Patents

Literature

161results about How to "Improve continuous working ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

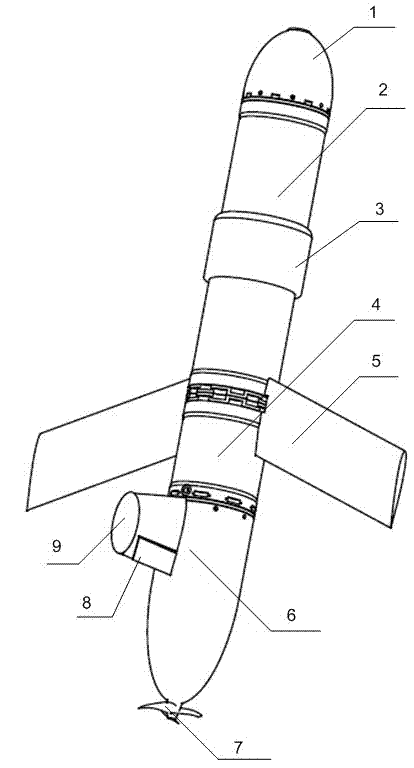

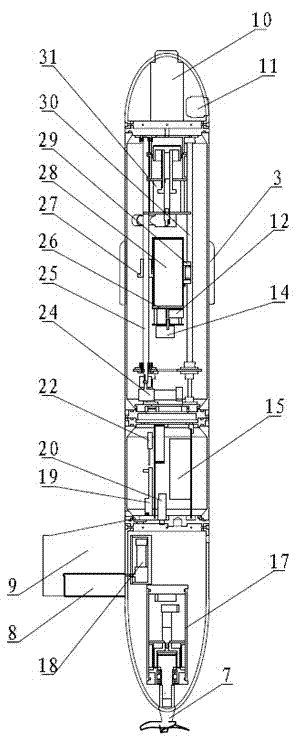

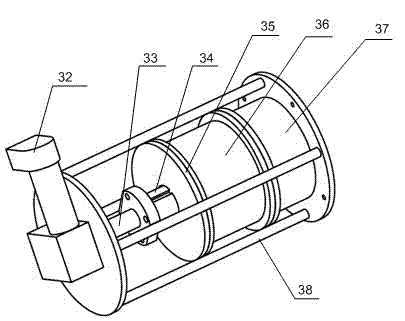

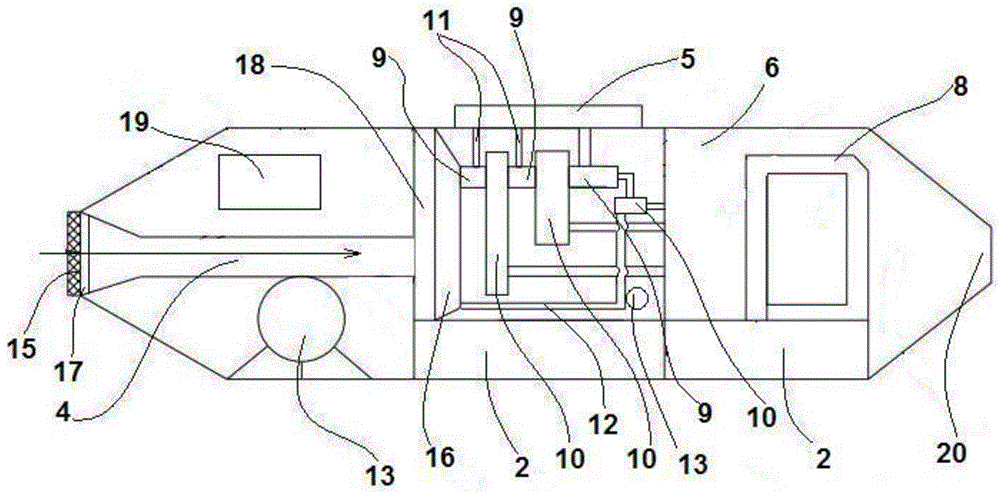

Mixed type underwater navigation detector

InactiveCN102862667AImprove continuous working abilityMeet the needs of stereo observationUnderwater vesselsUnderwater equipmentHybrid typeTransceiver

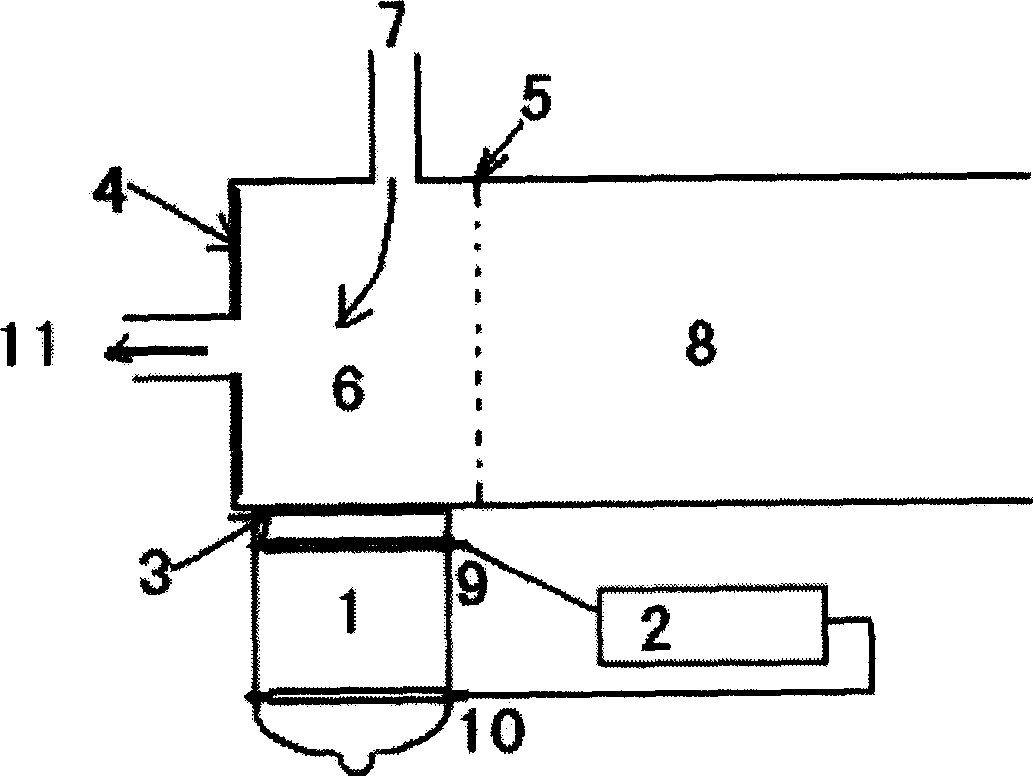

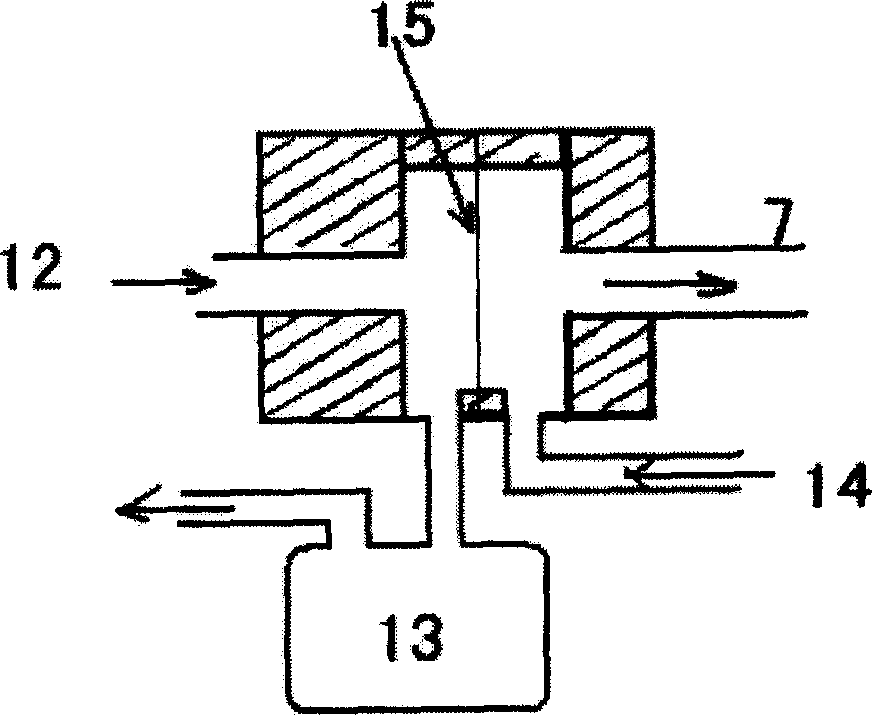

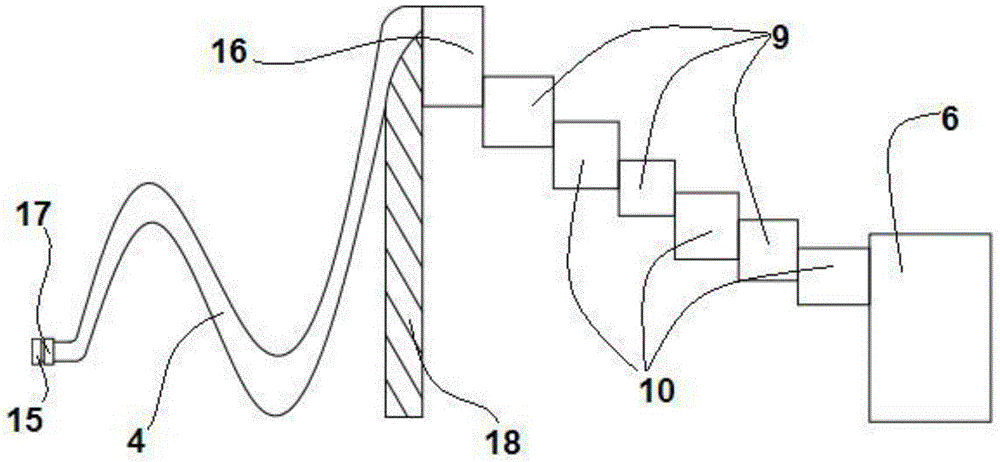

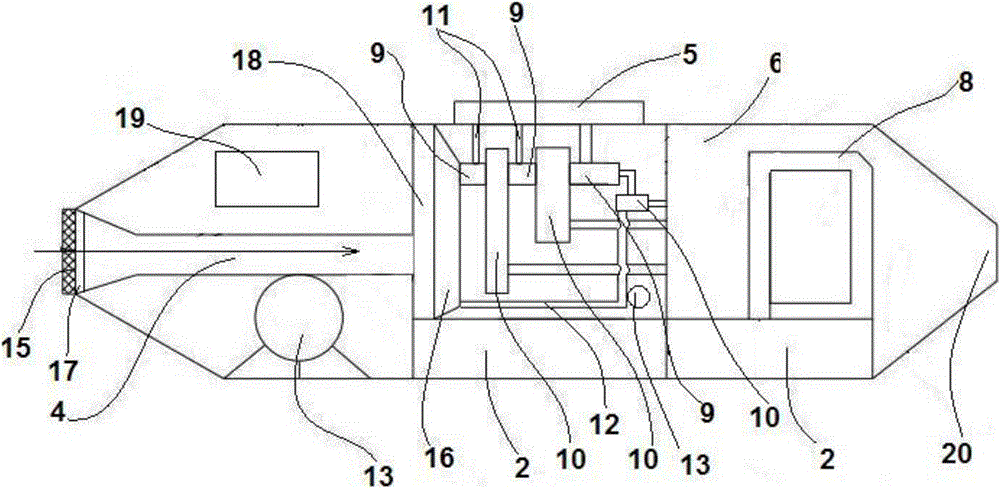

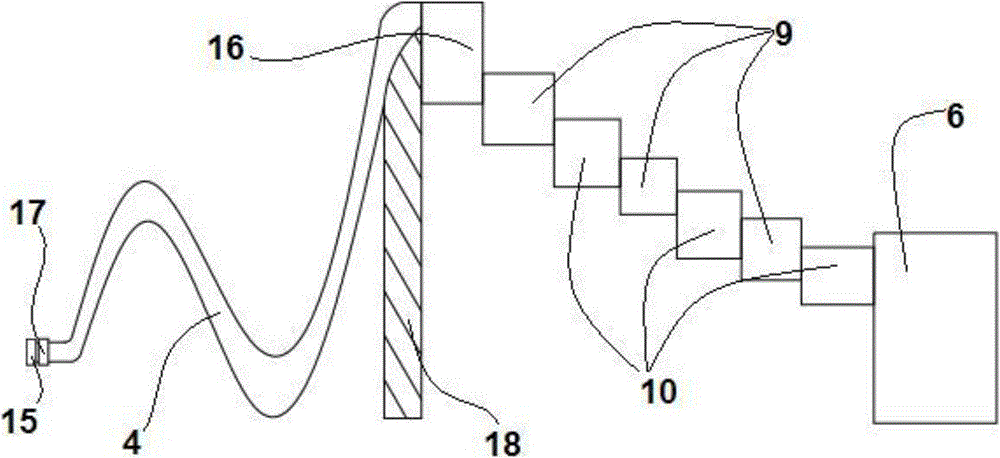

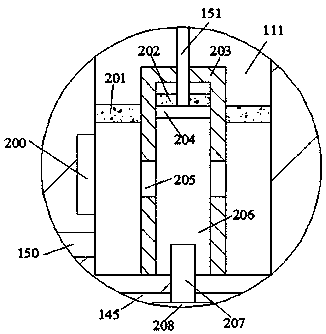

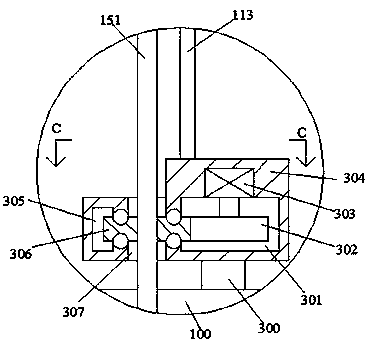

The invention discloses a mixed type underwater navigation detector which comprises a bow compartment, a main chamber, an electronic control chamber and a peak tank which are coaxially and sequentially connected, wherein the bow compartment and the peak tank are communicated with an outside water area; the main chamber and the electronic control chamber are sealing chambers; two wings are symmetrically installed at a connection position of the main chamber and the electronic control chamber; a sonar height gauge and an acoustic transceiver are installed in the bow compartment; a non-contact electric energy and signal transmission assembly is sleeved outside the main chamber; a gesture adjustment system and a buoyancy adjustment system are installed in the main chamber; the buoyancy adjustment system is installed on the front portion of the main chamber; buoyancy is adjusted through movement of a piston; two sides of the piston are isolated and sealed through rolling membranes; electronic equipment for controlling an aircraft is installed in the electronic control chamber; and a propeller propelling system and a steering control system are fixed on the peak tank. The mixed type underwater navigation detector has characteristics of underwater gliders and autonomous underwater vehicles, and can be abutted with an underwater connection platform to conduct non-contact charging and data transmission, so that continuous operational capability and applied range of underwater aircrafts can be increased.

