Upper-pressing-lower-sucking-type slurry injection structure of automatic plate production line

An automated production line and board technology, applied in the field of foam board grouting, can solve the problems of reduced fire performance of foam boards, inconsistent slurry intake, affecting board yield and fire performance, etc., so as to improve the grouting rate and efficiency. The effect of perfusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

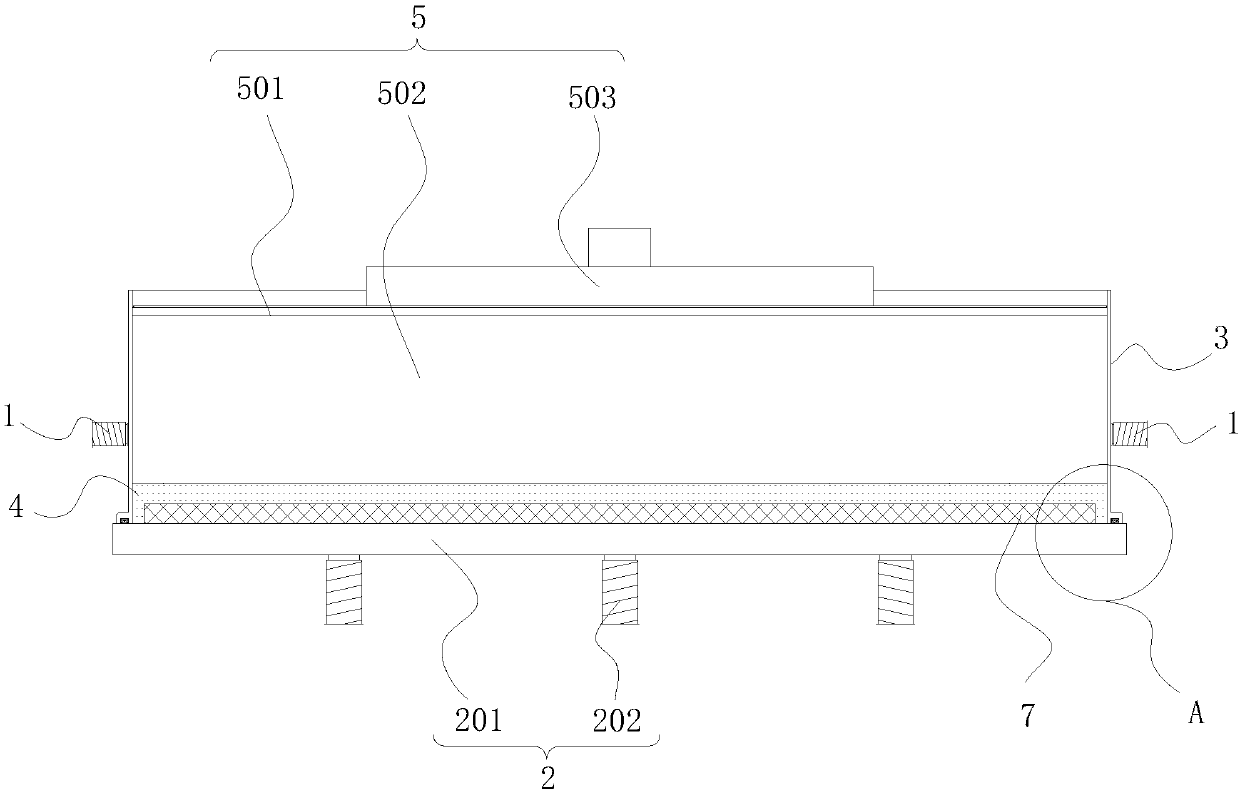

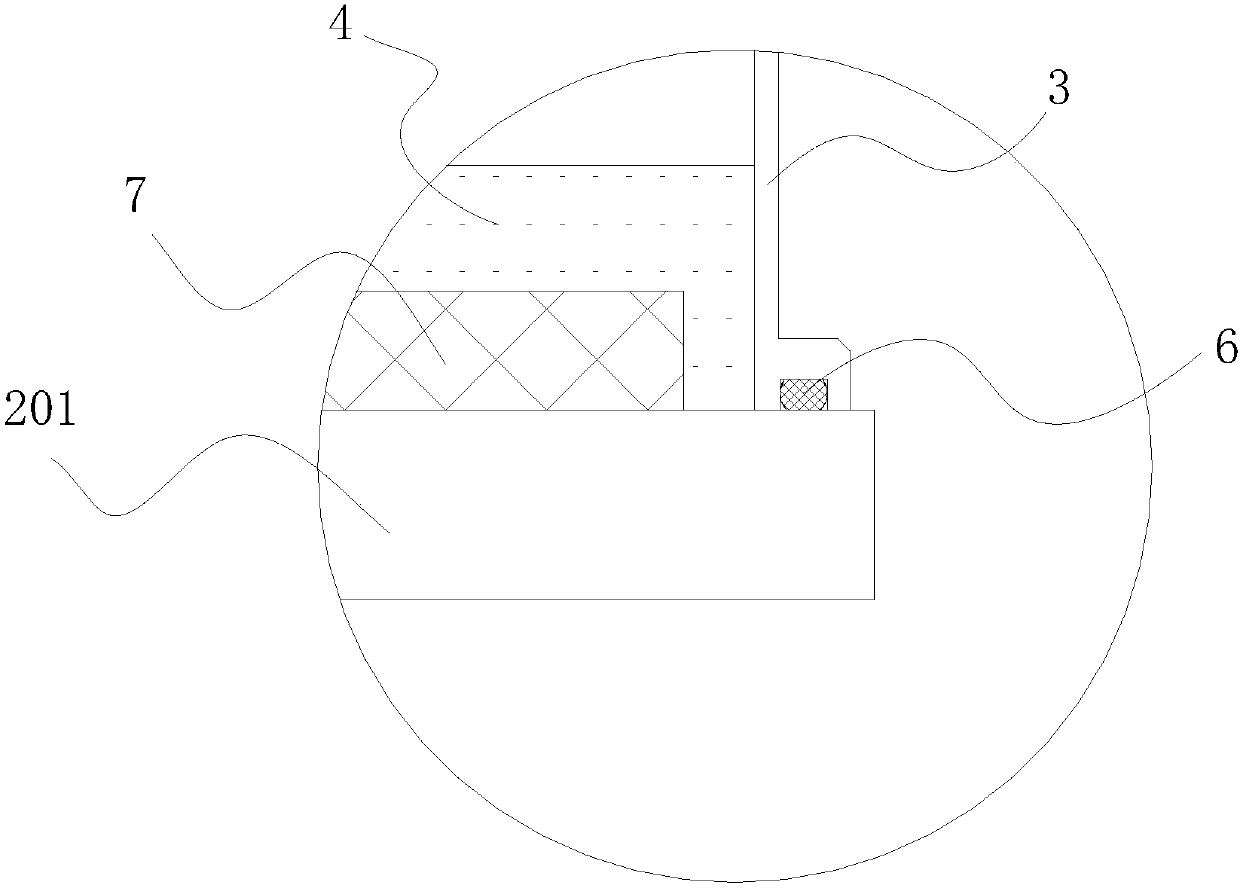

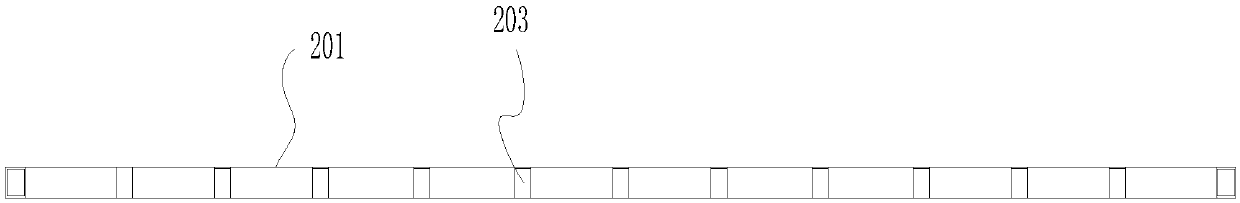

[0031] Such as Figure 1 to Figure 3 As shown, the press-down suction grouting structure of the plate automatic production line in this embodiment includes a material injection device 1 and a vacuum suction device 2, and the vacuum suction device 2 includes a vacuum plate 201 and a vacuum suction tube connected to the vacuum plate 201 202; the vacuum plate 201 is provided with a baffle 3 sealed with the vacuum plate 201, and the vacuum plate 201 and the baffle 3 together form an upwardly opening injection pool 4, and the injection device 1 and the injection pool 4 is connected, and the inner wall of the baffle plate 3 is sealed with a lower pressing member 5 . Wherein, the effect of injection device 1 is to inject slurry in injection tank 4, and vacuum suction device 2 should comprise the equipment that is used for extracting vacuum such as vacuum pump, and vacuum suction pipe 202 can vacuumize vacuum plate 201, and vacuum plate 201 A negative pressure is formed inside, and the...

Embodiment 2

