Intelligent horizontal injection press for plastic basin processing

An injection molding machine, intelligent technology, applied in the field of intelligent horizontal injection molding machine, can solve the problem of easy blockage of the material opening of the hopper, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

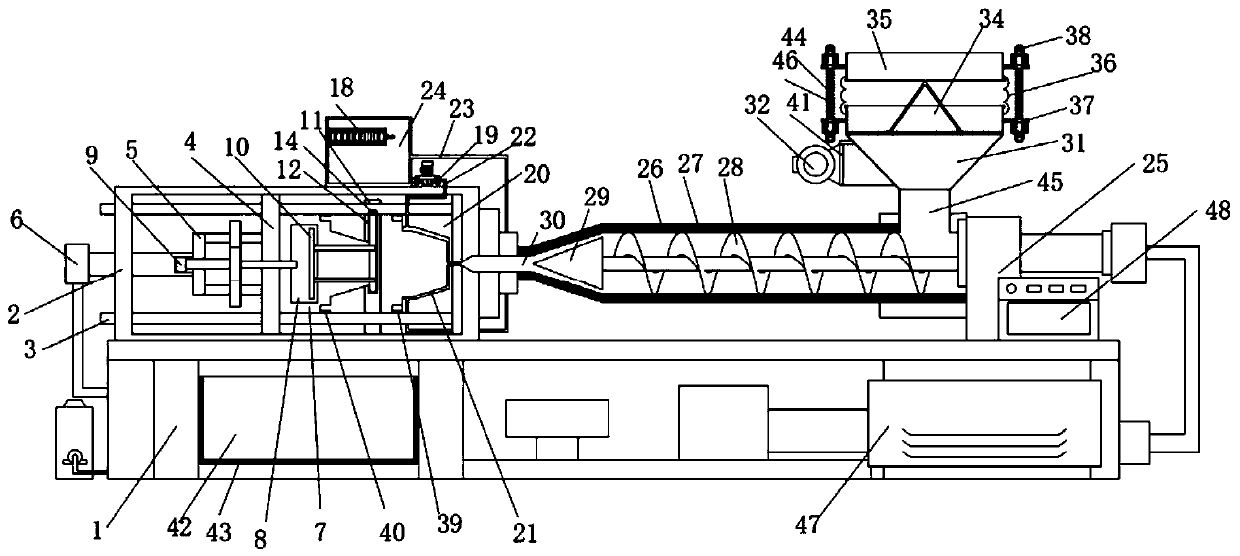

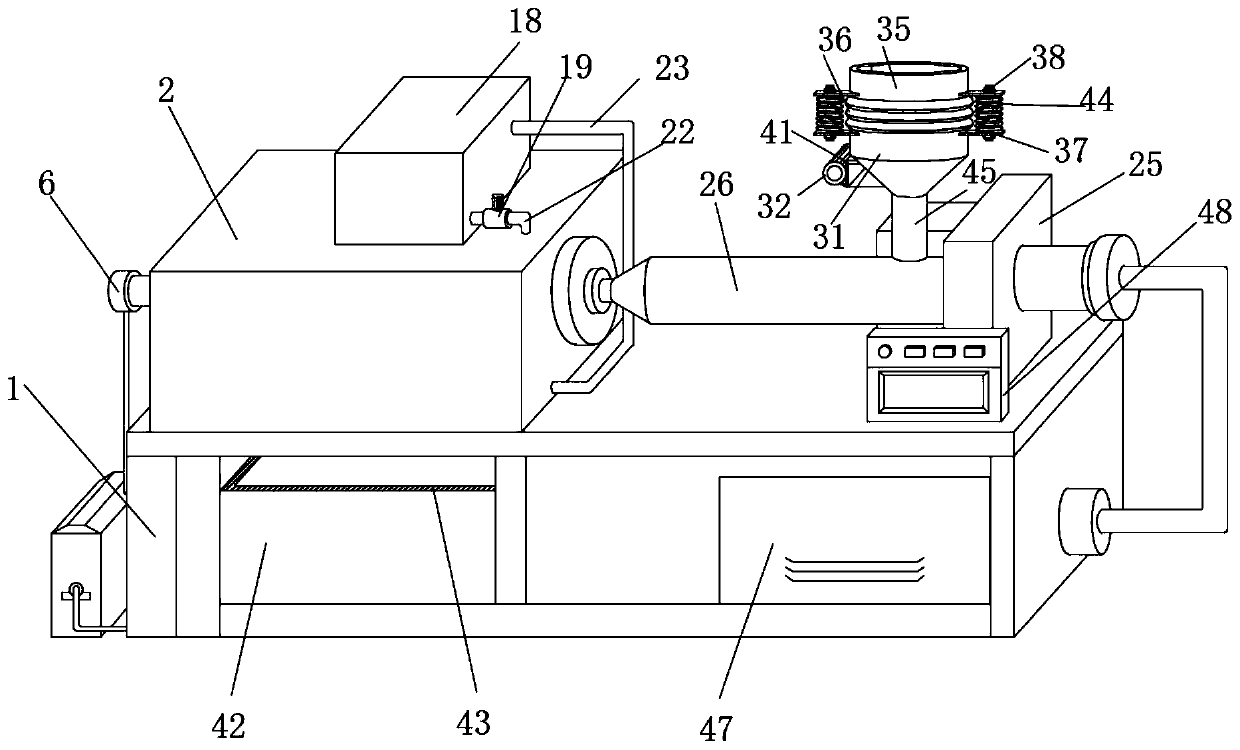

[0023] see Figure 1-5 , an intelligent horizontal injection molding machine for processing plastic pots, comprising a base 1, a box 2 is provided on one side of the top of the base 1, and a guide rod 3 is provided on the top and bottom of the inside of the box 2, and the box The inside of 2 is provided with a guide block 4 that is movably connected with the guide rod 3, and one side of the guide block 4 is provided with a movable mold 7, and the middle position of one side of the box body 2 is connected with a hydraulic rod 6 extending to the inside thereof, and One side of the internal hydraulic rod 6 of the box body 2 is connected with a first push rod 5, and the side of the first push rod 5 away from the hydraulic rod 6 is connected with the guide block 4, and the inside