A secondary coagulation system and drug doser for continuous sludge dehydration

A secondary coagulation and dosing device technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as cumbersome operation process, easy blockage of pipelines, low flocculation mixing intensity, etc. , to achieve the effect of uniform diffusion degree, accelerated diffusion speed and fast diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The pharmaceutical doser and secondary coagulation system for continuous sludge dehydration described in the present invention will be further explained in conjunction with the description of the accompanying drawings and specific implementation methods, but the explanation does not constitute a statement of the present invention. Improper limitation of technical solutions.

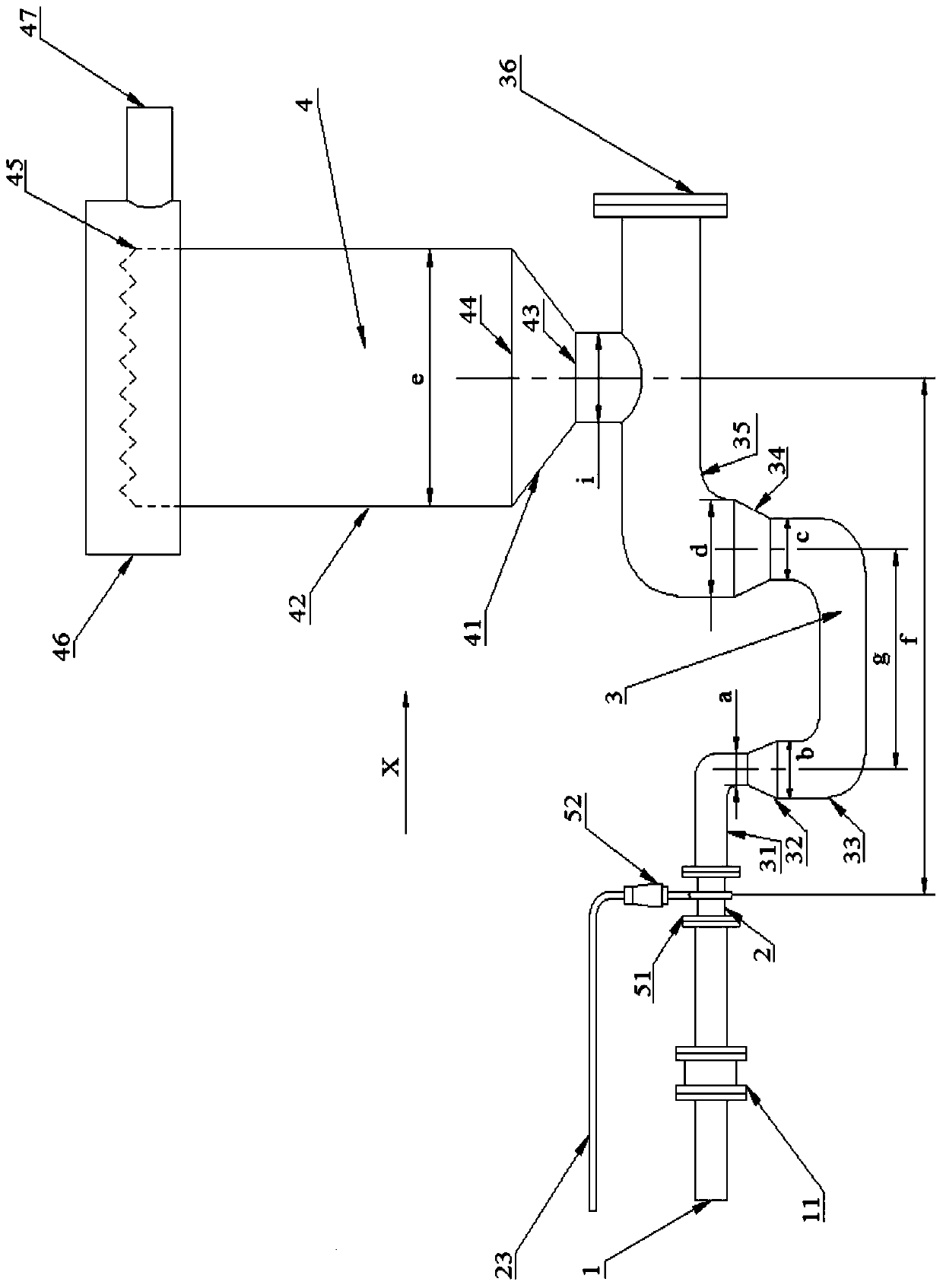

[0049] figure 1 The structure of the secondary coagulation system for continuous sludge dewatering according to the present invention is shown in one embodiment.

