Patents

Literature

46results about How to "Uniform perfusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

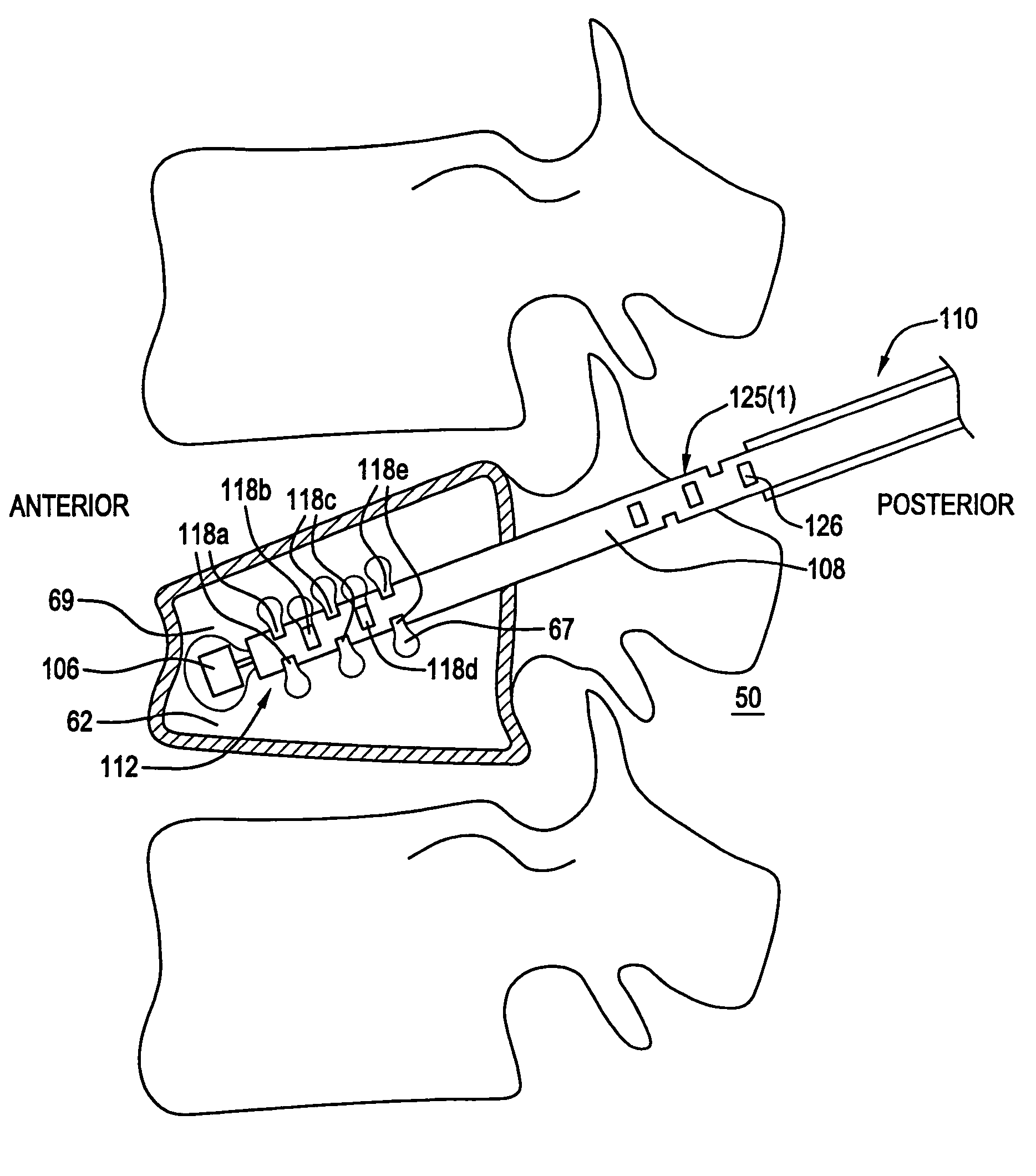

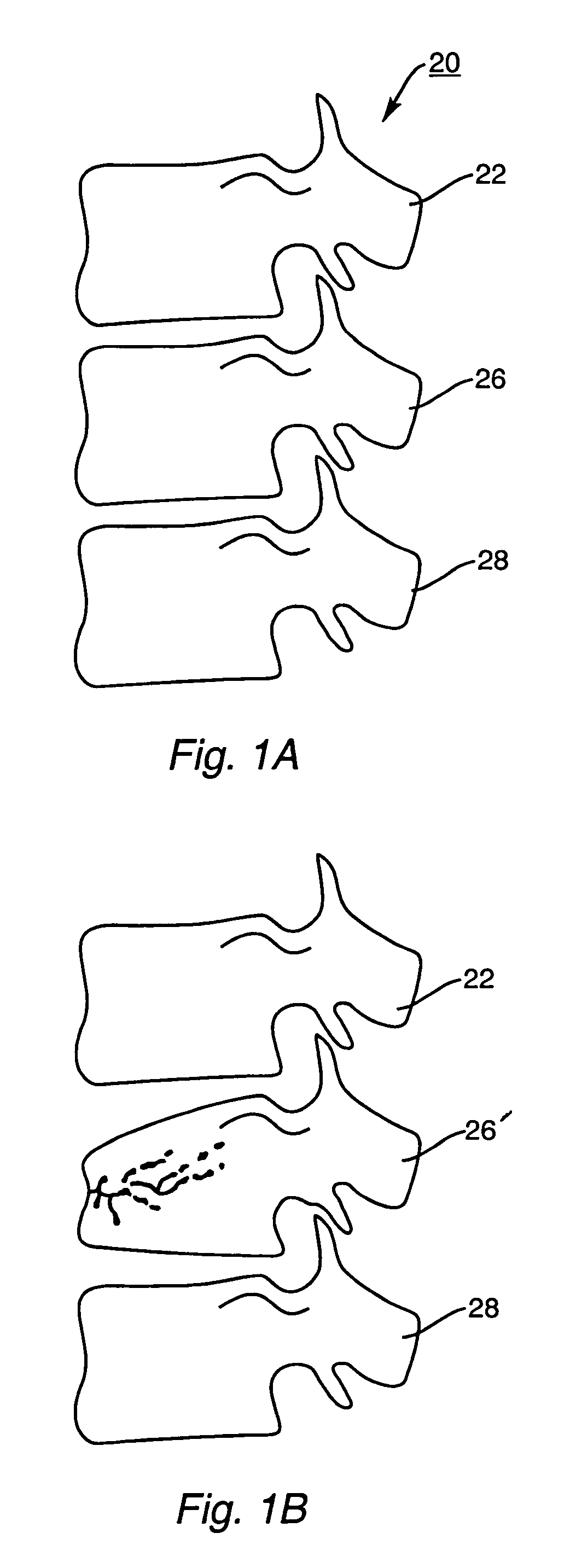

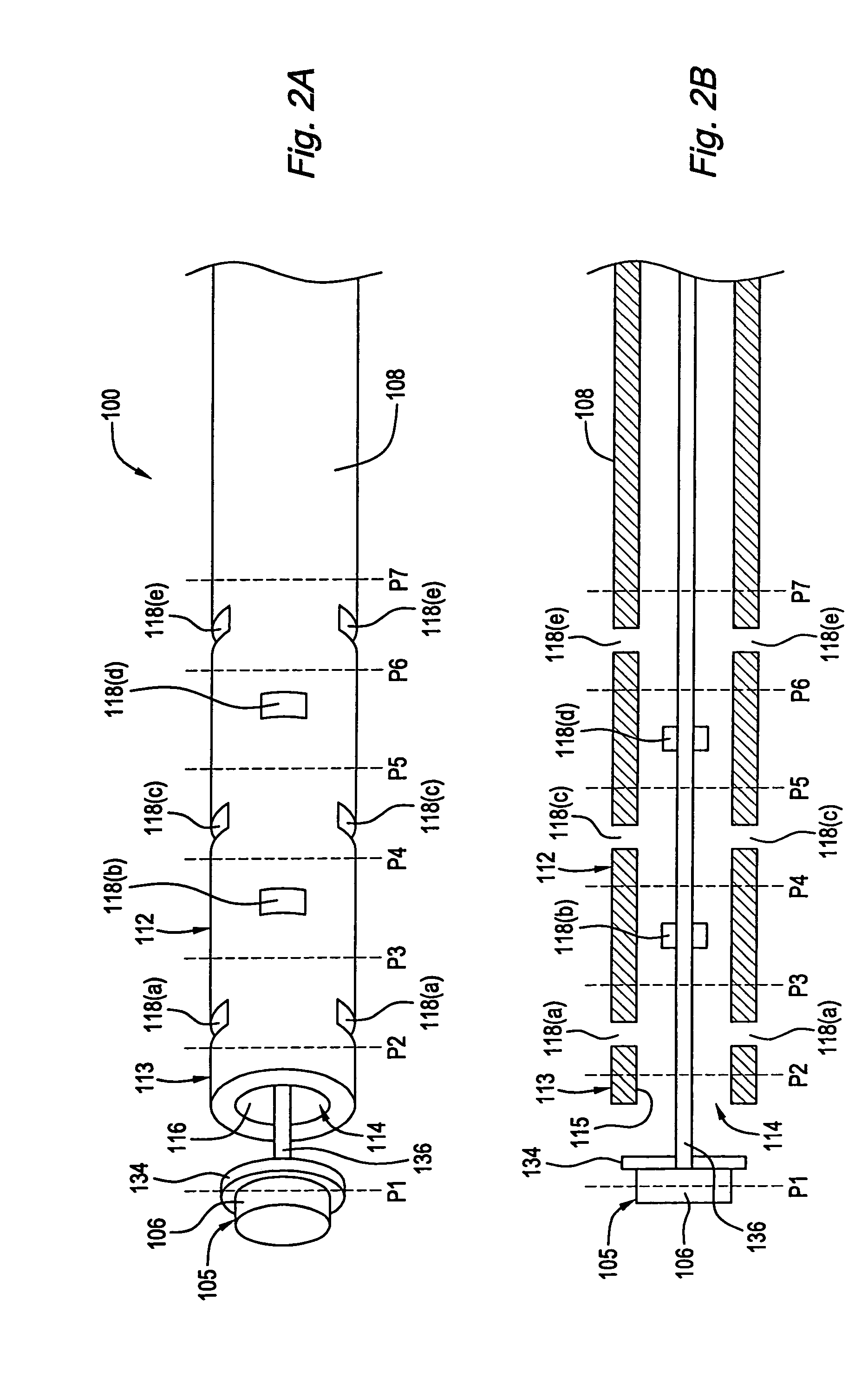

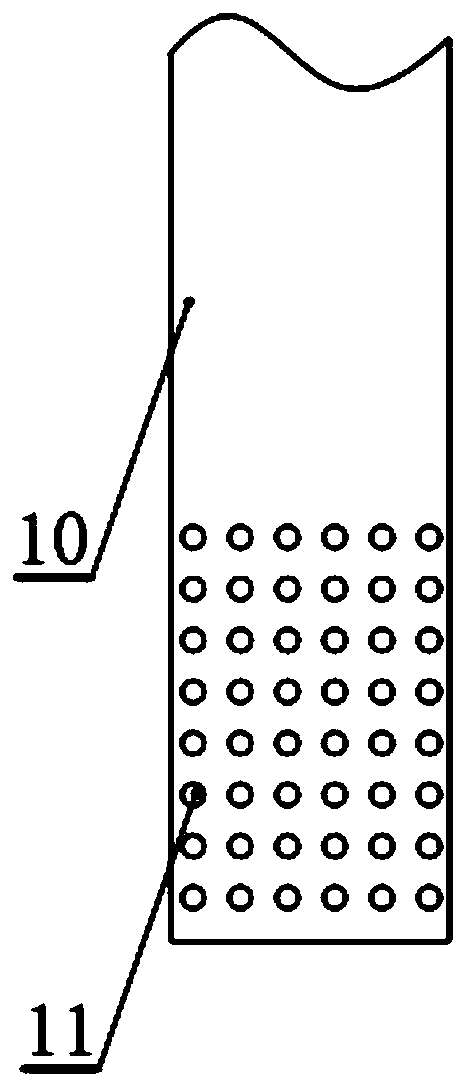

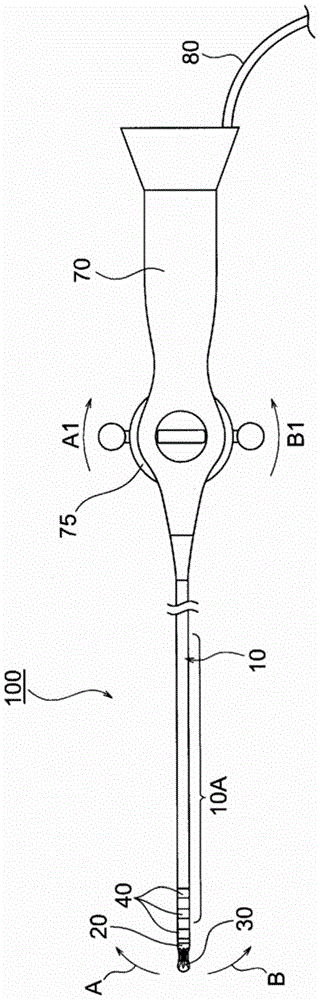

Retrograde plunger delivery system

InactiveUS7591822B2Uniform perfusionImprove sealingInternal osteosythesisMedical devicesSurgeryDelivery system

Cannulas are provided for delivering therapeutic material to a treatment site. The cannula includes a cannula body with a plurality of openings at the distal end, including a longitudinal opening and a plurality of transverse openings that are axially spaced from each other. The cannula also includes a plunger that is configured to be slidably disposed within the cannula lumen. When the plunger is proximally displaced in the cannula lumen, the plunger seals the distal end and deflects the therapeutic material out the transverse openings. As the plunger is proximally displaced within the lumen, the therapeutic material is forced to perfuse out transverse openings located proximal of the plunger position. In one embodiment, the plunger includes an additional pliable sealable member. In another embodiment, the distal end of the cannula body may be implanted by separating the distal end from the cannula body.

Owner:BOSTON SCI SCIMED INC

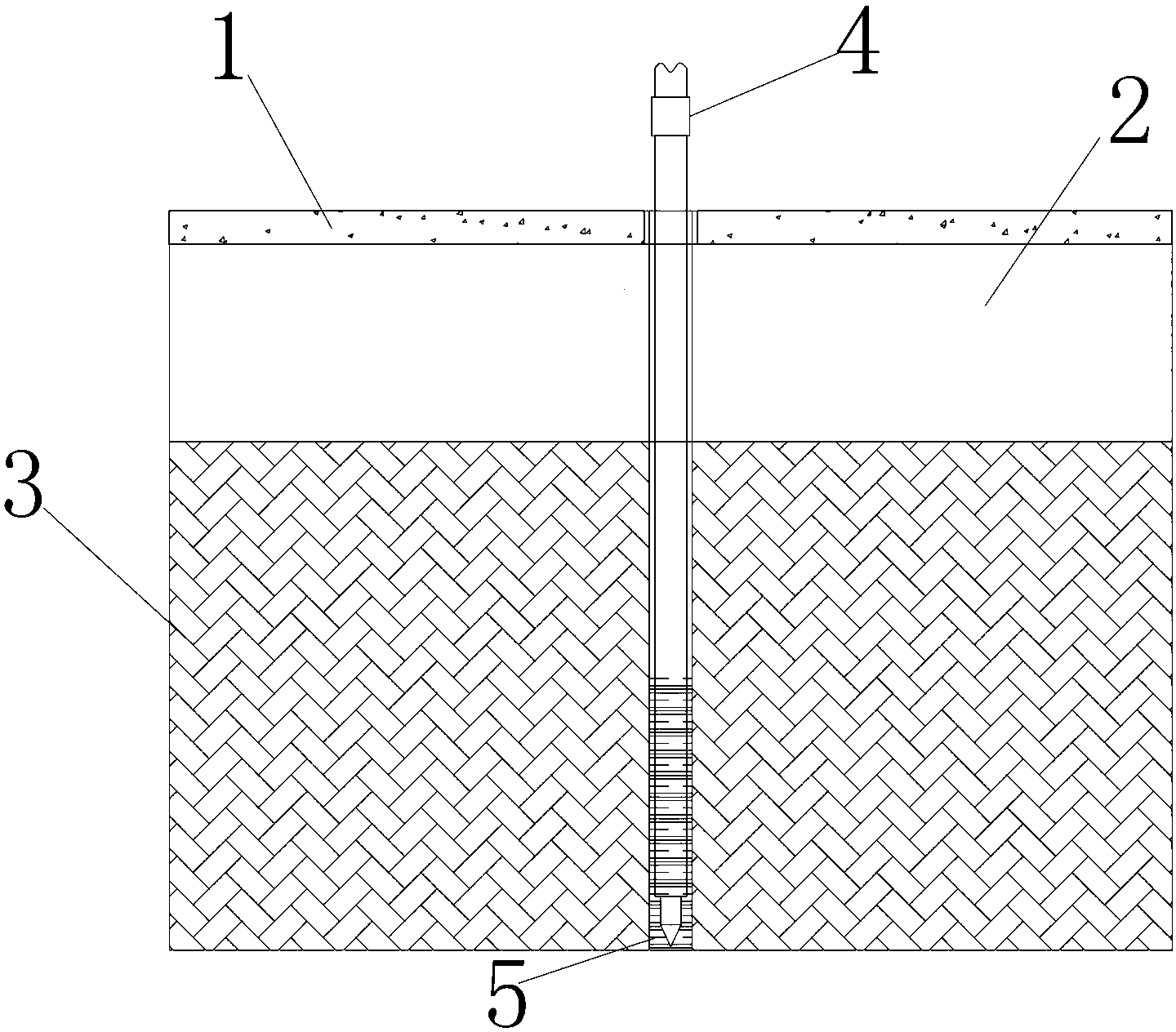

Hole sealing grout stop material and grouting hole sealing process

The invention discloses a hole sealing grout stop material, which is a hole sealing grout stop material for guaranteeing grouting pressurization under the condition of loose permeable rock-soil body, high underground level or confined water. The hole sealing grout stop material is mainly prepared from clay primary grout, cement and sodium metaaluminate, wherein every 2 L of clay primary grout is mixed with 700-900 g of cement and 12.5-17.5 g of sodium metaaluminate. A grouting hole sealing process comprises hole sealing operation and grouting operation, wherein the hole sealing operation specifically comprises the following steps of: after forming a hole, dropping a grouting pipe to the bottom of the hole and mounting a orifice closer; opening the orifice closer and injecting the hole sealing grout stop material; closing the orifice closer and flushing the grouting pipe by using stable grout; and opening the orifice closer, performing grouting operation after solidifying the hole sealing grout stop material, and guaranteeing reliable hole sealing grouting through continuous lift grouting. The grouting hole sealing process has the advantages of simple steps, less equipment investment, high applicability, capabilities of guaranteeing the reliability of the hole sealing grout and increasing the grouting efficiency and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