Owner:ZHEJIANG UNIV

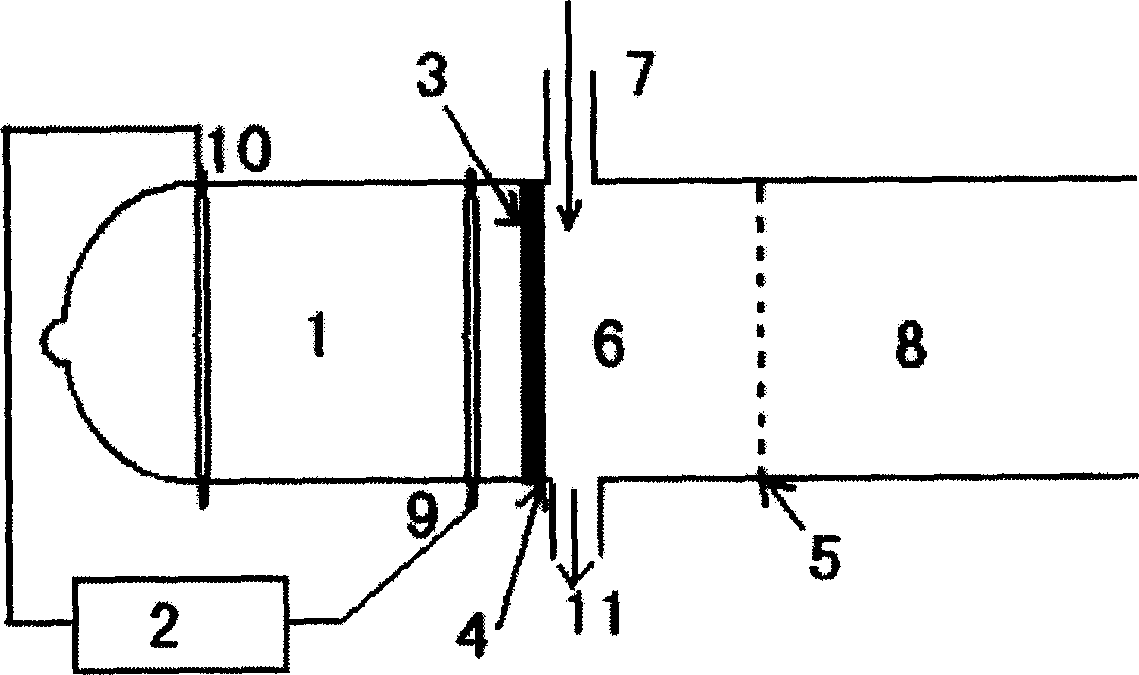

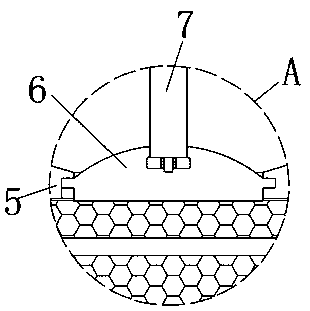

Ion migration spectrometer based on sample through membrane

InactiveCN1916619AReduce air pressureReduce humidityPreparing sample for investigationMaterial analysis by electric/magnetic meansGlass fiberAtmospheric pressure

Owner:上海新漫传感科技有限公司

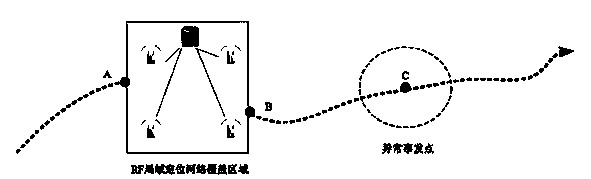

Method for achieving classification positioning by mobile monitoring terminal

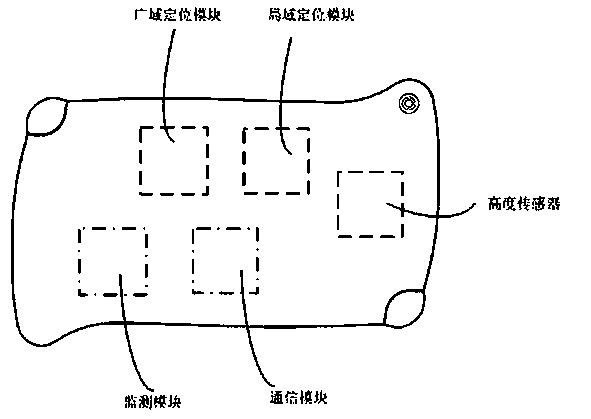

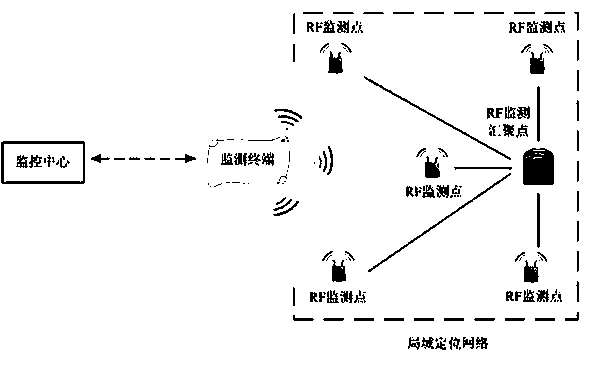

InactiveCN103763678AMeet the positioning needsSimple designSatellite radio beaconingLocation information based serviceComputer moduleDynamic positioning

The invention discloses a method for achieving classification positioning by a mobile monitoring terminal. The mobile monitoring terminal comprises a detection module, a communication module, a positioning module and a height sensor, the positioning module conducts classification positioning, dynamic positioning configuration is adopted in the monitoring terminal, the positioning module comprises a wide area positioning module and an RF local area positioning module, the wide area positioning module is based on satellite GPS tracking positioning or a mobile cellular base station or an LBS tracking positioning system or a GPSONE tracking positioning mode, the RF local area positioning module is based on a WiFi or a Zigbee or a Bluetooth or a UWB, the wide area positioning module is in the continuous working state all the time, when the monitoring terminal enters the local area positioning network range, the local area positioning module is started so as to timely send RF beacons at intervals with the set RF signals, and when the monitoring target is away from the local area positioning network range, a monitoring center turns off the local area positioning module of the terminal. The method has the advantages of being accurate in positioning, wide in coverage, high in intellectualization and cruising ability and the like.

Owner:COGLINK TECH SHANGHAI

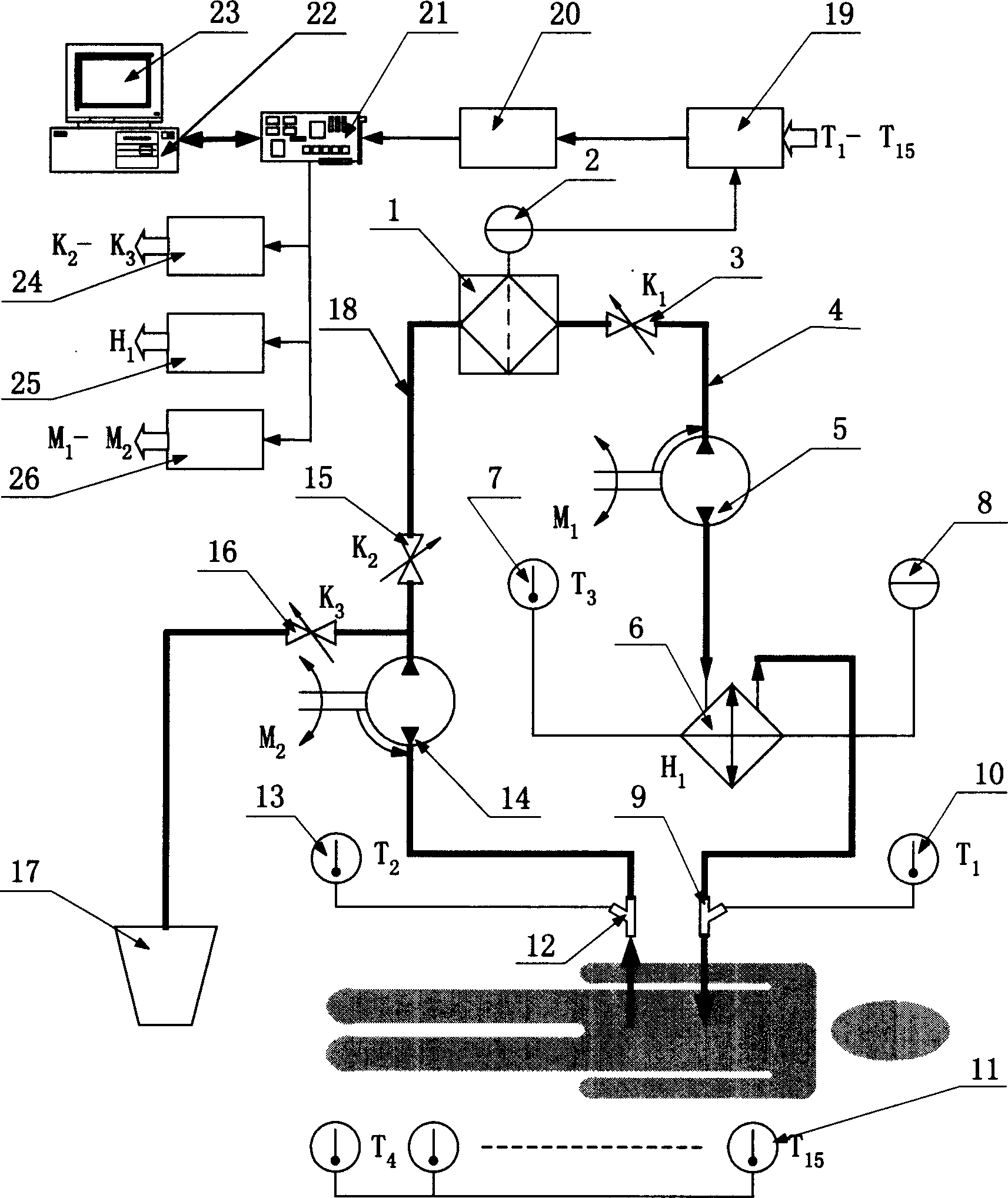

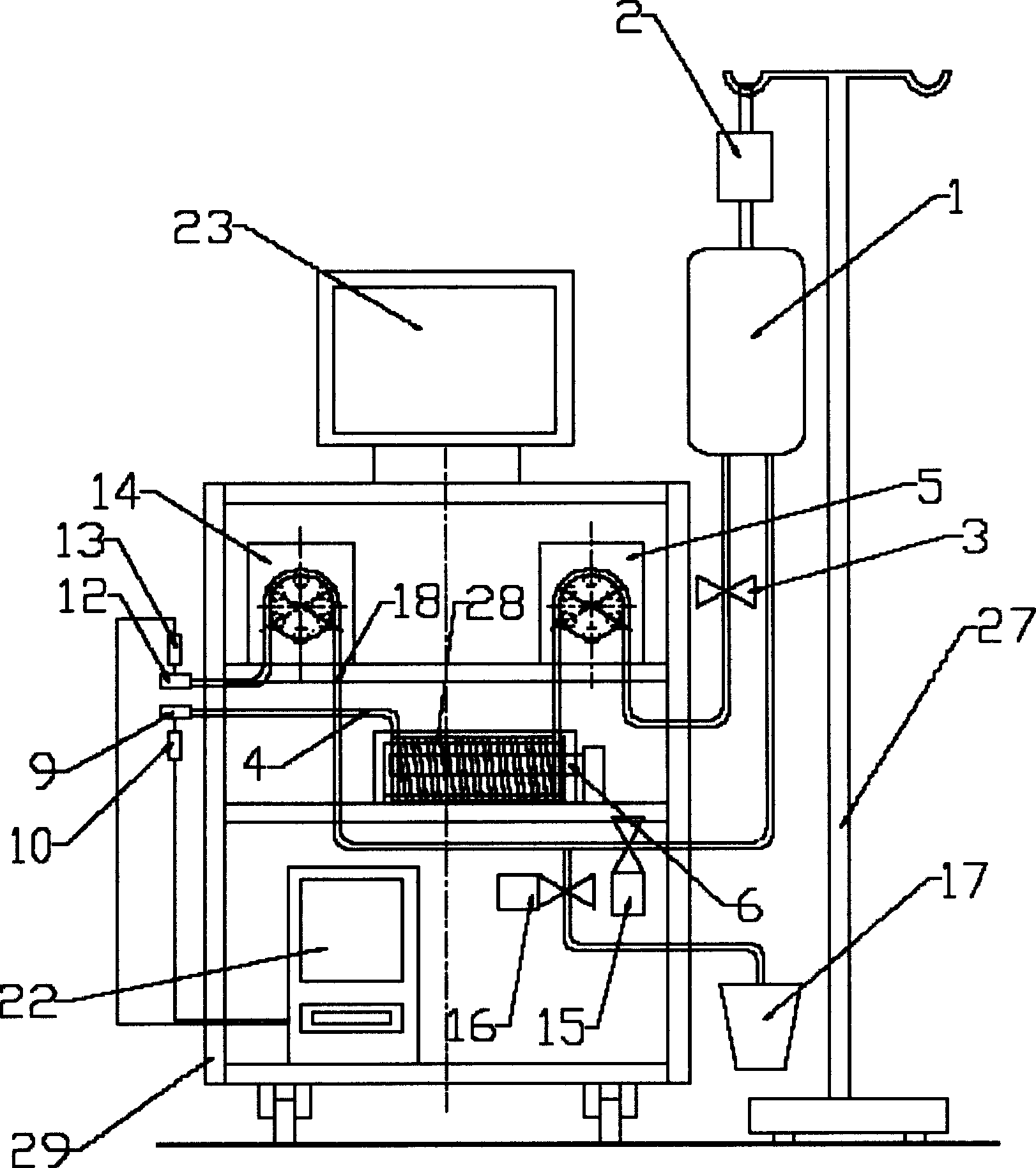

Infrared heat perfusion therapeutic apparatus

InactiveCN1562400APrevent cross infectionImprove heating efficiencyMedical devicesSurgical instruments for heatingNuclear medicineHeating time

An infrared heating perfusion apparatus for treating diseases features that the medicinal perfusion is indirectly heated by infrared heating tube, the temp measuring probe is used to measure the temp of perfusion, a hung weighing sensor is used to measure the dosage of perfusion, and an industrial control computer and the drivers of electromagntic valve, heater and peristaltic pump are used to control the heating time and circulated flow.

Owner:中山市中健药业有限公司

Water-borne oil spilling cleaning boat and control method thereof

ActiveCN104149944ALittle effect of wind and wavesImprove work efficiencyWater cleaningWaterborne vesselsWater storage tankLiquid storage tank

The invention discloses a water-borne oil spilling cleaning boat and a control method thereof. The water-borne oil spilling cleaning boat comprises a controller, a plurality of ballast tanks, a water inlet pipe, an oil-water separation system, an oil storage cabinet, a water storage tank, a wave-activated generator and a power system, wherein the controller is arranged on a boat body, the oil-water separation system is communicated with the water inlet pipe, the oil storage cabinet and the water storage tank are communicated with the oil-water separation system, the wave-activated generator is arranged in the water storage tank, and the power system is arranged on the rear portion of the boat body. A floating body is arranged on the lower surface of the boat body. The oil-water separation system comprises n levels of oil-water separators which are arranged sequentially from front to back, and a liquid storage tank is arranged behind each level of oil-water separator. The water-borne oil spilling cleaning boat and the control method thereof have the advantages that the water-borne oil spilling cleaning boat is half submersed in water, the stormy wave action is small, and the cleaning boat can work under severe sea conditions; there is no need to transport sewage to a bank to be treated, back-and-forth transportation time is shortened, the cleaning boat can operate continuously, and the working efficiency is high.

Owner:ZHEJIANG OCEAN UNIV

Semi-submersible type overwater overflow oil cleaning ship and control method thereof

ActiveCN104153333ALittle effect of wind and wavesReduce riskFatty/oily/floating substances removal devicesWater cleaningWireless transceiverShore

The invention discloses a semi-submersible type overwater overflow oil cleaning ship and a control method thereof. The semi-submersible type overwater overflow oil cleaning ship comprises a controller, a wireless transceiver, a plurality of ballast tanks and floating bodies, a water inlet pipe, an oil water separation system, an oil conservator, a water storage well and a power system, wherein the controller is arranged on a ship body; the plurality of ballast tanks and floating bodies are used for adjusting the submerging depth of the ship body; the oil water separation system is communicated with a water outlet of the water inlet pipe; the oil conservator, the water storage well and the power system are communicated with the oil water separation system; a turbogenerator is arranged in the water storage well; the floating bodies are located on the lower surface of the ship body; the ballast tanks are connected with the water inlet pipe and a water outlet pipe; water pumps are arranged on both the water inlet pipe and the water outlet pipe; water level sensors are arranged in the ballast tanks. The semi-submersible type overwater overflow oil cleaning ship has the characteristics that the ship bears a smaller wind wave effect by semi-submerging in water and can work under a severe sea condition; oil contamination can be recycled and treated on an oil overflow site, oily water is not required to be carried to a shore to be treated, back and forth transportation time is reduced, continue working can be realized as long as enough energy resources are provided, and the working efficiency is high.

