Explosive filling device for fireworks and crackers

A technology for fireworks, firecrackers and drugs, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of reduced production efficiency, loss of slurry, and reduced production speed, and achieves high work reliability, high production efficiency, and low production loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

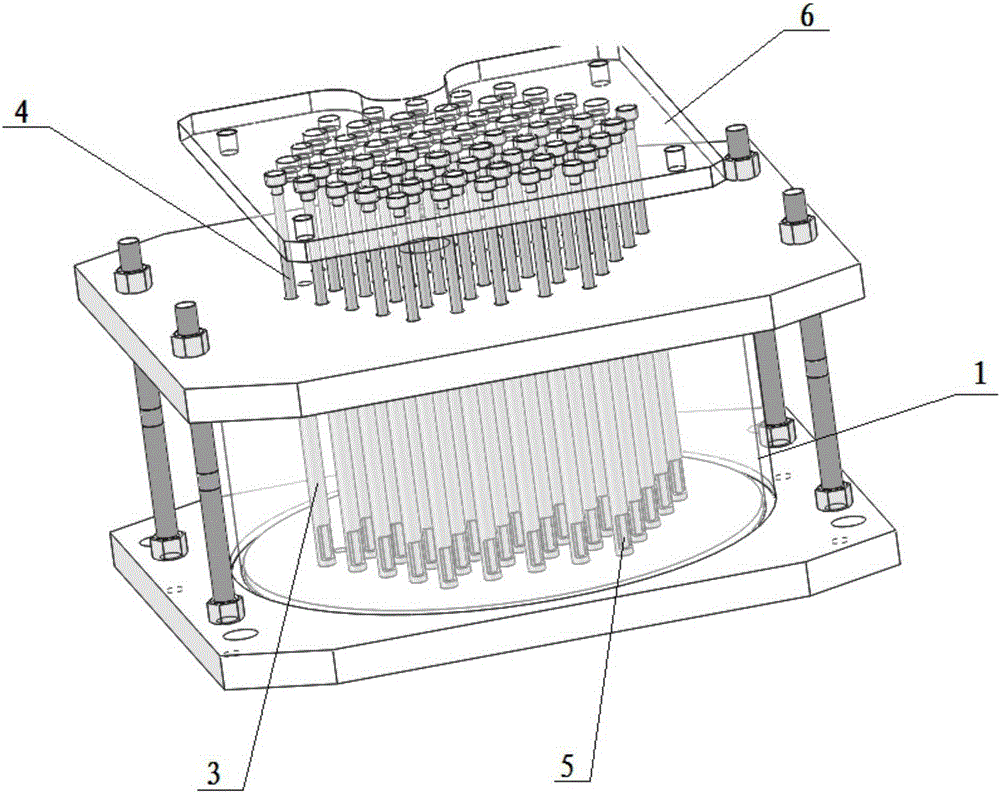

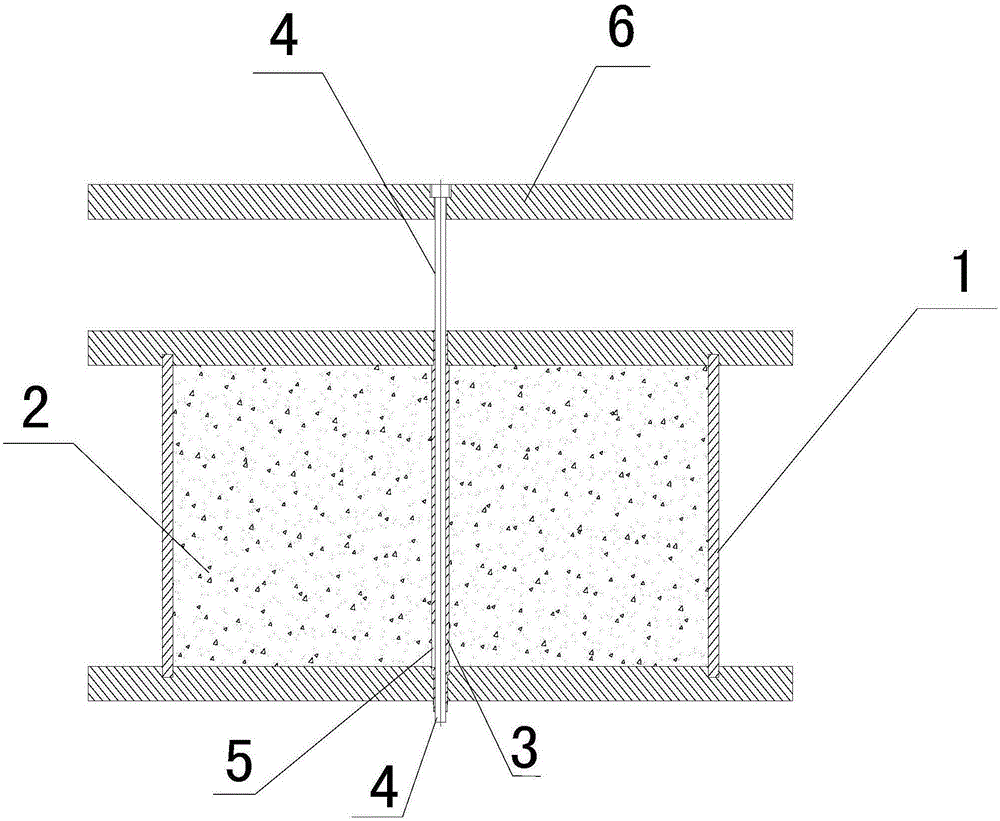

[0017] Embodiment 1: see attached Figure 1-3 , reflecting a specific structure of the present invention, the drug injection device for fireworks and firecrackers includes a cavity 1 loaded with drug slurry, and 61 casing tubes 3 are installed on the cavity 1 in a manner penetrating through the cavity 1. The quantity of pipe 3 is equal to the firecracker fireworks tube (not shown in the figure) quantity of lower tube cake, and sleeve pipe 3 positions are corresponding to the position of the firecracker fireworks tube of lower tube cake.

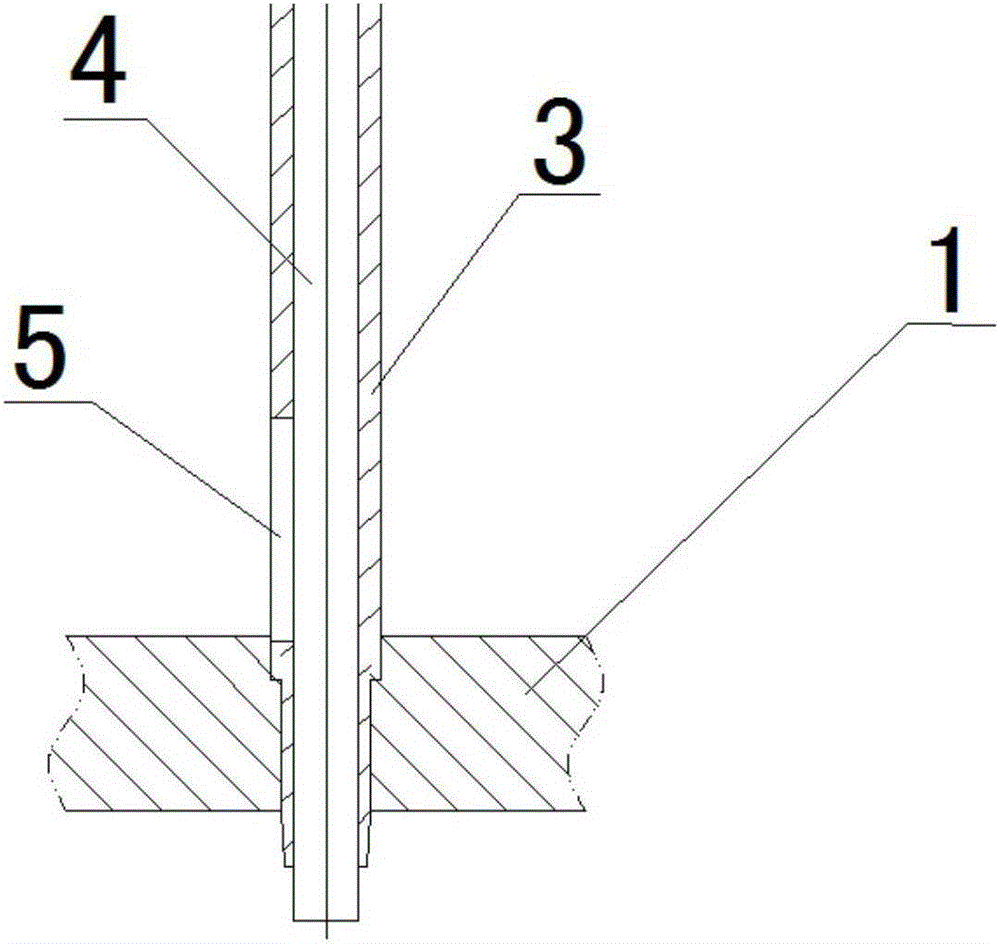

[0018] The side wall of the sleeve 3 located inside the cavity 1 is provided with an opening 5 through which the drug slurry enters the inner cavity of the sleeve 3 ; the opening 5 is a partial rectangular window on the side wall of the sleeve 3 .

[0019] The inner cavity of the casing 3 is nested with a sliding rod 4, and the top of the sliding rod 4 is fixed on the base body 6, and the base body 6 is driven by a driving mechanism (not show...

Embodiment 2

[0020] Embodiment 2: see attached Figure 4 , the difference from Embodiment 1 is that: the opening 15 is an annular fault on the casing 13, at this time the casing 13 is divided into two mutually independent parts, and the annular fault can be formed after cutting a whole section of the casing 13. It is formed on the side wall of the casing 13; it can also be formed by making the two parts separately. Part of the casing 13 below the annular fault is fixed by the bottom plate of the cavity 11 . The bottom end of the slide bar 14 is a needle-shaped structure 17 , and the slurry cannot condense on the bottom end surface of the slide bar 17 . The remaining parts of Embodiment 2 are similar to Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com