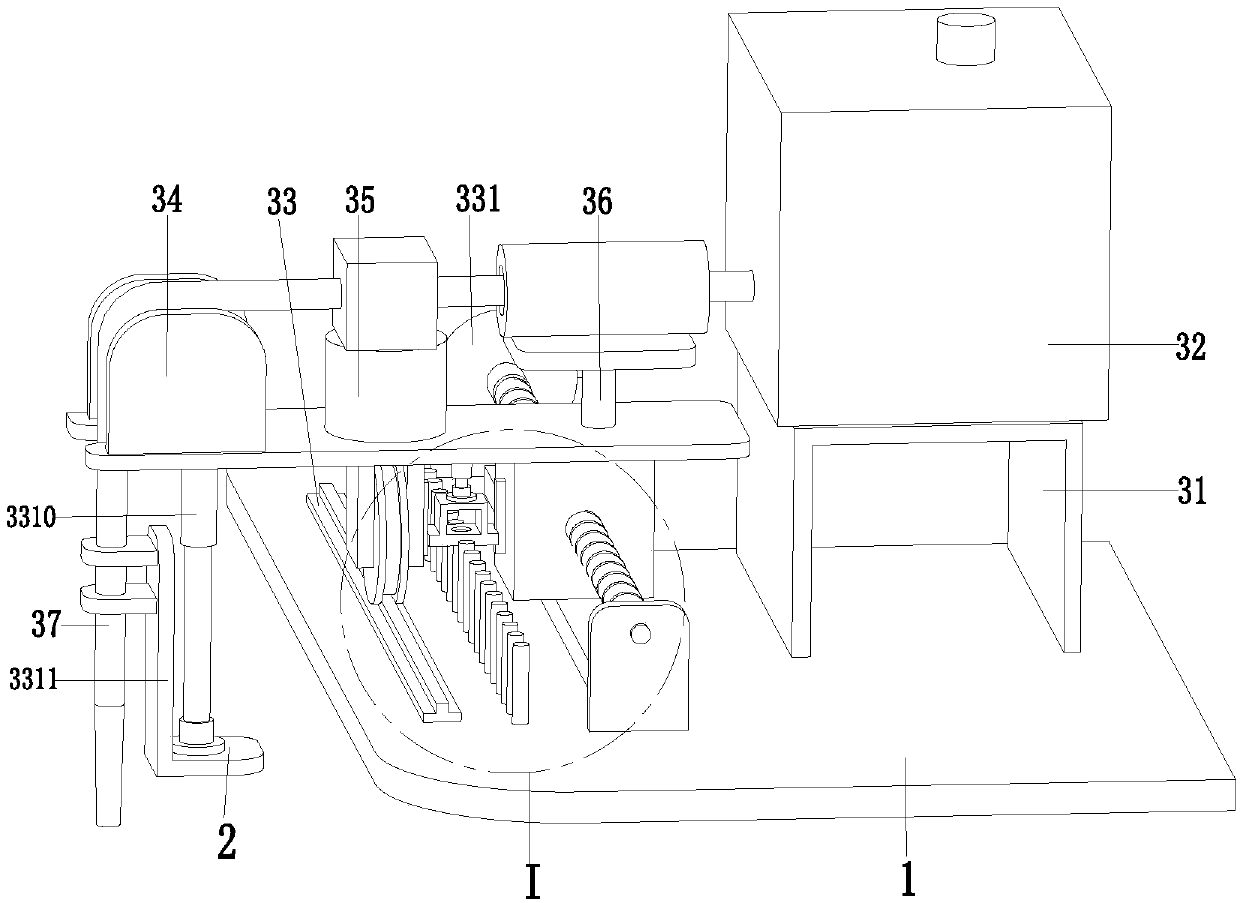

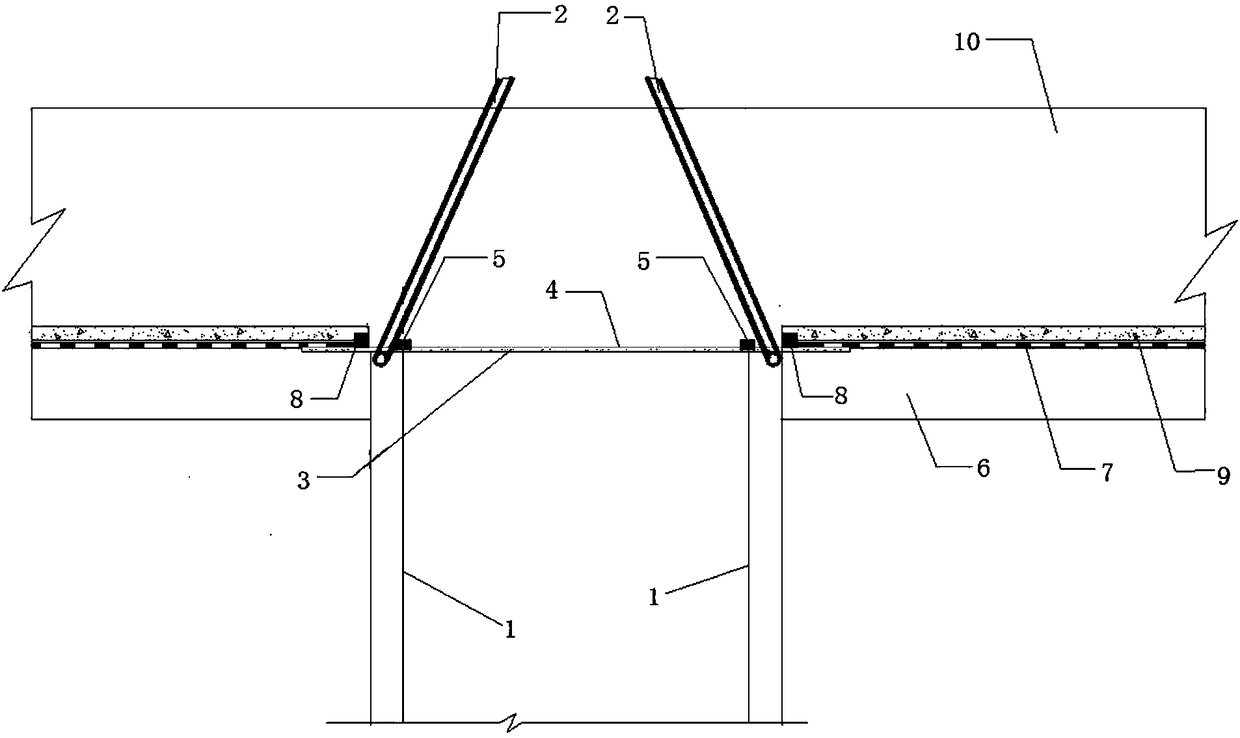

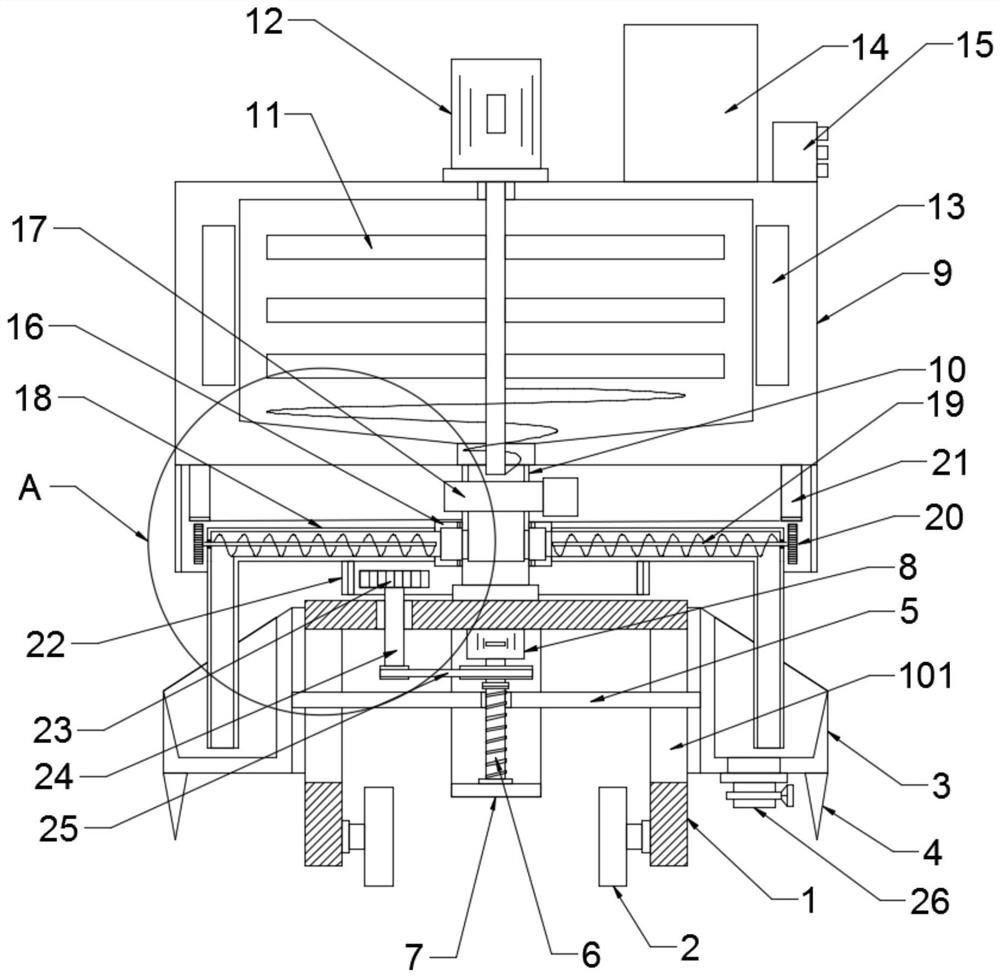

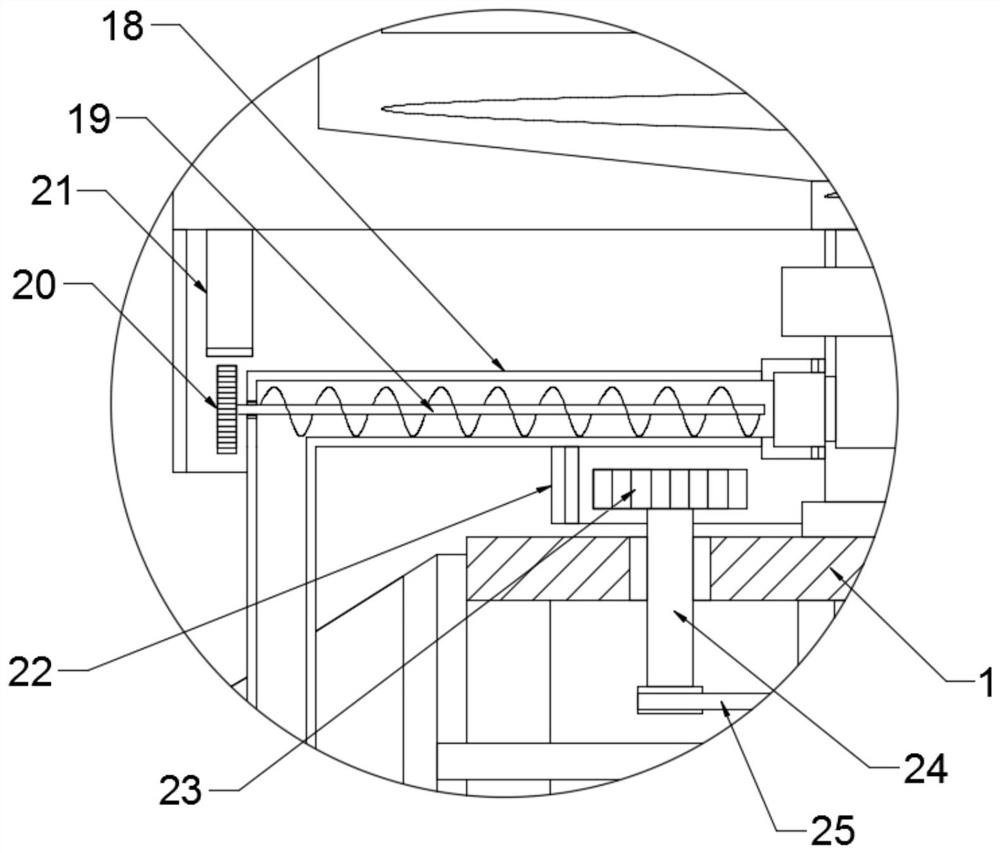

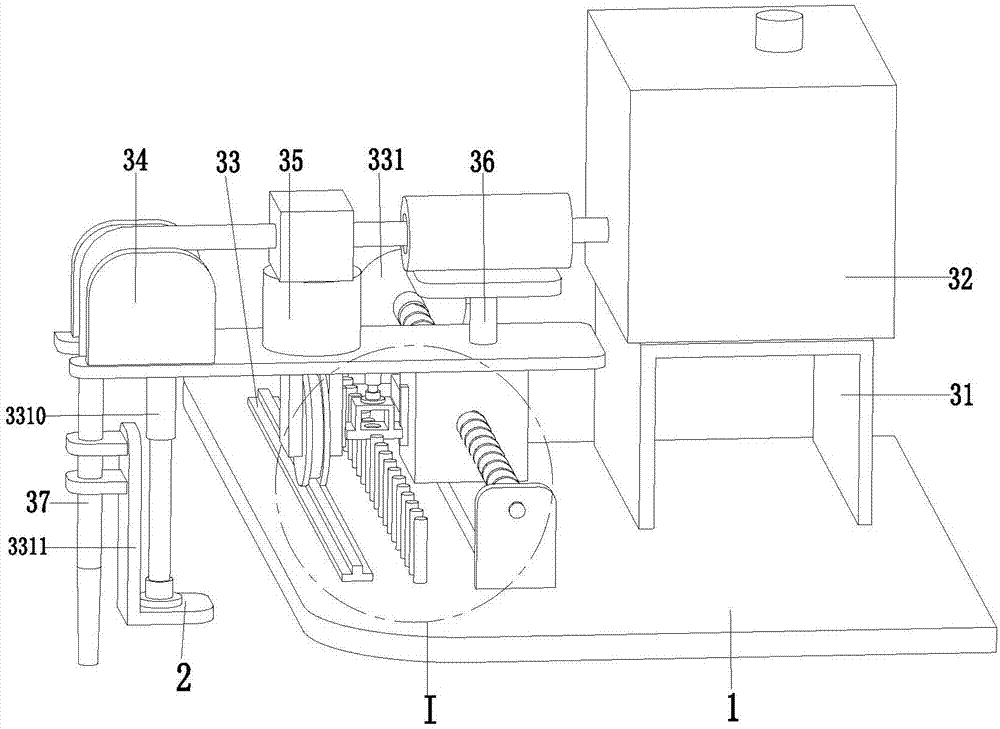

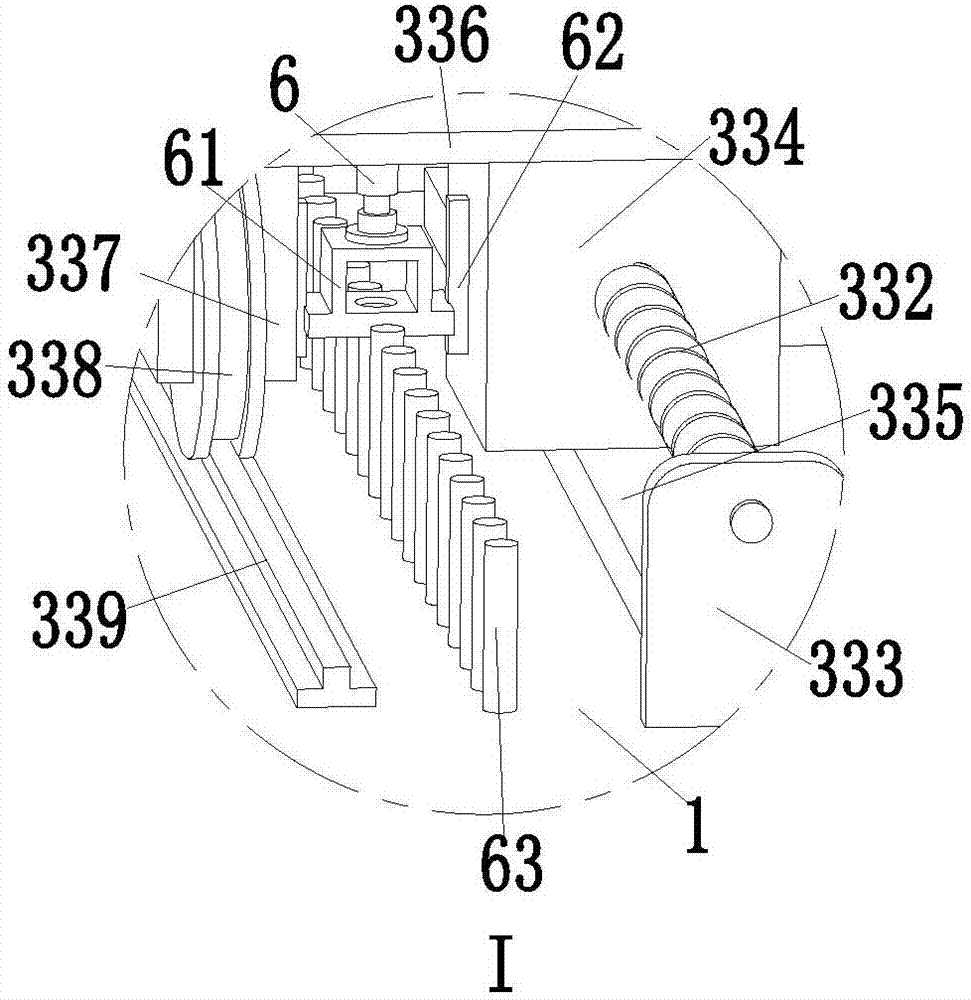

Reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine

InactiveCN107815972AStable jobThere is no security riskBridge erection/assemblyBridge materialsReinforced concreteEngineering

The invention relates to a reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine comprises a base plate, wherein two pairs of movable regulating tanks are formed in the base plate, the two pairs of movable regulating tanks are symmetrically formed in the left side and the right side of the base plate, a movable regulating device is arranged in each pair of movable regulating tanks, a perfusion device is arranged at the front end of the base plate, a vibrating and compacting device is arranged at the rear end of the base plate, the perfusion device comprises a perfusion storage tank arranged on the base plate by virtue of a perfusion supporting frame, a discharging hole is formed in the lower side of the front end of the perfusion storage tank, and a perfusion regulating mechanism is arranged at the front end of the base plate. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine provided by the invention can be used for solving the problems that concrete needs to be manually conveyed by virtue of existing movable equipment in an existing wet joint concrete pouring process, the poured concrete needs to be vibrated and compacted manually by virtue of existing vibrating equipment, a reinforcement cage needs to be avoided in a wet joint concrete pouring and vibrating process and the concrete can not be comprehensively vibrated by virtue of manpower.