[0035] Such as Figure 1 to Figure 3 As shown, the press-down suction grouting structure of the plate automatic production line in this embodiment includes a material injection device 1 and a vacuum suction device 2, and the vacuum suction device 2 includes a vacuum plate 201 and a vacuum suction tube connected to the vacuum plate 201 202; the vacuum plate 201 is provided with a baffle 3 sealed with the vacuum plate 201, and the vacuum plate 201 and the baffle 3 together form an upwardly opening injection pool 4, and the injection device 1 and the injection pool 4 is connected, and the inner wall of the baffle plate 3 is sealed with a lower pressing member 5 . Wherein, the effect of injection device 1 is to inject slurry in injection tank 4, and vacuum suction device 2 should comprise the equipment that is used for extracting vacuum such as vacuum pump, and vacuum suction pipe 202 can vacuumize vacuum plate 201, and vacuum plate 201 A negative pressure is formed inside, and t...

Embodiment 3

[0039] Such as Figure 1 to Figure 3 As shown, the press-down suction grouting structure of the plate automatic production line in this embodiment includes a material injection device 1 and a vacuum suction device 2, and the vacuum suction device 2 includes a vacuum plate 201 and a vacuum suction tube connected to the vacuum plate 201 202; the vacuum plate 201 is provided with a baffle 3 sealed with the vacuum plate 201, and the vacuum plate 201 and the baffle 3 together form an upwardly opening injection pool 4, and the injection device 1 and the injection pool 4 is connected, and the inner wall of the baffle plate 3 is sealed with a lower pressing member 5 . Wherein, the effect of injection device 1 is to inject slurry in injection tank 4, and vacuum suction device 2 should comprise the equipment that is used for extracting vacuum such as vacuum pump, and vacuum suction pipe 202 can vacuumize vacuum plate 201, and vacuum plate 201 A negative pressure is formed inside, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com