Owner:ZHEJIANG OCEAN UNIV

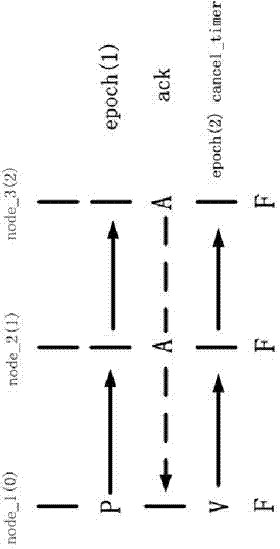

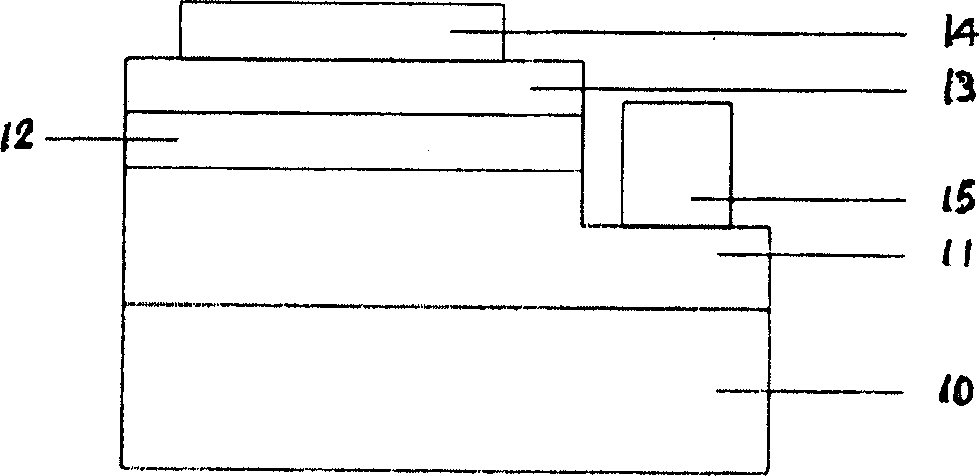

Cluster election design method

InactiveCN103491168AHigh availability serviceImprove continuous working abilityTransmissionLeader electionCluster based

The invention discloses a cluster election design method. In the election process, when a node processor initiates an election, the other nodes receive an election request and then judge the size of an initiator p_id of the a_id, if the a_id is smaller than the p_id, the node processor initiates the election again, if the a_id is larger than the p_id, the nodes reply the ack, and the nodes show to agree that the node processor is used as the leader node. When more than half of the nodes reply the ack, the node processor becomes the new leader. If the election is initiated for more than 5 seconds, the half of nodes still do not reply the ack, and a new leader is not generated, the node processor initiates the election again until the new leader is generated. According to the election algorithm based on the cluster nodes, the leader election among the cluster nodes is achieved, after the leader fails, the new election is initiated again, the high available service of a cluster can be ensured, and the continuous working capability of the cluster is improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

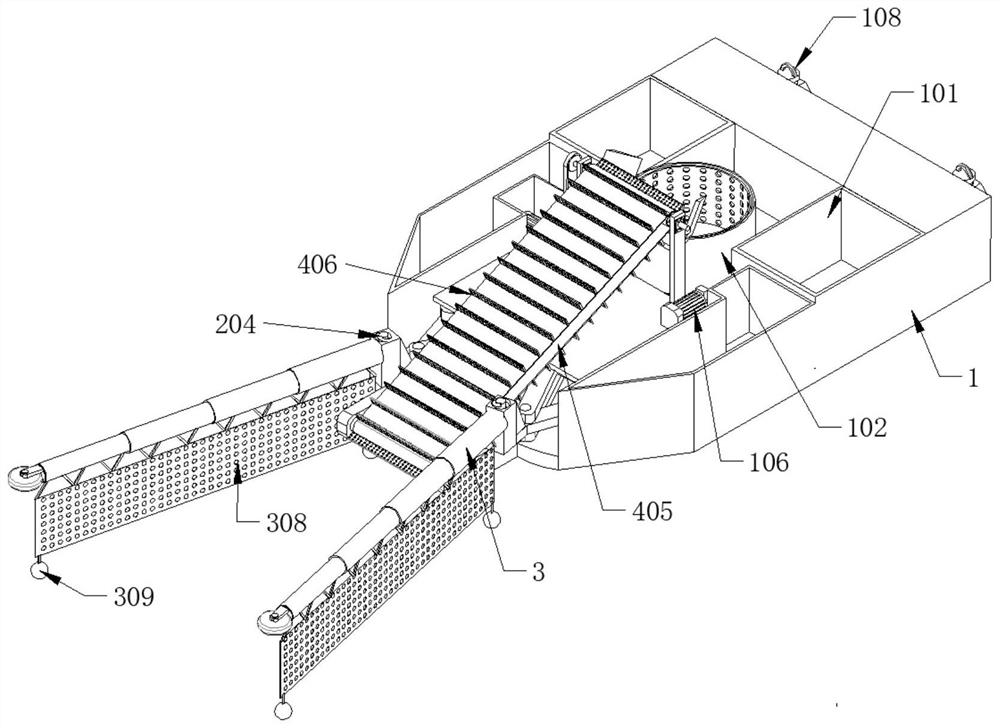

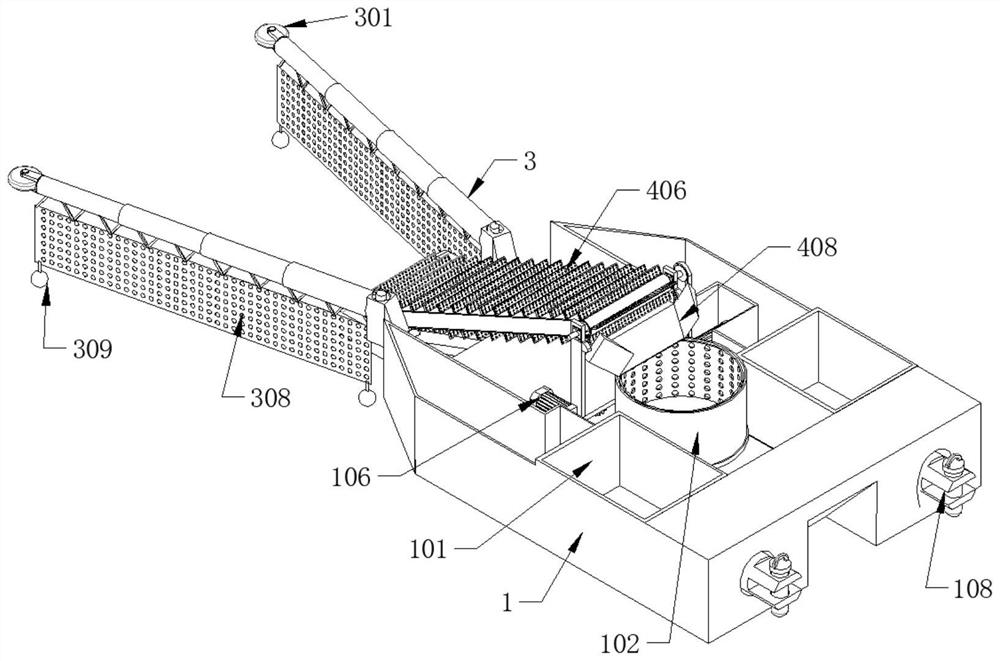

Environment-friendly waste salvaging device for water body pollution

PendingCN112429163AAvoid bump damageAvoid damageConveyorsWater cleaningRiver routingElectric machine

The invention discloses an environment-friendly waste salvaging device for water body pollution, and belongs to the field of riverway garbage salvaging. The environment-friendly waste salvaging devicefor water body pollution comprises a shell, a box and a front support, the box is arranged on the inner wall of the bottom of the shell, the front support is connected to the side wall of the front end of the shell, an angle adjusting assembly is arranged at the top of the box, the angle adjusting assembly is connected with a telescopic rod, and elastic assemblies are arranged at the two ends ofthe telescopic rod; a collecting net is connected to the bottom of the stretching assembly, a cover plate is arranged at the top of the angle adjusting assembly, two supporting rods are arranged at the top of the cover plate, a vibration assembly is arranged at the tops of the supporting rods, a conveying assembly is arranged between the vibration assembly and the rotating rollers, and a dehydration device, a pollutant classification box and a rotating motor are arranged at the bottom of the shell; according to the device, riverways with different widths can be automatically fished, the bearing capacity of the shell can be increased through dehydration, the continuous working time can be prolonged, and pollutants can be conveniently classified and treated.

Owner:陈毅

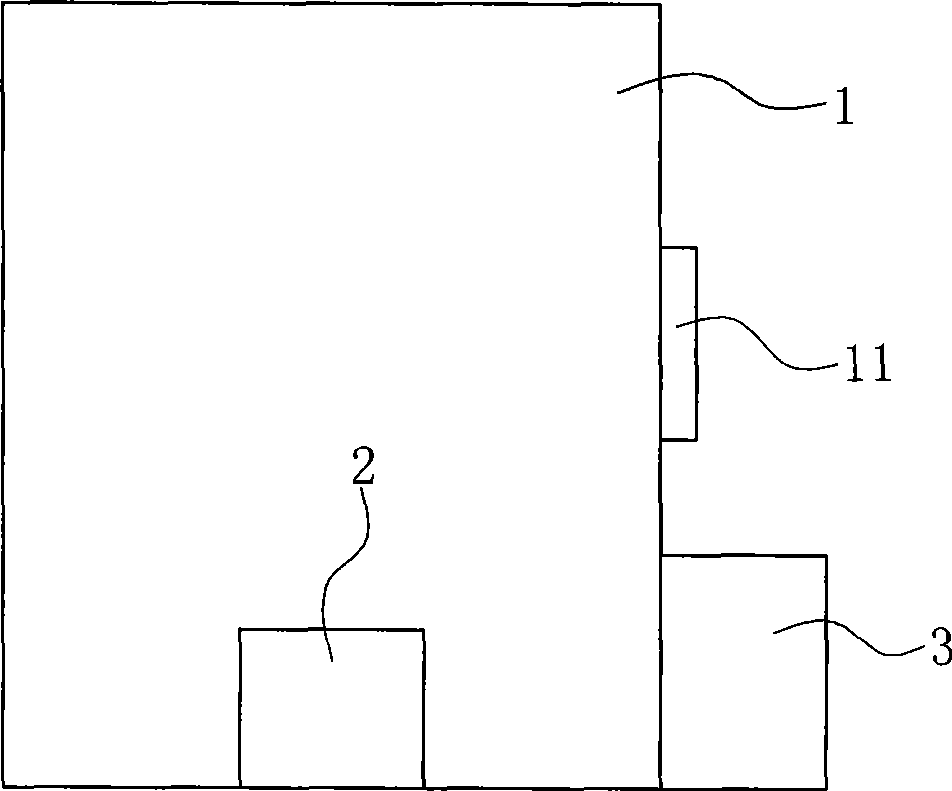

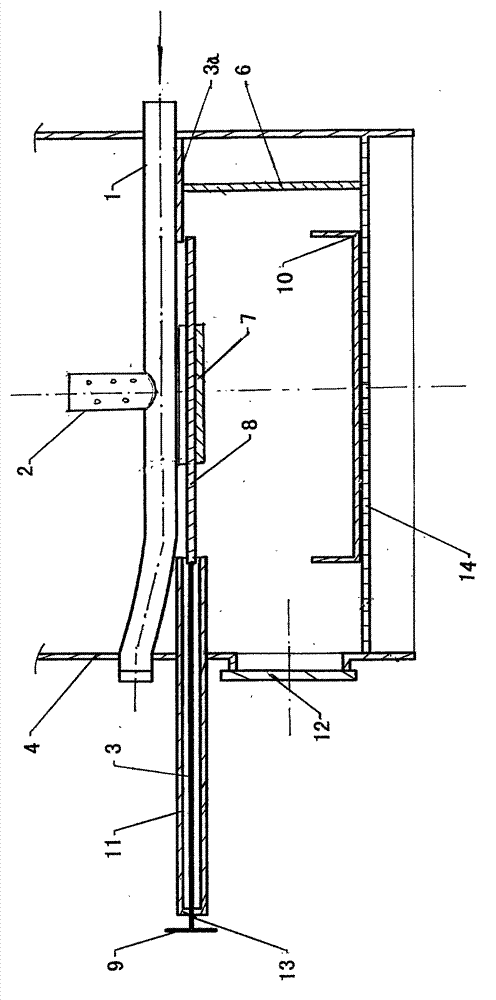

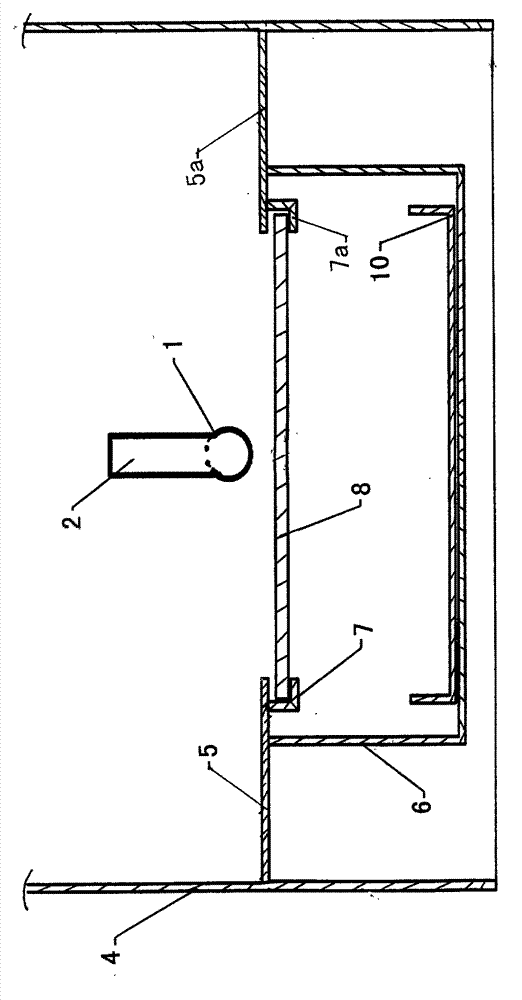

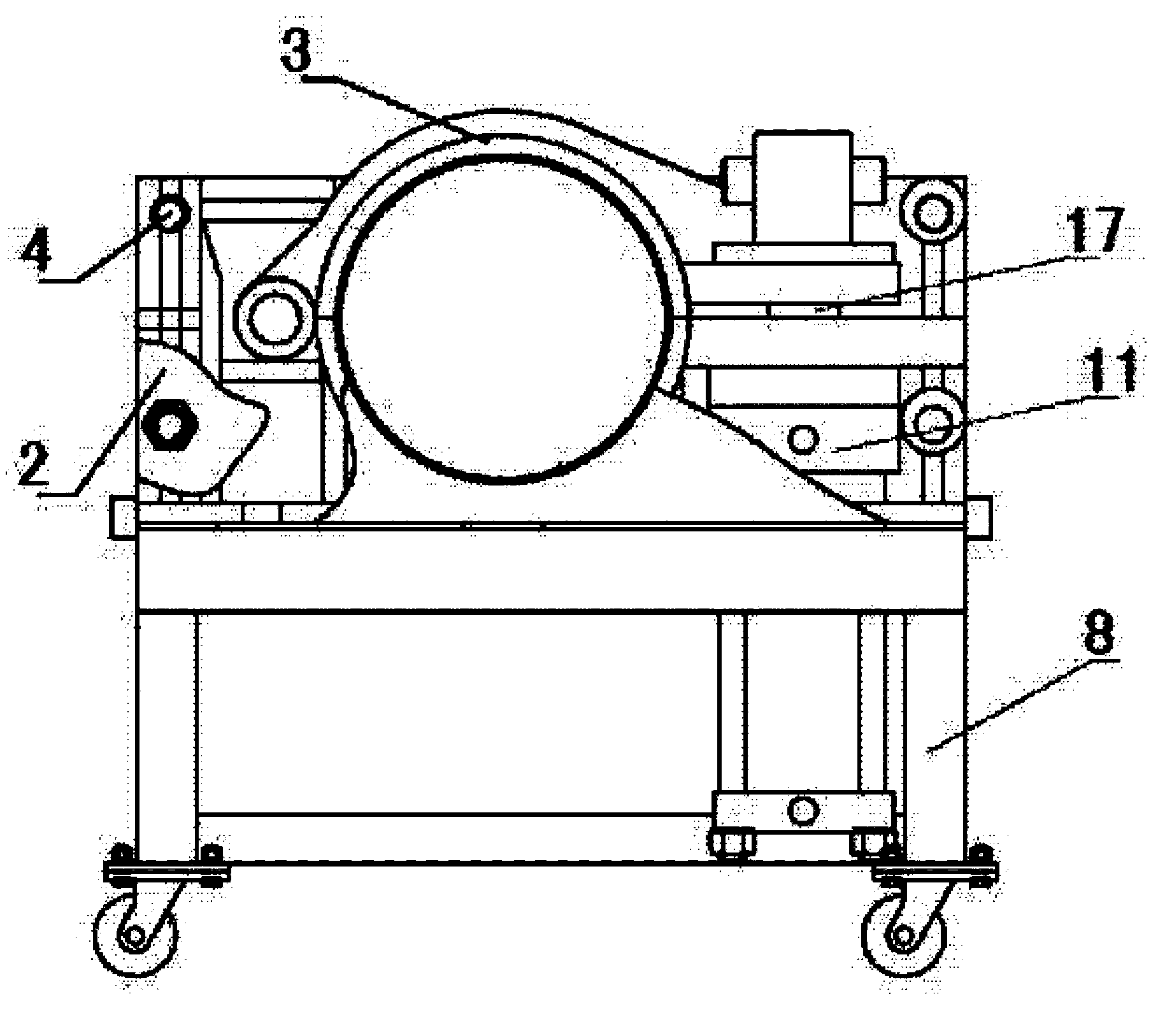

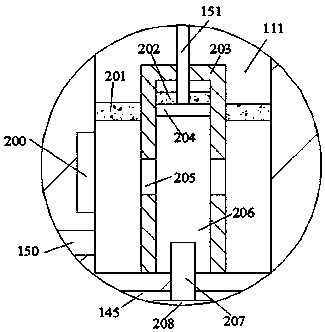

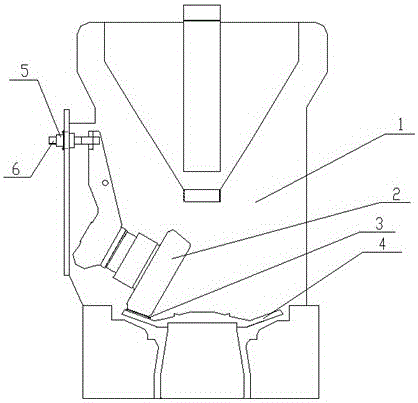

Vacuum hotpressing machine

ActiveCN101468523AImprove continuous working abilityReduce waiting timeManipulatorPressesEngineeringHydroforming

The invention relates to a vacuum hot press, which comprises a main work room provided with an observing window, wherein the main work room is provided with a vacuumizing system, a heating source and a hydraulic forming system inside; a transition cabin and a glove box device are arranged on the vacuum hot press and communicated with the main work room respectively; because the transition cabin is arranged as a transfer to place blanks and take out a product after hot pressing and the glove box device with high gas tightness is used for taking and placing the blanks and pressing, a furnace door of the main work room does not need to be opened every time, and the main work room does not need to be vaccumized every time when the hot press performs pressing every time, so as to reduce waiting time, greatly improve the continue working capacity of the whole hot press equipment system and be applicable to batch industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