Owner:吴秋敏

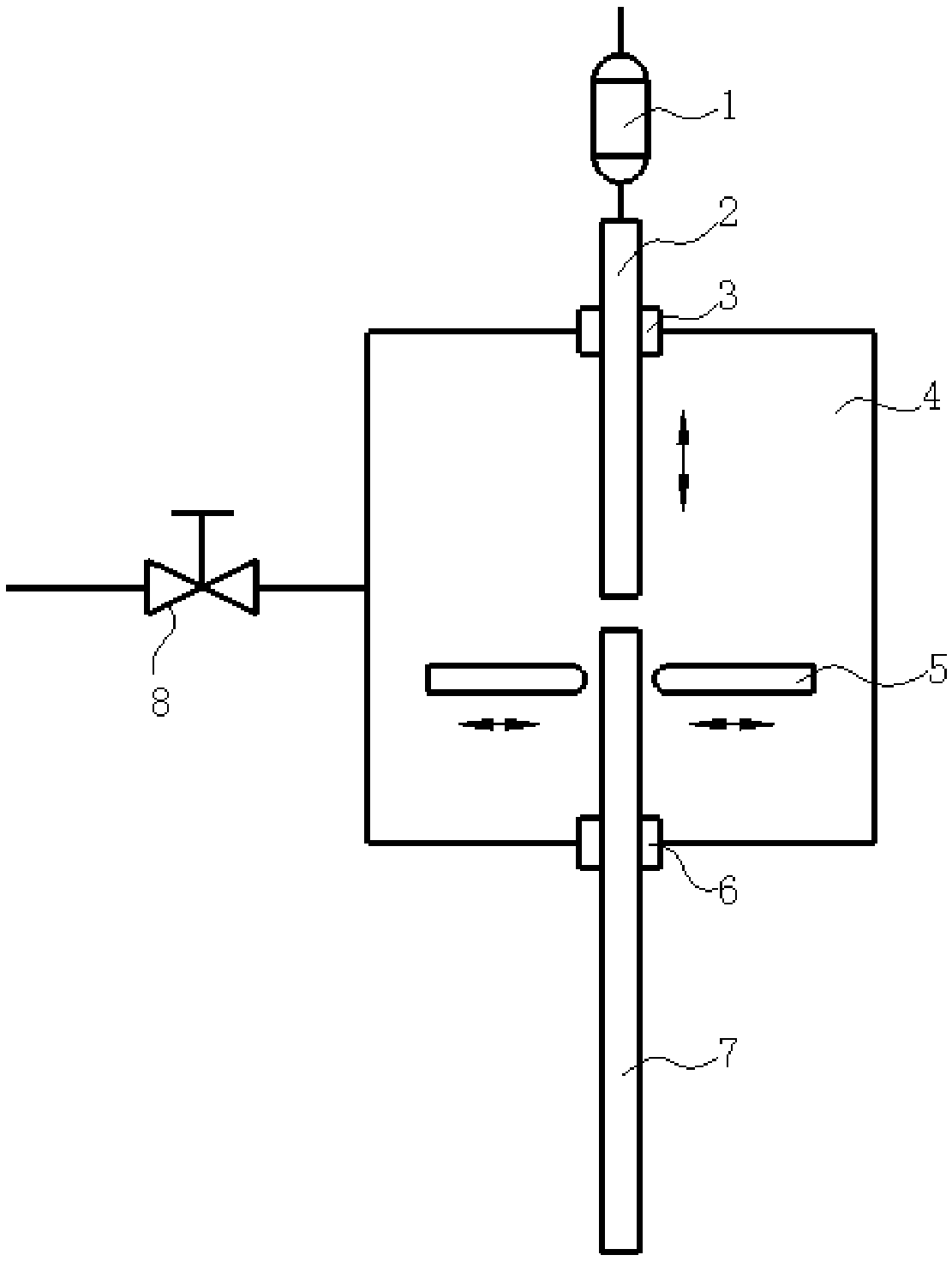

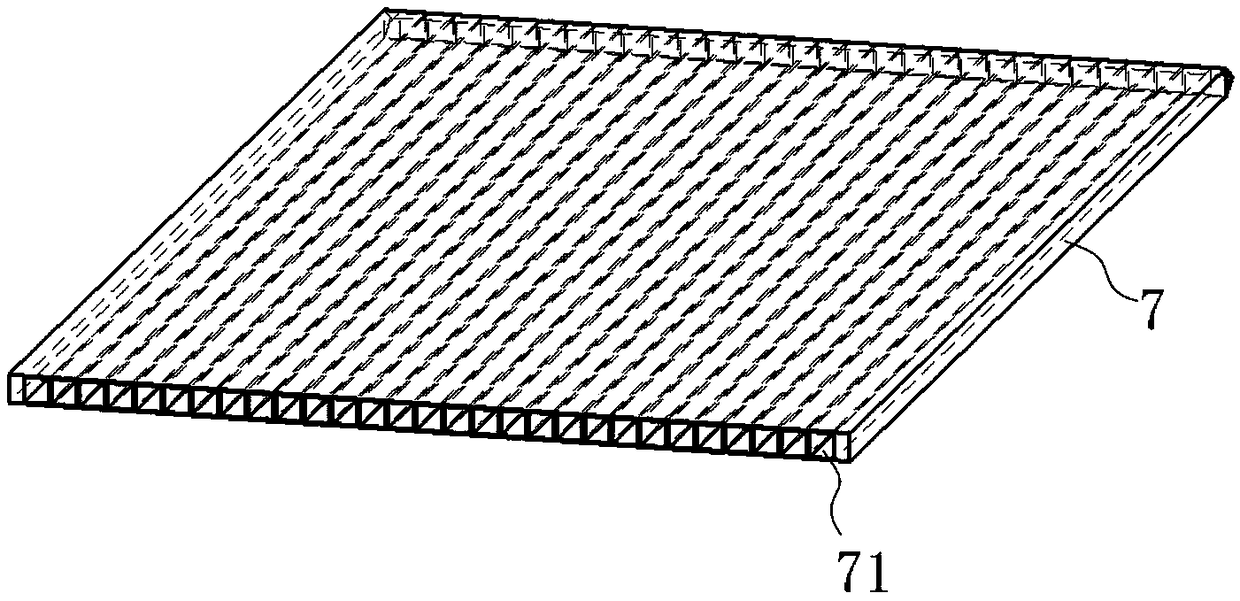

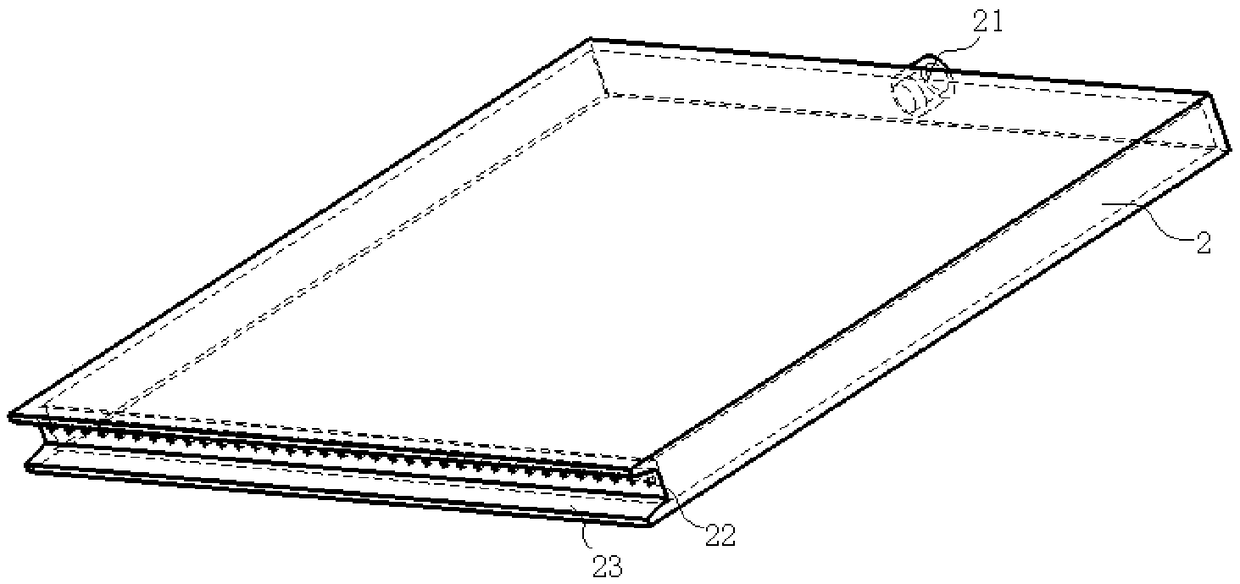

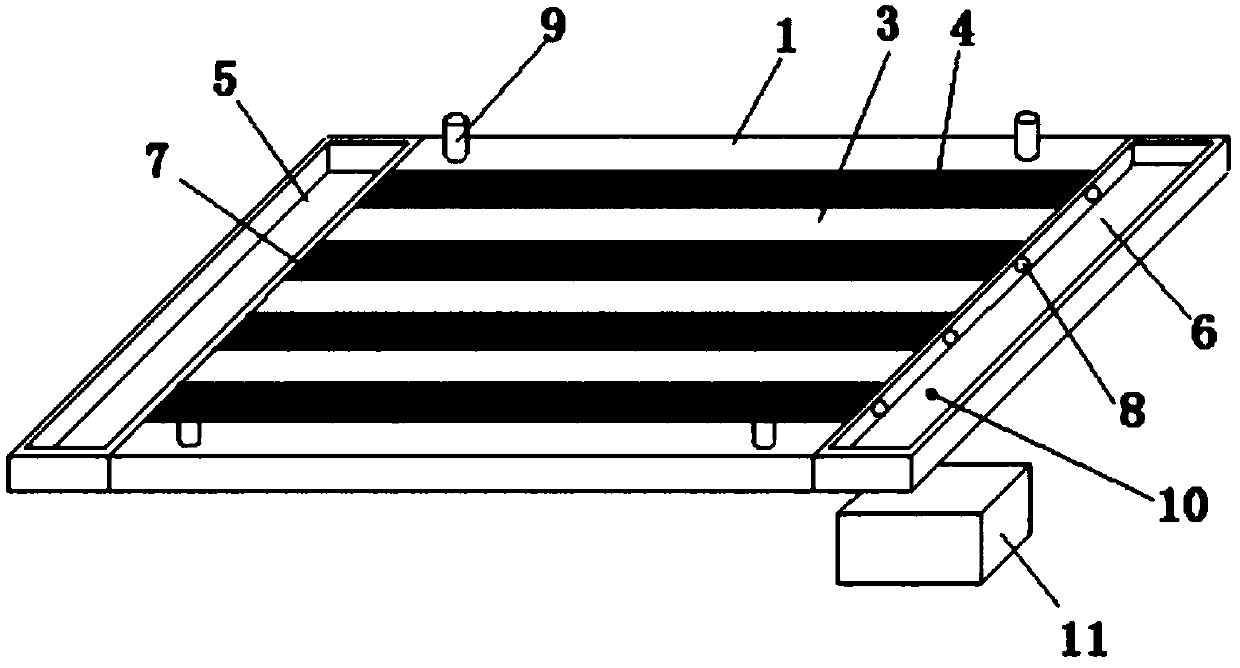

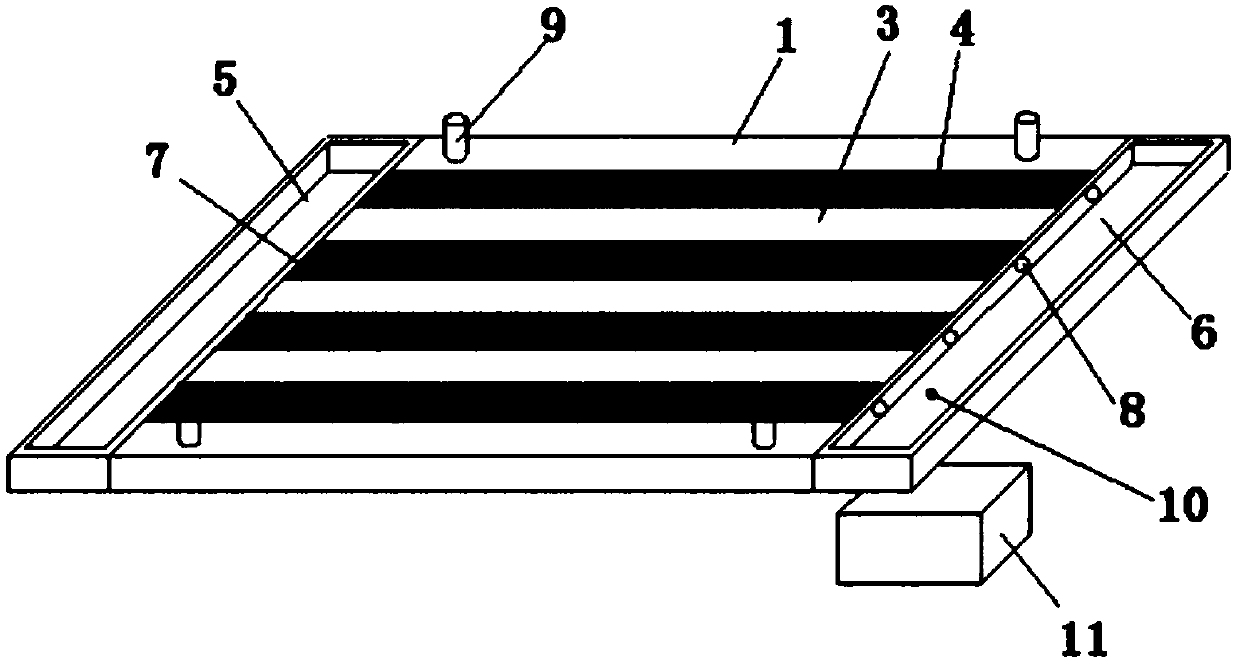

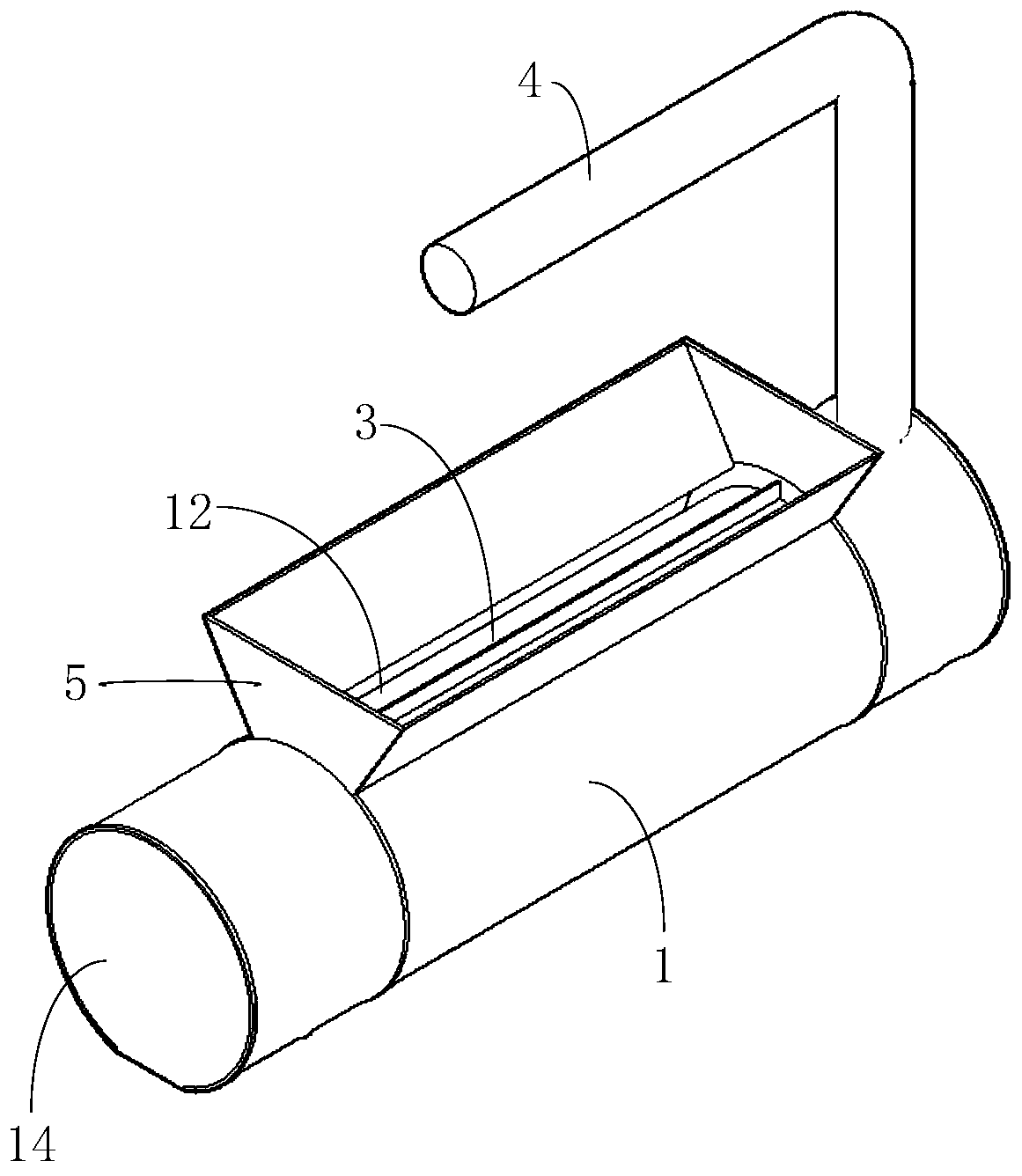

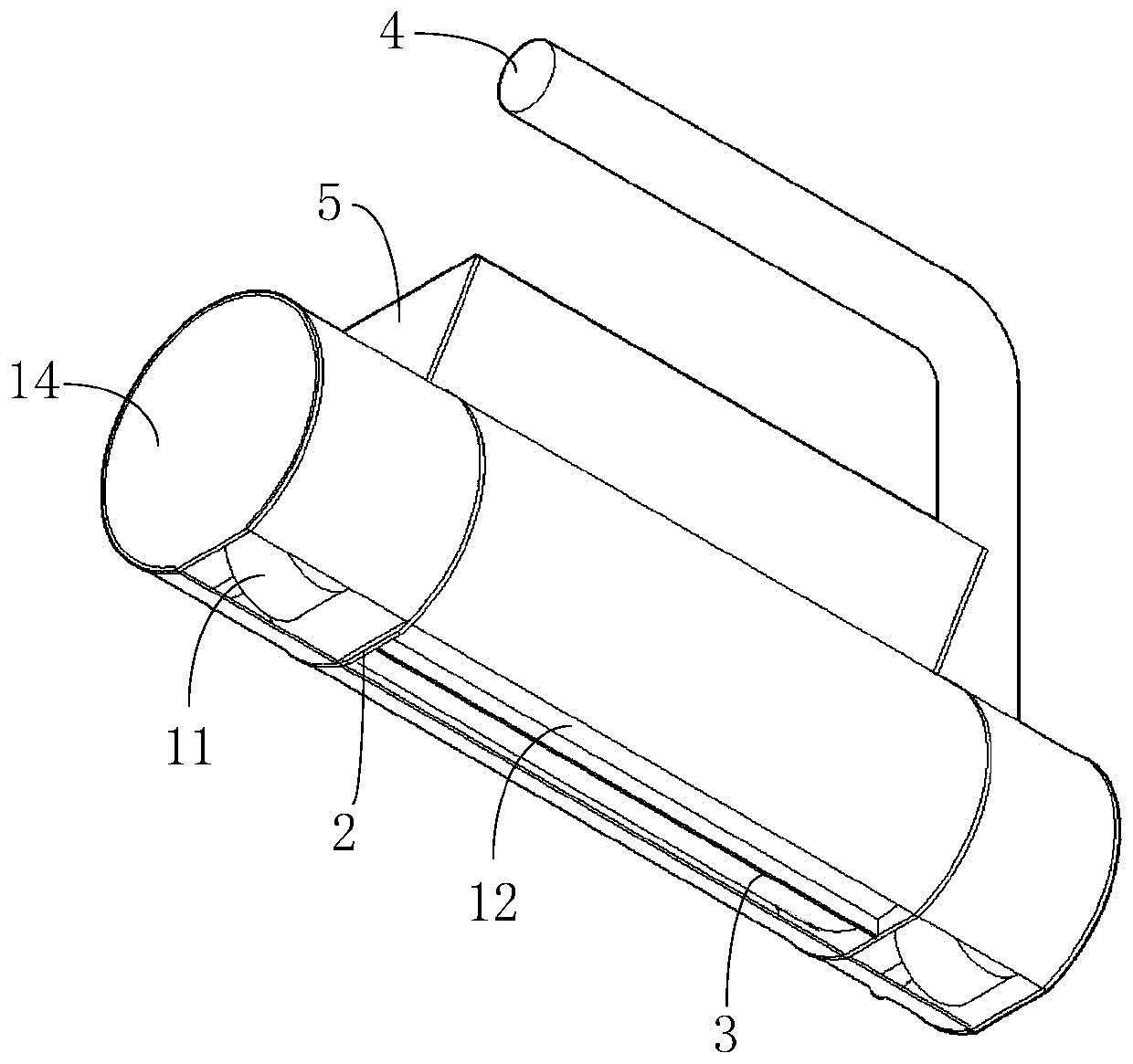

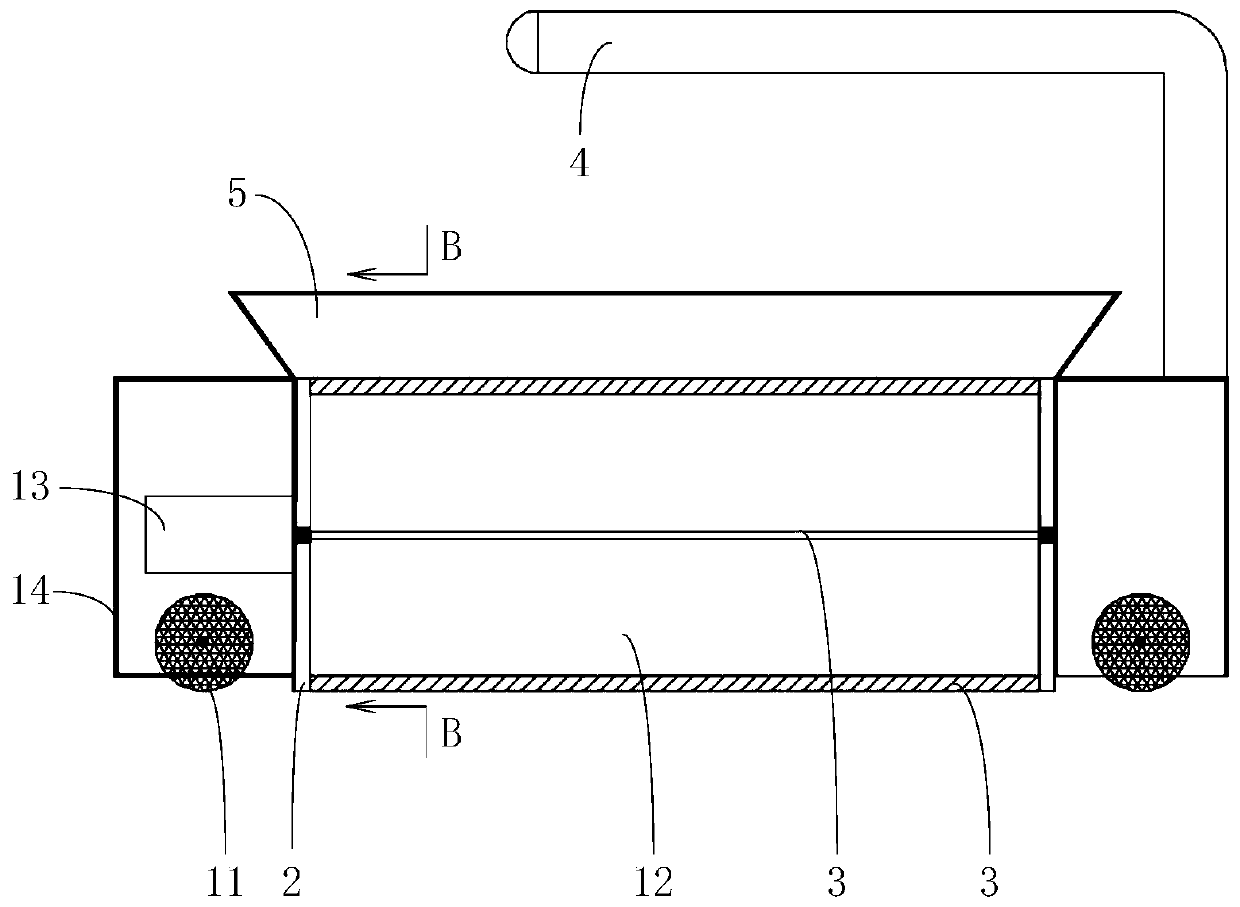

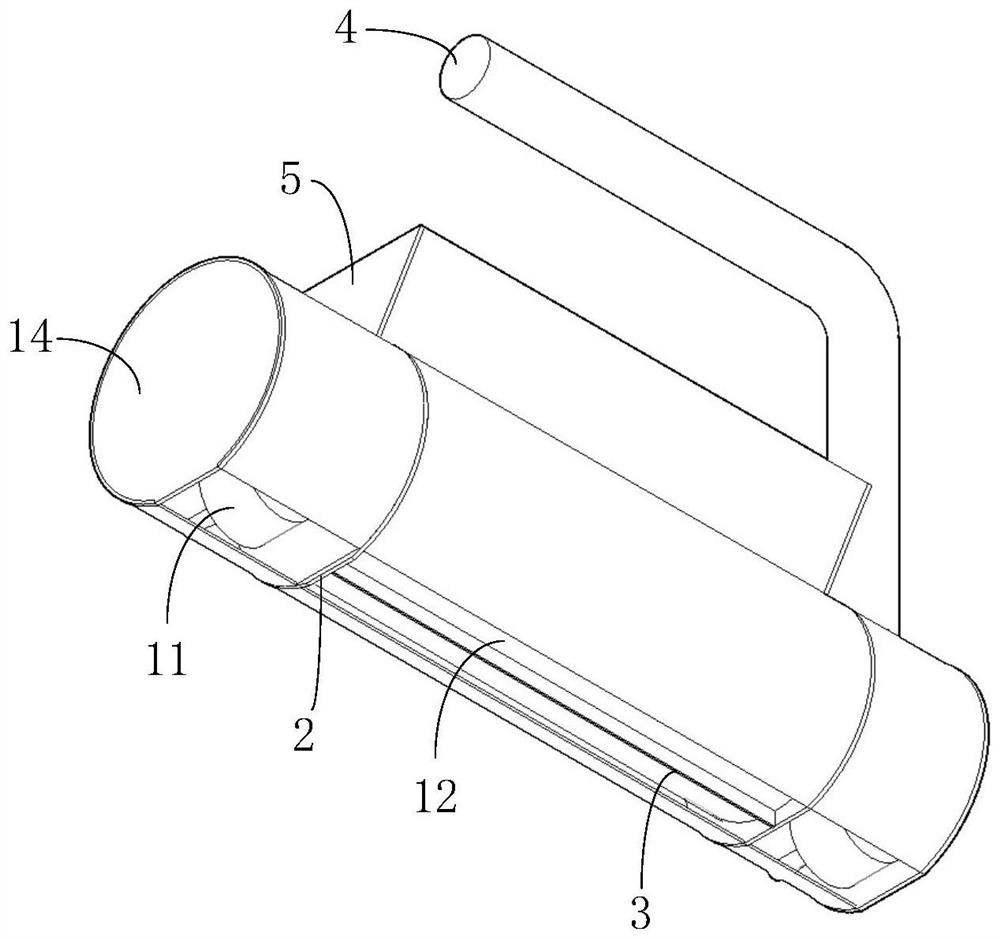

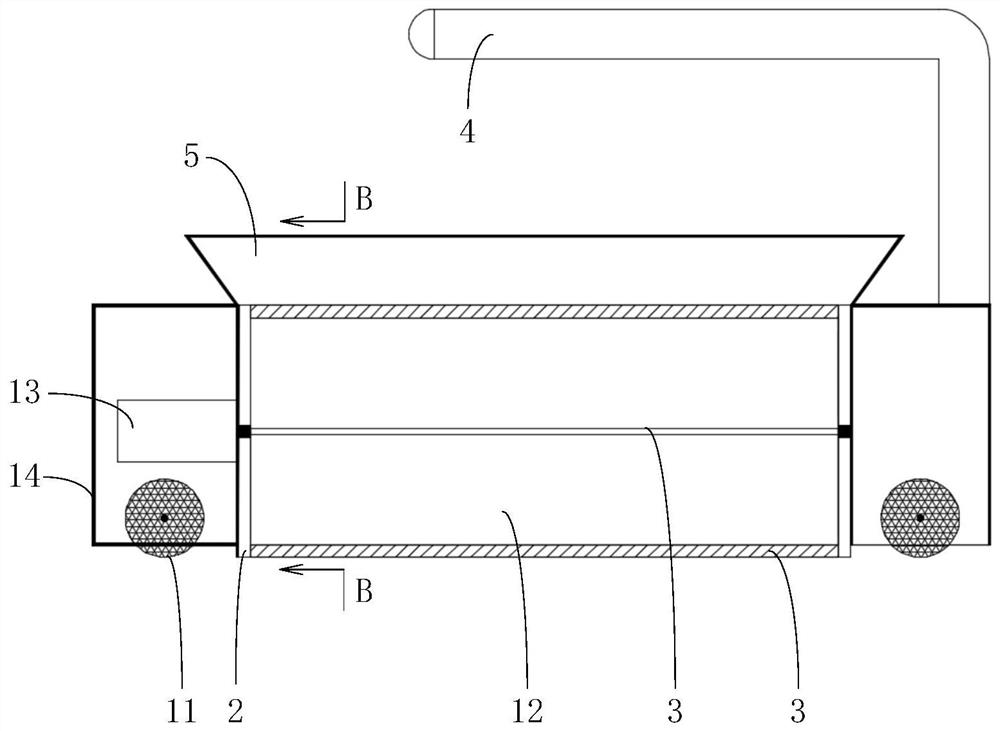

Vacuumizing, liquid filling and sealing device and method for plate multi-channel heat pipe

PendingCN108709442ASimple structureAccurate injection volumeIndirect heat exchangersEngineeringFlat panel

The invention discloses a vacuumizing, liquid filling and sealing device for a plate multi-channel heat pipe. The vacuumizing, liquid filling and sealing device comprises a vacuum cavity connected with a vacuum valve, a quantitative liquid filling pump, a liquid filling plate and sealing molds; a cavity is formed in the liquid filling plate, one end of the liquid filling plate is provided with a liquid inlet connected with the quantitative liquid filling pump, and the other end of the liquid filling plate is provided with a plurality of liquid filling holes of which the number is the same as that of channels of the plate heat pipe and the positions correspond to those of the channels of the plate heat pipe one to one; the liquid inlet is connected with the quantitative liquid filling pumpthrough a pipeline, and the end with the liquid filling holes vertically stretches into the vacuum cavity from the upper end of the vacuum cavity in a sealing and matching mode; and sealing ports usedfor allowing the plate heat pipe to be filled with liquid to stretch into the vacuum cavity in a sealing and matching mode are oppositely arranged at the lower end of the vacuum cavity, and the sealing molds are arranged in the vacuum cavity and located on the two sides of the plate heat pipe. The invention further discloses a vacuumizing, liquid filling and sealing method for the plate multi-channel heat pipe. According to the vacuumizing, liquid filling and sealing device and method for the plate multi-channel heat pipe, the efficiency is high, the cost is low, the filling amount of all thechannels is same and precise, and the vacuumizing, liquid filling and sealing device and method are suitable for filling volatile and toxic working media.

Owner:SOUTH CHINA UNIV OF TECH +1

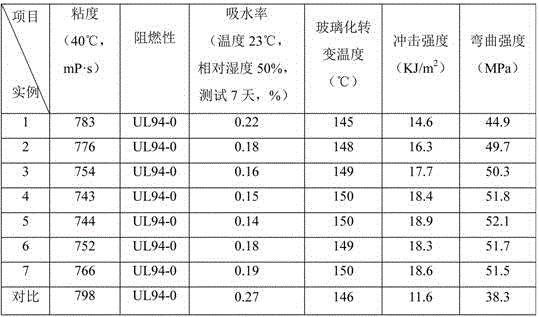

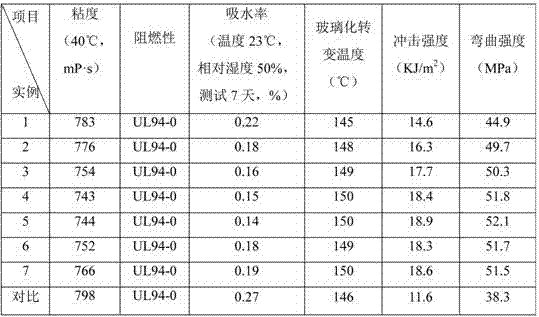

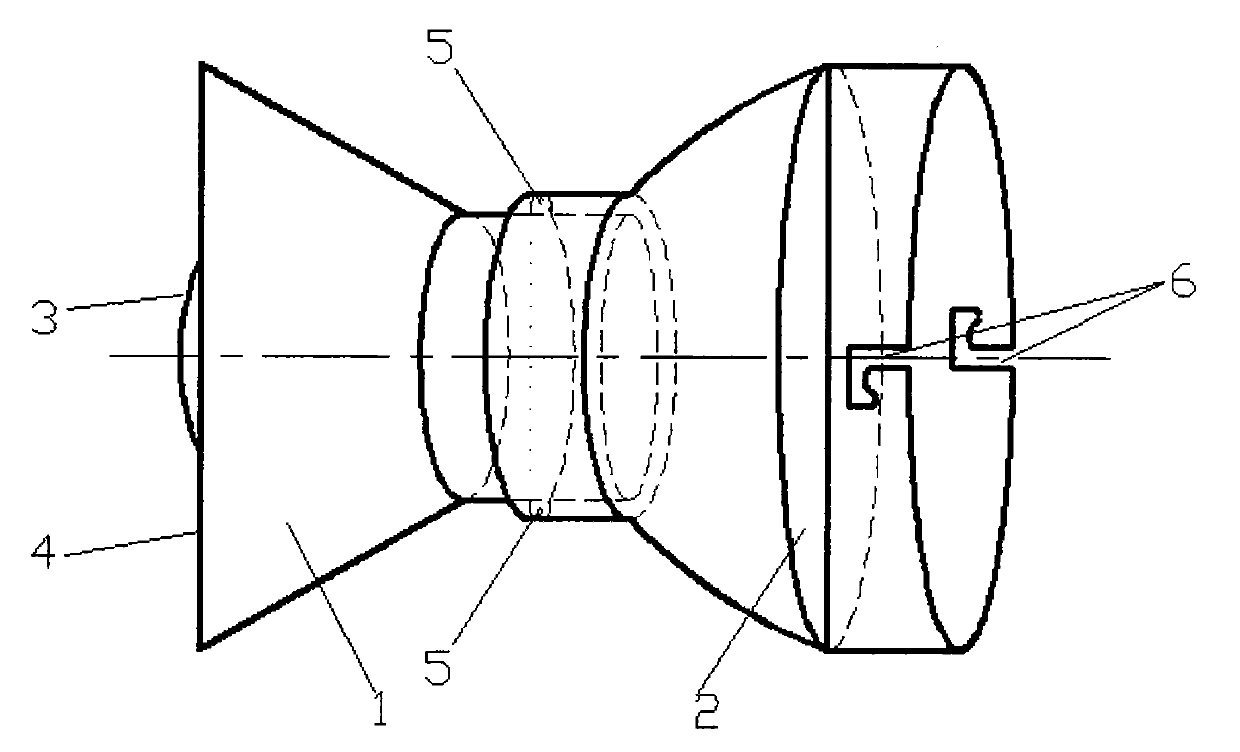

Injection process for metalized polypropylene film dielectric capacitor

InactiveCN105820512APrevent splashingUniform perfusionThin/thick film capacitorStacked capacitorsPolypropyleneDefoaming Agents

The invention discloses an injection process for a metalized polypropylene film dielectric capacitor .The injection process includes the following steps that an injection head for an epoxy resin filling adhesive is closely attached to the inner wall of a capacitor shell, the epoxy resin filling adhesive flows downwards along the inner wall of the capacitor shell, the level of the epoxy resin filling adhesive rises gradually, the position of the injection head shifts upwards constantly, and finally injection is completed .An injection tube serves as the injection head, and the outer wall of the injection tube is defined by an arc outer wall and a planar outer wall .The epoxy resin filling adhesive is prepared from, by weight, 45-60 parts of epoxy resin, 10-18 parts of polyester resin, 5-10 parts of a fire retardant, 30-45 parts of a filling material, 30-45 parts of a diluent, 0.5-1.5 parts of a defoaming agent, 22-35 parts of a curing agent and 0-1.5 parts of a curing accelerator .The epoxy resin filling adhesive is uniformly injected without bubbles inside, the injection process is simple, and the injection efficiency is high.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

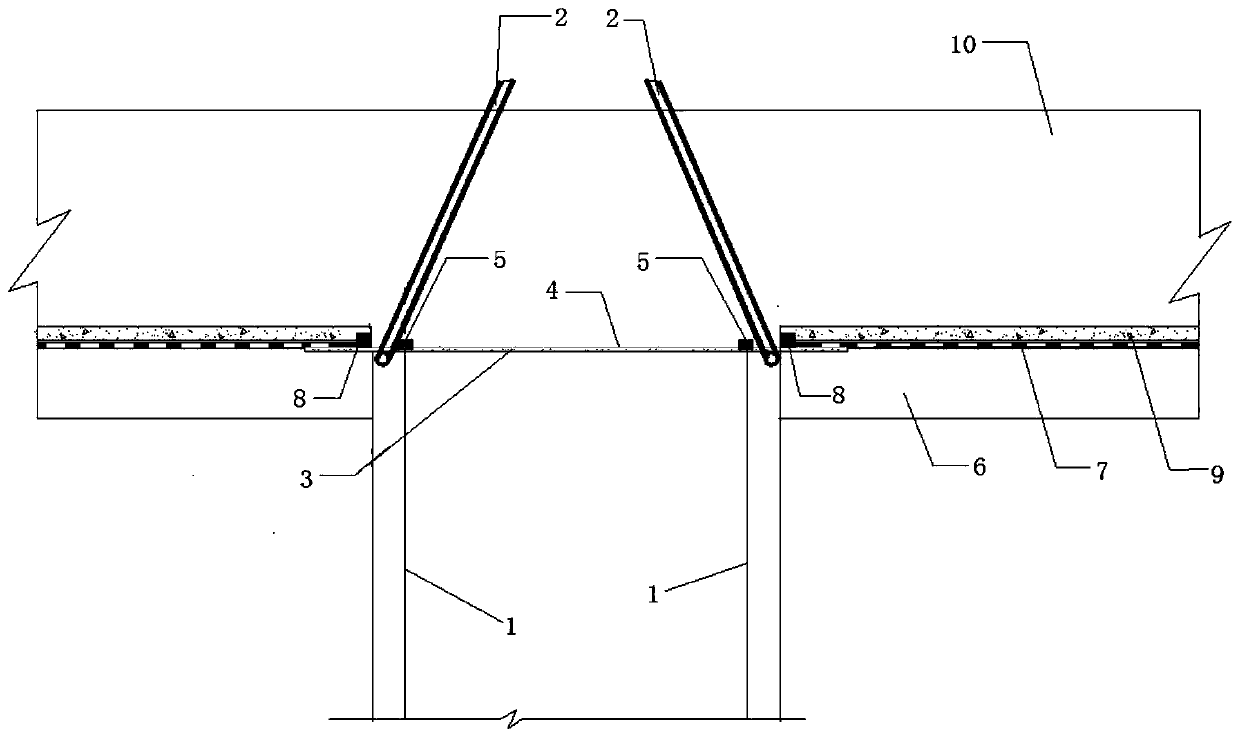

Construction method of waterproof structure of connection gap between anti-pulling pile and bottom plate

ActiveCN108517898AInto the uniformImprove waterproof performanceArtificial islandsProtective foundationAdhesiveSlurry

The invention provides a construction method of a waterproof structure of a connection gap between an anti-pulling pile and a bottom plate. The method comprises the following steps: breaking a pile head of an anti-pulling pile and straightening steel bars exposed out of the pile head part of the anti-pulling pile; arranging a plurality of slurry injection pipes on the pile head of the anti-pullingpile, wherein the bottom ends of the slurry injection pipes are located in the connection gap between the pile head of the anti-pulling pile and the bottom plate, and the top ends of the grouting pipes are higher than the top surface of the bottom plate; firstly coating a layer of cement-based crystallization waterproof coating and epoxy mortar on the top of the anti-pulling pile; arranging a circle of water-swelling water stop adhesive in contact positions between the steel bars on the pile head part of the anti-pulling pile and the concrete of the anti-pulling pile; paving waterproof rolls;arranging a circle of polyurethane sealant in the junctions between the waterproof rolls and the anti-pulling pile along the periphery of the anti-pulling pile body; casting a fine aggregate concreteprotection layer; and injecting the slurry into the plurality of slurry injection pipes. According to the construction method, the gap between the bottom plate and the anti-pulling pile is filled byinjecting the slurry into the slurry injection pipes, so that the waterproof effect is ensured.

Owner:CHINA COMM NORTH ROAD & BRIDGE

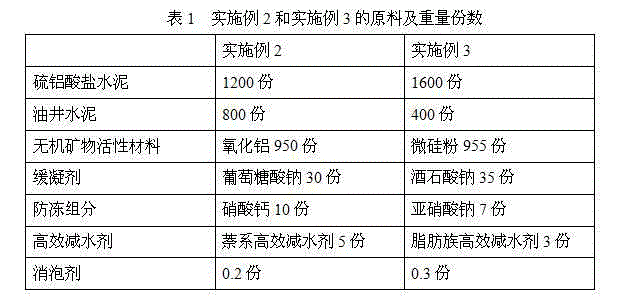

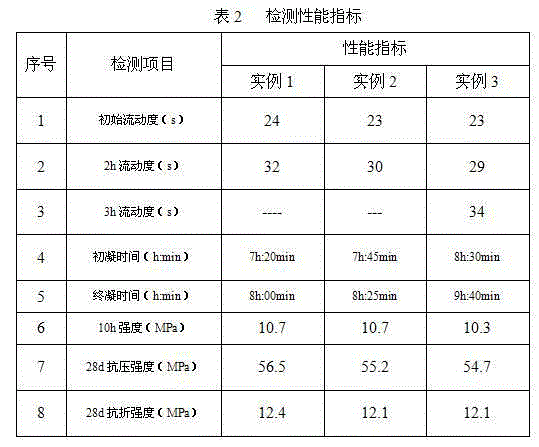

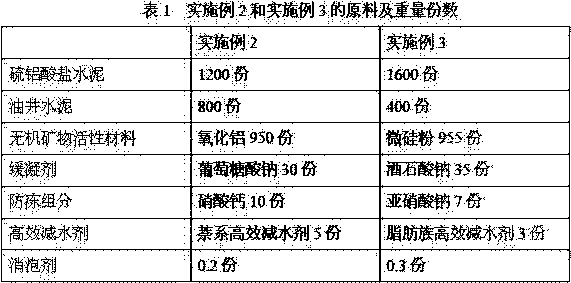

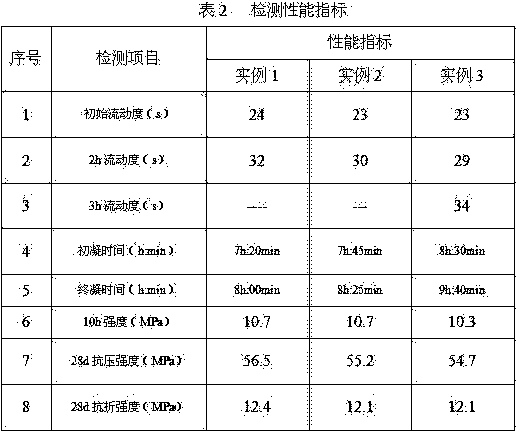

Low temperature rapid hardening grouting material for offshore oil well and preparation method thereof

The invention relates to a low temperature rapid hardening grouting material for an offshore oil well. The low temperature rapid hardening grouting material for the offshore oil well comprises the following raw materials in parts by weight: 2,000 parts of gel materials, 950-965 parts of inorganic mineral active materials, 25-35 parts of retarders, 5-10 parts of anti-freezing ingredients, 3-5 parts of high efficiency slushing agents, and 0.1-0.3 part of defoaming agents, wherein the gel materials are quick-hardening sulphate aluminium cement and oil well cement; the mass ratio of the quick-hardening sulphate aluminium cement and oil well cement is 5:5-8:2. The invention also provides a preparation method thereof. The grouting material is suitable for construction under a well cementation low-temperature environment, slurry can maintain better mobility and is high in early strength, the slurry is full without shrinkage, the long-term strength is high, and the well cementation construction time and the underground grouting environment parameter requirement are effectively ensured.