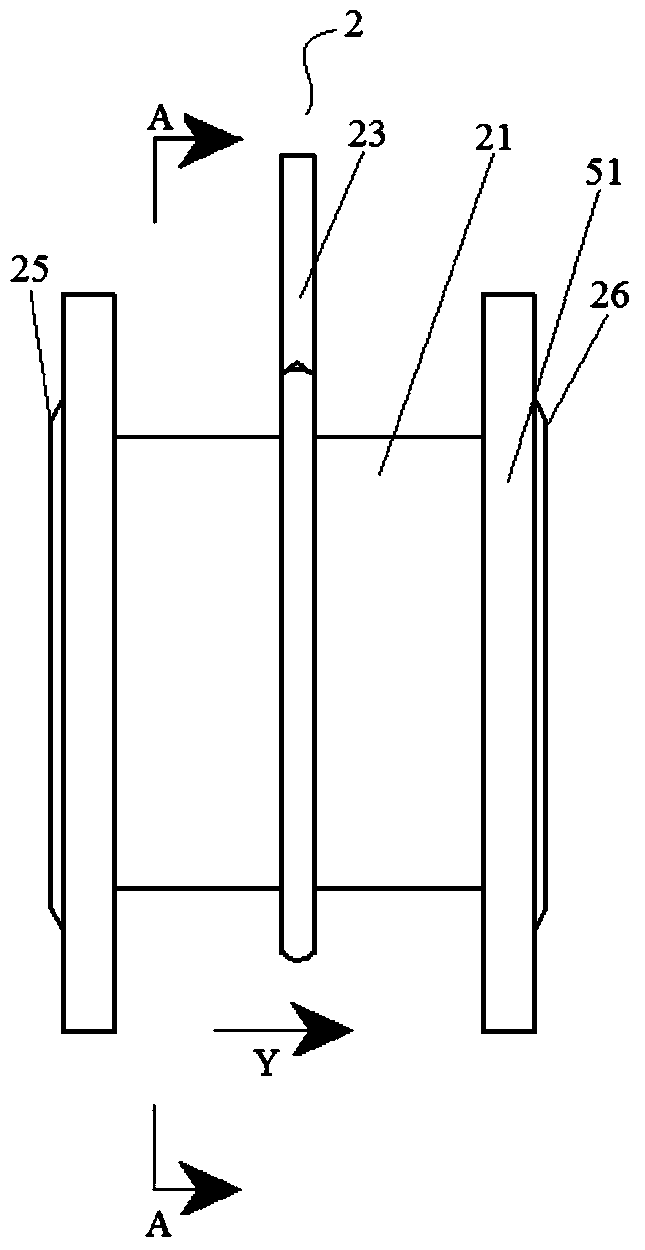

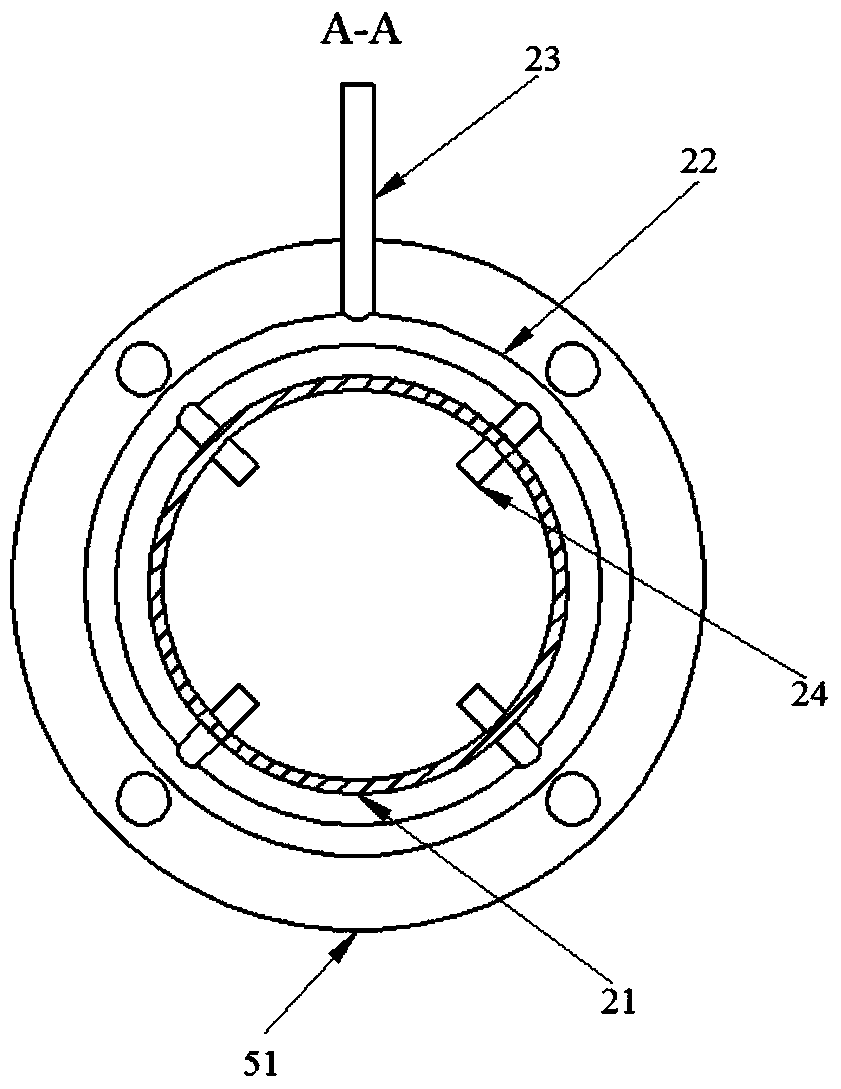

[0050] Such as figure 1 As shown, in the above embodiment, along the secondary coagulation system for continuous sludge dehydration, the liquid inlet pipe 1, the drug doser 2, the mixing pipe 3 and the coagulation cylinder 4 are sequentially included, wherein the mixing pipe 3 is It includes in turn: an inlet elbow 31 , an inlet reducing joint 32 , a U-shaped pipe 33 , an outlet reducing joint 34 and an outlet elbow 35 . To this end, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com