High-power-density membrane electrode for proton exchange membrane fuel cell and preparation method thereof

A technology of proton exchange membrane and fuel cell membrane, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of low power density of fuel cell membrane electrodes and the gap between the requirements of membrane electrode power density, etc., and achieve a simple and easy preparation method , Improve battery performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

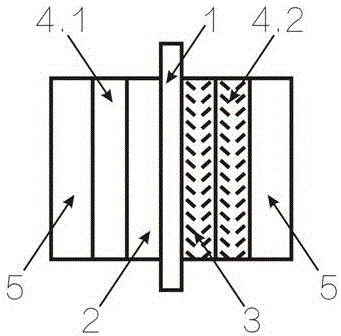

Image

Examples

Embodiment 1

[0055] The first step is to take a 4cm×4cm Nafion211 proton exchange membrane, first place it in 5% hydrogen peroxide at 80°C for 1 hour, wash it with distilled water, and put it in 0.5mol L -1 treated in a sulfuric acid solution at 80°C for 1 hour, and then washed with distilled water. Place the treated Nafion membrane on the fixed frame of the prepared membrane electrode and fix it, the size of the active area is 5cm 2 , to prevent the membrane from shrinking and deforming during the spraying of the catalyst slurry;

[0056] In the second step, the carbon nanotubes are placed in a concentrated sulfuric acid / concentrated nitric acid solution with a volume ratio of 3:1 and ultrasonically treated for 30 minutes, refluxed at 80°C for 8 hours, filtered and washed with deionized water until the carbon nanotubes are neutral, and the obtained Acid treatment of carbon nanotubes;

[0057] The third step puts the acid-treated carbon nanotubes in the second step into a quartz tube fur...

Embodiment 2

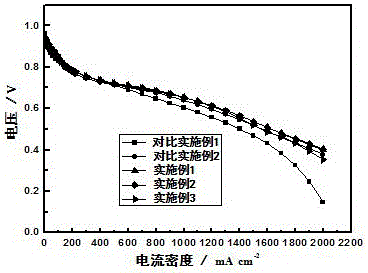

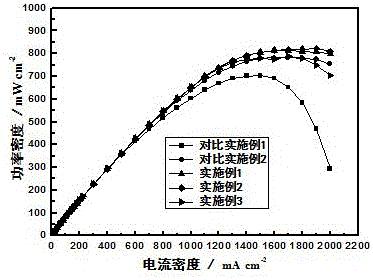

[0066] Except weighing the carbon-supported platinum catalyst, perfluorosulfonic acid polymer, carbon nitride nanotube and isopropanol by the mass ratio of 10:2.5:2:500, other steps are the same as Example 1, battery activation mode and test The method is exactly the same as Example 1. The battery polarization curve is shown in Figure 2. When the voltage is 0.7V and 0.6V, the current density can reach 700 mA cm -2 and 1300 mA cm -2 . Maximum power density of 822 mW cm -2 .

Embodiment 3

[0068] Except weighing carbon-supported platinum catalyst, perfluorosulfonic acid polymer, carbon nitride nanotube and isopropanol by mass ratio of 10:2.5:3:500, other steps are the same as Example 1, battery activation method and test The method is exactly the same as Example 1. The battery polarization curve is shown in Figure 2. When the voltage is 0.7V and 0.6V, the current density can reach 700 mA cm -2 and 1250 mA cm -2 . Maximum power density of 780 mW cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com