Owner:河北铁园科技发展有限公司

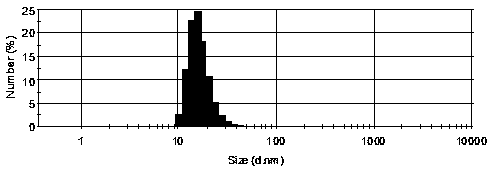

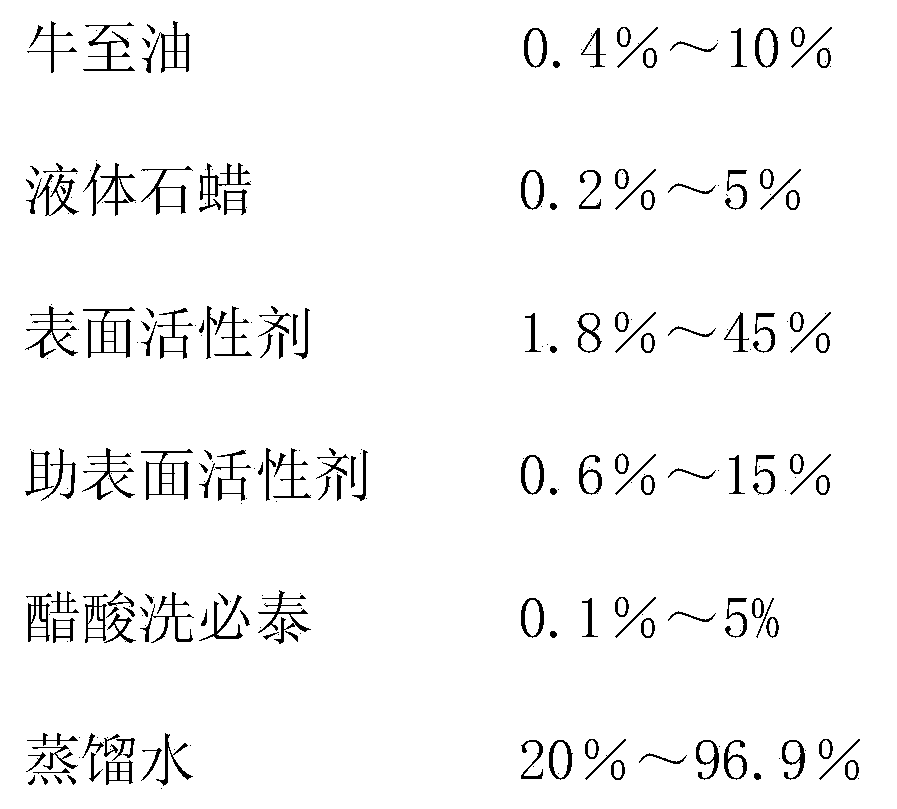

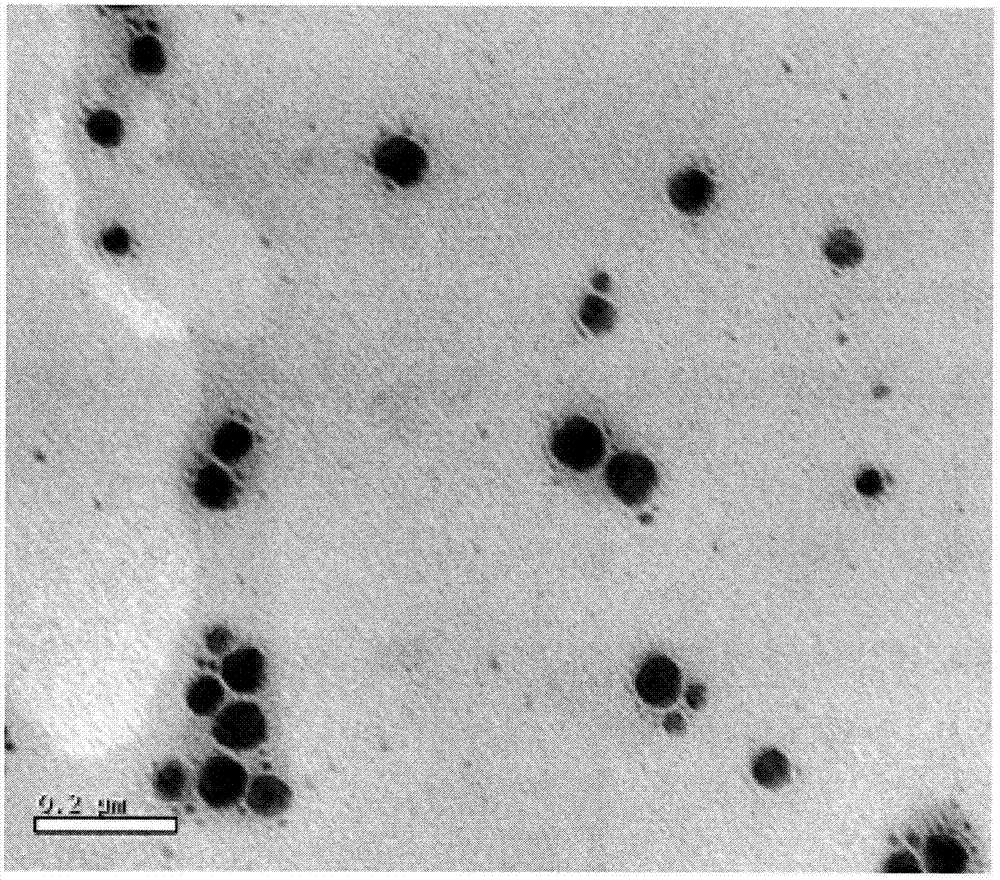

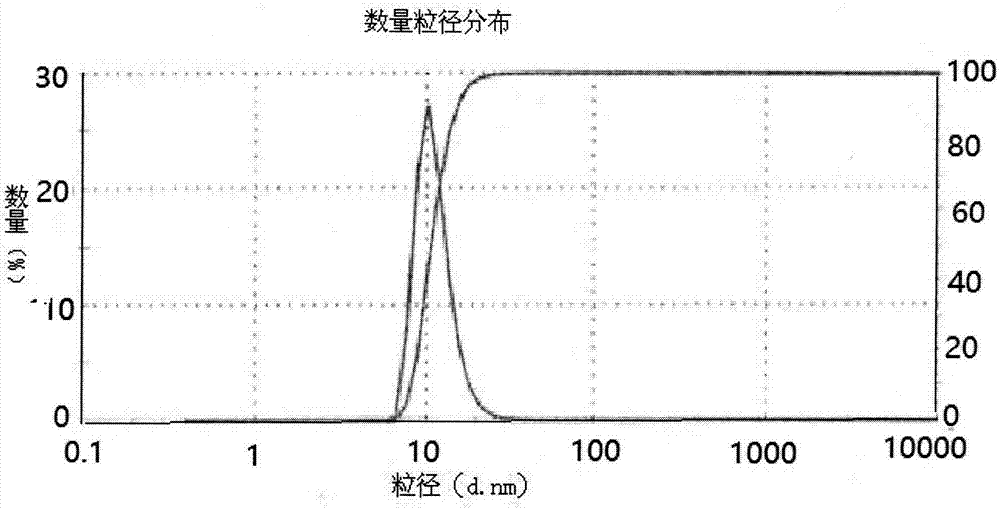

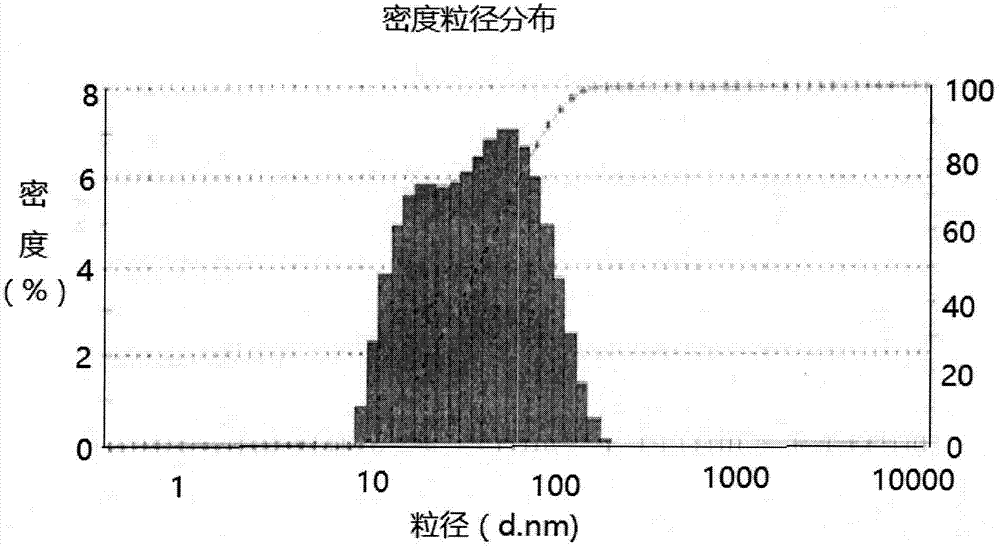

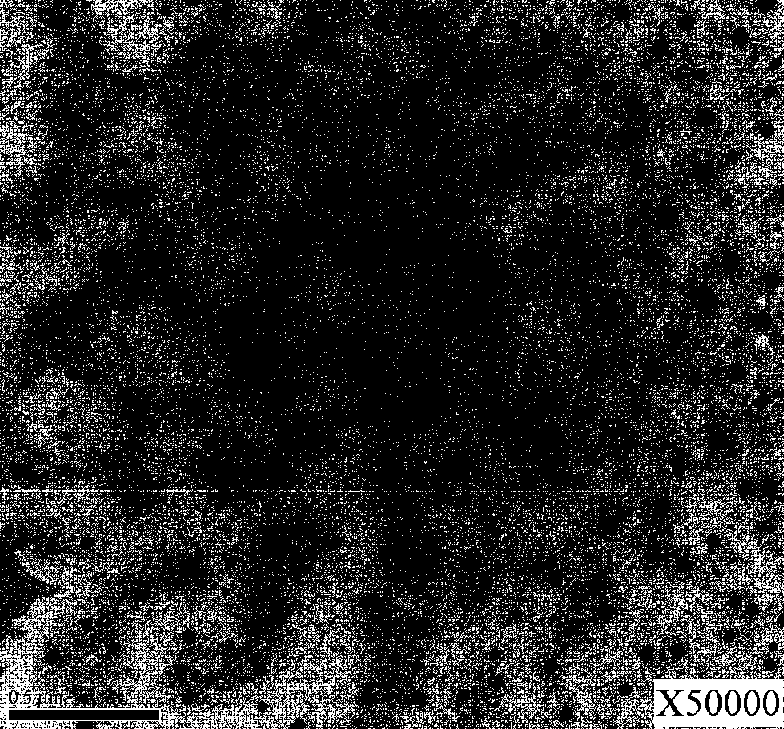

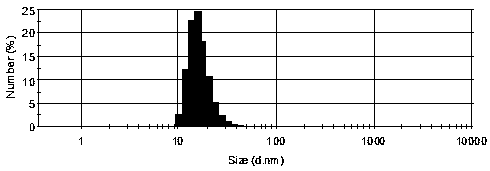

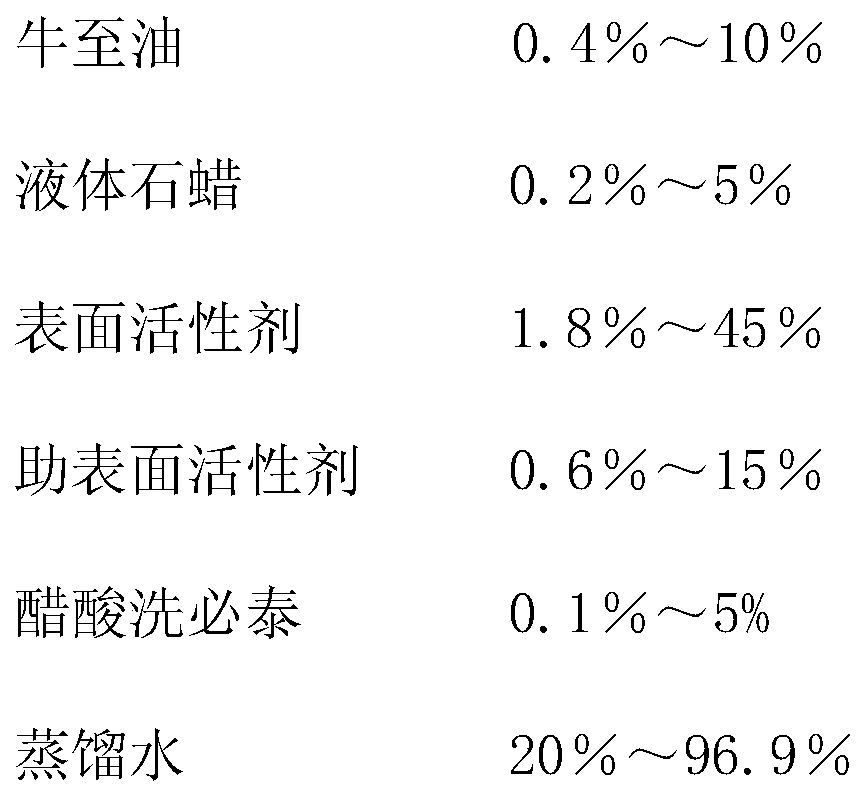

Nano-medicine for treating dairy cow endometritis and preparation method of nano-medicine

InactiveCN104288222ACan't solveSolve the problems of water miscibility and poor water solubility of chlorhexidine acetateAntibacterial agentsOrganic active ingredientsChlorhexidine AcetateSpanish oregano

The invention discloses a nano-medicine for treating dairy cow endometritis. The nano-medicine is prepared from the following components in percentage by mass: 0.4-10% of oregano oil, 0.2-5% of liquid paraffin, 1.8%-45% of surfactant, 0.6%-15% of cosurfactant, 0.1%-5% of chlorhexidine acetate and 20%-96.9% of distilled water. The nano-medicine is used for treating the dairy cow endometritis and administrated in such a manner of uterus perfusion, and is remarkable in curative effect, and capable of diminishing inflammation and sterilizing, contracting the uterus to drain pus and promoting the recovery of the functions of the dairy cow uterus. The nano-medicine for treating the dairy cow endometritis is antibiotic-free, residual-free, and safe and reliable.

Owner:XIANYANG VOCATIONAL TECHN COLLEGE

A potting process of metallized polypropylene film dielectric capacitor

InactiveCN105820512BUniform perfusionStable flowThin/thick film capacitorStacked capacitorsDielectricEpoxy

The invention discloses an injection process for a metalized polypropylene film dielectric capacitor .The injection process includes the following steps that an injection head for an epoxy resin filling adhesive is closely attached to the inner wall of a capacitor shell, the epoxy resin filling adhesive flows downwards along the inner wall of the capacitor shell, the level of the epoxy resin filling adhesive rises gradually, the position of the injection head shifts upwards constantly, and finally injection is completed .An injection tube serves as the injection head, and the outer wall of the injection tube is defined by an arc outer wall and a planar outer wall .The epoxy resin filling adhesive is prepared from, by weight, 45-60 parts of epoxy resin, 10-18 parts of polyester resin, 5-10 parts of a fire retardant, 30-45 parts of a filling material, 30-45 parts of a diluent, 0.5-1.5 parts of a defoaming agent, 22-35 parts of a curing agent and 0-1.5 parts of a curing accelerator .The epoxy resin filling adhesive is uniformly injected without bubbles inside, the injection process is simple, and the injection efficiency is high.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

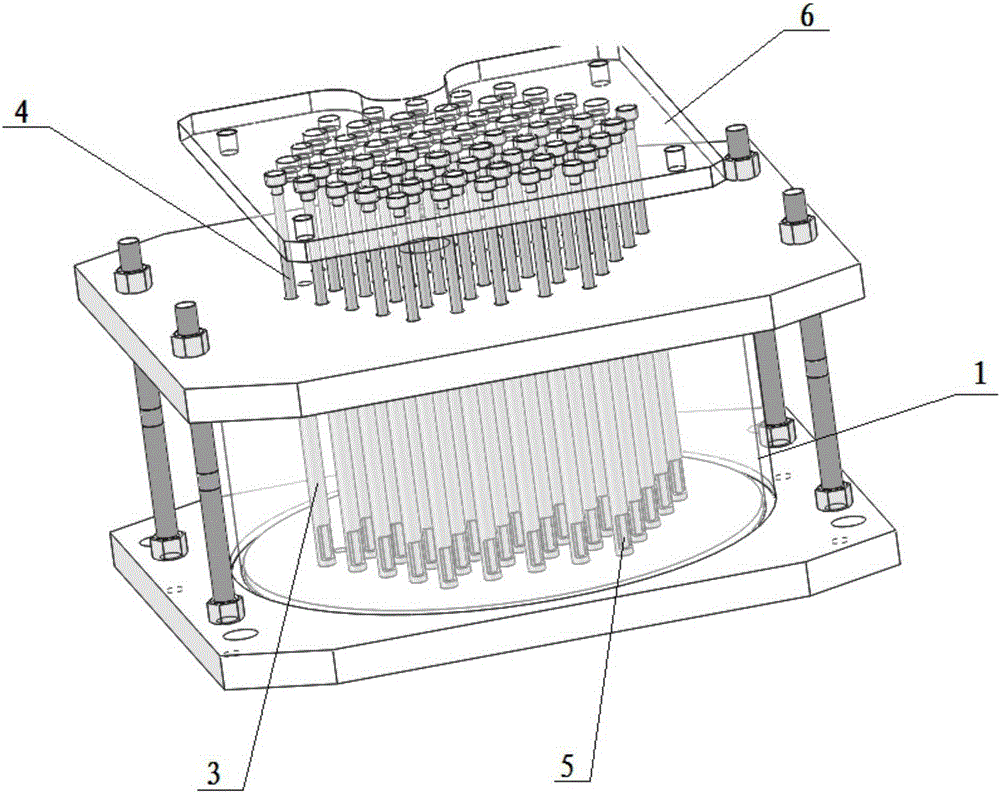

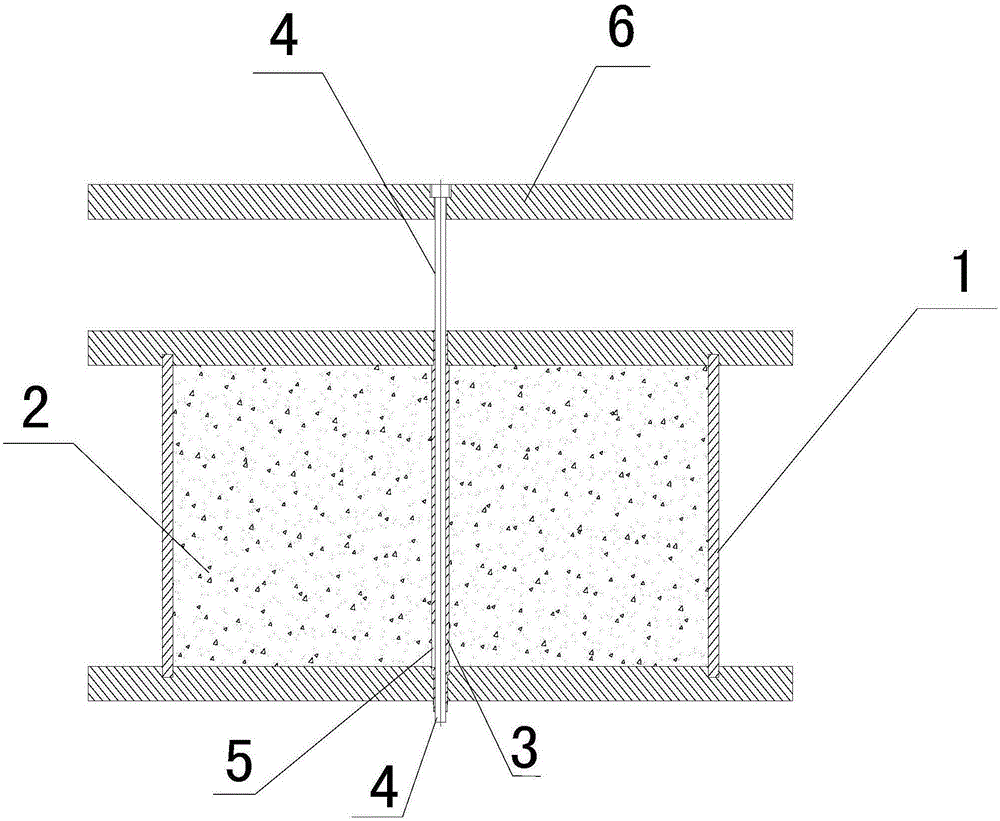

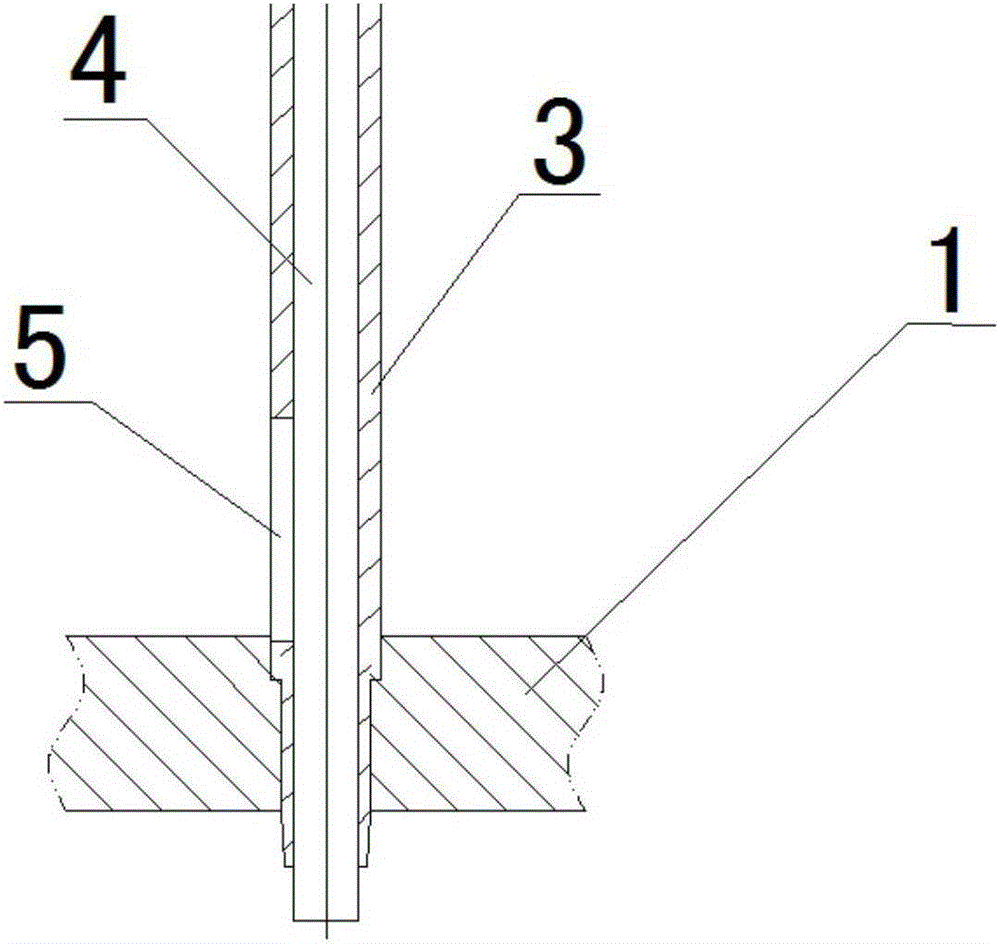

Vacuum circuit chip packaging mould

InactiveCN109834895AFast installationFlat surfaceSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringElectron

The invention discloses a vacuum circuit chip packaging mould. The vacuum circuit chip packaging mould is characterized in that the vacuum circuit chip packaging mould comprises a lower mould(1) and an upper mould (2), the lower mould (1) comprises a plurality of platforms (3) and a mold cavity (4), wherein the platforms are horizontally arranged at intervals, the mold cavity (4) is used for placing electron components, feeding grooves (5) and residual material discharging grooves (6) are correspondingly formed in the two ends of the platforms (3) and the mold cavity (4), feeding holes (7) areformed in the connecting ends of the mold cavity (4) and the feeding grooves (5), and discharging holes (8) are formed in the connecting ends of the mold cavity (4) and the residual material discharging grooves (6); and vacuum holes (10) are formed in the bottom ends of the residual material discharging grooves (6), and the vacuum holes (10) are connected with a vacuum pump (11). According to thevacuum circuit chip packaging mould, the degassing effect is great, and the vacuum circuit chip packaging mould is particularly suitable for degassing and packaging of packaging materials with largestickiness and bad mobility.