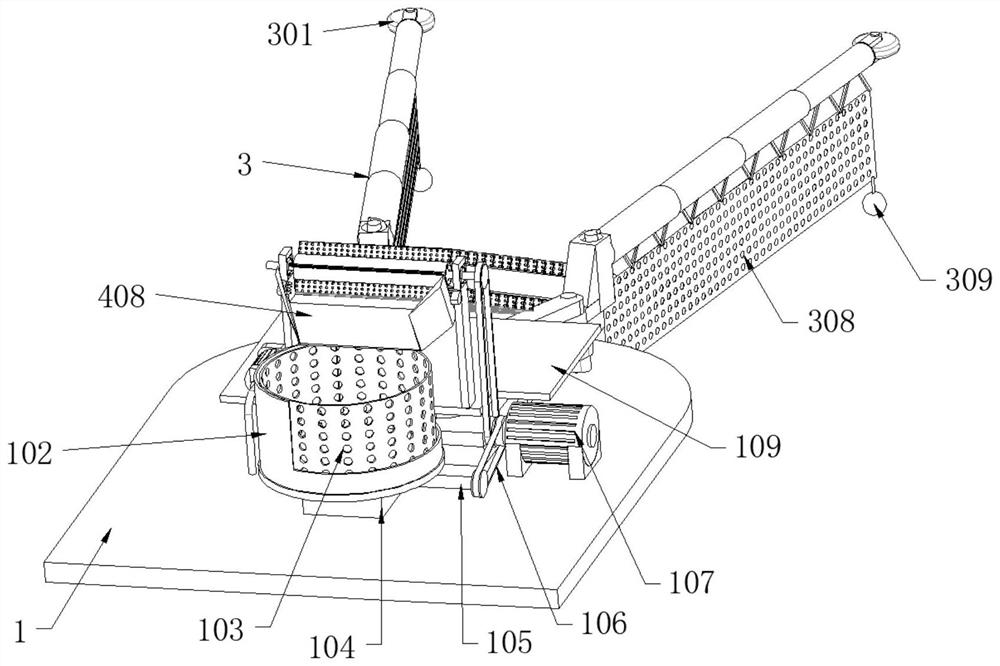

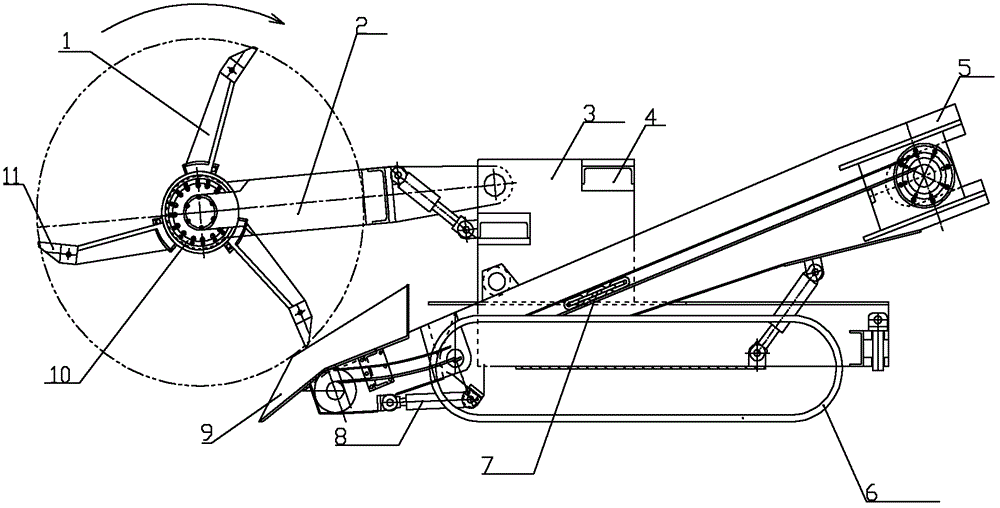

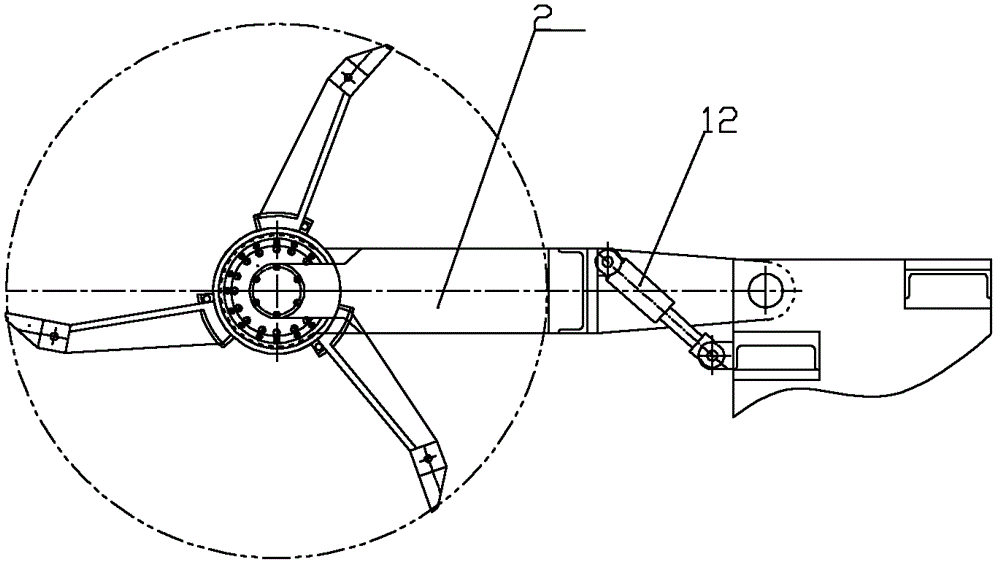

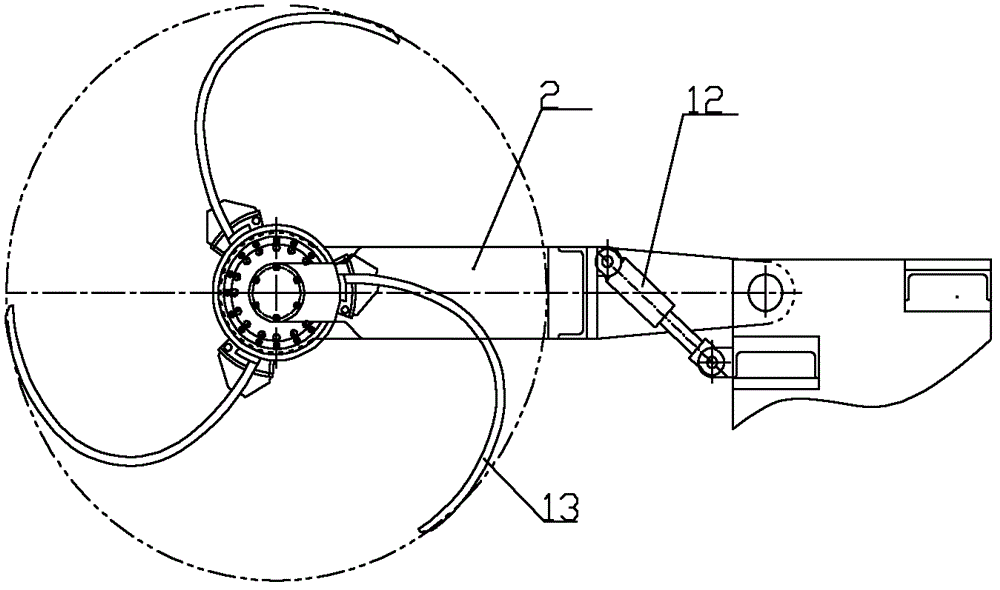

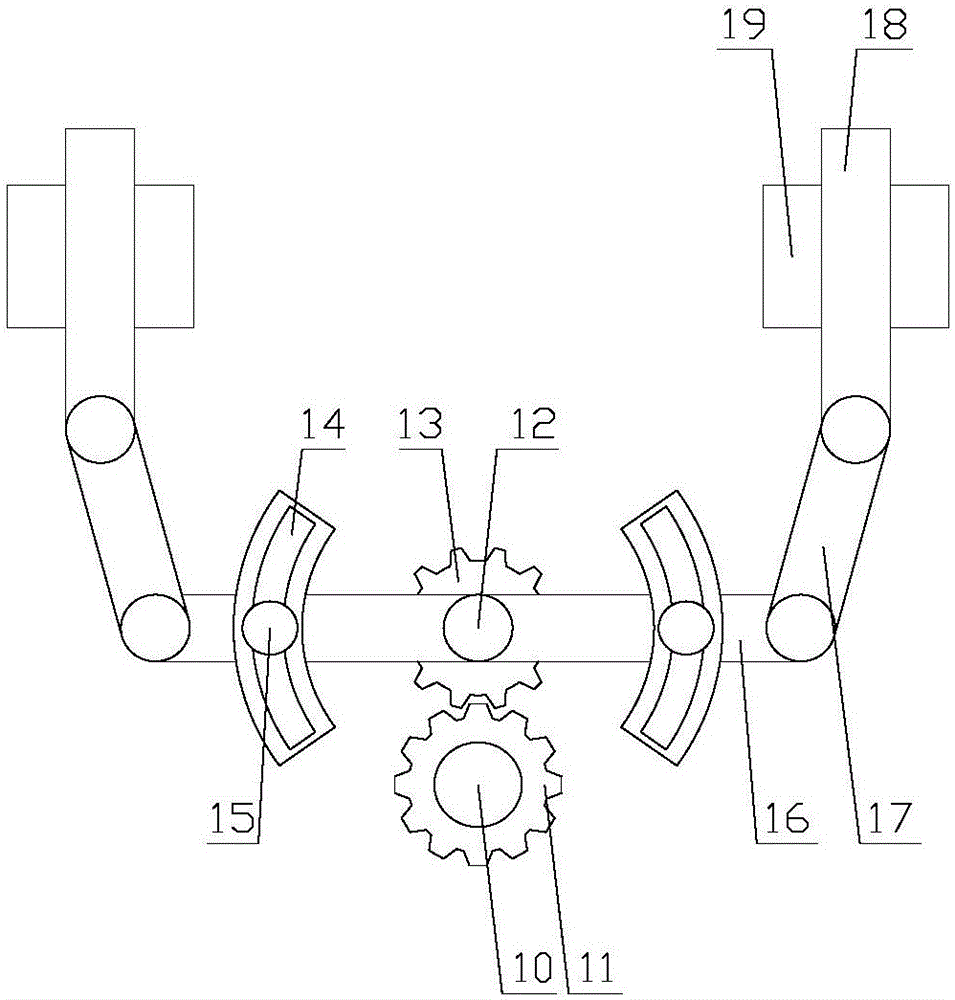

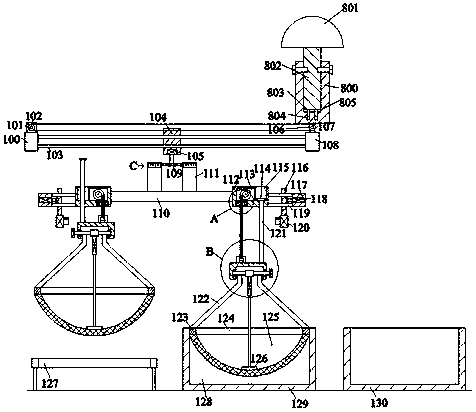

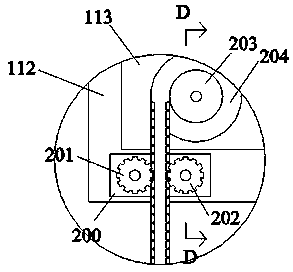

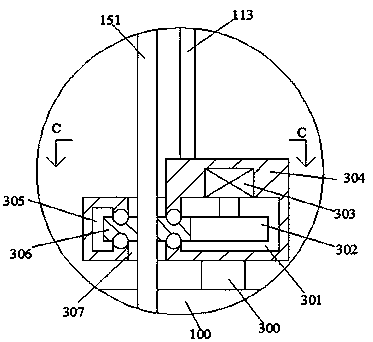

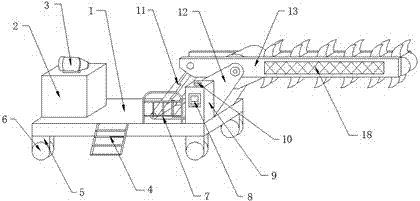

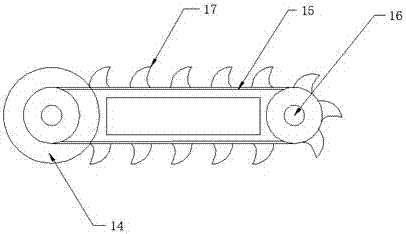

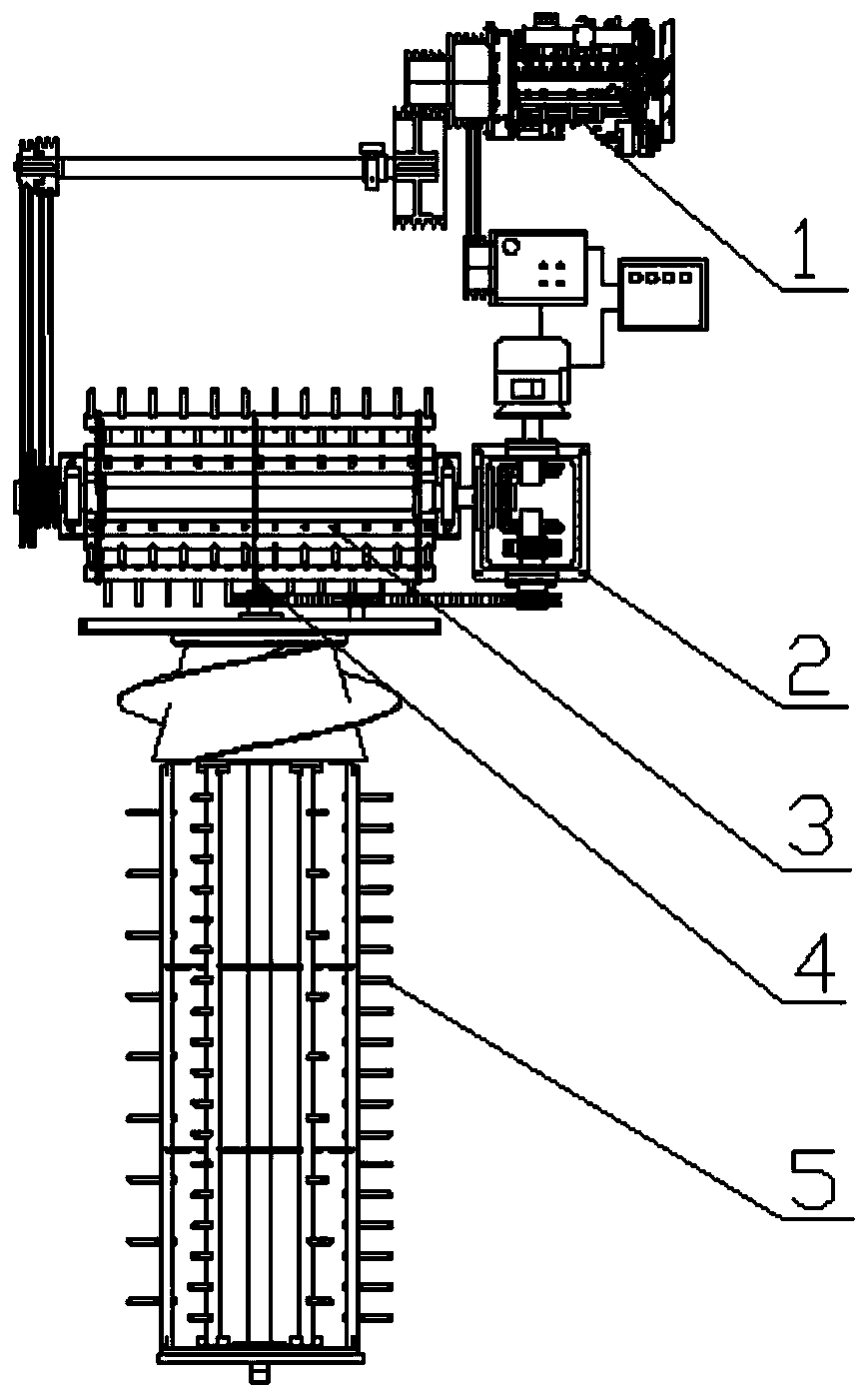

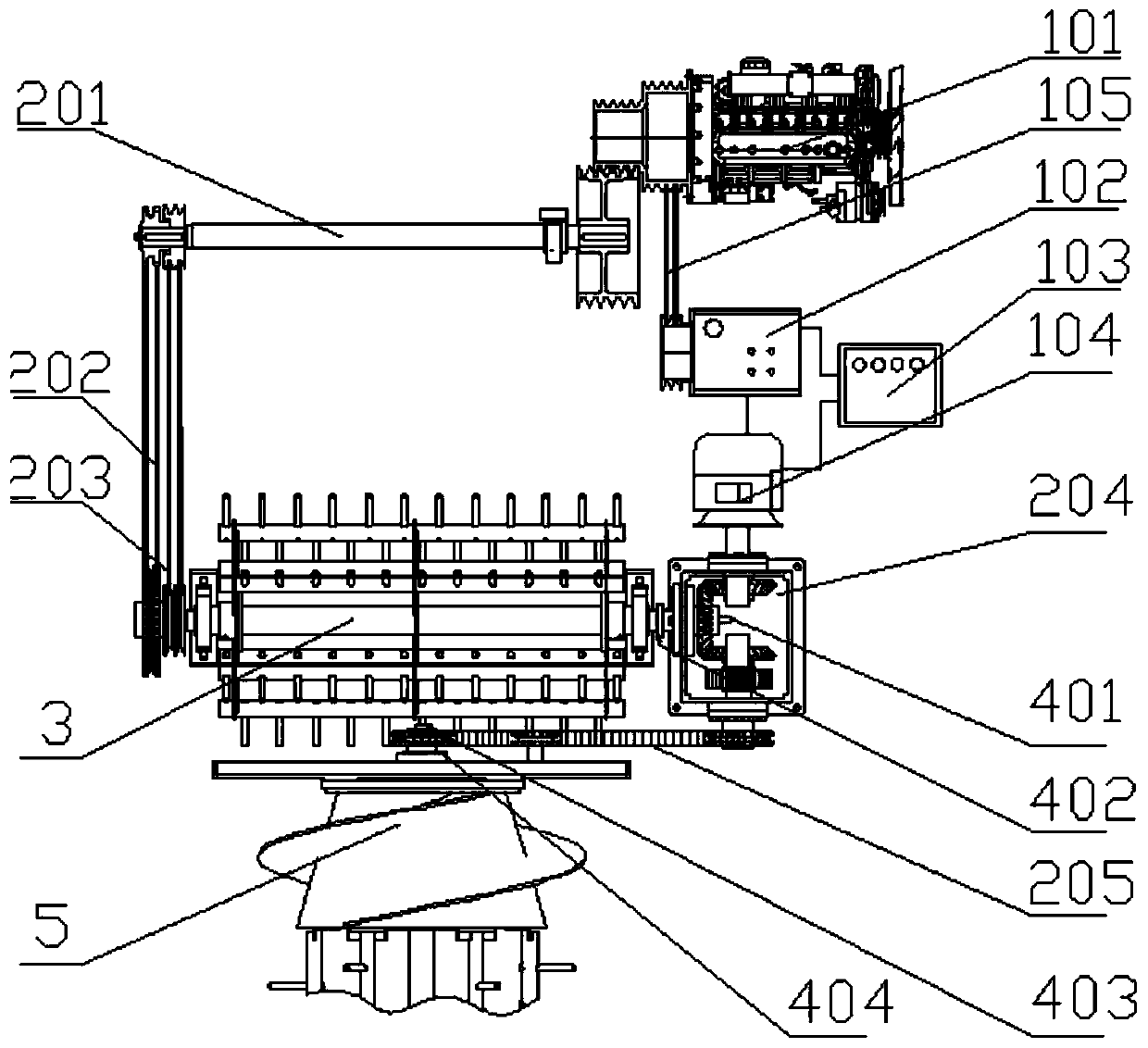

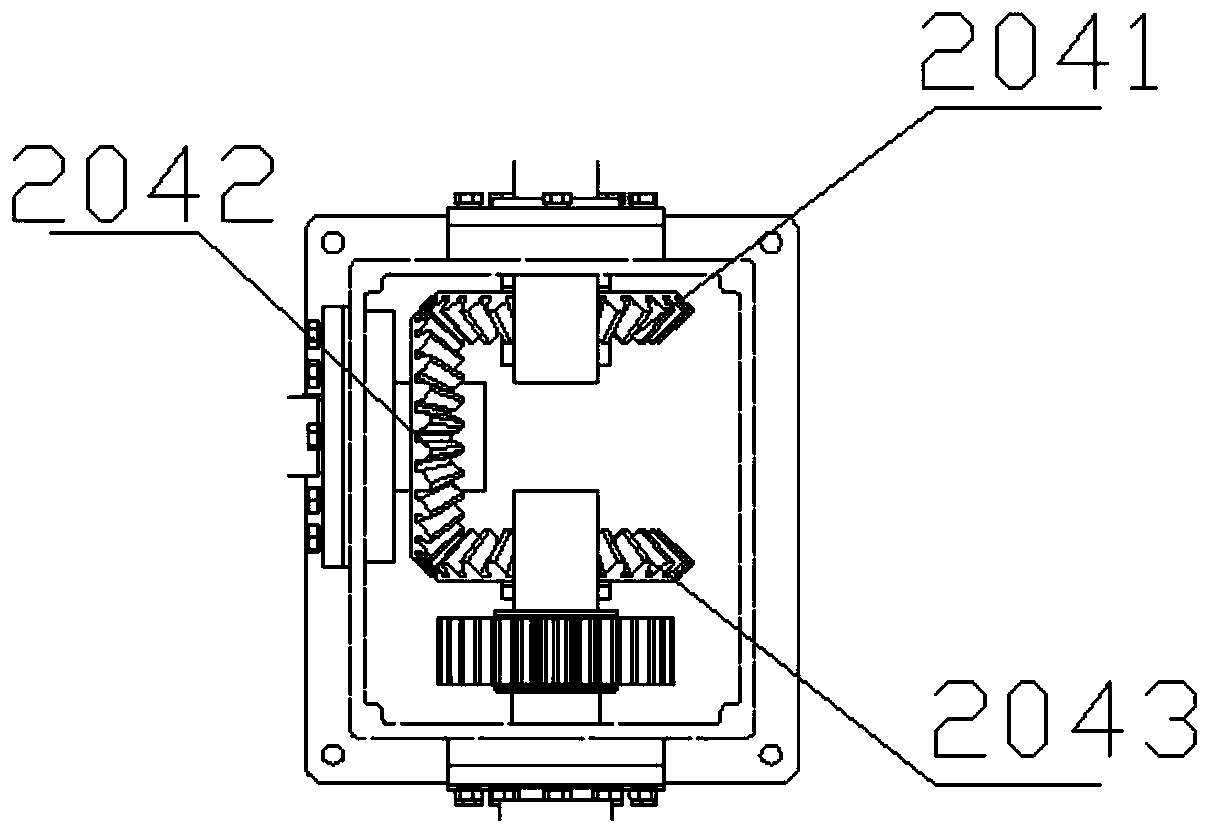

Rolling harrow-based, material-turnover, material-charging and high-efficiency loader and loading method therefor

InactiveCN102720494AImprove continuous working abilityReduce resistanceSlitting machinesEngineeringClockwise

The invention belongs to the fields of material loading, mining, driving and tunneling and especially relates to a rolling harrow-based, material-turnover, material-charging and high-efficiency loader and a loading method therefor. The rolling harrow-based, material-turnover, material-charging and high-efficiency loader comprises a rolling harrow, a transportation mechanism and a driving mechanism. The transportation mechanism comprises a walking device. The rolling harrow comprises harrow teeth and a supporting arm. One end of the supporting arm is connected to the transportation mechanism. The harrow teeth rotate relatively to the transportation mechanism along a clockwise direction. The harrow teeth of the rolling harrow are inserted into materials from a part below the materials. The rolling harrow-based, material-turnover, material-charging and high-efficiency loader and the loading method therefor have the advantages that the harrow teeth of the rolling harrow are inserted into materials from a part below the materials and the materials are taken up from the bottom and are rotatingly discharged to a conveying mechanism, and because an upper part above the materials is open, material sticking is avoided and continuous working performances of equipment are greatly improved.

