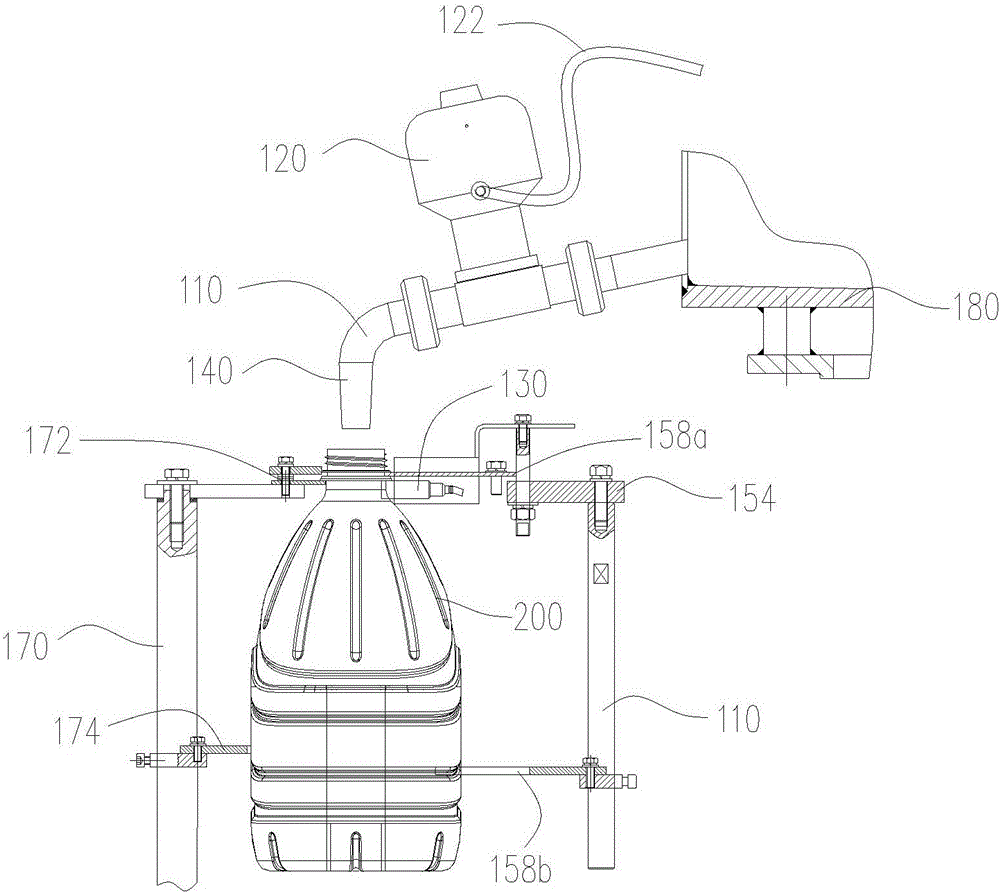

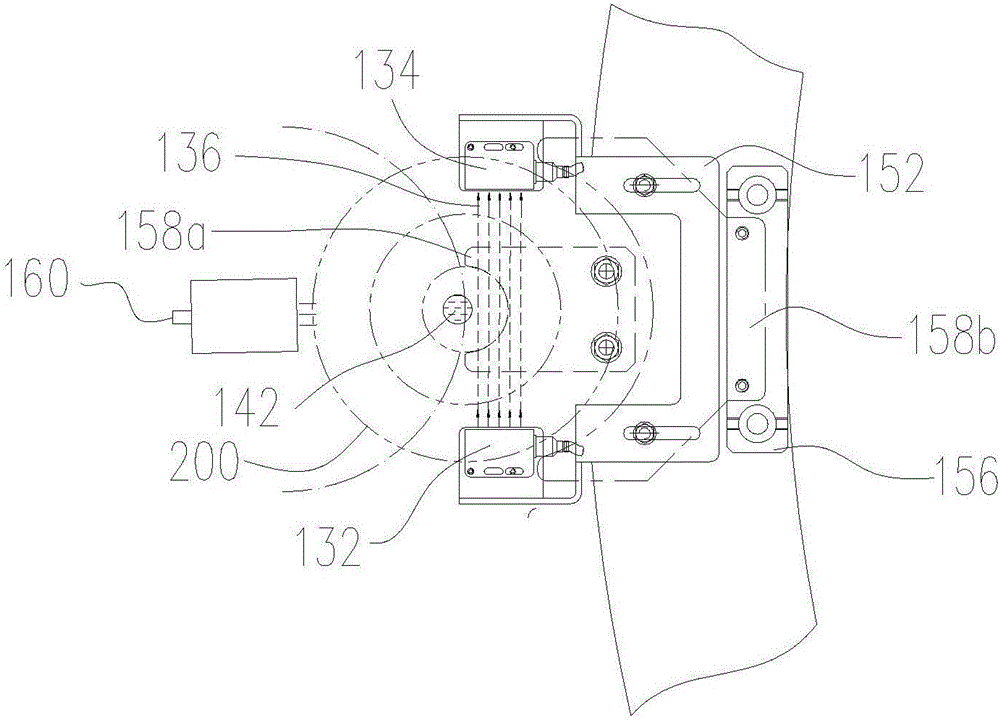

[0051] From figure 1As shown, the quantitative filling device of the present invention includes a filling pipe 110, the filling pipe 110 is provided with a water outlet 112; a switch valve 120, the switching valve 120 communicates with the filling pipe 110; a photoelectric detection device 130, the photoelectric detection device 130 includes a light source transmitter 132 and a receiver 134, the light source transmitter 132 and the receiver 134 are both arranged directly below the water outlet 112; and a controller 190, the control The device 190 is electrically connected to the photoelectric detection device 130 and the switch valve 120 .

[0052] The light source transmitter 132 and the receiver 134 are arranged symmetrically below the water outlet 112, so that the photoelectric detection device 130 can identify the rising liquid medium in the container without identifying the liquid mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com