Owner:湖南正美光电科技有限公司

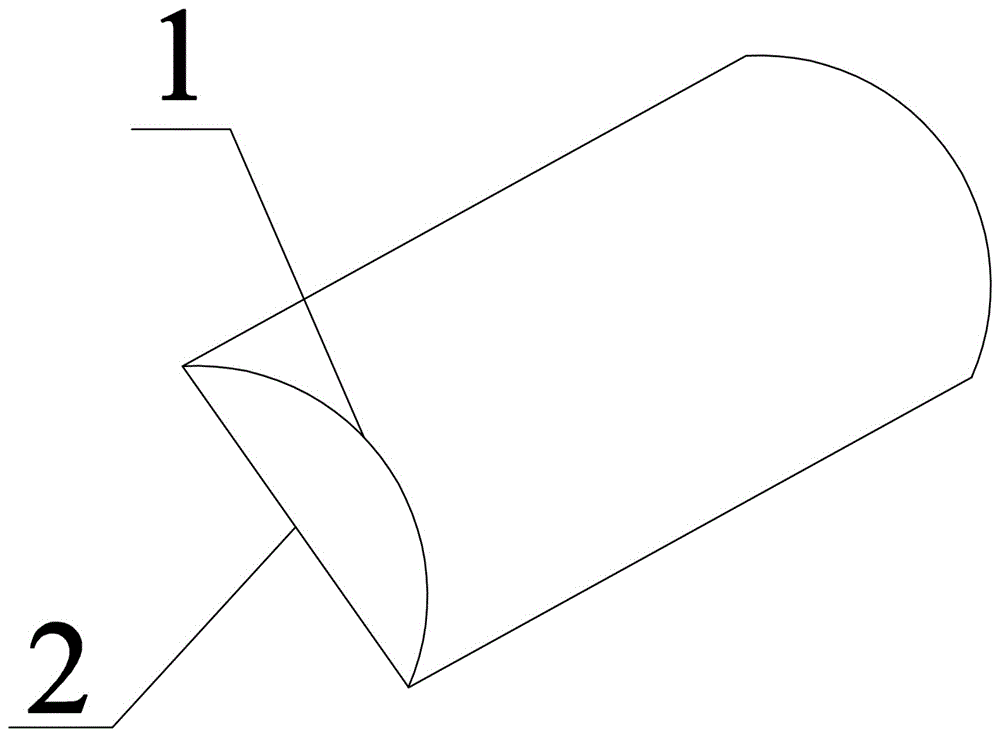

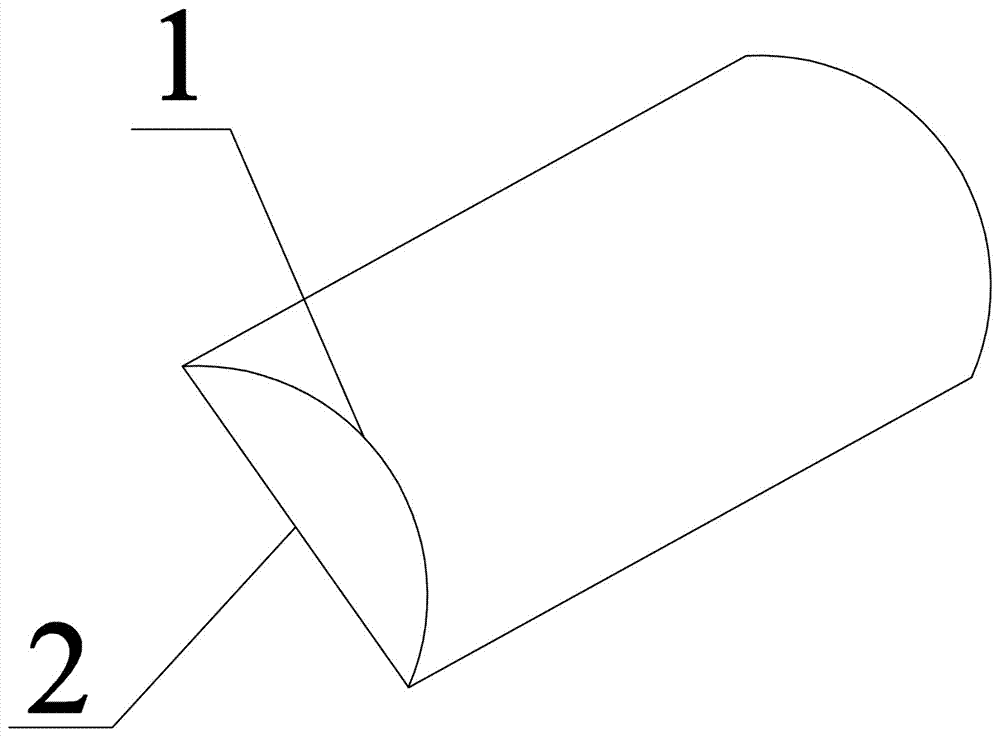

Novel pouring gun head for silicone joint material of concrete expansion joint

InactiveCN104195932ALarge amount of glueNot easy to mixRoads maintainenceRailway track constructionExpansion jointUltimate tensile strength

The invention relates to a novel pouring gun head for a silicone joint material of a concrete expansion joint. The novel pouring gun head for the silicone joint material of the concrete expansion joint comprises a pouring head and a base, wherein the pouring head is connected with the base, and the base is connected with a glue gun. The novel pouring gun head has the characteristics of being uniform in pouring and being difficultly mingled with bubbles; pouring and surface concave scrapping of a joint material can be simultaneously realized, and the pouring quality and the pouring efficiency are remarkably improved. The pouring head is connected with the base by adopting a bayonet and the base is connected with the glue gun by adopting a bayonet, thus the novel pouring gun head is easy to disassemble, brings convenience in immediately cleaning a glue material inside, and can be repeatedly used. The problems of poor construction quality, low pouring efficiency, large labor intensity and the like of an existing joint material are solved, and the novel pouring gun head is suitable for constructing joint materials in the fields of high-speed railways, expressways, airfield runways and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

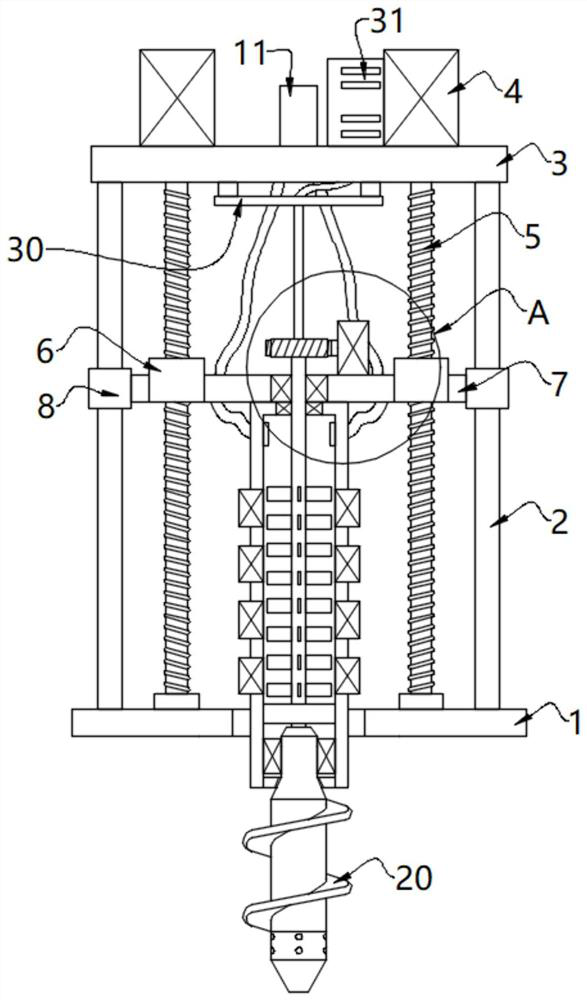

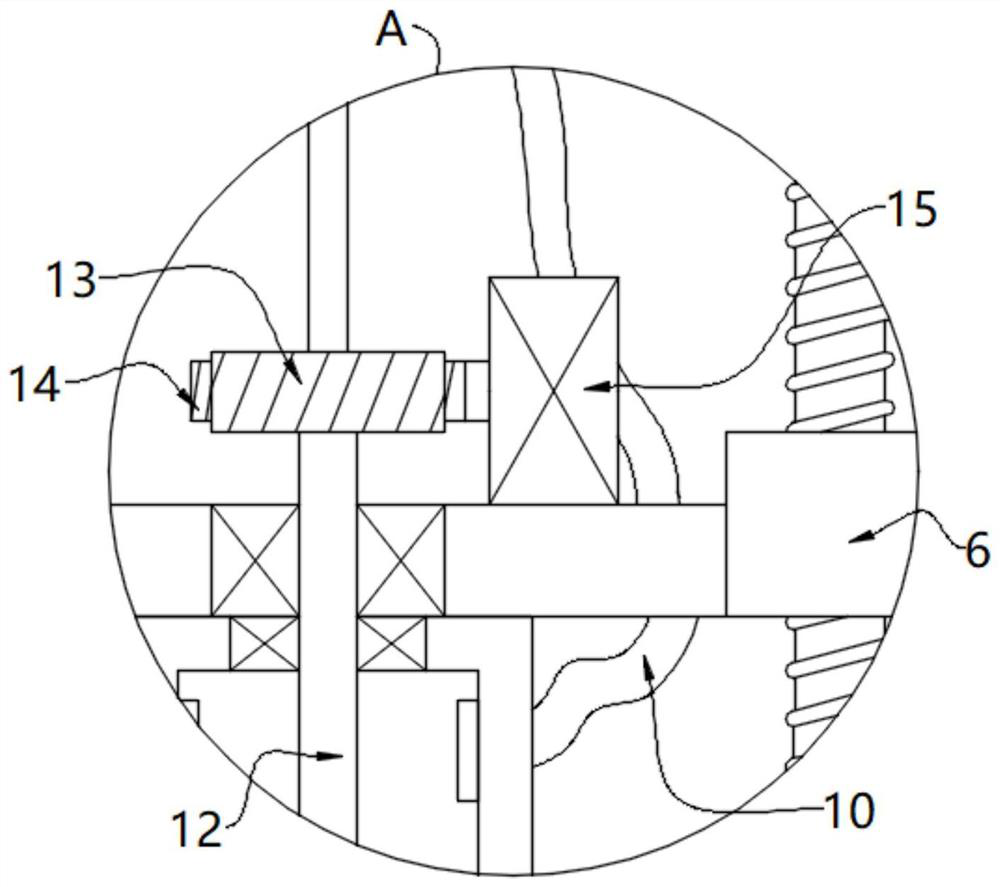

Grouting device for coal mine water disaster prevention and control

PendingCN112963200AWell mixedIncrease kinetic energyUnderground chambersDrainageElectric machineryDrive motor

The invention relates to the technical field of coal mine water disaster prevention and control, and discloses a grouting device for coal mine water disaster prevention and control. The grouting device for coal mine water disaster prevention and control comprises a bottom plate, wherein supporting columns are fixedly mounted on two sides of the top of the bottom plate, a top plate is fixedly mounted on the tops of the supporting columns, and a lifting motor is fixedly mounted on the top of the top plate; a screw rod is fixedly mounted at the top of an output shaft of the lifting motor, a nut is in threaded connection with the outer wall of the screw rod and fixedly mounted in a lifting plate, and the lifting motor operates to drive the lifting plate and a grouting cylinder to descend through transmission of the screw rod and the nut, so that the grouting cylinder penetrates into a ground hole; a driving motor runs to drive a rotating shaft, a connecting column and a soil loosening auger to rotate through transmission of a worm gear and a worm, the soil loosening auger rotates to loosen a rock-soil body below the grouting cylinder, sinking of the grouting cylinder is facilitated, and the grouting cylinder cannot be blocked by the hard rock-soil body. The grouting device for coal mine water disaster prevention and control has the advantages of being convenient to drill into ground pores, uniform in grouting and large in grouting force.

Owner:魏贺

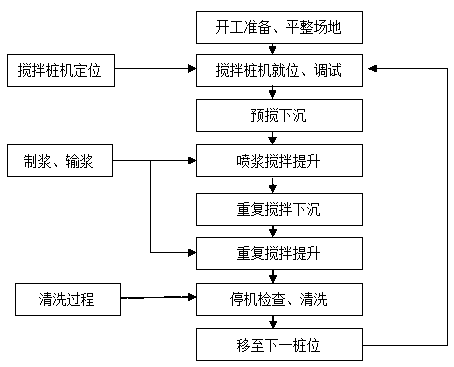

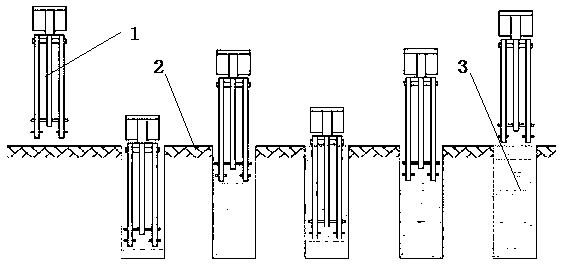

Novel cement mixing pile construction method

InactiveCN110409435AGuaranteed verticalityUniform perfusionBulkheads/pilesSoil mixingHydraulic engineering

The invention relates to the technical field of hydraulic engineering, in particular to a novel cement mixing pile construction method. The novel cement mixing pile construction method is characterized in that before construction, a field is leveled to make a preparation for operation, before the construction is started, test detection is carried out on cement soil mixing piles in different areas,and optimal parameters are obtained through data analysis, thereby determining the parameters of cement soil, and after test, the constriction is started. The construction method comprises the following construction steps of (1) positioning a pile machine; (2) preparing cement paste; (3) premixing and sinking; (4) lifting and spouting; (5) repeatedly mixing; (6) cleaning; and (7) moving the pilemachine. The cement paste is uniformly poured by lifting and spouting at constant speed, and then the repeated mixing is carried out to enhance the construction quality. In the whole process, the drilling precision is higher, the ratio of cement to soil is reasonable, the possibility of reducing project errors is greatly reduced, and the construction progress of a project is improved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

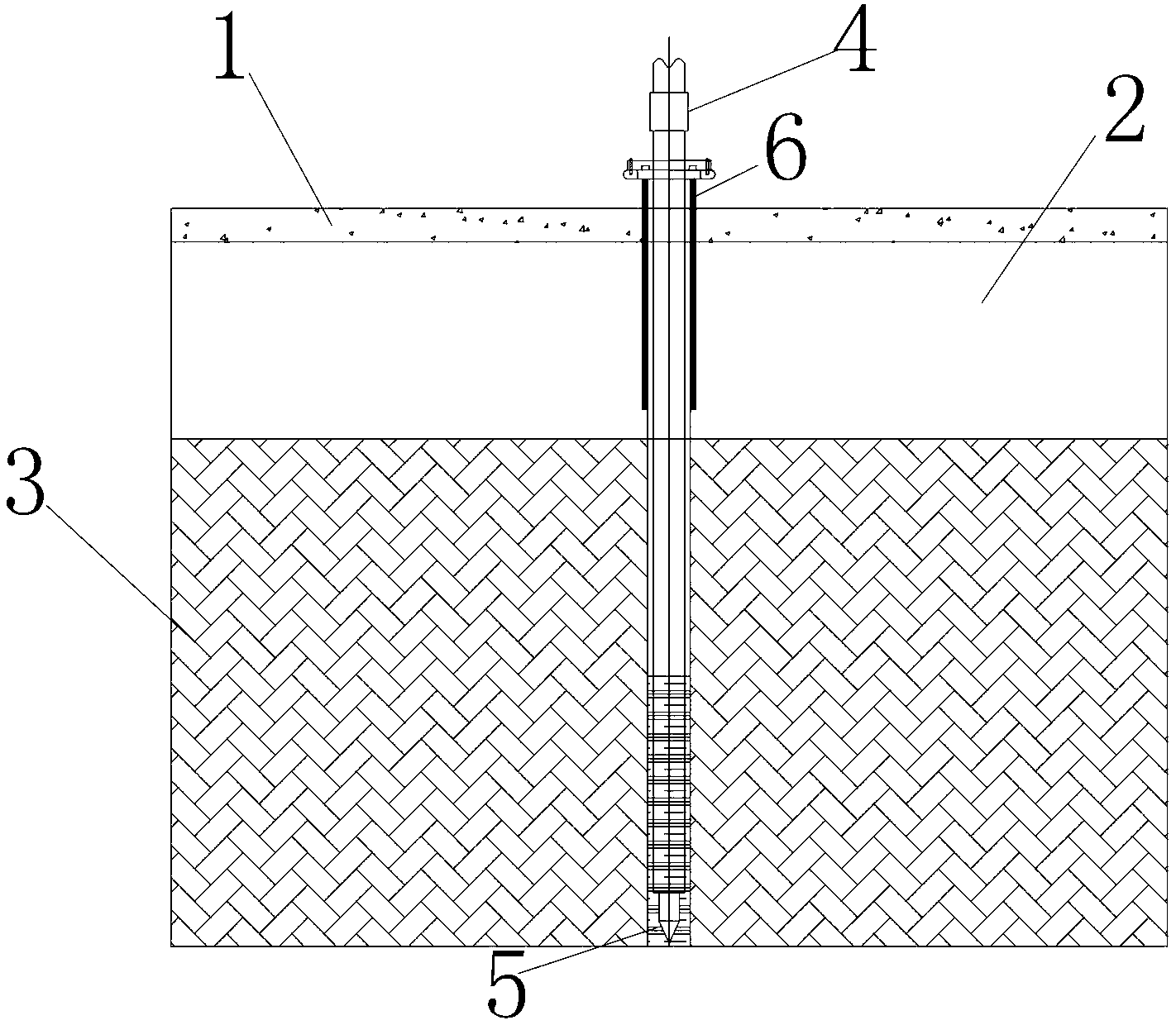

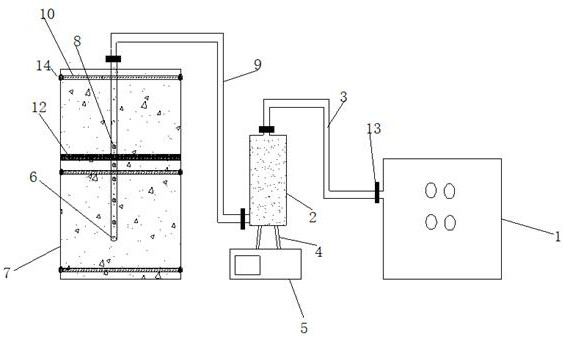

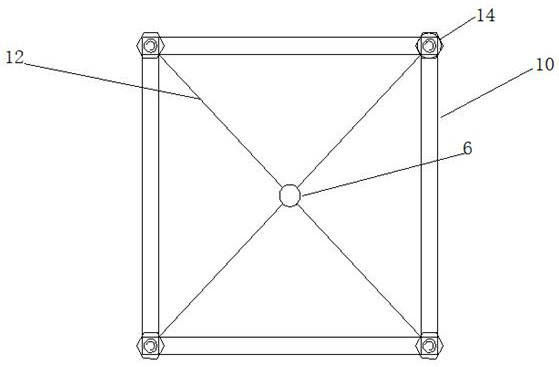

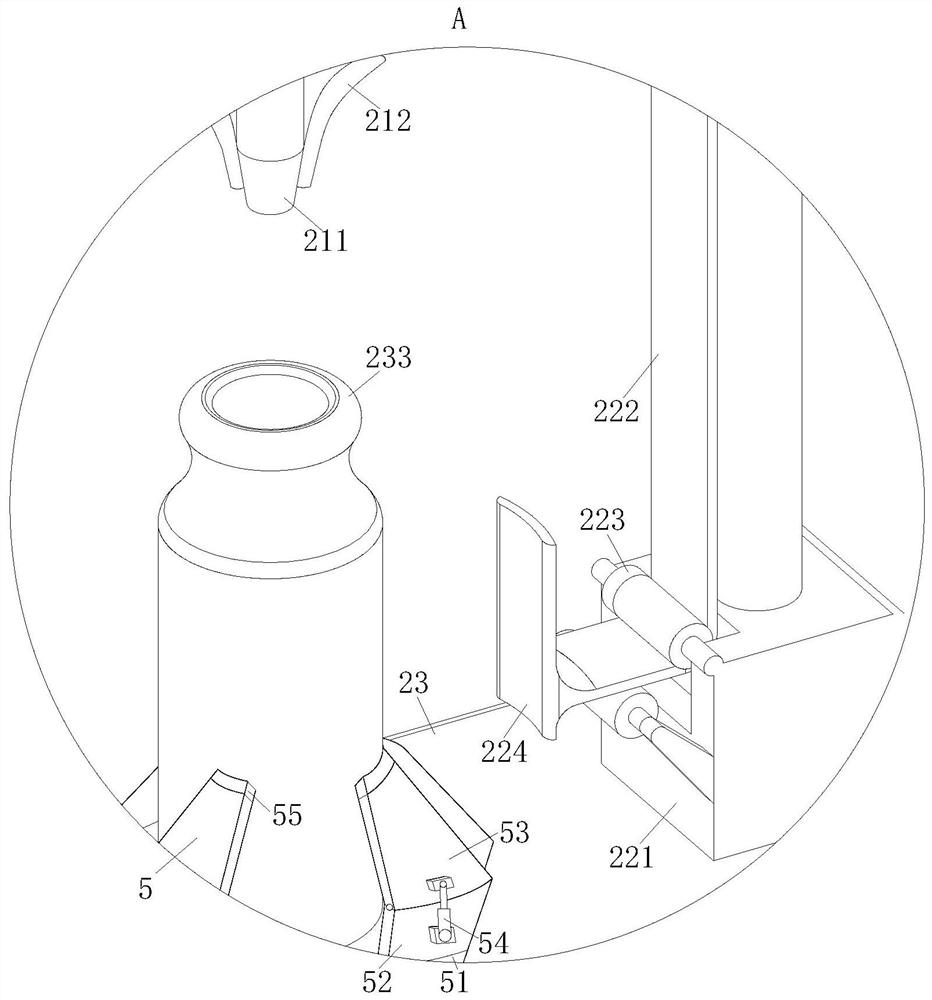

Experimental device for simulating soil splitting grouting indoors

The invention belongs to the technical field of constructional engineering instruments and equipment, and particularly relates to an experimental device for simulating soil splitting grouting indoors. The experimental device comprises a pressure supply device, a slurry storage tank, a support, an electronic scale, a grouting pipe and a model box. The pressure supply equipment is used for supplying pressure and pouring grout, simultaneous grouting is conducted through the grouting holes of different heights, and grouting work in the experiment process can be efficiently and evenly conducted. Acrylic glass plates and steel trusses on the periphery of the model box can be disassembled, assembling and disassembling are convenient, meanwhile, the model box can be directly filled with a soil body needing to be researched, the actual engineering environment can be simulated, the influence of slurry on the soil body can be visually observed, and the research requirement of the slurry diffusion mechanism is met. According to the experimental device, after a grouting experiment is completed and slurry is solidified, a soil body in the model box is excavated, and the trend of the slurry in the soil body, the distribution of slurry veins and the diffusion distance can be clearly observed due to the fact that a coloring agent is doped in the slurry.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD

Feeding device for animal husbandry

The invention discloses a feeding device for animal husbandry. The feeding device comprises moving seats, feeding troughs and a processing box. Roller are arranged inside the moving seats, the movingseats are sleeved with the feeding troughs, a lifting plate is fixedly connected inside the feeding troughs, a screw penetrates through the middle of the lifting plate, and the upper end of the screwis connected with a screw motor through a coupling; fixing cones are fixedly connected with the bottoms of the feeding troughs. The moving seats, the rollers, the feeding troughs, the fixing cones, the lifting plate and the screw are arranged, so that the whole feeding device can be conveniently fixed and moved in the pasture, stability of the feeding device is improved, and livestock can eat conveniently; a support cylinder, a sleeve, discharging pipes, a second gear ring, a transmission gear, a transmission shaft, a transmission belt, spiral feeding rollers, rolling gears and first gear rings are arranged, the feeding troughs are fixed and feed is uniformly poured, so that operation efficiency is improved.

Owner:马迎松

Explosive filling device for fireworks and crackers

InactiveCN105222655AImprove continuous working abilityHigh working reliabilityFireworksFirecrackerFireworks

The invention discloses an explosive filling device for fireworks and crackers. A plurality of sleeves are arranged on a cavity for loading explosive slurry in a mode of penetrating through the cavity; side walls of the sleeves inside the cavity are provided with openings for introducing the explosive slurry into inner cavities of the sleeves; slide rods are embedded into the inner cavities of the sleeves; the top ends of the slide rods are connected with a drive mechanism so as to move up and down in the sleeves; descending end points at the bottom ends of the slide rods can be parallel to bottom end openings of the sleeves or extend out of the bottom end openings of the sleeves; ascending end points at the bottom ends of the slide rods are higher than the openings. The device is high in working reliability, accurate, uniform and controllable in filling amount, high in production efficiency and low in production loss.

