SF6 gas insulated power equipment leakage plugging device and control method thereof

A technology of gas insulation and electric power equipment, applied in the direction of switchgear, switchgear setting, electrical components, etc., can solve the problems of operation effect influence, uneven coating amount, unsatisfactory lamination effect, etc., and achieve perfect function and uniform perfusion , the effect of simple structure

Active Publication Date: 2018-12-28

MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

View PDF18 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) The equipment is often under pressure, and the sealing agent is directly coated, and the bonding effect is not ideal;

(3) Direct coating, SF6 inside the equipment is not replenished, and for power equipment with large leakage, the later operation effect is likely to be affected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

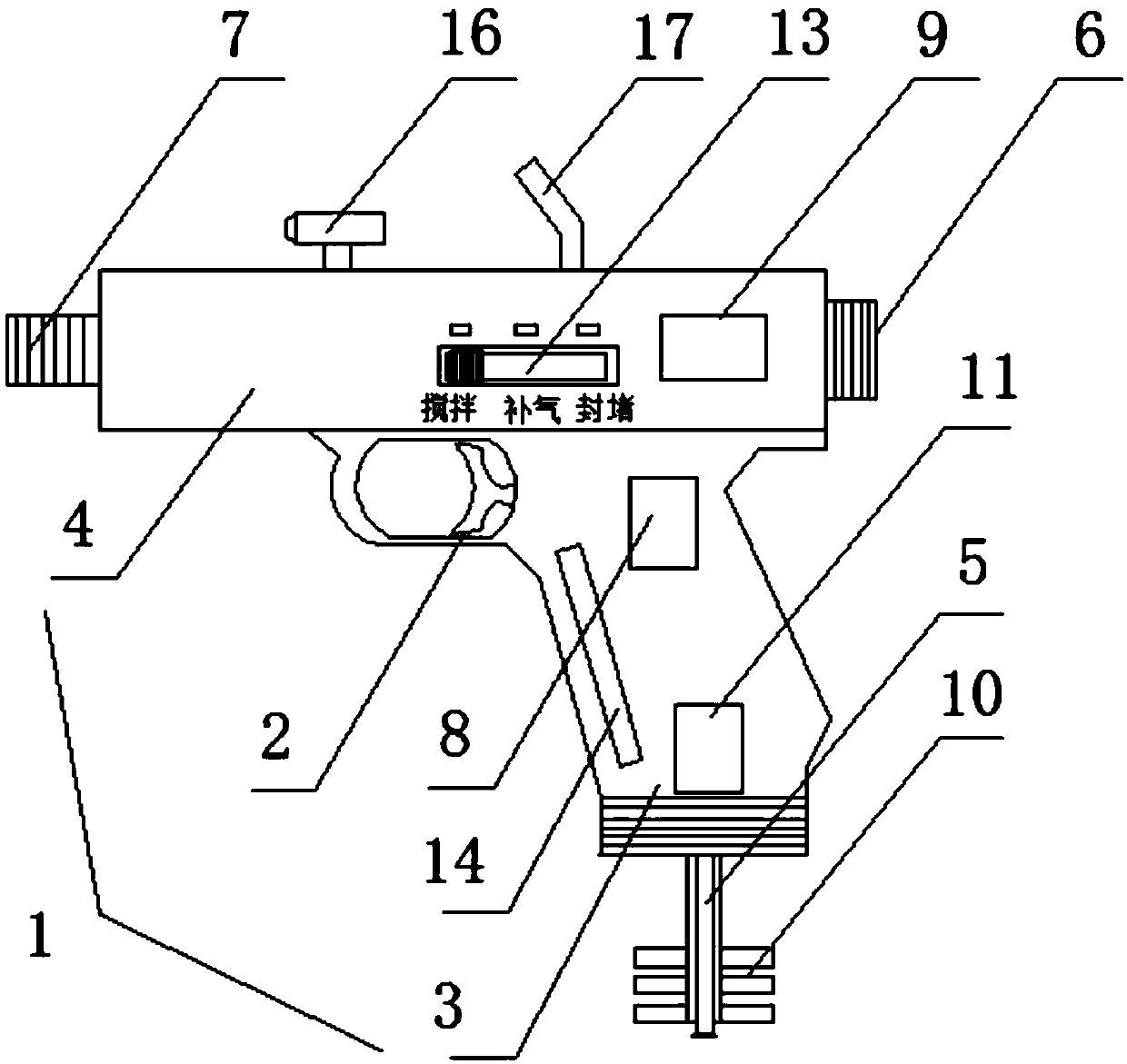

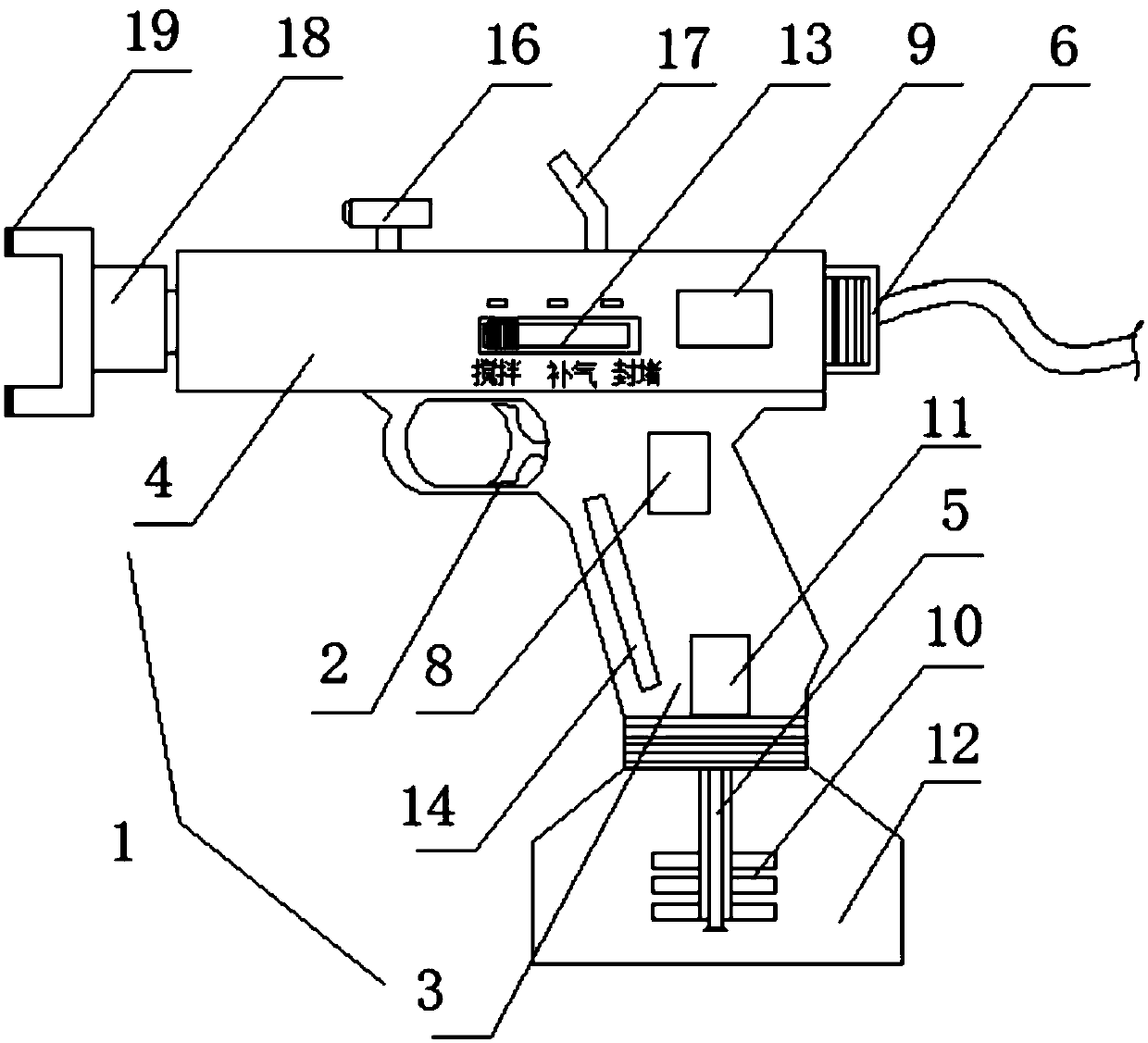

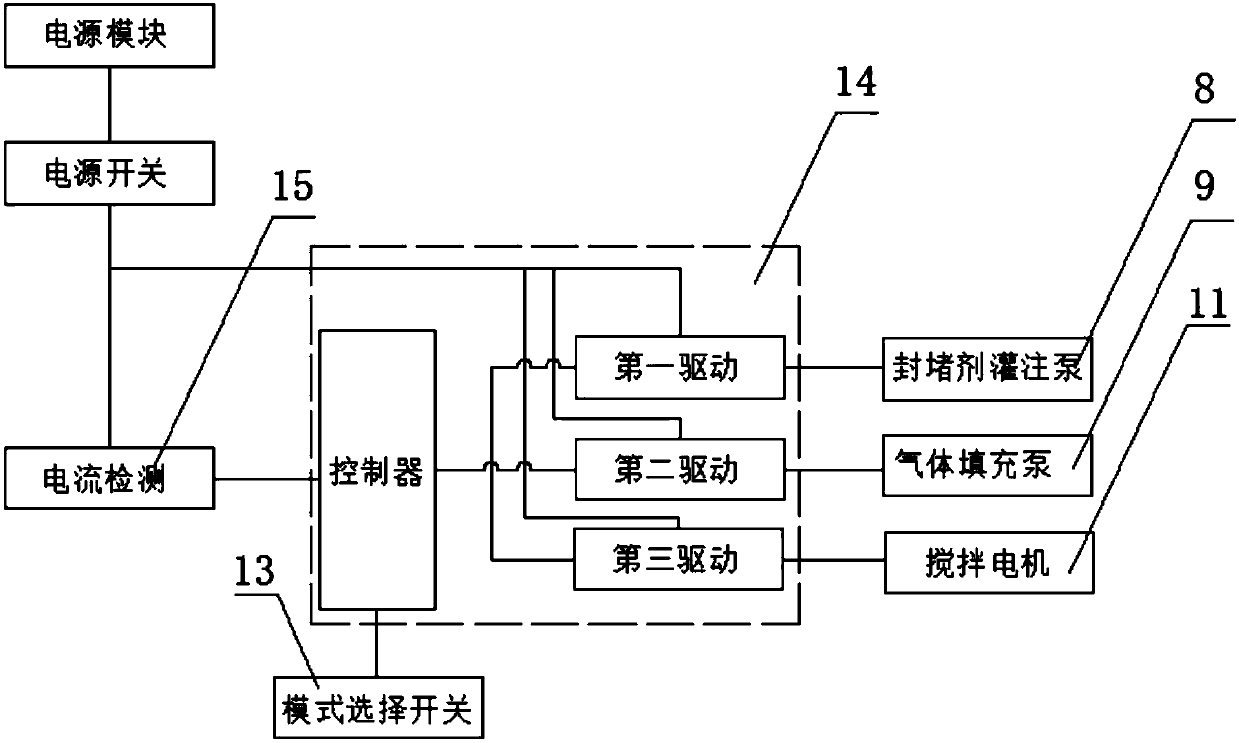