Owner:刘素华

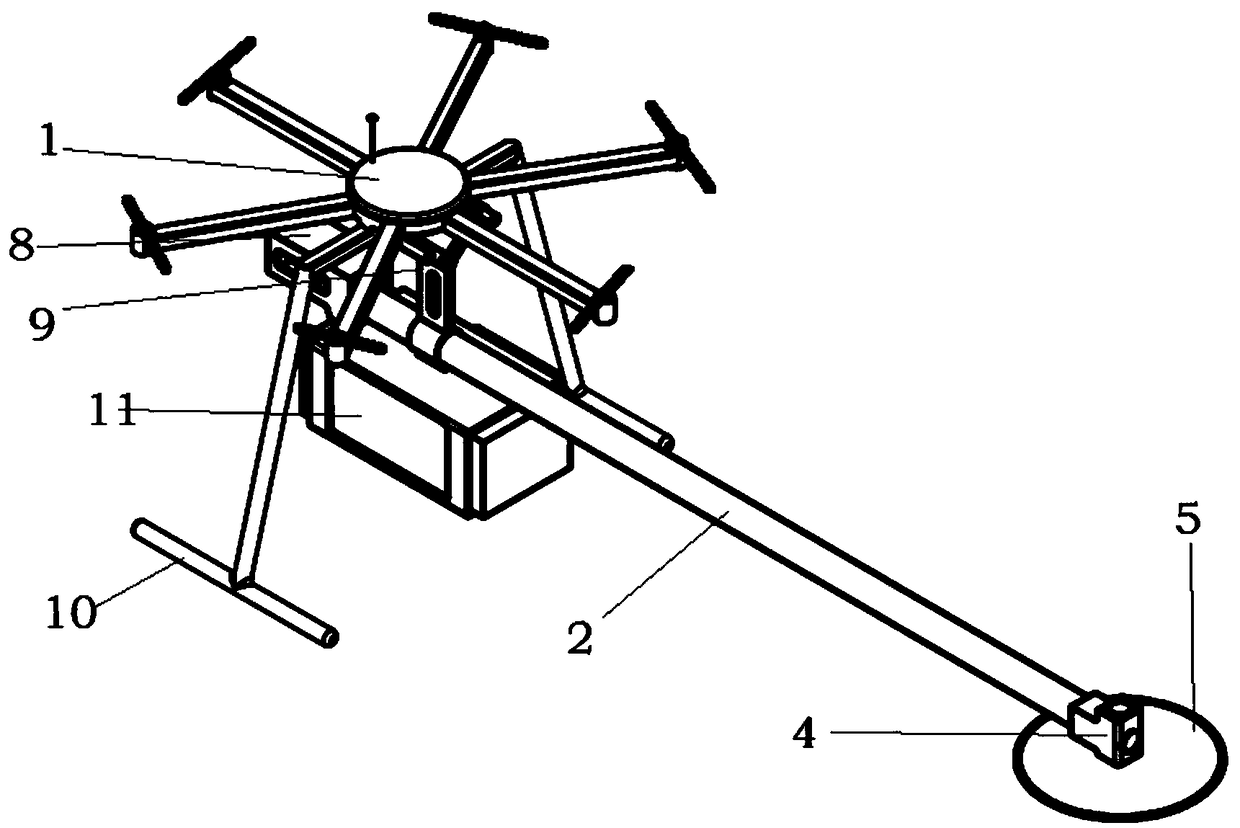

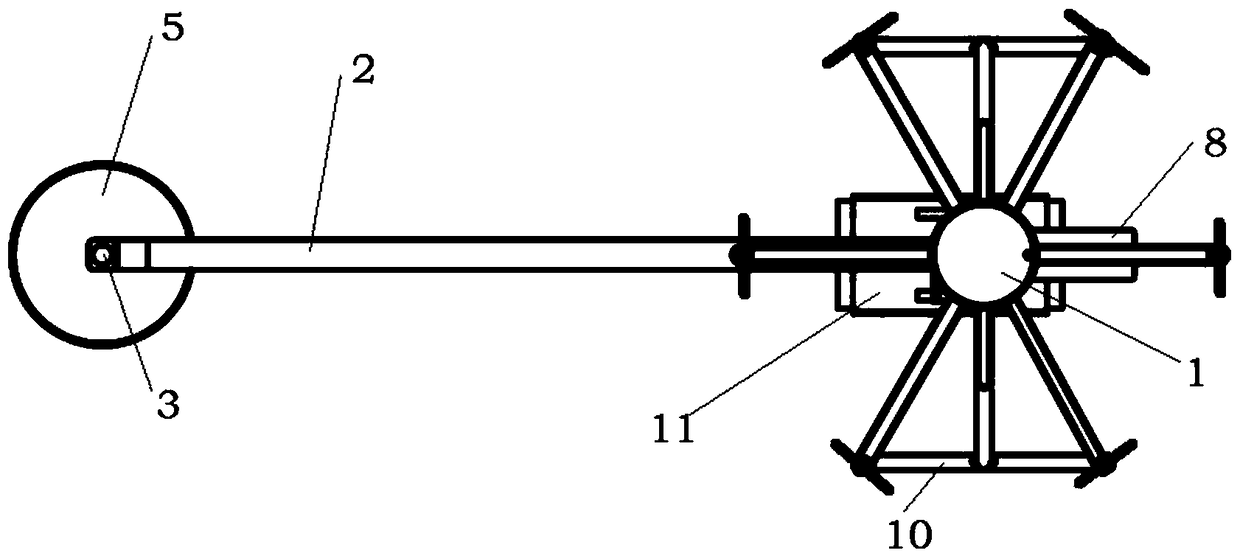

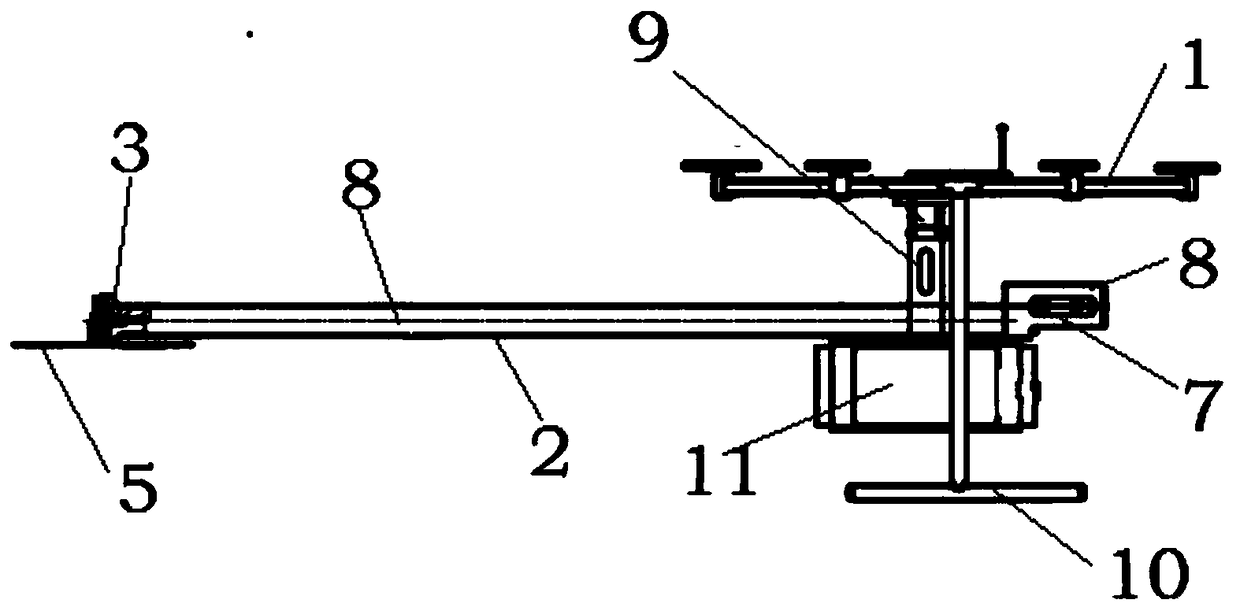

Unmanned-aerial-vehicle airborne tree-barrier clipping device

PendingCN108934532AFast cleaningPrecision removal workAircraft componentsCuttersElectricityDrive shaft

The invention discloses an unmanned-aerial-vehicle airborne tree-barrier clipping device, and belongs to the field of tree clipping. The unmanned-aerial-vehicle airborne tree-barrier clipping device comprises a multi-rotary-wing unmanned aerial vehicle, a power system, a control system, an insulation supporting rod, a transmission shaft, a reversing transmission device, an unmanned-aerial-vehicleconnecting frame and a cutter bit; the power system is fixedly arranged at one end of the insulation supporting rod, the reversing transmission device is fixedly arranged at the other end of the insulation supporting rod, the multi-rotary-wing unmanned aerial vehicle is fixed to the end, close to the power system, of the insulation supporting rod through the unmanned-aerial-vehicle connecting frame, a multi-rotary-wing unmanned aerial vehicle support is arranged on the multi-rotary-wing unmanned aerial vehicle, the transmission shaft penetrates through the insulation supporting rod, one end ofthe transmission shaft is connected with the power system, the other end of the transmission shaft is connected with the reversing transmission device, the cutter bit is connected below the reversingtransmission device, the control system is electrically connected with the power system, and the power system is also sued for driving the multi-rotary-wing unmanned aerial vehicle. The multi-rotary-wing unmanned aerial vehicle carries a custom electric saw to reach a high-altitude tree-barrier position, the power system drives the cutter bit to rapidly remove tree barriers or clip ultrahigh trees.

