Low-temperature quick-setting grouting material for offshore oil wells and preparation method thereof

A technology of grouting materials and gel materials, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of simplifying raw material composition and preparation process, high water reduction effect, and ensuring early strength and consistency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

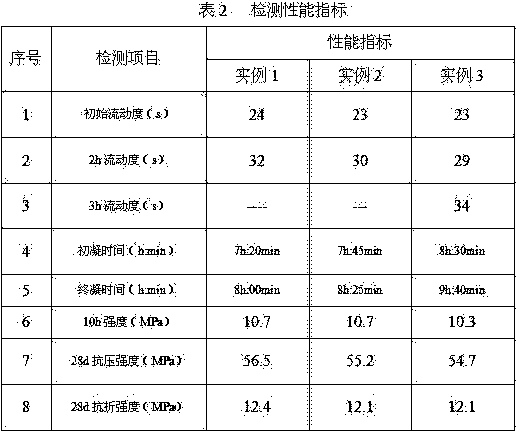

Examples

experiment example 1

[0026] Weigh the raw materials according to the following proportions, 1000 parts by weight of commercially available quick-hardening sulfoaluminate cement, 1000 parts by weight of oil well cement, 965 parts by weight of mineral powder, 25 parts by weight of sodium tripolyphosphate, and 5 parts by weight of sodium nitrite. Foam agent 0.1 weight part, polycarboxylate superplasticizer powder 4 weight parts.

[0027] The commercially available rapid-hardening sulfoaluminate cement is selected from Tangshan Polar Bear Special Cement Co., Ltd.

[0028] Mix the raw materials of the grouting material in Example 1 with water according to the water-binder ratio of 0.38-0.40 to obtain the product.

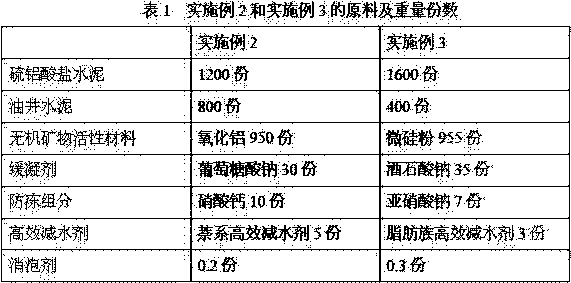

experiment example 2、3

[0030] The raw materials and weight proportions of Examples 2 and 3 are shown in Table 1.

[0031]

Embodiment 3

[0032] The silicon powder described in Example 3 is selected from Gansu Sanyuan Silicon Materials Co., Ltd.

[0033] Mix the raw materials of Example 2 and Example 3 according to the proportion, and stir them evenly with water according to the water-binder ratio of 0.38~0.40 to obtain the grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com