A SF6 gas insulated power equipment leakage plugging device and a control method thereof are provided. The device includes a filling gun, the filling gun comprising a handle, a trigger and a frame, the lower end of the handle is provided with a plugging agent suction pipe, the rear end of the gun frame is provided with an SF6 gas suction pipe, a nozzle is arranged at the front end of the gun frame, a plug agent filling pump and a gas filling pump are arranged inside the handle, the plugging agent suction pipe is connected with the inlet of the plugging agent filling pump, the outlet of the plugging agent filling pump is connected with the nozzle through a first pipeline, the SF6 gas suction pipe is connected with the inlet of the gas filling pump, and the outlet of the gas filling pump isconnected with the nozzle through a second pipeline. The device has the advantages of simple structure, convenient operation, gas compensation and rapid plugging under the condition of leakage of SF6gas insulated electric power equipment with pressure, uniform plugging agent injection, and guaranteed plugging effect.

Description

technical field The invention relates to a gas leakage sealing technology, in particular to a SF6 gas-insulated power equipment leakage sealing device and a control method thereof. Background technique SF6 gas has strong insulating properties, so it is widely used in high-voltage electrical equipment. With the popularization of applications, the leakage of SF6 gas-insulated power equipment has become a major problem in the power industry. SF6 leakage will greatly reduce the insulation performance of the equipment and affect the normal operation of the power system. In the prior art, plugging technology is often used for remediation, such as a plugging technology for leakage of SF6 gas-insulated power equipment disclosed in Chinese patent 200710037563.8. The technology is to mix the mixture formed by mixing nano-powder filler and curing agent into the base material, and apply it on the surface of the leakage part. After the mixture is partially dried, coat the mixture formed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02B13/035H02B3/00

CPCH02B3/00H02B13/035

Inventor 谢希李汶江刘航曾湘隆熊浩邓旭东胡敏李翠英魏钢石岩

Owner MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com