of the movable mold 7 is provided with a guide groove 8, and The inside of the guide groove 8 is movably connected with a push rod 10, and the middle position of the first push rod 5 is movably connected w...

Embodiment 2

[0026] Please focus on figure 1 , the fixed mold 20 is provided with a guide block 39 on one side close to the movable mold 7, and a guide groove 40 matched with the guide block 39 is provided on one side of the movable mold 7. The present invention is provided with a matched guide block 39 and guide groove 40, so that the size of the cavity formed by the movable mold 7 and the fixed mold 20 is consistent each time.

Embodiment 3

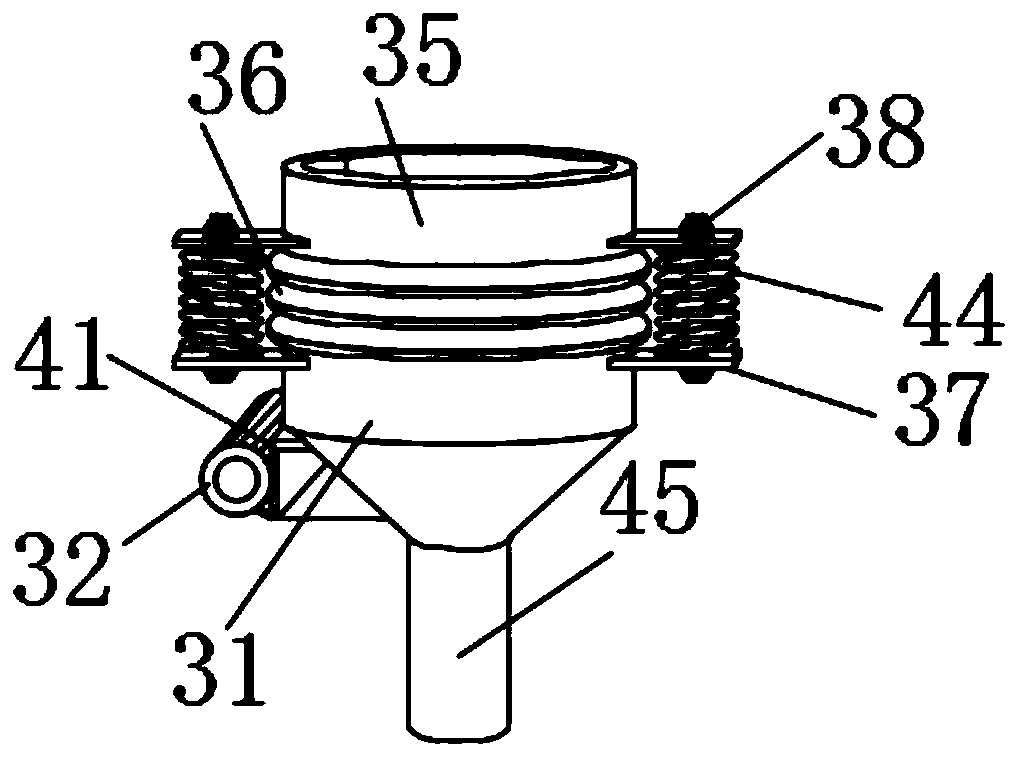

[0028] Please focus on figure 1 , figure 2 , image 3 and Figure 4 One side of the hopper 31 is provided with a connecting frame 41, and the hopper 31 is equipped with a vibration motor 32 through the connecting frame 41. The present invention is provided with a connecting frame 41 on one side of the hopper 31 and is equipped with a vibration motor 32, so that the vibration motor 32 It is more firmly installed on one side of the hopper 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com