Micro-needle array chip, percutaneous administration device, percutaneous administration patch and preparation method thereof

A microneedle array and chip technology, applied in the directions of microneedles, needles, and drug devices, can solve the problems of blockage of needle orifices, and the aspect ratio and firmness of solid microneedle structures need to be improved. Conducive to diffusion and absorption, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Microneedle array chip and its preparation method

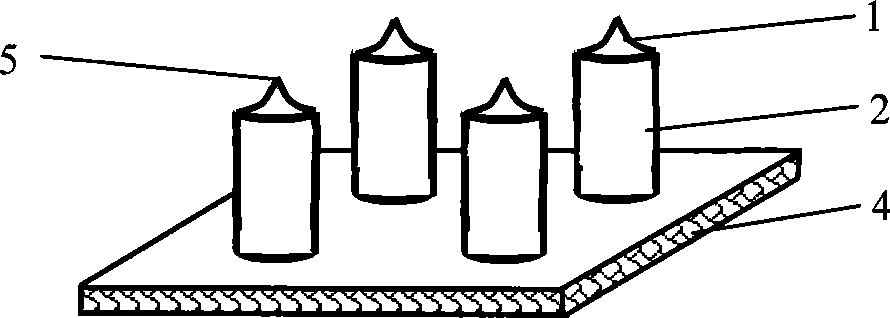

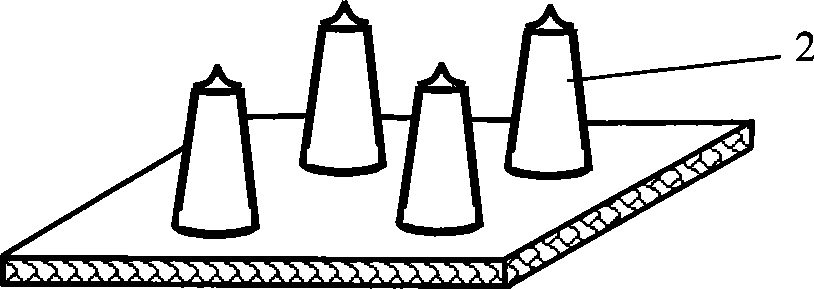

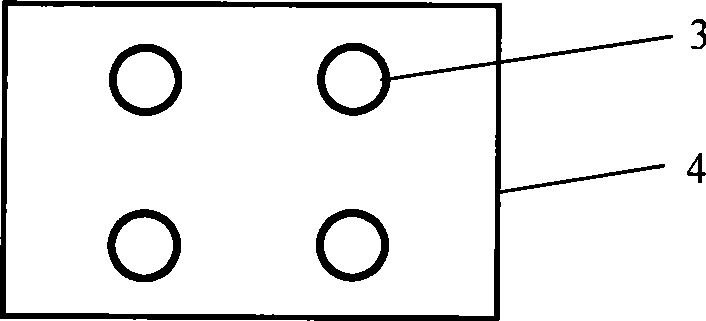

[0092] The microneedle array chip includes a microneedle and a substrate 4. The microneedle is composed of a needle head 1, a needle bar 2 and a needle seat 3. The top of the needle head is a needle point 5. The microneedle is fixed on the substrate 4 through the needle seat 3. The needle bar 2 and the needle seat 3 is a cylinder or a cone, and the microneedles are vertically fixed on the substrate 4, such as figure 1 and figure 2 As shown, the needle head 1 is conical; or the microneedle is fixed on the substrate 4 at an inclined setting angle, and the setting angle is preferably 15 to 90 degrees, such as Figure 4 ~ Figure 7 As shown, the upper surface of the needle point 5 is an elliptical plane parallel to or inclined to set an acute angle with the substrate 4, so the needle point 5 is an elliptical needle point 5 or the elliptical needle point is further processed to make it have a sharper angle 5a , that is, t...

Embodiment 2

[0115] Fabrication of Solid or Hollow Stainless Steel Microneedle Array Chips

[0116] Insert a stainless steel wire rod or capillary tube with an outer diameter of 350 microns into each hole of the through-hole array mold, and then insert these wire rods or capillary tubes at a certain angle at the same time or penetrate the heat-softened polyacrylic resin with a thickness of 2mm. methacrylate substrate. After cooling in water, the wire rods or capillary tubes are cut off at a distance of 1-8 mm from the plate by a cutting machine, thereby forming a wire rod or capillary tube array chip. Use a grinding machine to grind one side of the substrate of the chip. If electrochemical polishing is required in the subsequent process, it must be ensured that all wire rods or capillaries are exposed on the surface of the substrate on this side; grind and polish the fracture of the stainless steel wire rod or capillary on the other side to the desired microneedle height. Finally, immers...

Embodiment 3

[0118] Fabrication of Solid or Hollow Stainless Steel Microneedle Array Chips

[0119] Insert a stainless steel wire rod or capillary tube with an outer diameter of 350 microns into each hole of the through-hole array mold, and then insert these stainless steel wire rods or capillary tubes at a certain angle at the same time or penetrate through the heat-softened polyester with a thickness of 2mm. Methyl methacrylate substrate. After cooling in water, the wire rods or capillary tubes are cut off at a distance of 1-8 mm from the substrate by a cutting machine, thereby forming a wire rod or capillary tube array chip. Use a grinding machine to grind the substrate side of the chip. If electrochemical corrosion or polishing is required in the subsequent process, it must be ensured that all wire rods or capillaries are exposed on the surface of the substrate on this side; the stainless steel wire rods or capillary fractures on the other side are ground. Polished to the required mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com