Construction method of waterproof structure at joint between uplift pile and base plate

A technology of waterproof structure and construction method, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve problems such as poor waterproof effect of waterproof construction, eliminate hidden dangers of structural water leakage, improve adhesion, and prevent water seepage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

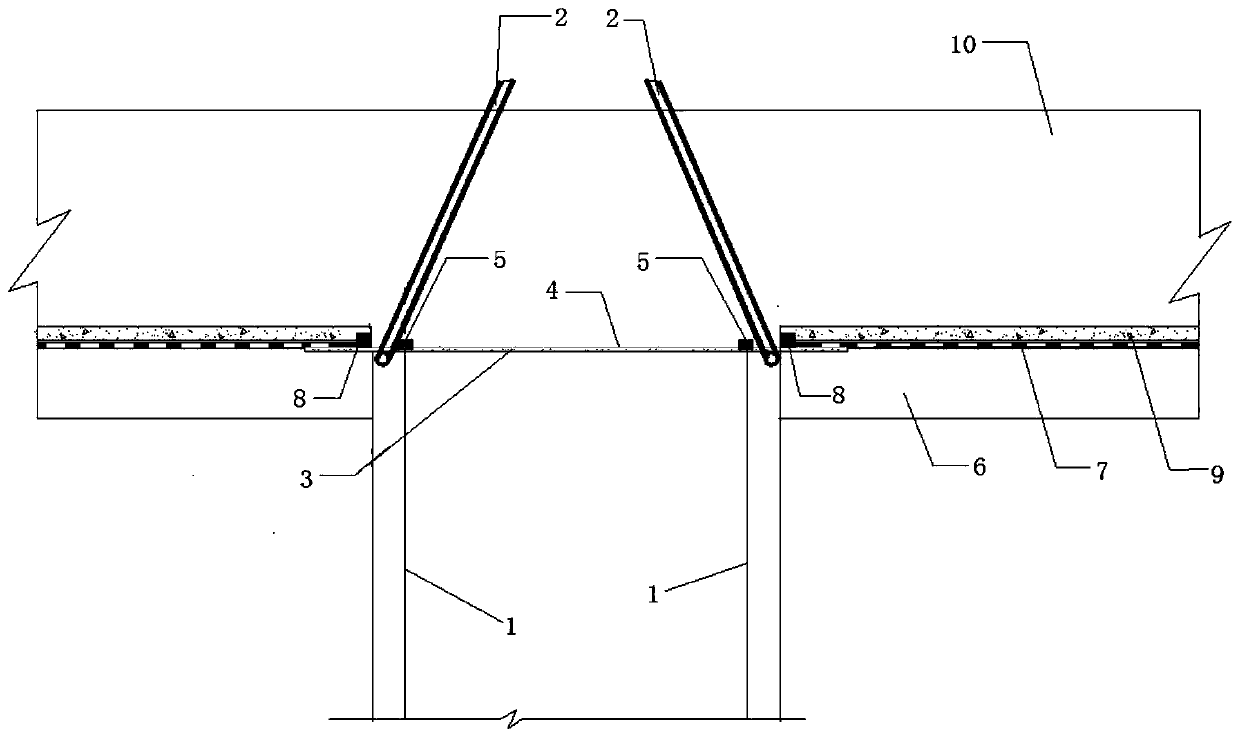

[0027] Such as figure 1 As shown, the invention provides a construction method of a waterproof structure at the joint between the uplift pile and the base plate, comprising the following steps:

[0028] S1: Remove the pile heads of the uplift piles. The removed pile heads are flush with the bottom surface of the bottom plate. When the uplift piles are poured, the top surface is generally higher than the bottom surface of the bottom plate. Destroy the pile head, and then clean up the concrete shavings, ash, dust, etc. generated during the removal process, and then straighten the exposed steel bars 1 at the head of the uplift pile;

[0029] S2: Multiple grouting pipes 2 are set at the head of the uplift pile. In this embodiment, for the convenience of operation, two grouting pipes are set at the head of the pile. The two grouting pipes both inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com