Owner:中国南方电网有限责任公司超高压输电公司百色局

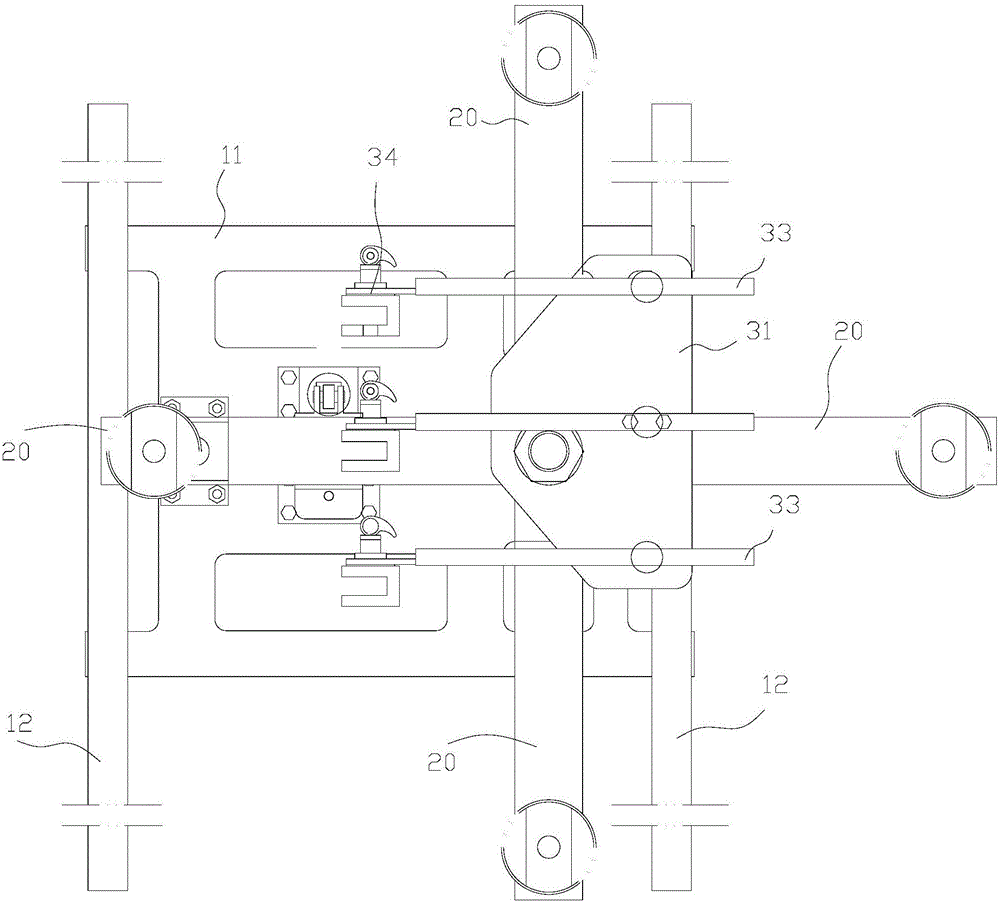

Semi-automatic paint spraying machine

ActiveCN106733320AReduce usageSimple structureLiquid surface applicatorsCoatingsSemi automaticPneumatic valve

The invention discloses a semi-automatic paint spraying machine and belongs to the technical field of paint spraying equipment. The semi-automatic paint spraying machine comprises a base plate assembly, a rotating assembly, spraying frame assemblies, spraying gun assemblies, an air supply device and a control box. The base plate assembly comprises a base plate and supporting rods. The rotating assembly comprises a cross-shaped rotating frame, a pneumatic motor, a holding frame assembly, a push assembly and a fixing seat. The spraying frames assemblies are arranged at the upper end of the base plate assembly and used for clamping the spraying gun assemblies. Each spraying gun assembly comprises a spraying gun and a spraying gun air cylinder. The control box comprises a box body, an electro connecting pressure gauge installed in the box body, a first electromagnetic pneumatic valve, a second electromagnetic pneumatic valve, a first time relay and a second time relay. According to the semi-automatic paint spraying machine, through a simple and compact mechanism and low cost, semi-automatic spraying over general parts such as reflecting mirrors is achieved, the labor intensity is lowered, the influence of gunner factors on the product quality is solved, and corporate profitability is improved.

Owner:南宁星焱科技有限公司

Hearth push-pull type ash discharging device for biomass gasifying furnace

InactiveCN102925217AEasy to operateImprove operating conditionsGranular/pulverulent flues gasificationBiomass gasifierLevel line

The invention discloses a hearth push-pull ash discharging device for a biomass gasifying furnace. The hearth push-pull ash discharging device is characterized in that an ash storing tank door is arranged on a sidewall of the lower end of a furnace body; a bottom fixing plate is fixedly connected to a transverse internal wall of an internal chamber at the lower end of the furnace body; a three-wall type ash storing box is manufactured on the bottom fixing plate; an ash storing box is positioned in an ash storing tank; the top end of one sidewall of the ash storing tank opposite to an ash storing tank door is close to a rear supporting plate; an ash falling plate guiding box is arranged on the sidewall of the furnace body; and an ash falling plate push-pull rod with a handle penetrates through an oil seal and then is connected to one end side of ash falling plates. A left supporting plate and a right supporting plate are fixedly connected to two longitudinal sidewalls of the furnace body; a front push-pull groove and a rear push-pull groove are fixedly connected to internal side edges of the left supporting plate and the right supporting plate; two end sides of the ash falling plates are positioned into the front push-pull groove and the rear push-pull groove; and the ash falling plates arranged in the front push-pull groove and the rear push-pull groove are positioned on the same level line as the ash falling plate push-pull rod. The push-pull ash discharging device is simple in structure and convenient to operate, and can effectively separate ash residue (dust) from a carbonized material or a semi-carbonized material, so that a continuous working capacity of the biomass gasifying furnace is improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

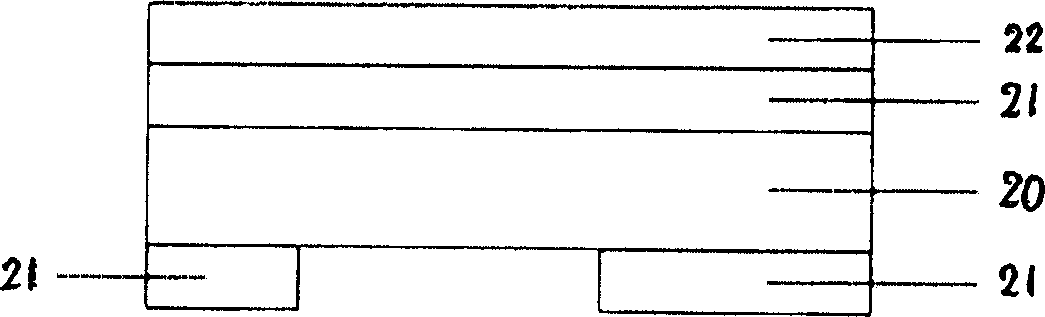

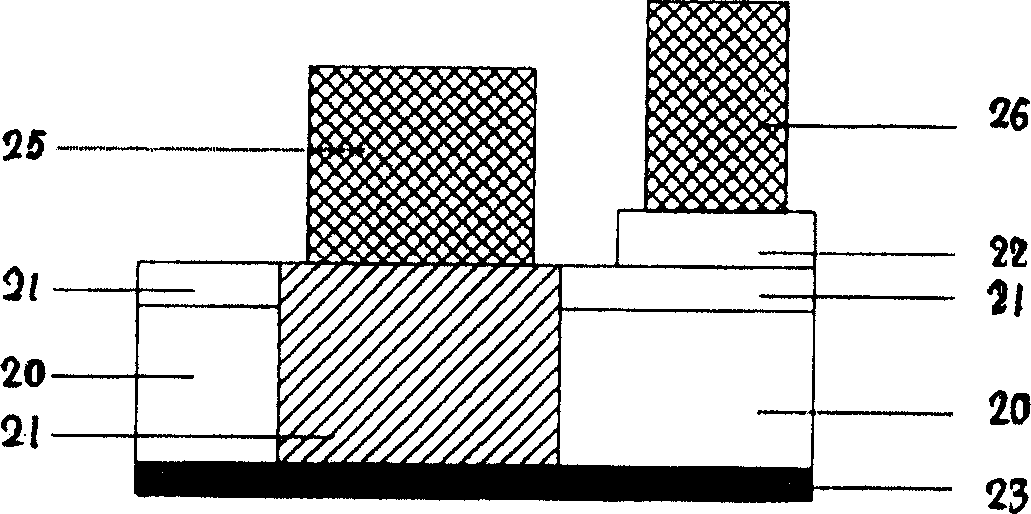

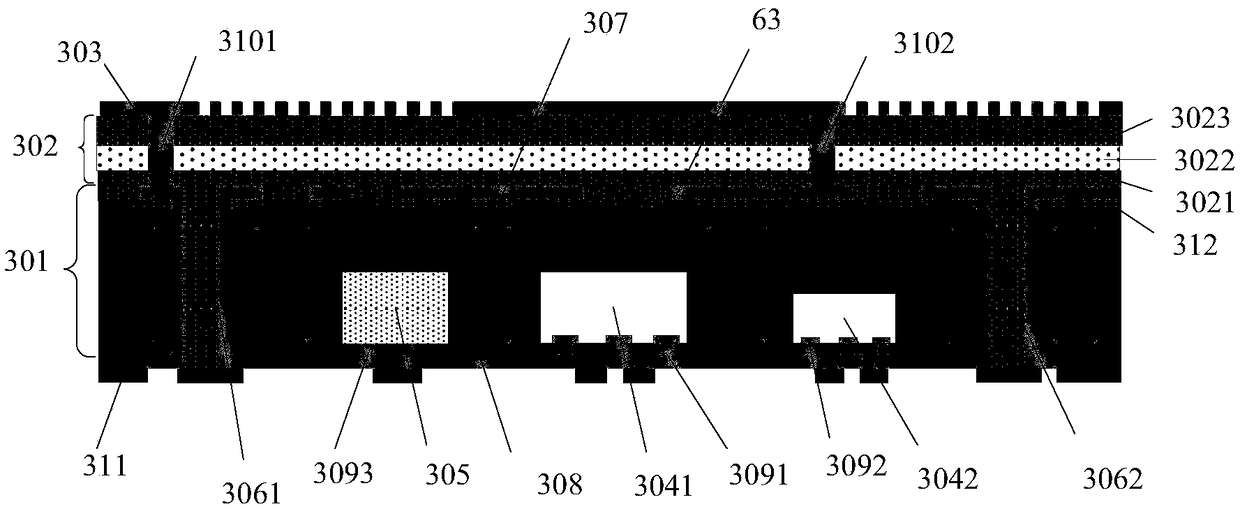

Method for making GaN-based LED with back hole structure

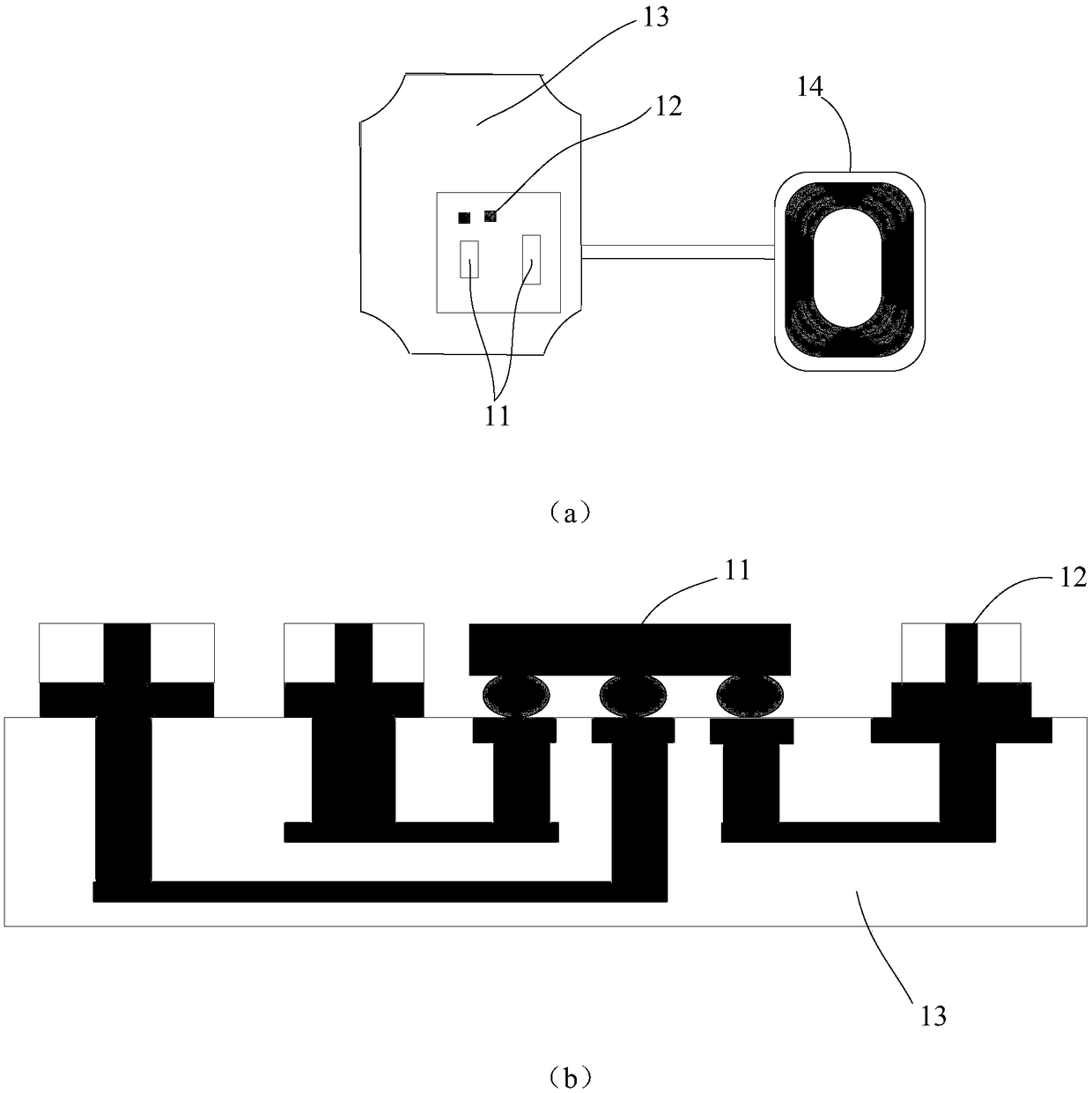

ActiveCN1755954AImprove continuous working abilityImprove performanceNanotechSolid-state devicesAlloyGallium nitride

Disclosed a manufacturing method of gallium nitride light-emitting diode in the back hole structure comprises: N type gallium nitride layer which sequentially extends on the insulating substrate of blue stone, multiple quantum trap luminous active region and a P type gallium nitride layer; processing photo-etching on the N type gallium nitride layer to preparing the P type ohm contact electrode and N type ohm contact electrode; the scribing divides the tube core of epitaxial slice into single tube core; forming a silicon dioxide insulating dividing layer on the two surfaces of silicon slice while preparing the metal electrode on the right face and light etching the back-hole pattern on the back surface; forming the back holes; utilizing the thick paste to light etch and electric plate the protruding point pattern on the right face of silicon slice; preparing a layer of alloy with lower fusible point on the back of silicon to form the tube base; connecting the back of tube base and the tube housing via heat sink; welding the tube core and the right surface of tube base via the metal protruding point, educing the N electrode of light-emitting diode from the metal electrode made on the right surface of silicon slice and educing the P electrode of light-emitting diode from the heat sink back surface of tube housing.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

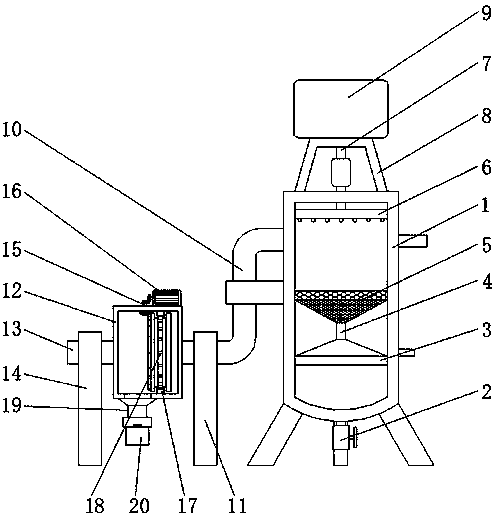

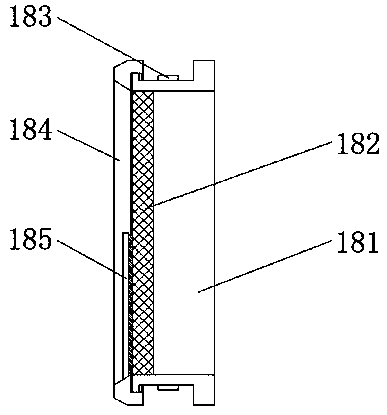

Environment-friendly waste gas treatment device for factory production and processing

InactiveCN109200809AAvoid cloggingImprove continuous working abilityHuman health protectionGas treatmentSlagFixed frame

The invention discloses an environment-friendly waste gas treatment device for factory production and processing, and relates to the technical field of waste gas treatment. The environment-friendly waste gas treatment device comprises a reaction chamber, a slag discharge pipe, a flow guide cover, a fixed pipe, a filter funnel, a nozzle, a conveying device, a fixed frame, a storage bin, a gas guiding pipe, a first fixed rod, a filter tank, an intake pipe, a second fixed rod, a transmission rod, a motor, a snap ring, a filter device, a dust collecting pipe and a collecting device. In the environment-friendly exhaust treatment device, a driving lever can be moved to drive a second blade to rotate to block a gap of a first blade, and the driving lever can be moved to drive the second blade andthe first blade to effectively prevent flying dust from being generated when dust inside the collecting device is cleaned, thereby solving the problem that when an existing exhaust treatment device is used for treating filtered dust, the flying dust is likely to generate and secondary pollution is caused to air.