Owner:LIUYANG CITY DAYAO TOWN BOSHENG TECH MACHINERY FACTORY

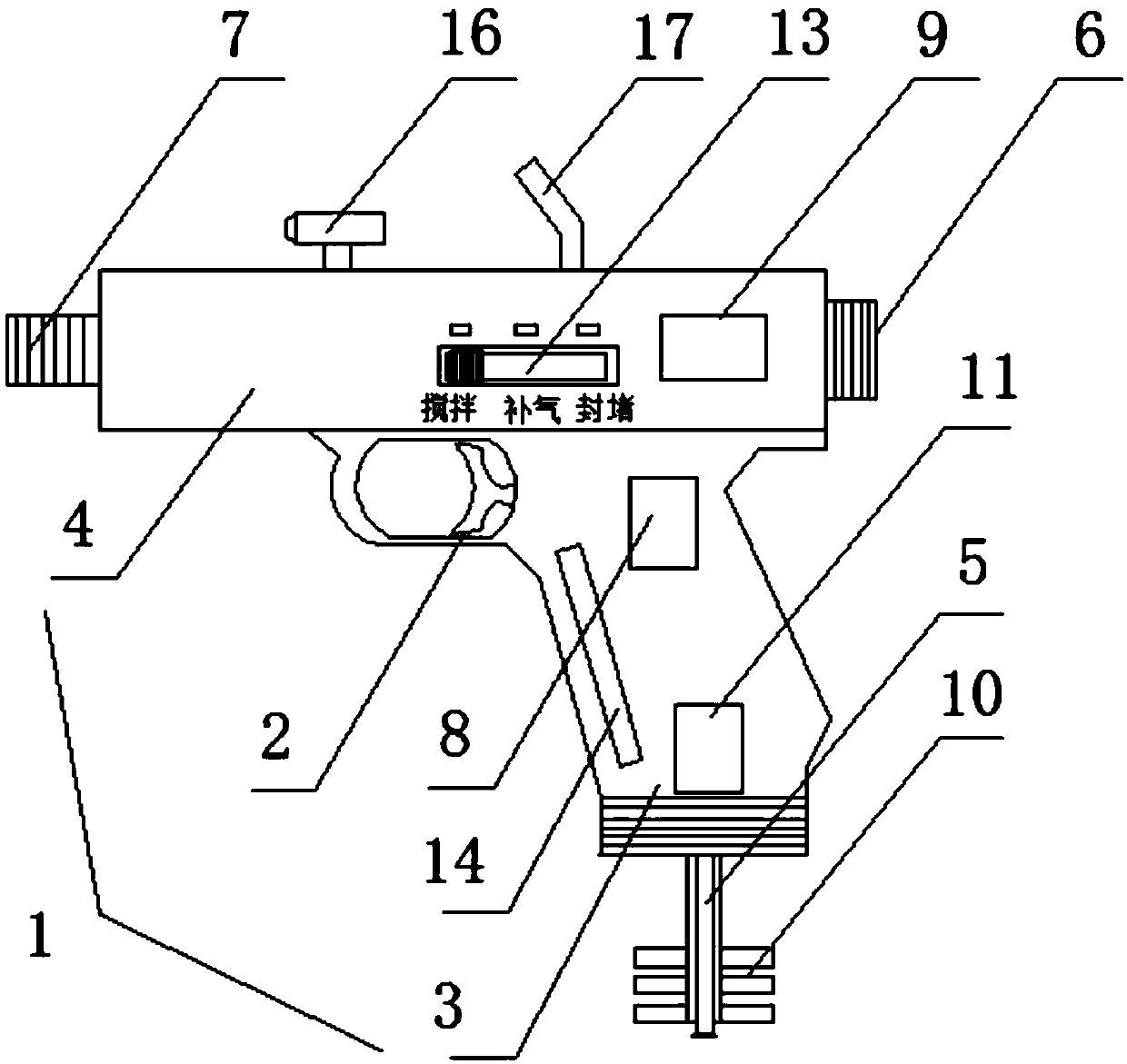

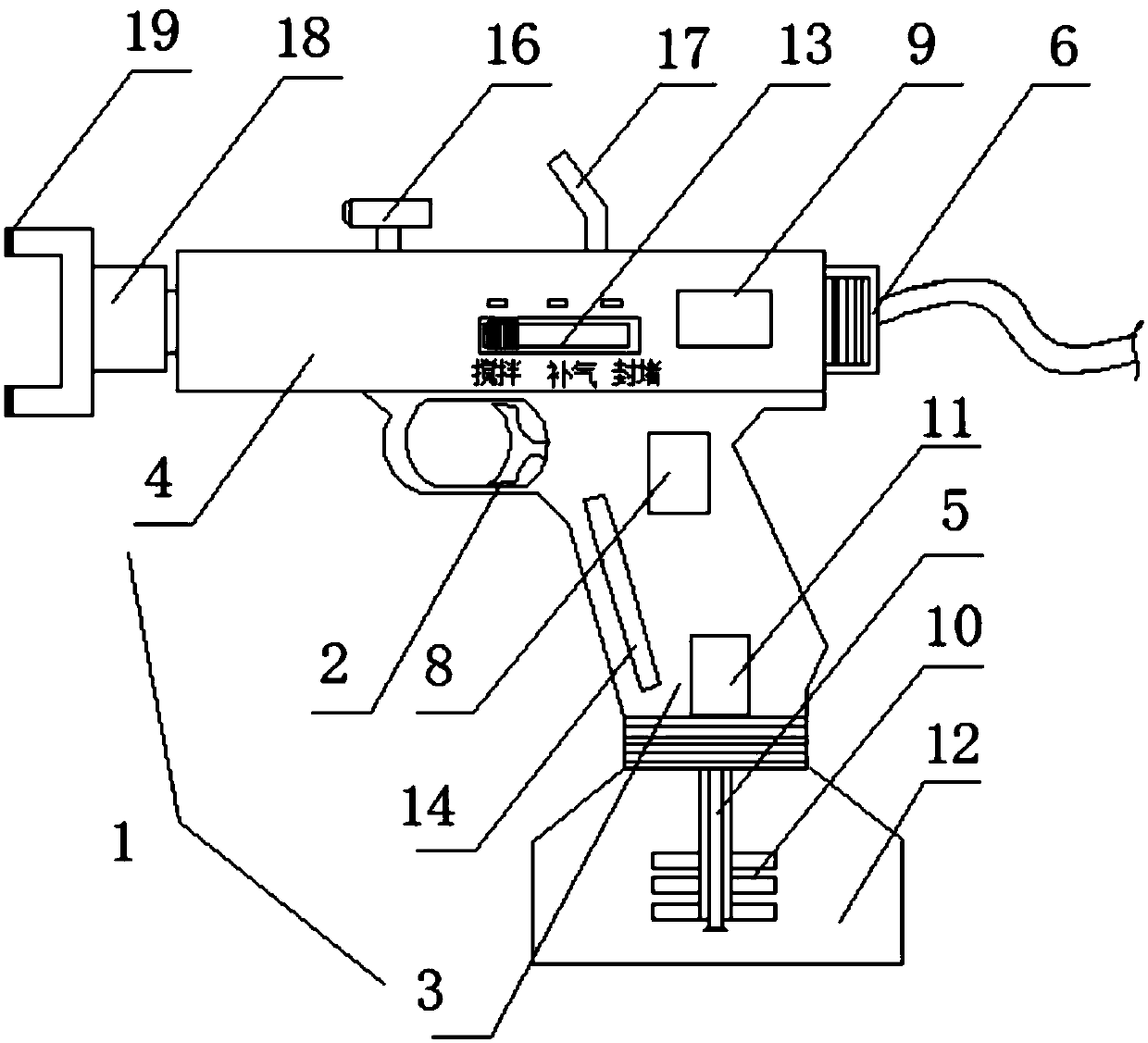

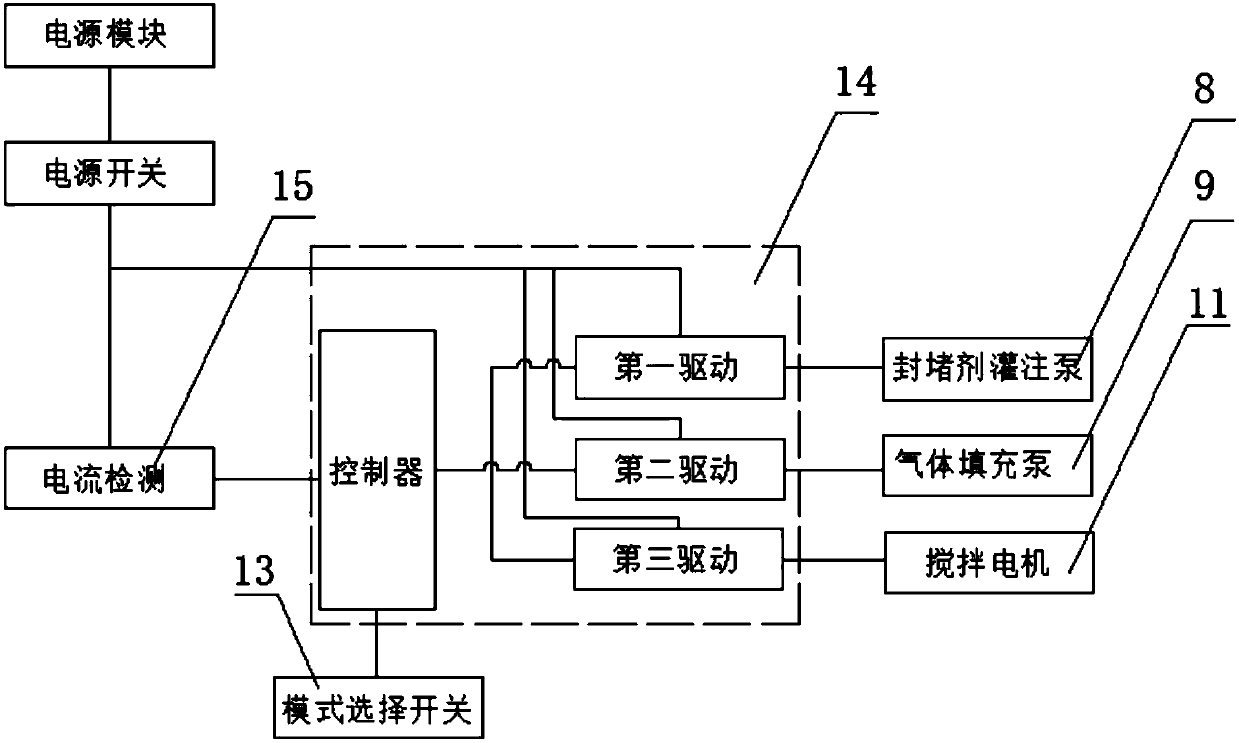

SF6 gas insulated power equipment leakage plugging device and control method thereof

ActiveCN109103801AUniform perfusionSimple structureSwitchgear arrangementsElectric power equipmentPower equipment

A SF6 gas insulated power equipment leakage plugging device and a control method thereof are provided. The device includes a filling gun, the filling gun comprising a handle, a trigger and a frame, the lower end of the handle is provided with a plugging agent suction pipe, the rear end of the gun frame is provided with an SF6 gas suction pipe, a nozzle is arranged at the front end of the gun frame, a plug agent filling pump and a gas filling pump are arranged inside the handle, the plugging agent suction pipe is connected with the inlet of the plugging agent filling pump, the outlet of the plugging agent filling pump is connected with the nozzle through a first pipeline, the SF6 gas suction pipe is connected with the inlet of the gas filling pump, and the outlet of the gas filling pump isconnected with the nozzle through a second pipeline. The device has the advantages of simple structure, convenient operation, gas compensation and rapid plugging under the condition of leakage of SF6gas insulated electric power equipment with pressure, uniform plugging agent injection, and guaranteed plugging effect.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

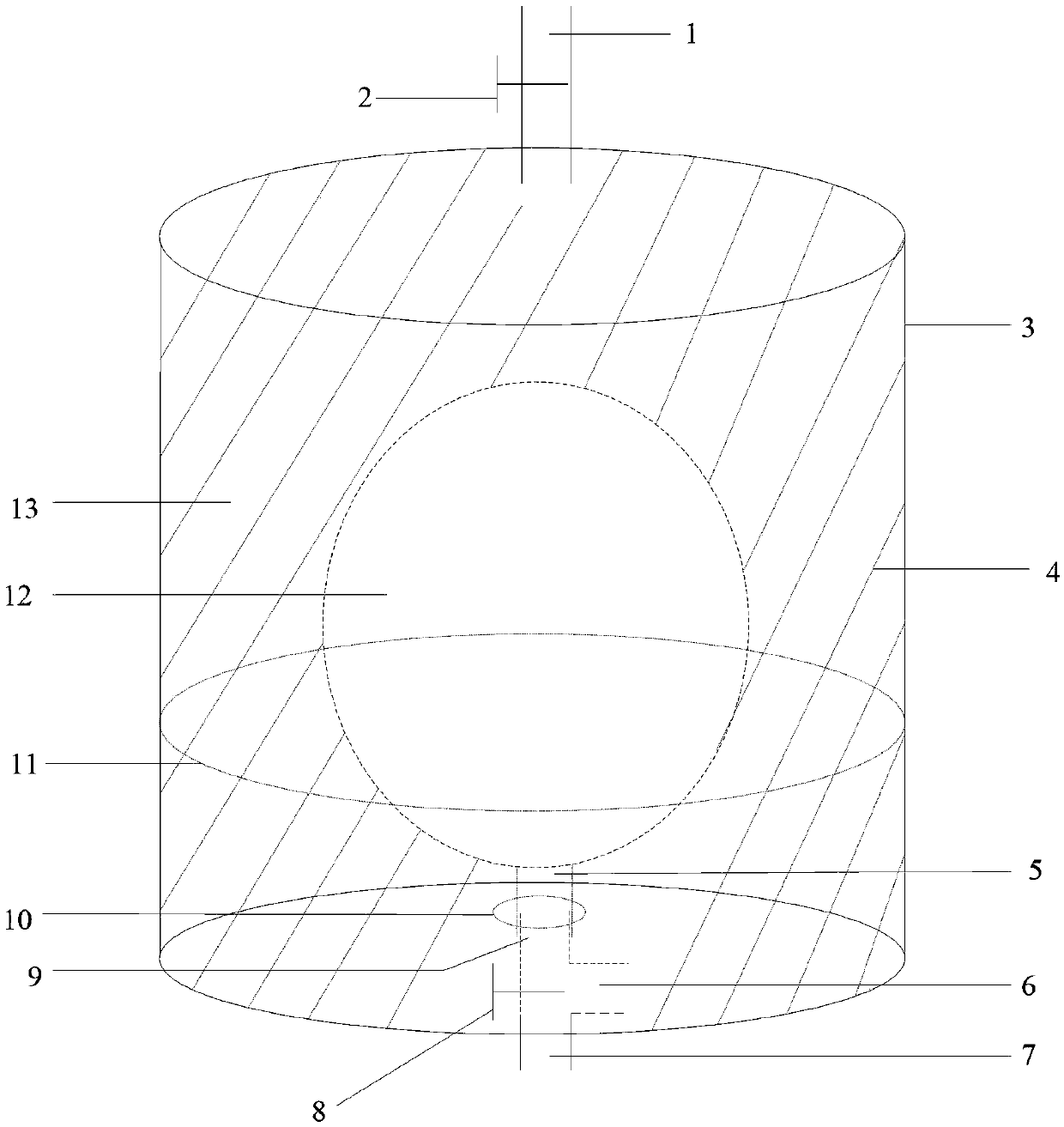

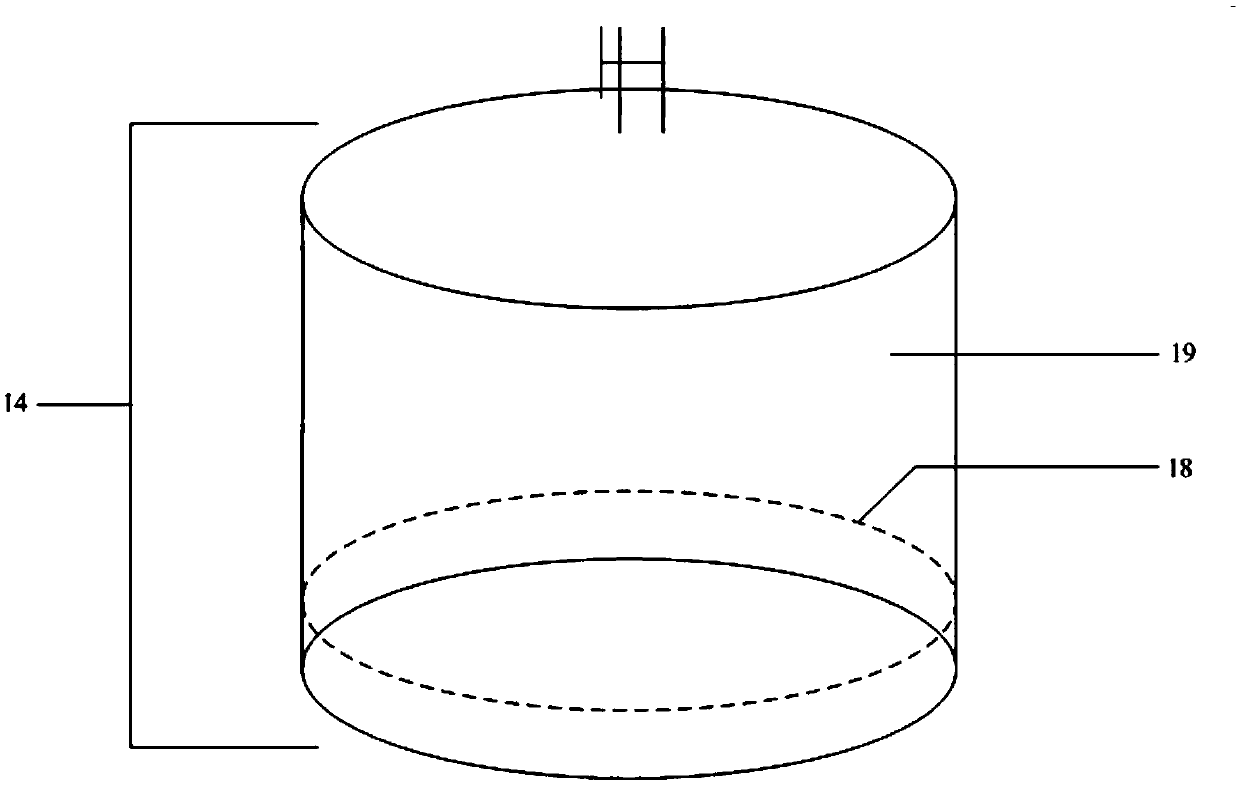

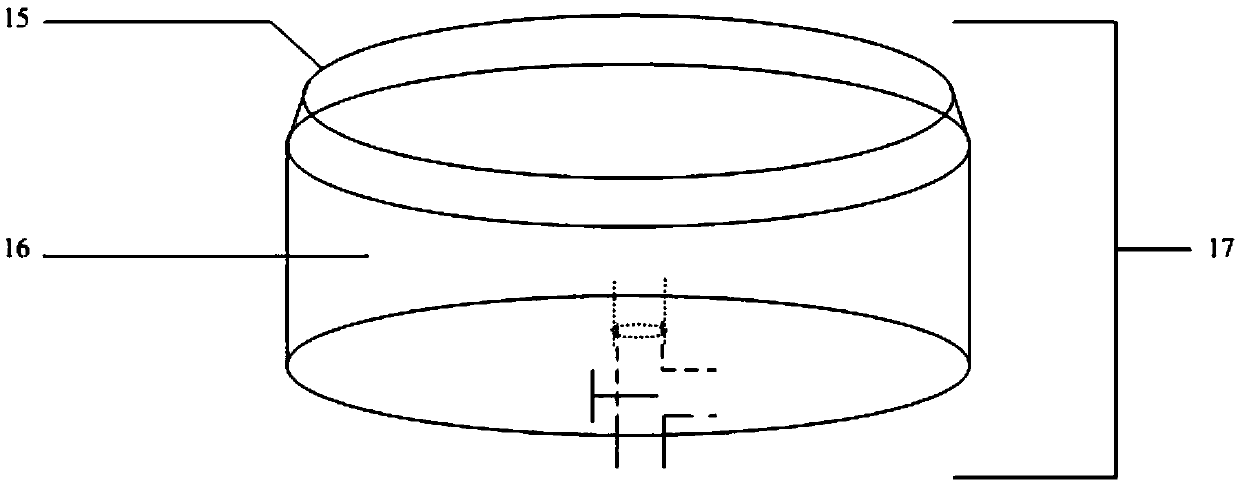

Acellularized scaffold type bioreactor for artificial liver and utilization method of acellularized scaffold type bioreactor for artificial liver

InactiveCN105498005APrevent leakageUniform perfusionDialysis systemsDecellularized scaffoldPerfusion

The invention discloses an acellularized scaffold type bioreactor for an artificial liver and a utilization method of the acellularized scaffold type bioreactor for the artificial liver. The acellularized scaffold type bioreactor comprises a bioreactor shell, an acellularized scaffold, a filling scaffold, liquid inlets and a liquid outlet. The bioreactor shell comprises an upper portion and a lower portion, each of the upper portion and the lower portion is in a hollow structure, and a first cavity in the upper portion and a second cavity in the lower portion are in threaded connection to form a cylindrical inner cavity. A middle region of the top of the upper portion is provided with an inner cavity liquid outlet, and a center region of the bottom of the lower portion is provided with an inner cavity main liquid inlet. The main liquid inlet is branched into a first liquid inlet and a second liquid inlet, the first liquid inlet is connected to a liquid inlet of the acellularized scaffold, and the second liquid inlet is connected to the filling scaffold. By the acellularized scaffold type bioreactor for the artificial liver, in-vivo perfusion can be simulated, and uniformity in perfusion and reduction of dead spaces are realized; shear force applied to liver cells can be reduced, a three-dimensional growing environment for the liver cells can be simulated, and the amount of the liver cells in the bioreactor is increased.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

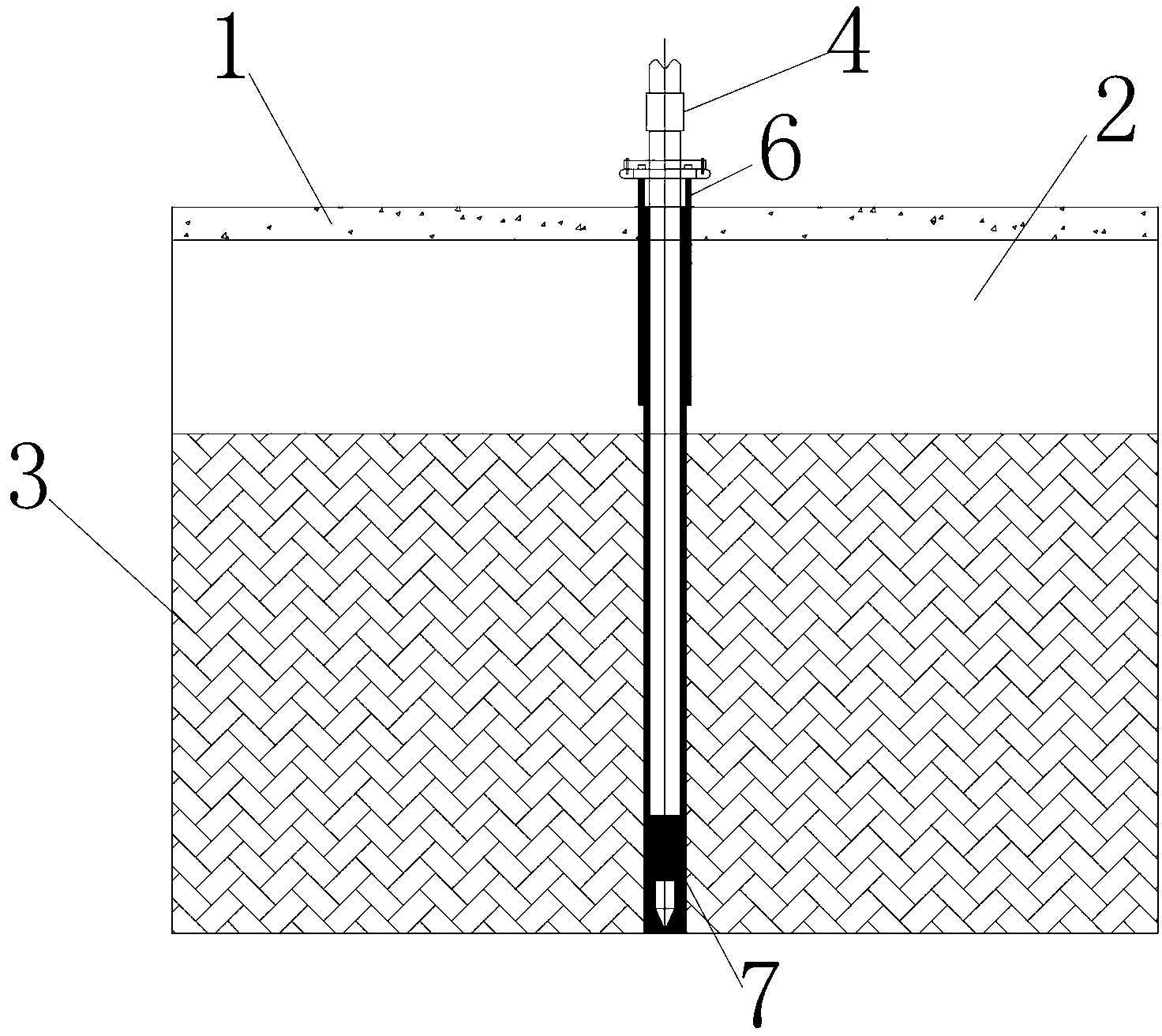

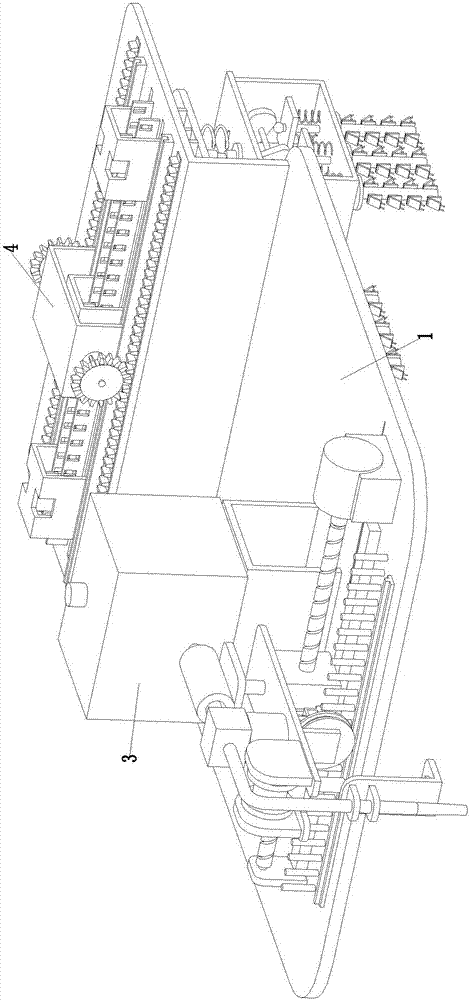

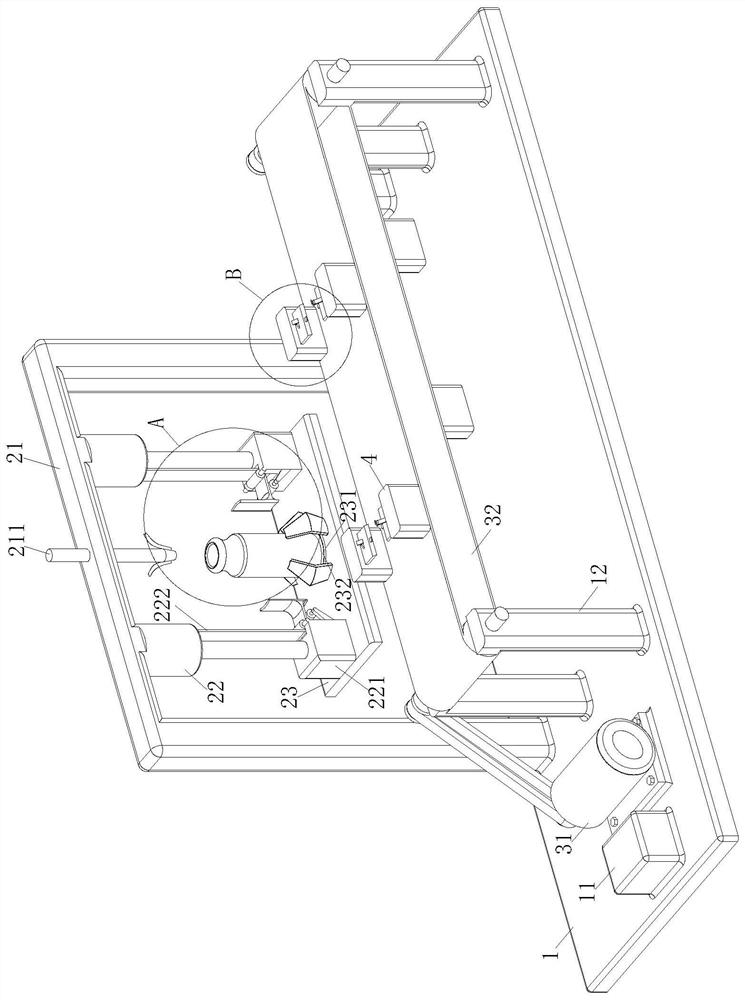

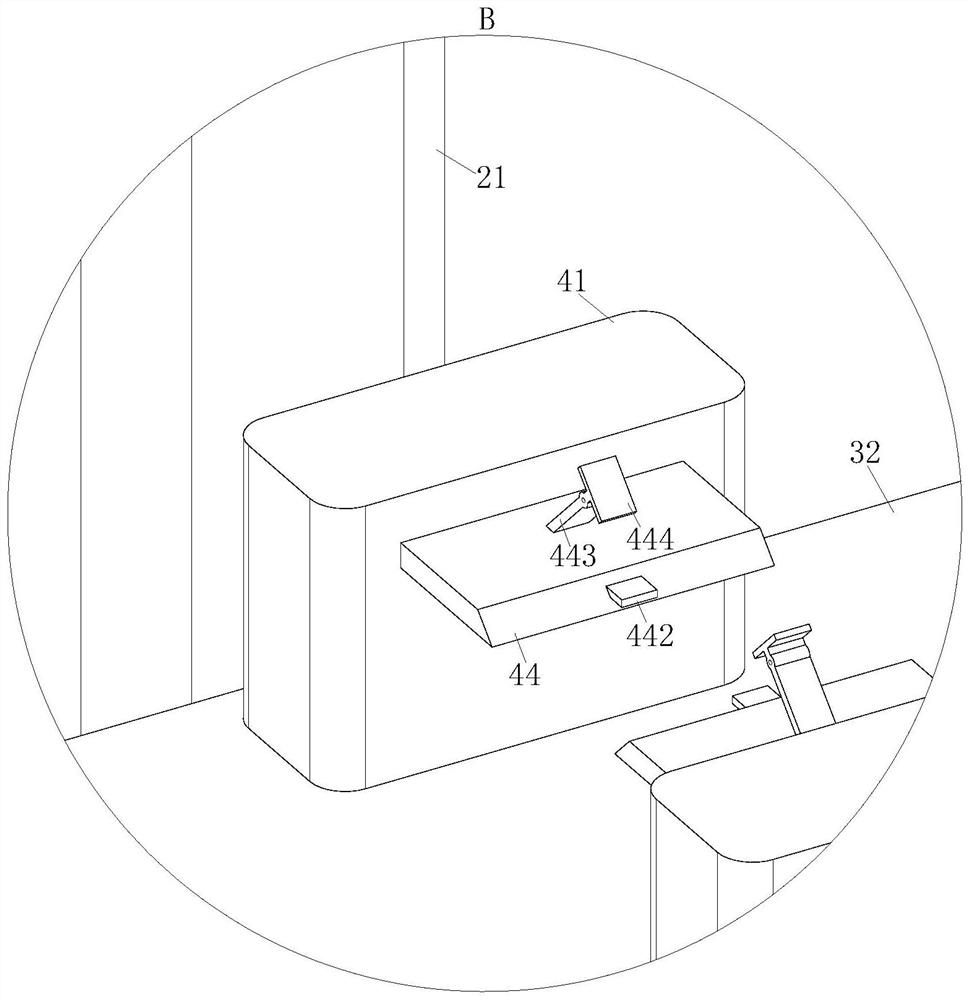

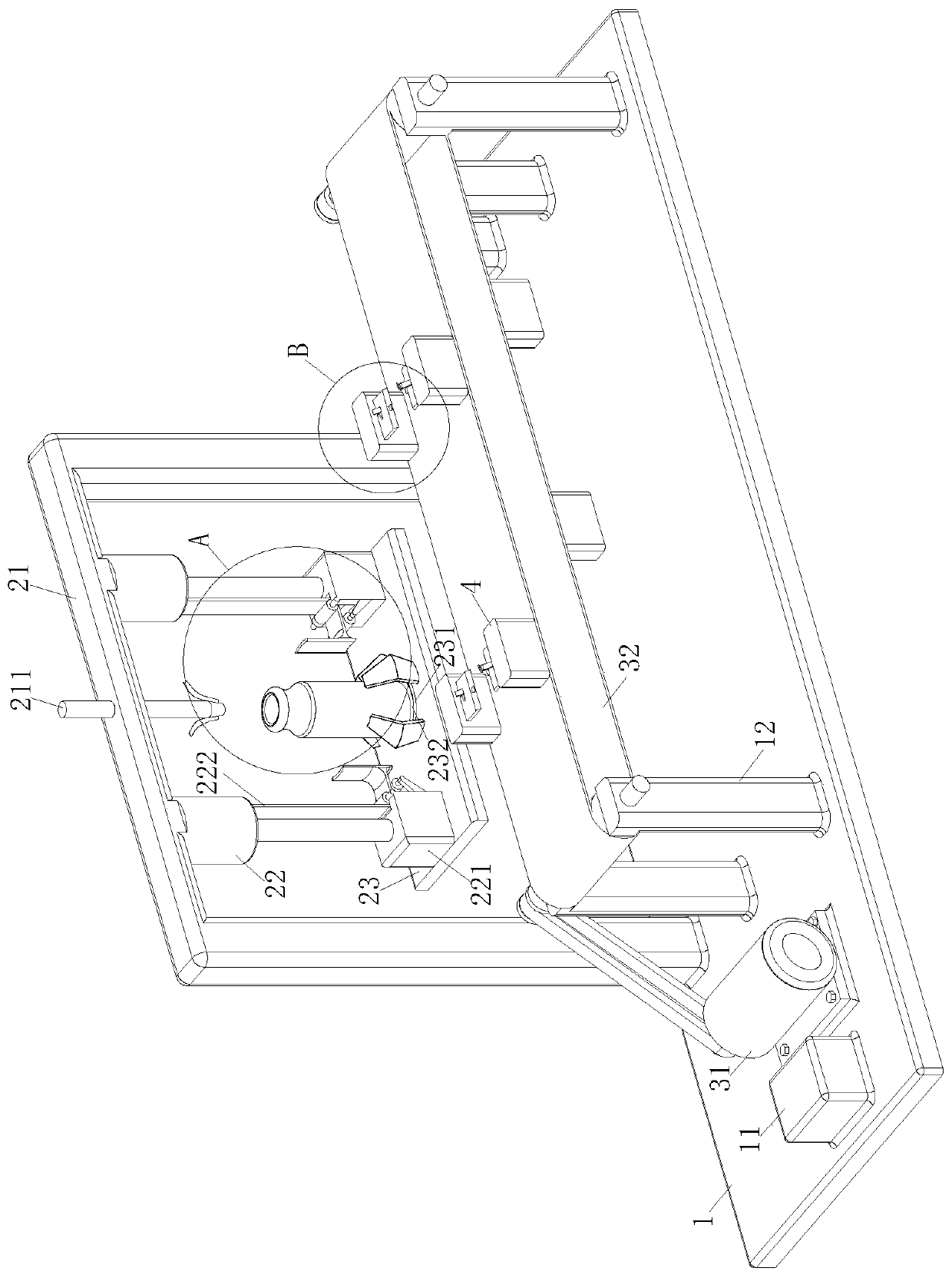

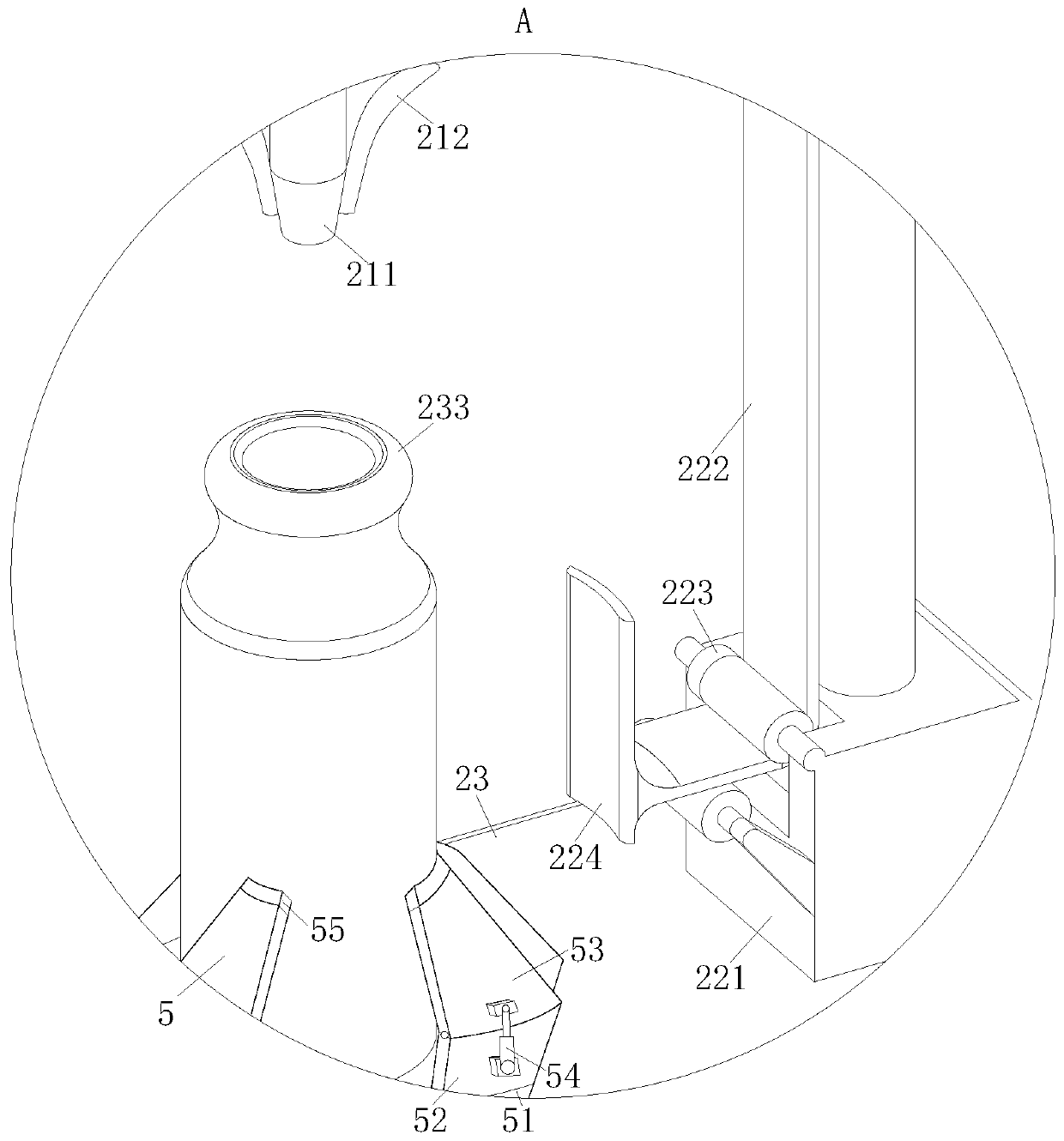

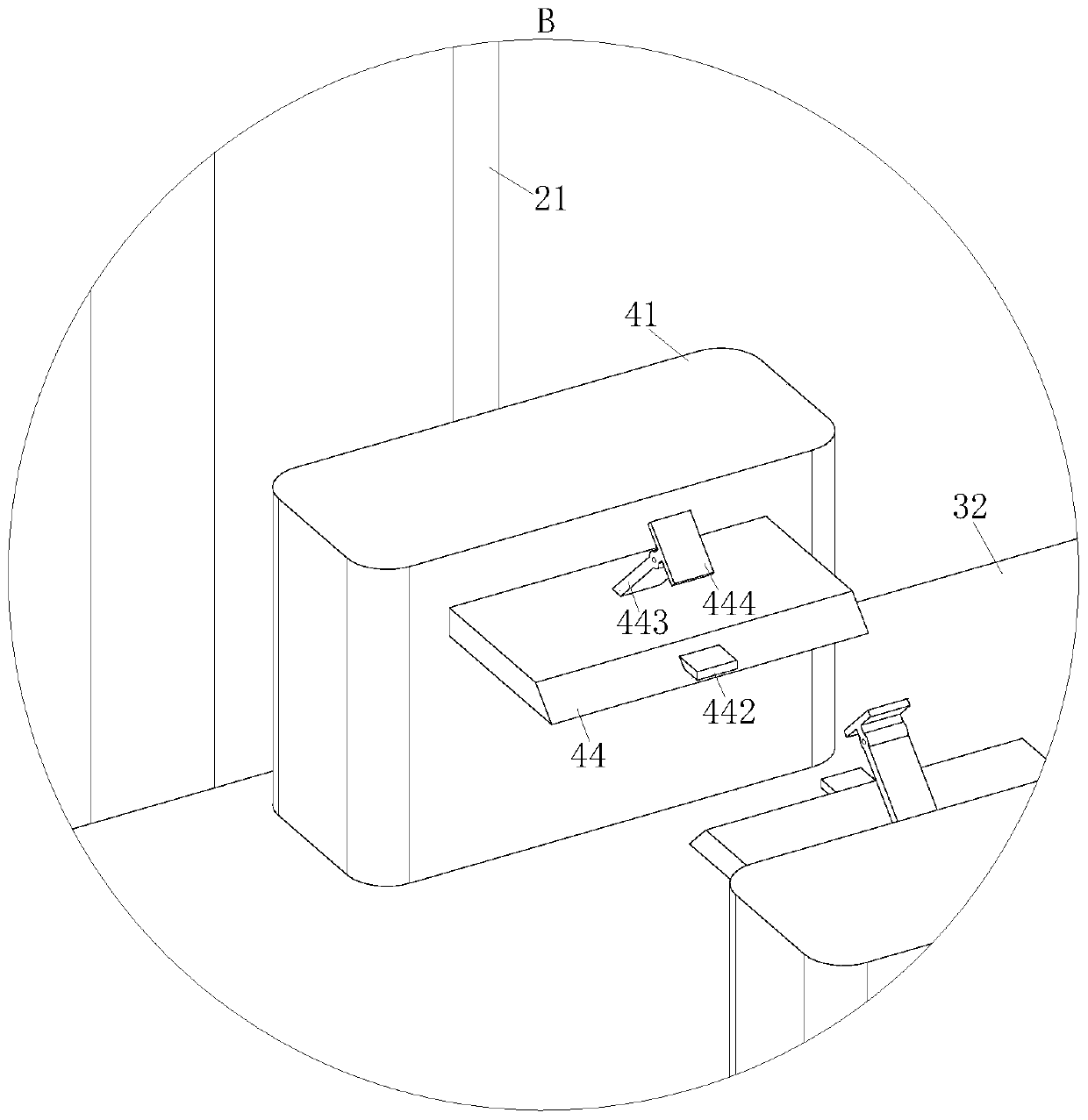

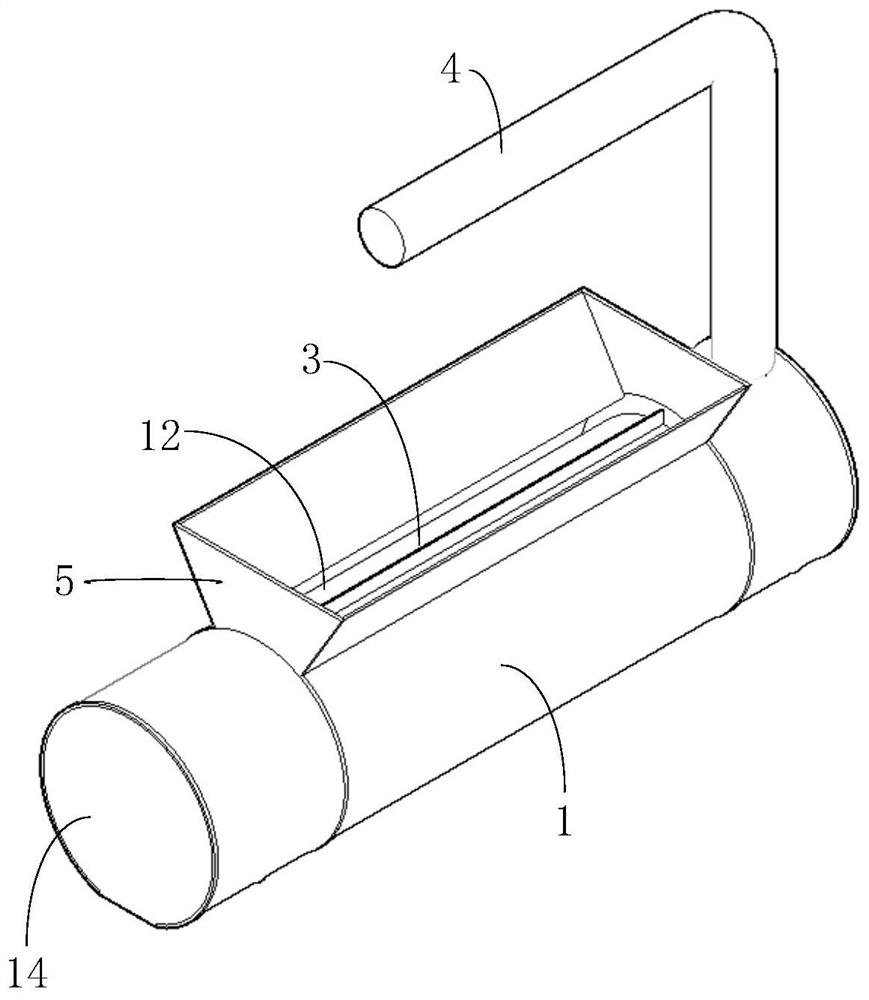

Intelligent cantilever assembling type long-span bridge wet joint pouring device

InactiveCN107964876AReduce labor intensityImprove perfusion efficiencyBridge erection/assemblyBridge materialsEngineeringLong span

The invention relates to a cantilever-assembled large-span bridge wet joint pouring intelligent equipment, comprising a bottom plate, a pouring device is arranged at the front end of the bottom plate, a vibrating compaction device is arranged at the rear end of the bottom plate, and the pouring device includes a pouring support frame installed In the perfusion storage box on the bottom plate, a discharge port is arranged on the lower side of the front end of the perfusion storage box, and a perfusion adjustment mechanism is installed on the front end of the bottom plate. The present invention can solve the instability of artificially conveyed and poured concrete existing in the existing wet joint concrete pouring process, and it is easy to make the concrete splash to the position other than the connecting joint. Manual conveying of concrete cannot ensure the uniformity of concrete pouring, and manual use of existing vibration is required. The equipment vibrates and compacts the poured concrete. During the vibration process of wet joint concrete pouring, it is necessary to avoid the reinforcement cage. The operation is complicated, and the concrete cannot be fully vibrated manually, and the compactness of the concrete cannot be ensured, and the concrete will have holes. .

Owner:范满香

Pharmaceutical composition for treating bovine mastitis and preparation method thereof

InactiveCN107252441ARelieve symptomsIncrease milk productionAntibacterial agentsOrganic active ingredientsORIGANUM OILSide effect

The invention discloses a pharmaceutical composition for treating bovine mastitis and a preparation method thereof. The composition is prepared from the following raw materials in percentages by weight: 0.2-12% of origanum oil, 0.05-6% of eugenol, 0.05-0.5% of chlorhexidine acetate, 0.9-48% of a surfactant, 0.3-16% of a cosurfactant and 17.5-98.5% of distilled water, and the total parentages by weight of the raw materials is 100%. The Chinese herbal medicine extracts, namely the origanum oil and the eugenol and a chemical drug chlorhexidine acetate are compounded to prepare a nano emulsion; the particle sizes are 1-100nm and the appearance is a transparent liquid; the pharmaceutical composition can be infinitely diluted, bovine mastitis can be treated through breast perfusion; and the pharmaceutical composition is free of resistance, free of a residue, small or free of toxic and side effect, convenient to use, safe and efficient.

Owner:XIANYANG VOCATIONAL TECHN COLLEGE

Ceramic tile joint filling device

ActiveCN111550018AUniform perfusionSmooth appearanceBuilding constructionsElectric machineryDrive motor

The invention provides a ceramic tile joint filling device. The ceramic tile joint filling device comprises a movably box body, a scraping part and a filler blade, wherein the movably box body is usedfor accommodating joint filling slurry and provided with a front end and a rear end, and a feeding inlet and a discharging outlet are formed in the movably box body; the scraping part is used for pressing against tiles on two sides of tile joints and connected to the outside of the movably box body, and the scraping part is arranged directly behind the discharging outlet; and the filler blade isrotatably installed in the movably box body, the filler blade extends to the outside of the discharging outlet and scrapes the tile joints after rotating, the movably box body is provided with a driving motor, and the driving motor is in transmission connection with the filler blade. The problems of inconvenient construction and difficulty in ensuring construction quality due to manual use of a scraper knife to fill the tile joints are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A filling device for sunscreen

The invention belongs to the technical field of sunscreen production, in particular to a filling device for sunscreen, comprising a worktable, a filling unit, a transmission unit, a stabilizing unit and a controller; the filling unit is located on the upper surface of the workbench; the upper beam of the bracket is symmetrical Two cylinders are fixedly connected, and there is a discharge pipe in the middle of the upper beam of the bracket; the lower end of the piston of each cylinder is connected to the bearing platform through a connecting block, and an electronic scale is installed on the upper surface of the bearing platform; the groove is used to hold packaging bottles; the electronic scale The outer ring is provided with a clamping unit, which includes a fixed ring, a fixed rod, a clamped rod and a No. 1 cylinder; the front end of the bracket is provided with a transmission unit; the motor is fixed on the workbench and connected to the conveyor belt through a belt; the conveyor belt is set on the motor On the support frame on one side, the conveyor belt is equipped with a stabilization unit; through the filling unit, clamping unit, transmission unit, stabilization unit and controller, the filling of the compound plant essential oil sunscreen liquid into the packaging bottle and the stable transmission of the packaging bottle are realized .

Owner:SUZHOU QINGZHI NETWORK TECH CO LTD

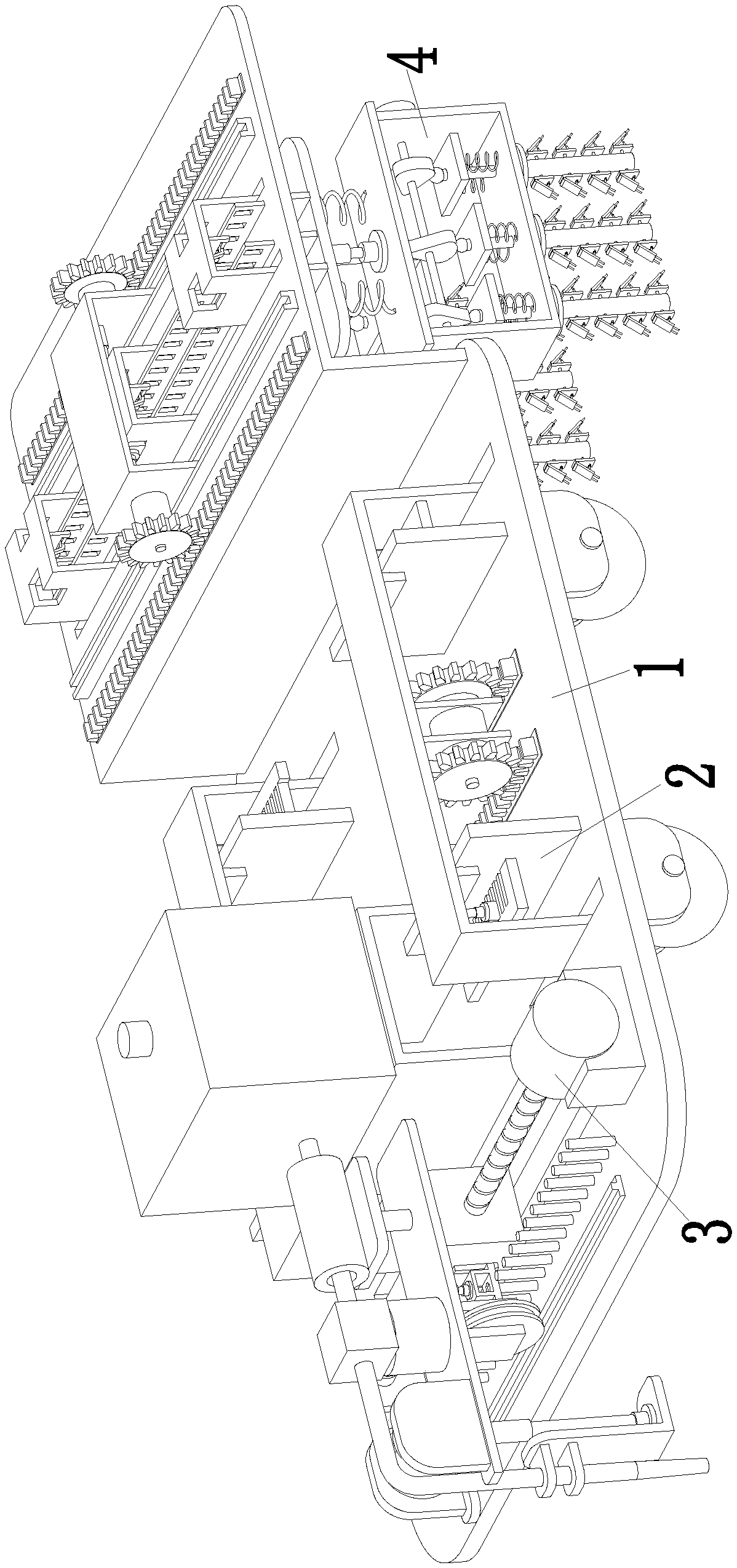

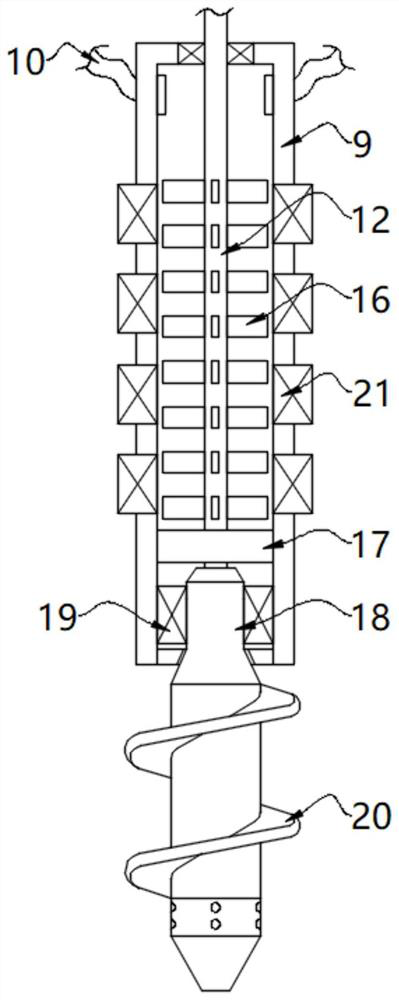

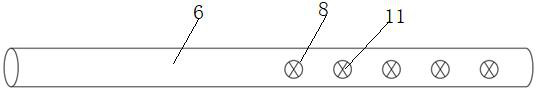

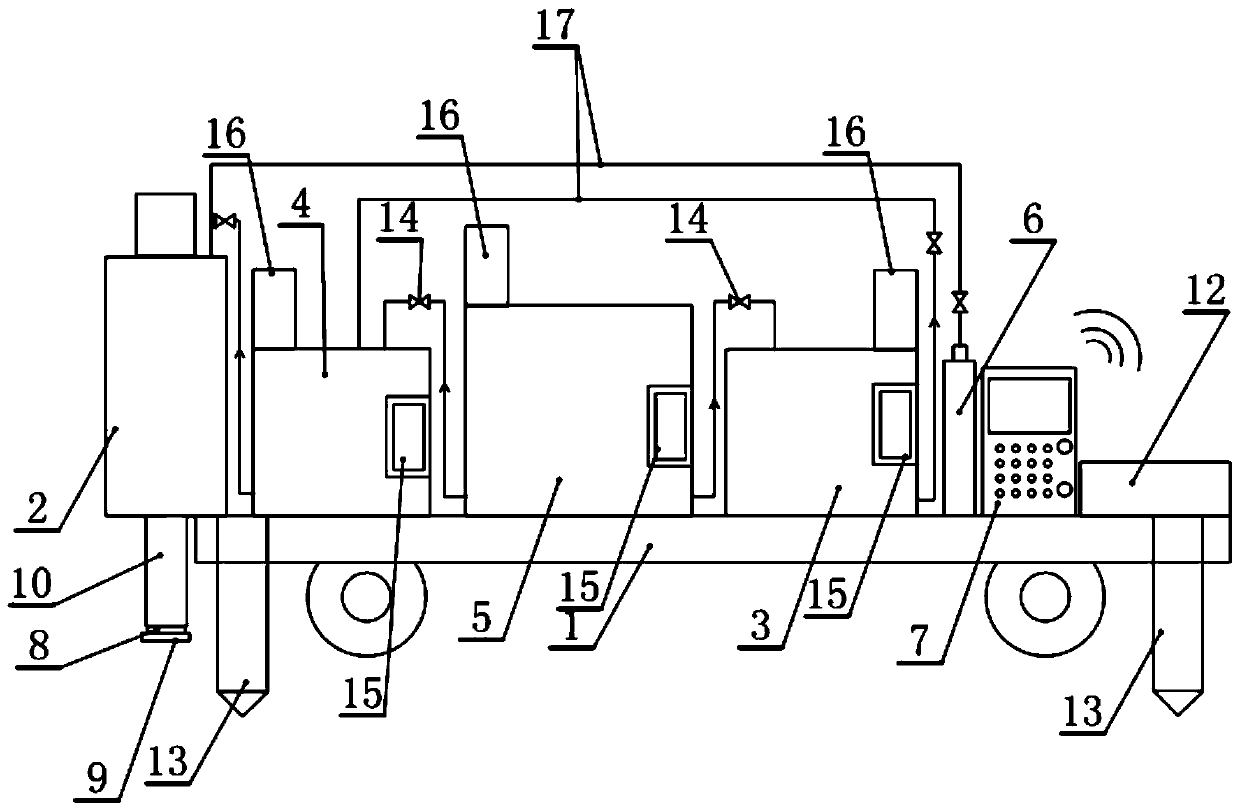

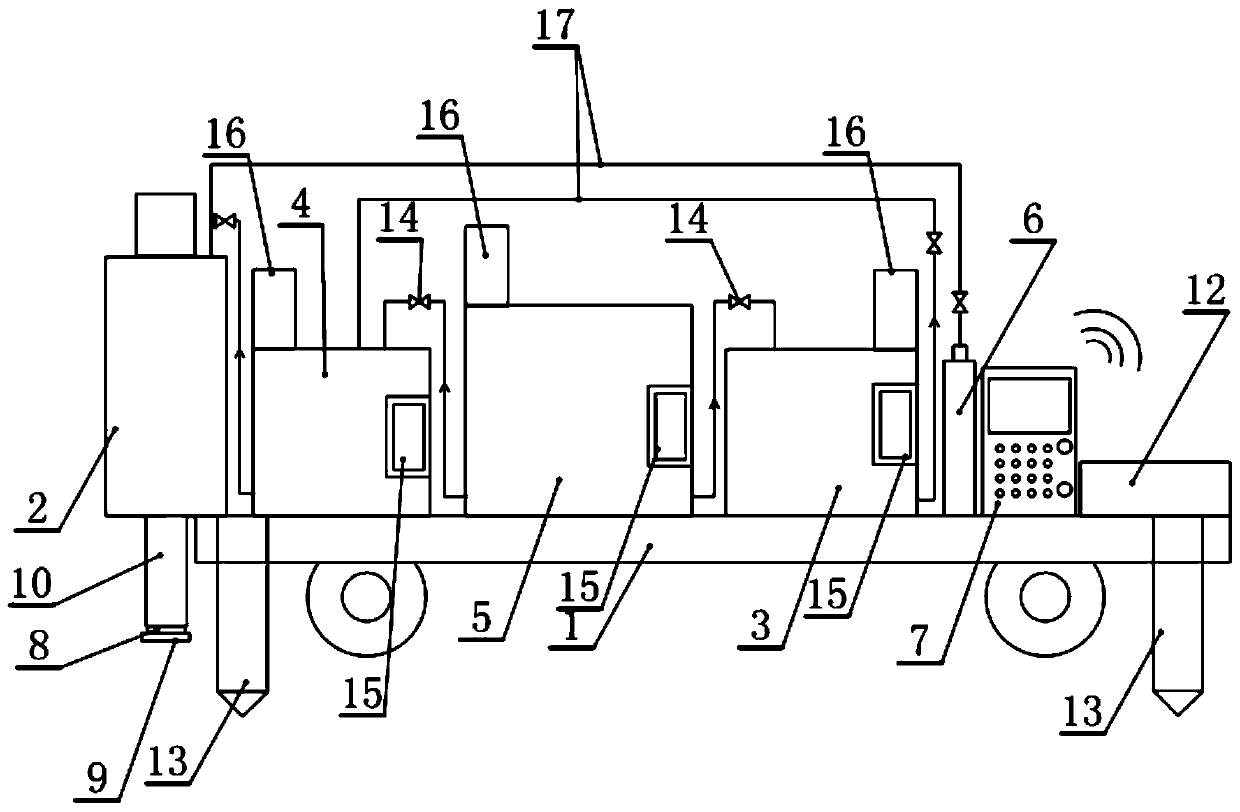

Automation equipment and method for pouring microbial agent in continuous lifting mode to cure tailings