Owner:杭州富阳锦丰纸业有限公司

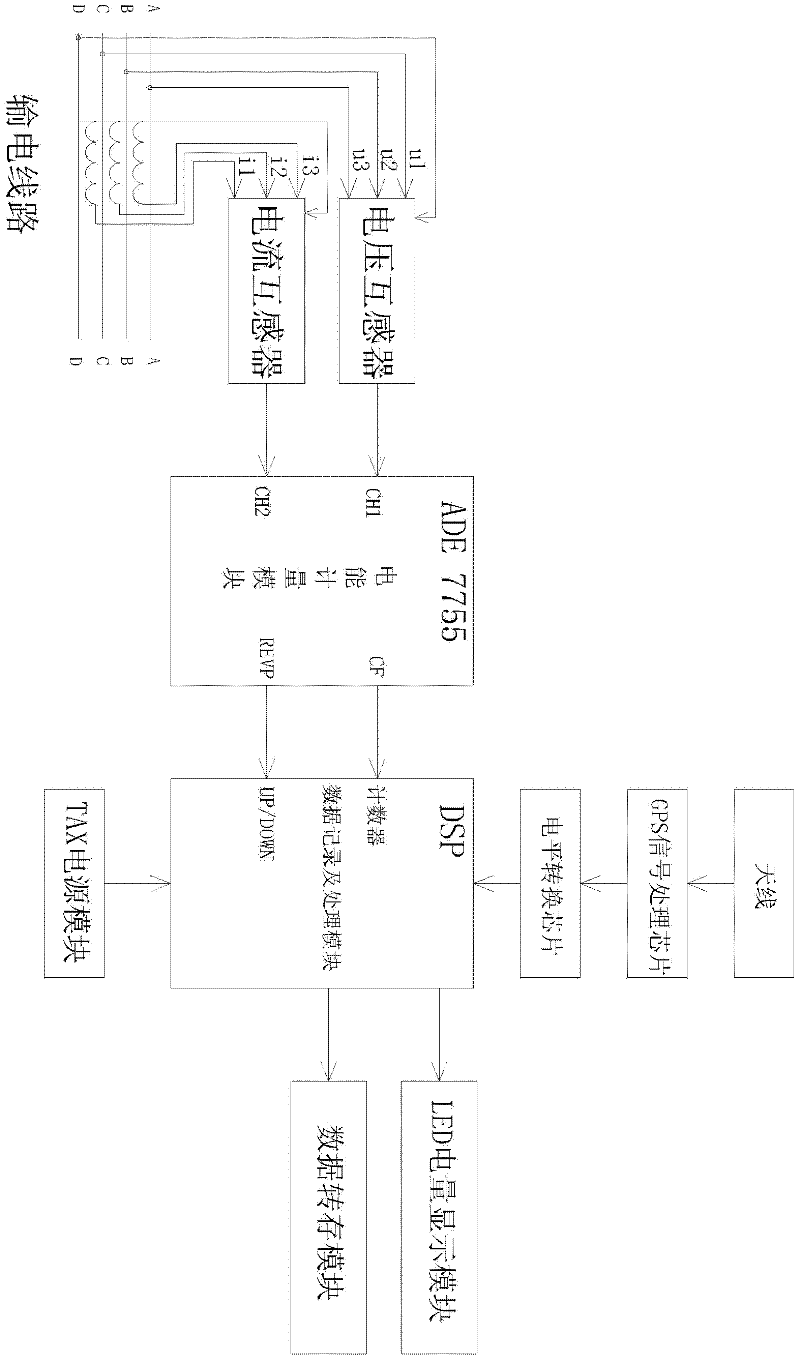

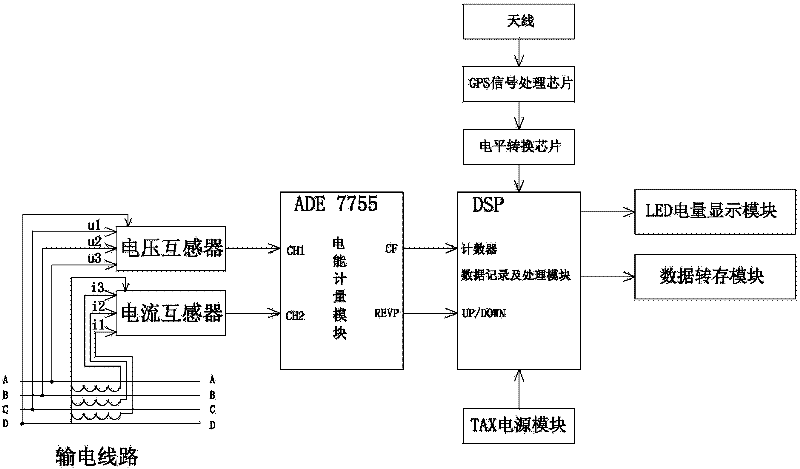

Electric energy meter for electric locomotive

The invention discloses an electric energy meter for an electric locomotive, which comprises a data recording and processing module, a power module, an electric energy metering module and an inductive measuring device, wherein the electric energy metering module is connected with an alternating-current electric wire. The power module is connected with the data recording and processing module, the electric energy metering module is connected with the data recording and processing module, and the inductive measuring device is connected between the alternating-current electric wire and the electric energy metering module. The electric energy meter avoids the impact of high voltage and high current coming down from a pantograph on the electric energy metering module, so that accuracy of electric energy metering data is ensured.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

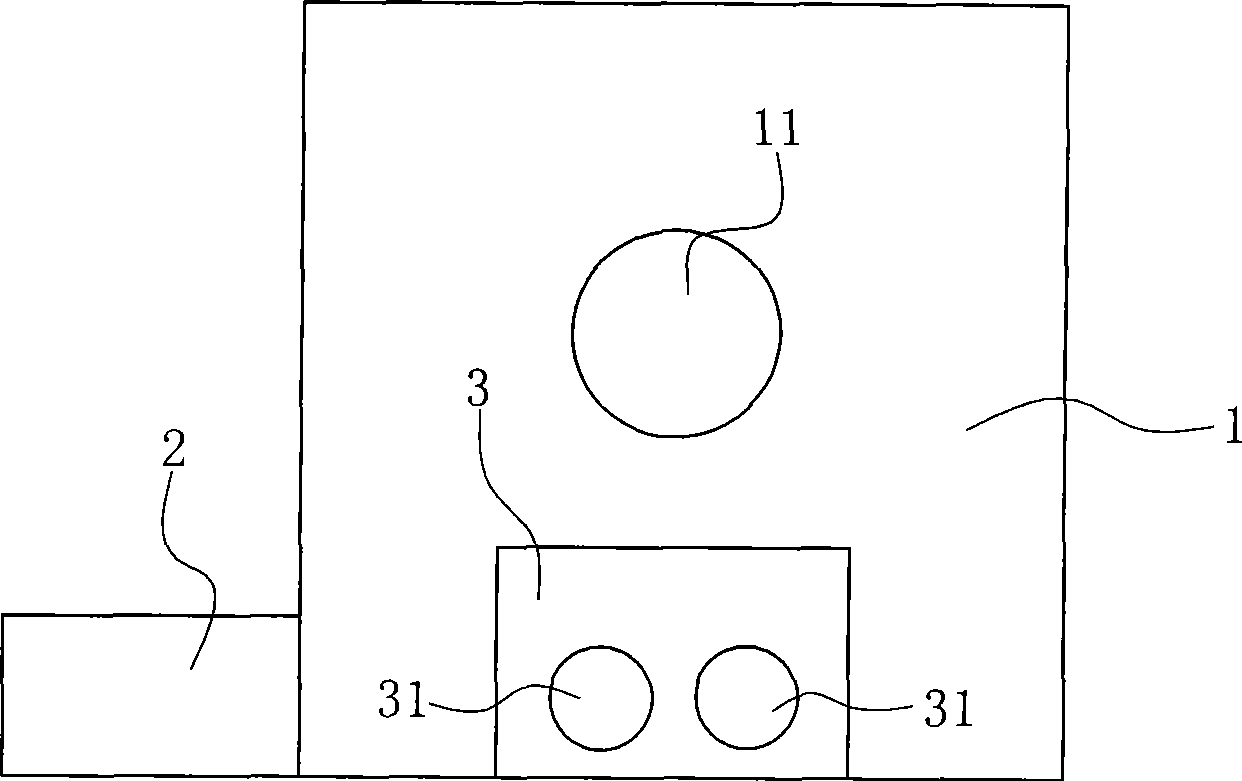

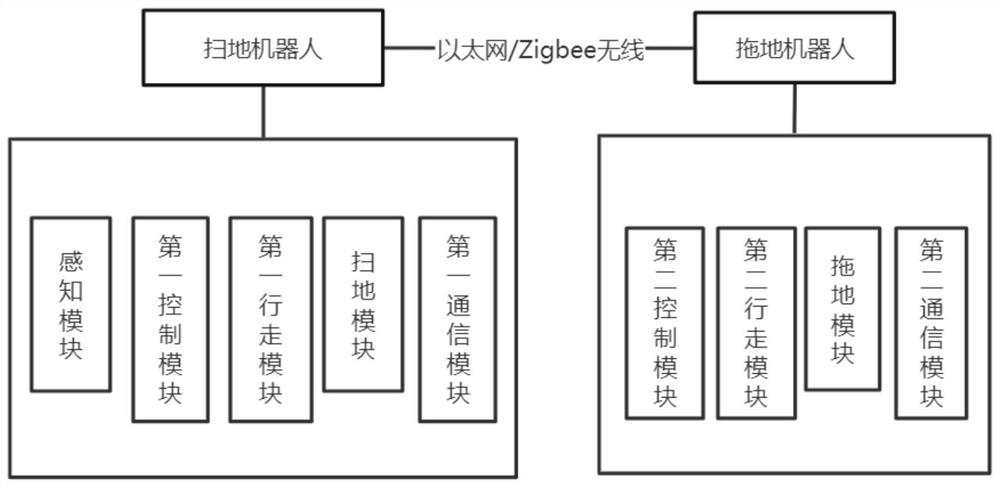

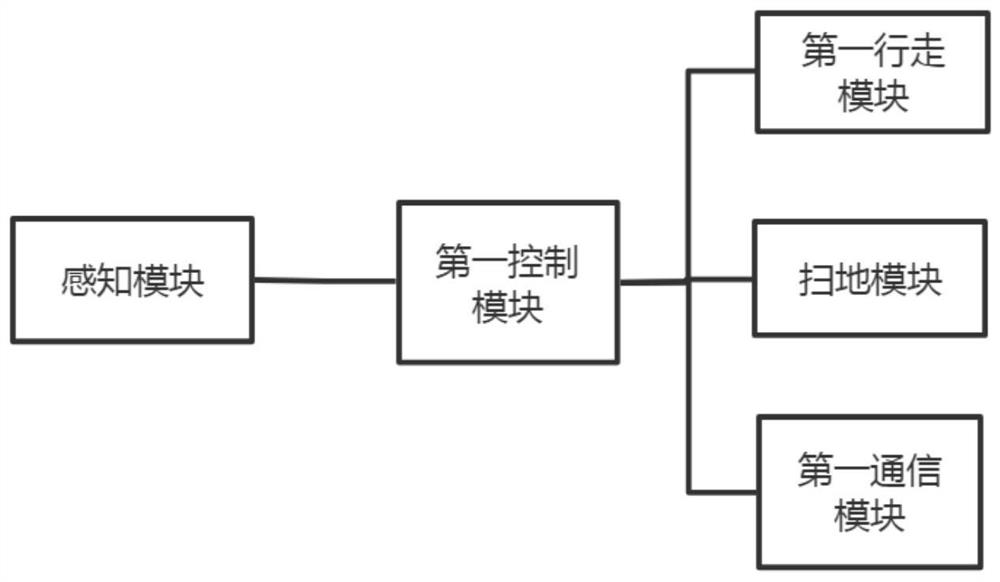

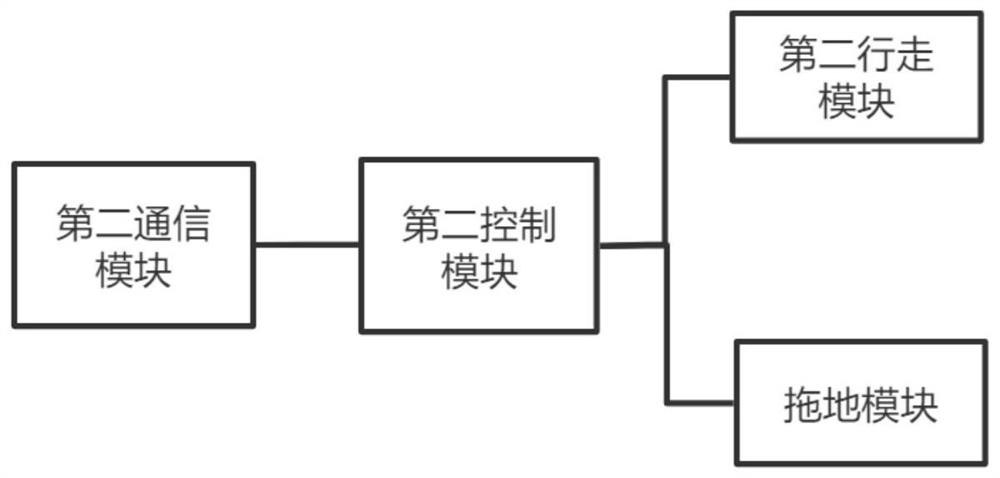

Indoor intelligent cleaning system and control method

The invention relates to the technical field of intelligent electric appliances, and provides an indoor intelligent cleaning system and a control method. The indoor intelligent cleaning system comprises a sweeping robot used for sensing indoor space information, generating a control instruction and conducting movable sweeping indoors, and transmitting indoor space information data and path information data after cleaning operation to the mopping robot; and a floor mopping robot which is used for receiving the information data transmitted by the floor mopping robot and performing floor mopping work along a path after the sweeping work of the floor mopping robot. The sweeping robot and the mopping robot can work cooperatively during cleaning, the sweeping robot conducts sweeping in front, the mopping robot conducts mopping work behind, and the cleaning efficiency is improved; functions of a conventional sweeping and mopping integrated robot are separated, so that the appearance size of the equipment is effectively reduced, and the cleaning requirement of an indoor narrow space is met; meanwhile, the capacity of the water tank is increased, and the continuous working capacity of the mopping robot is improved.

Owner:HEBEI UNIV OF TECH

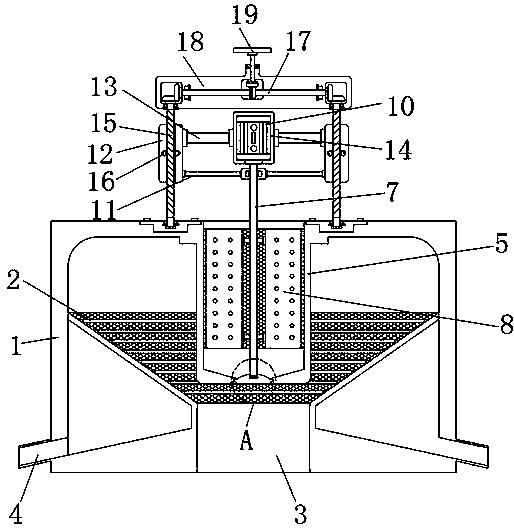

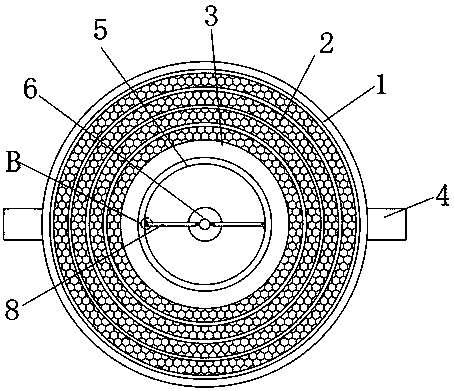

Efficient sewage treatment device

InactiveCN111167204AIncrease centrifugal forceImprove the primary filter effectStationary filtering element filtersSewage outfallElectric machinery

The invention discloses an efficient sewage treatment device, which comprises a device body and a motor, wherein a filter plate is fixedly welded in the device body, an opening in the lower end of thefilter plate is in seamless butt joint with an opening in the upper end of a sewage draining port, the sewage draining port is fixedly formed in the lower end of the device body, water outlets are symmetrically formed in the left end and the right end of the device body, a filter cylinder is fixedly welded to the upper end in the device body, a bottom cover is arranged at the lower end of the filter cylinder and installed at the lower end of a rotating shaft through a bearing, two sets of rotating plates are symmetrically welded to the rotating shaft, and bristles are fixedly installed at theends, away from the rotating shaft, of the rotating plates. According to the sewage treatment device, impurities with large sizes in sewage are preliminarily filtered by arranging the filter cylinder, and the sewage accumulated in the filter cylinder can be driven to rotate by the rotating plates through the rotation of the rotating plates, so that the speed of the sewage passing through the filter cylinder is increased by centrifugal force during rotation so as to enhance the preliminary filtering effect of the sewage.