PendingCN110038895ANo leaksAvoid Contamination TransferDrilling rodsContaminated soil reclamationMicrobial agentHigh pressure

The invention discloses automation equipment and a method for pouring a microbial agent in a continuous lifting mode to cure tailings. The automation equipment comprises a vehicle body, a drilling machine, a microbial agent mixing system, a high pressure air pump and a central control system, wherein the drilling machine, the microbial agent mixing system, the high pressure air pump and the central control system are all arranged on the vehicle body; a drill bit is arranged at the bottom of a drill stem of the drilling machine, the drill stem is a hollow pipe, a plurality of injection holes communicated with the outside are evenly drilled at one end, close to the drill bit, of the drill stem in the axial direction of the drill stem, the drill stem is sleeved with a protecting sleeve whichcan move up and down, the microbial agent mixing system and the high pressure air pump are both communicated with the hollow drill stem through pipelines, a microbial agent and high pressure air are respectively introduced into the drill stem and pumped into underground tailings through the drill stem, and the drilling machine, the microbial agent mixing system and the high-pressure air pump are all connected with the central control system and are controlled by the central control system. The automation equipment has the advantage of high automation degree; automation control on switch on-and-off of all valves, time setting, temperature control, pressure control, sensor data transmission and the like is achieved, and the pouring efficiency is improved.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

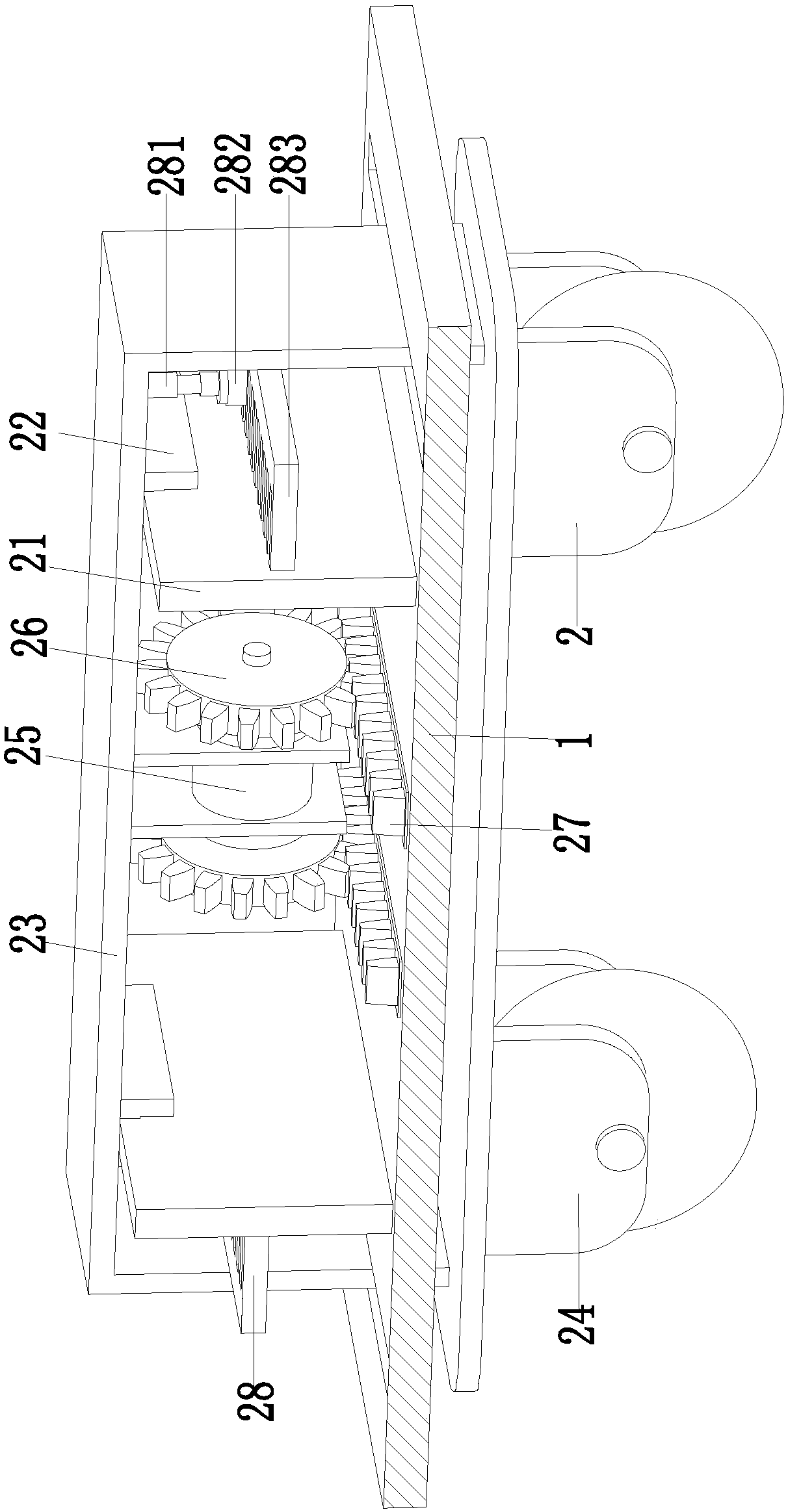

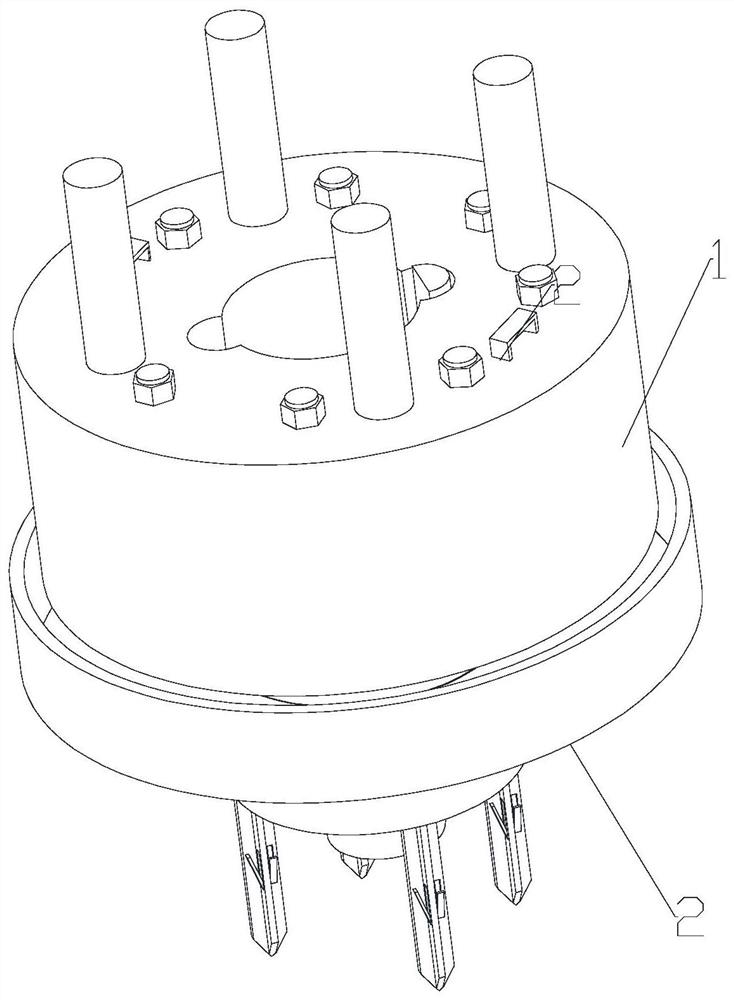

A prefabricated tubular pile static pressure construction device and method integrating positioning and sealing piles

ActiveCN112323798BImprove effectivenessImprove stabilityBulkheads/pilesCircular discArchitectural engineering

The invention relates to the technical field of prefabricated pipe piles, and discloses a static pressure construction device and method for prefabricated pipe piles integrating positioning and sealing piles. The ring-shaped pressure distribution block, the pressure-bearing fixed base includes a disc-shaped pressure-bearing platform and a pipe-shaped discharge bin fixedly connected up and down, and a plurality of positioning pins are fixedly connected to the bottom surface of the discharge bin. Through the mutual cooperation of the pressure distribution body and the pressure-bearing fixed base, the present invention can not only effectively ensure the initial alignment and correction of the pile sinking, but also effectively reduce the influence of the pile body deviating from the pile position caused by the floating of the pile body during the pile sealing process, and further enhance the stability of the pile. The overall bearing capacity of the foundation improves the turnover rate of pile foundation construction equipment and has high practical value.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

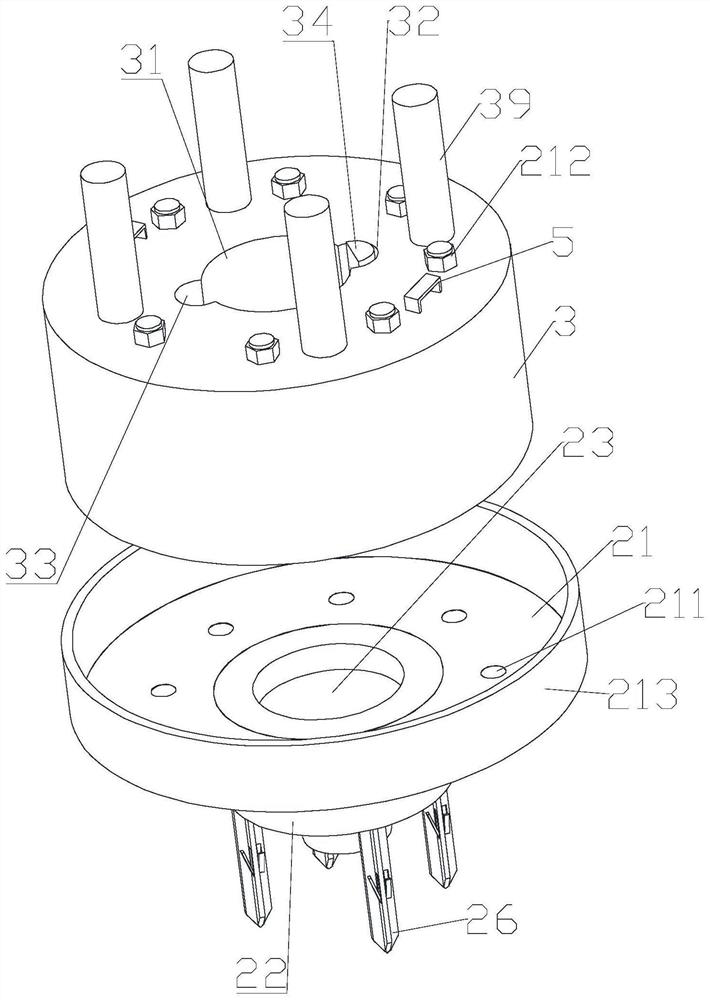

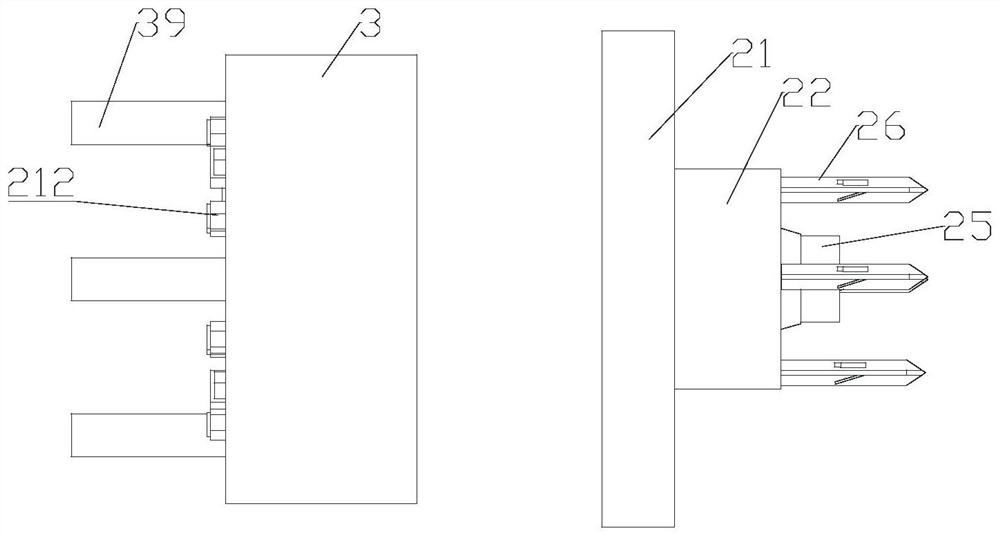

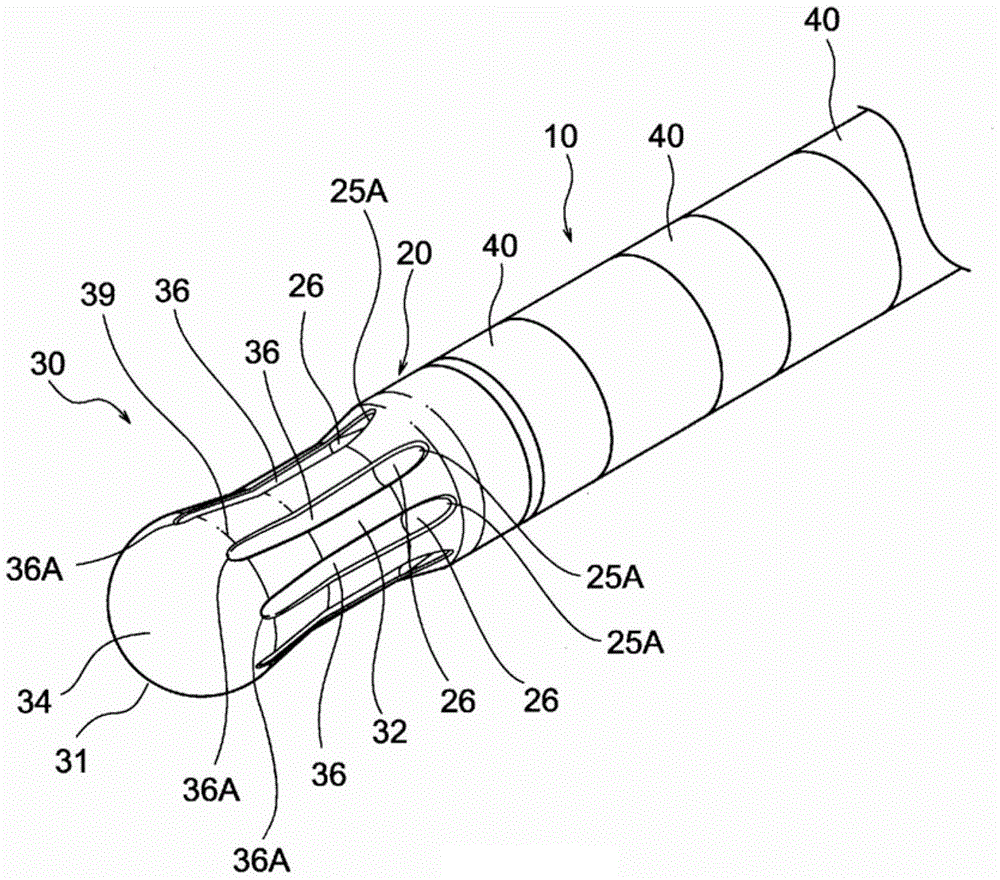

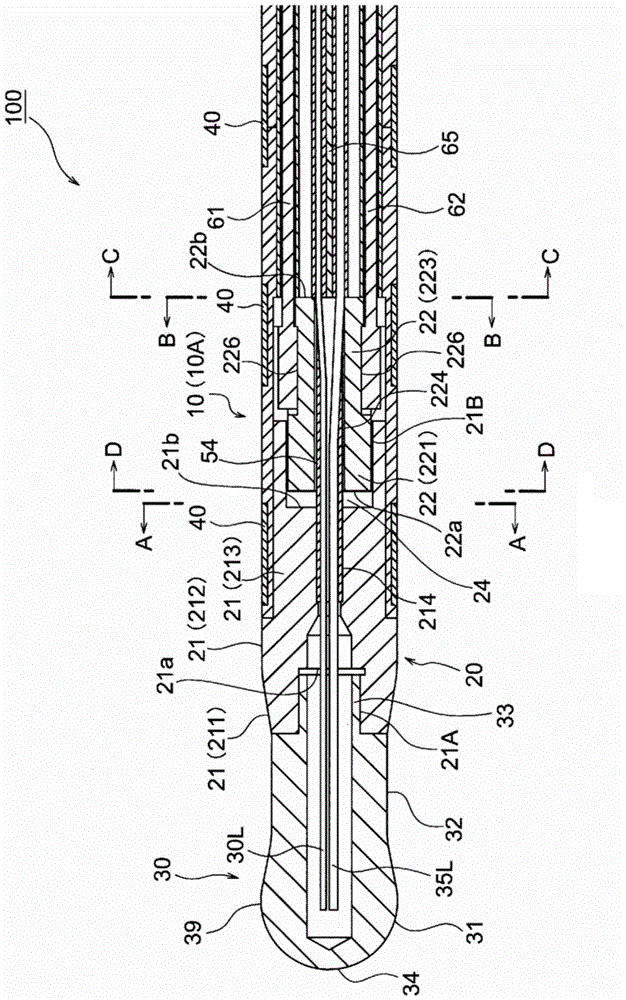

Lead

ActiveCN104470452BUniform perfusionSpray evenlySurgical instruments for heatingSurgical instruments for irrigation of substancesMaximum diameterMedicine

An electrode catheter is provided with: a shaft (10) having a lumen (11) serving as a fluid passage; an irrigation member (20); and a distal end electrode (30). Irrigation openings (25A) for supplying liquid, which is supplied from the shaft (10), to the surface of the distal end electrode (30) are provided in the irrigation member (20) at equal angular intervals. The distal end of the irrigation member (20) has formed therein liquid guide grooves (26) respectively extending from the irrigation openings (25A) toward the distal end. The distal end electrode (30) has a spherical distal end section (31) including a maximum-diameter section (39) and also has a proximal end section (32). Liquid guide grooves (36) are formed in the surface of the distal end electrode (30), and the liquid guide grooves (36) respectively continue to the guide grooves (26) in the irrigation member (20) and extend toward the distal end until the liquid guide grooves (36) reach at least the maximum-diameter section (39). As a result, the electrode catheter is configured in such a manner that cauterization does not cause an abnormal temperature rise in a part of the distal end electrode, that the surface of the distal end electrode exhibits an excellent cooling effect and an excellent effect of preventing the formation of a thrombus, and that the electrode catheter can perform efficient cauterization treatment.

Owner:JAPAN LIFELINE CO LTD

Low-temperature quick-setting grouting material for offshore oil wells and preparation method thereof

ActiveCN105199692BEffective Support Strength RequirementsShort coagulation timeDrilling compositionAnti freezingMass ratio

The invention relates to a low temperature rapid hardening grouting material for an offshore oil well. The low temperature rapid hardening grouting material for the offshore oil well comprises the following raw materials in parts by weight: 2,000 parts of gel materials, 950-965 parts of inorganic mineral active materials, 25-35 parts of retarders, 5-10 parts of anti-freezing ingredients, 3-5 parts of high efficiency slushing agents, and 0.1-0.3 part of defoaming agents, wherein the gel materials are quick-hardening sulphate aluminium cement and oil well cement; the mass ratio of the quick-hardening sulphate aluminium cement and oil well cement is 5:5-8:2. The invention also provides a preparation method thereof. The grouting material is suitable for construction under a well cementation low-temperature environment, slurry can maintain better mobility and is high in early strength, the slurry is full without shrinkage, the long-term strength is high, and the well cementation construction time and the underground grouting environment parameter requirement are effectively ensured.

Owner:河北铁园科技发展有限公司

Filling device for sunscreen cream

The invention belongs to the technical field of sunscreen cream production, and specifically discloses a filling device for sunscreen cream. The filling device comprises a workbench, a filling unit, aconveying unit, a stable unit and a controller, wherein the filling unit is positioned on the upper surface of the workbench; the upper beam of a bracket is symmetrically and fixedly connected with two gas cylinders; a discharge tube is arranged on the middle position of the upper beam of the bracket; the lower end of the piston of each gas cylinder is connected with a bearing table through a connecting block, and an electronic scale is arranged on the upper surface of the bearing table; a groove is used for containing a packaging bottle; the outer ring of the electronic scale is equipped with a clamping unit, and the clamping unit comprises a fixed ring, a fixed rod, a clamping rod and a gas cylinder I; the front end surface of the bracket is equipped with the conveying unit; a motor isfixedly arranged on the workbench, and is connected with a conveyor belt through a belt; the conveyor belt is arranged on a supporting frame at one side of the motor, and the stable unit is arranged on the conveyor belt; and the filling unit, the clamping unit, the conveying unit, the stable unit and the controller realize filling composite plant essential oil sunscreen cream liquid in the packaging bottle, and stable conveying of the packaging bottle.

Owner:SUZHOU QINGZHI NETWORK TECH CO LTD

A kind of nano-medicine for treating cow endometritis and preparation method thereof

InactiveCN104288222BSmall granularityUniform perfusionAntibacterial agentsOrganic active ingredientsChlorhexidine AcetateSpanish oregano

Owner:XIANYANG VOCATIONAL TECHN COLLEGE

Tile caulking device

ActiveCN111550018BEfficient and quick caulkingThe caulking is neat and beautifulBuilding constructionsElectric machineStructural engineering

The invention provides a ceramic tile caulking device, comprising: a movable box for accommodating the caulking slurry, the movable box has a front end and a rear end, and the movable box is provided with a A material opening and a discharge opening; the scraper for pressing against the tiles on both sides of the tile seam is connected to the outside of the movable box, and the scraper is arranged directly behind the discharge opening and a filling blade, which is rotatably installed in the movable box, and after being rotated, the filling blade extends to the outside of the discharge port and scrapes the tile seam, and the movable box is equipped with a drive A motor, the drive motor is connected to the filler blade through transmission. The invention solves the problems of inconvenient construction and difficulty in guaranteeing the construction quality by manually using spatulas to fill the joints of tiles.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Construction method of waterproof structure at joint between uplift pile and base plate

ActiveCN108517898BInto the uniformImprove waterproof performanceArtificial islandsProtective foundationAdhesiveSlurry

The invention provides a construction method of a waterproof structure of a connection gap between an anti-pulling pile and a bottom plate. The method comprises the following steps: breaking a pile head of an anti-pulling pile and straightening steel bars exposed out of the pile head part of the anti-pulling pile; arranging a plurality of slurry injection pipes on the pile head of the anti-pullingpile, wherein the bottom ends of the slurry injection pipes are located in the connection gap between the pile head of the anti-pulling pile and the bottom plate, and the top ends of the grouting pipes are higher than the top surface of the bottom plate; firstly coating a layer of cement-based crystallization waterproof coating and epoxy mortar on the top of the anti-pulling pile; arranging a circle of water-swelling water stop adhesive in contact positions between the steel bars on the pile head part of the anti-pulling pile and the concrete of the anti-pulling pile; paving waterproof rolls;arranging a circle of polyurethane sealant in the junctions between the waterproof rolls and the anti-pulling pile along the periphery of the anti-pulling pile body; casting a fine aggregate concreteprotection layer; and injecting the slurry into the plurality of slurry injection pipes. According to the construction method, the gap between the bottom plate and the anti-pulling pile is filled byinjecting the slurry into the slurry injection pipes, so that the waterproof effect is ensured.

Owner:CHINA COMM NORTH ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com