Owner:西安中威环境技术有限公司

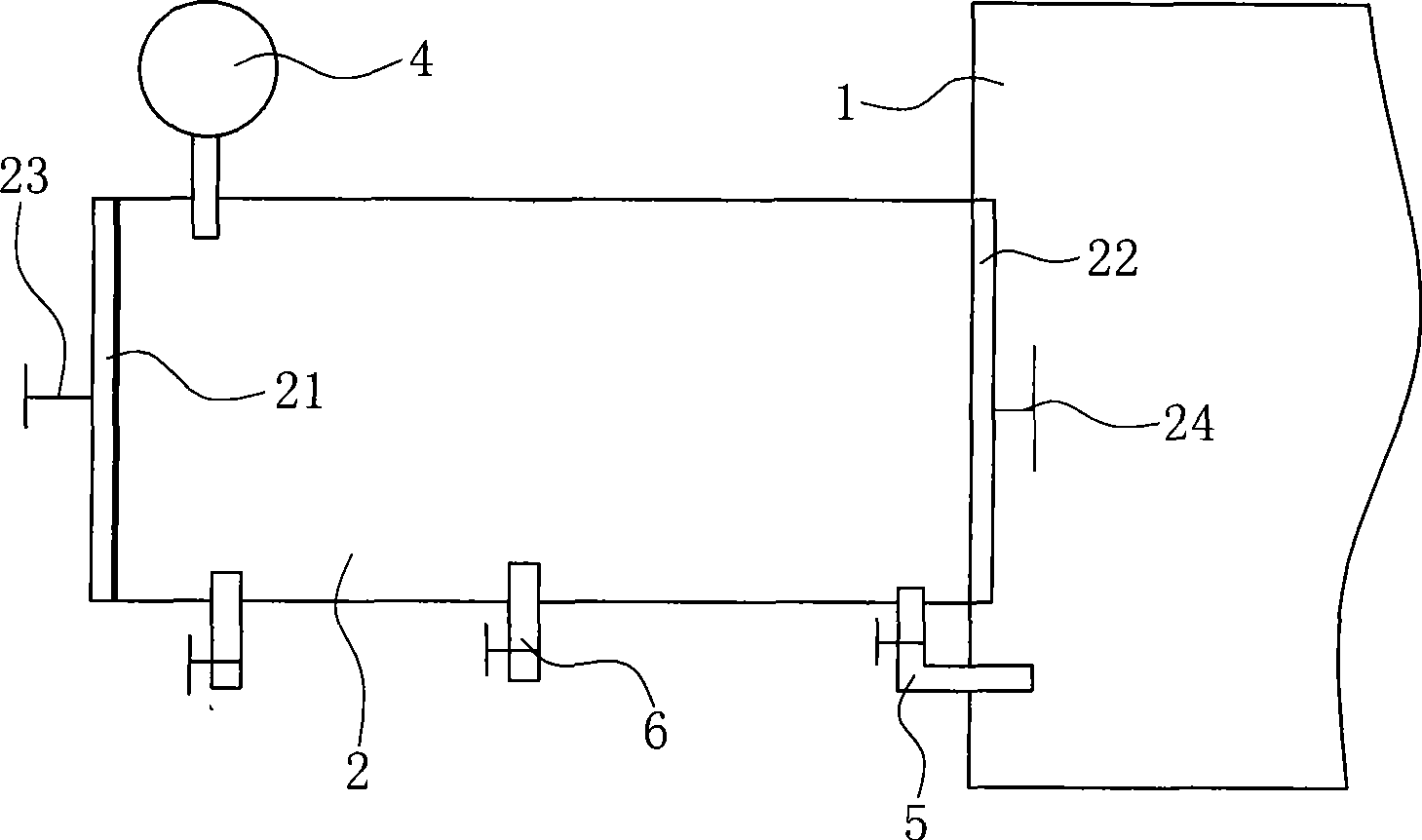

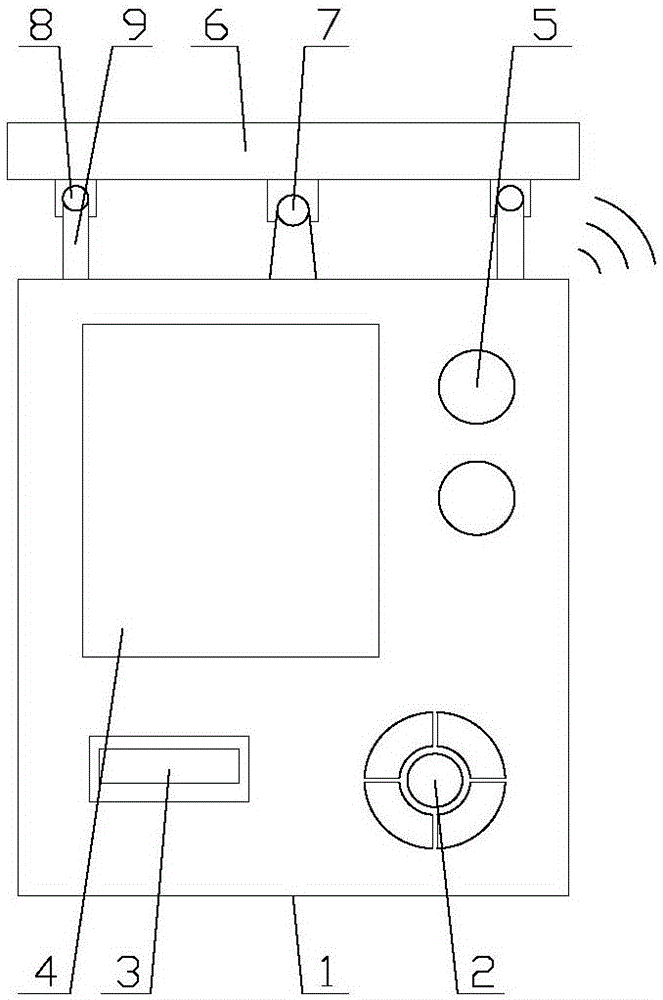

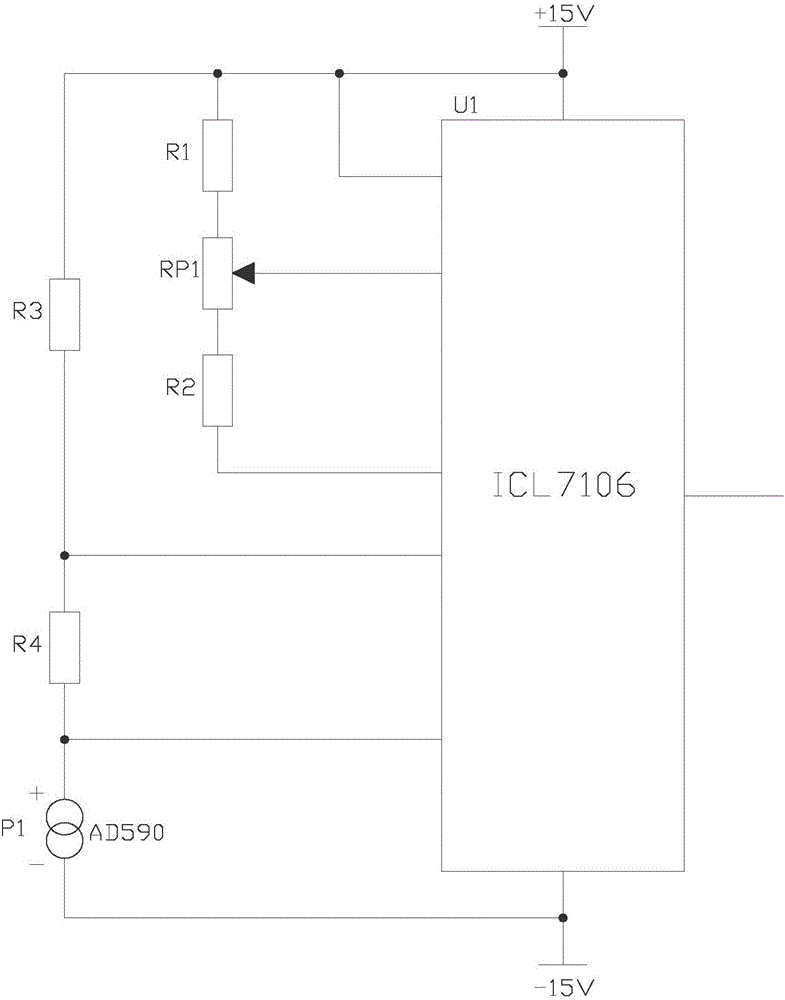

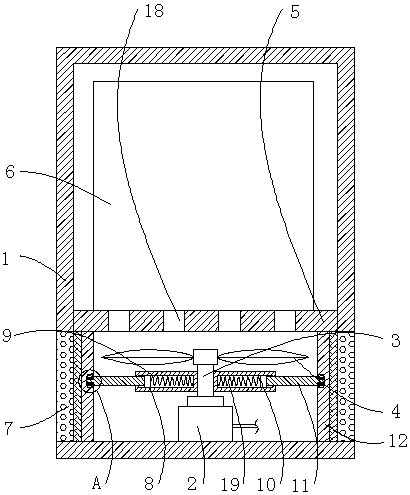

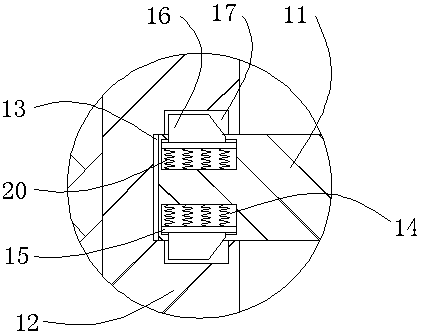

Outdoor communication apparatus used for network communication engineering

InactiveCN106468921AImprove continuous working abilityImprove practicalityControl using feedbackDrive shaftComputer module

The invention relates to an outdoor communication apparatus used for network communication engineering. The apparatus comprises a body and a solar generating plate, the inner part of the body is provided with an angle adjusting mechanism, and the angle adjusting mechanism comprises two angle adjusting assemblies. According to the outdoor communication apparatus used for network communication engineering, during usage, a driving shaft is driven by a driving motor, and a driven gear is driven through a driving gear; the driven gear and a driven shaft are connected in a transmission manner so that a transmission rod swings up and down, guide columns slide in arc guiding slide rails so that elevating units at two ends of the transmission rod complete elevation, the solar generating plate can change the orientation, the generating efficiency of equipment is improved, and the continuous work ability of the outdoor communication apparatus is improved; besides, in a temperature detection circuit, data change of a temperature sensor is detected through an integrated circuit and is then directly displayed so that the work efficiency of a central control module is improved, and the practicality of the outdoor communication apparatus is improved.

Owner:SHENZHEN NAISHIDI TECH DEV CO LTD

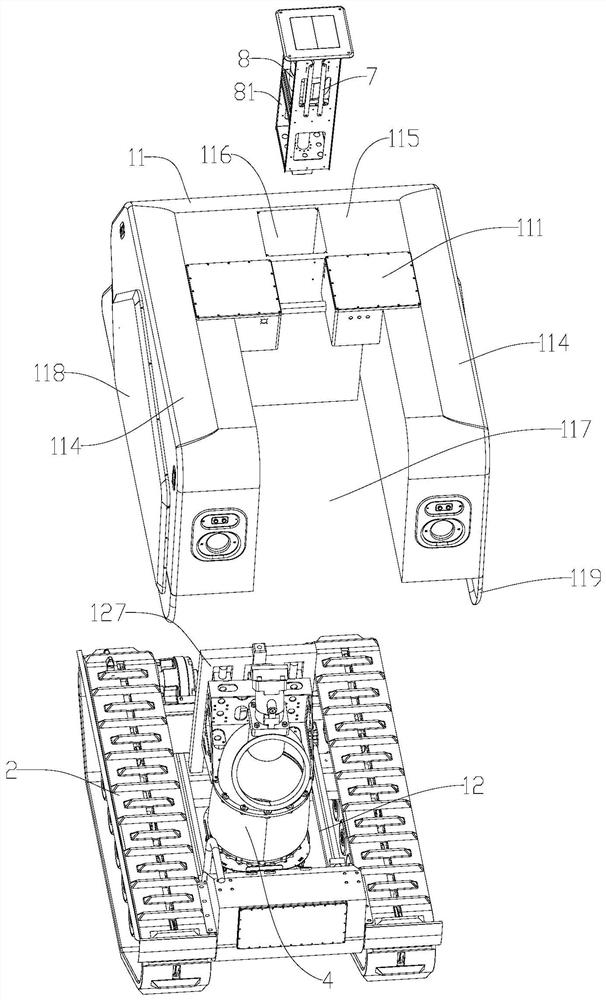

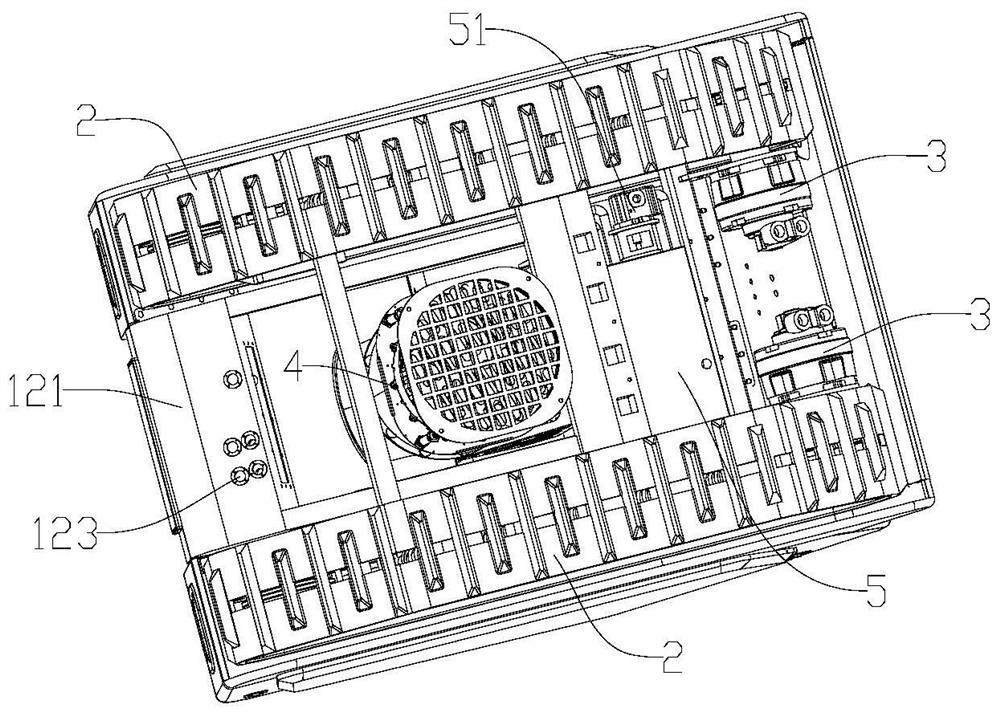

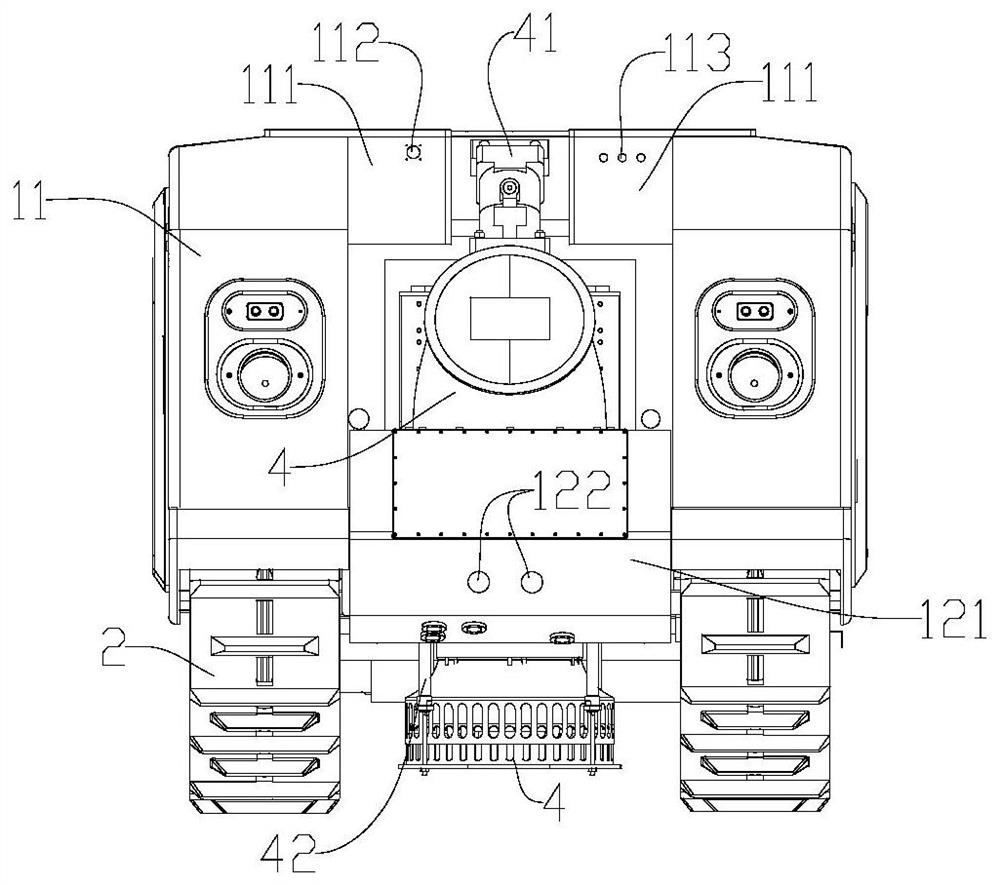

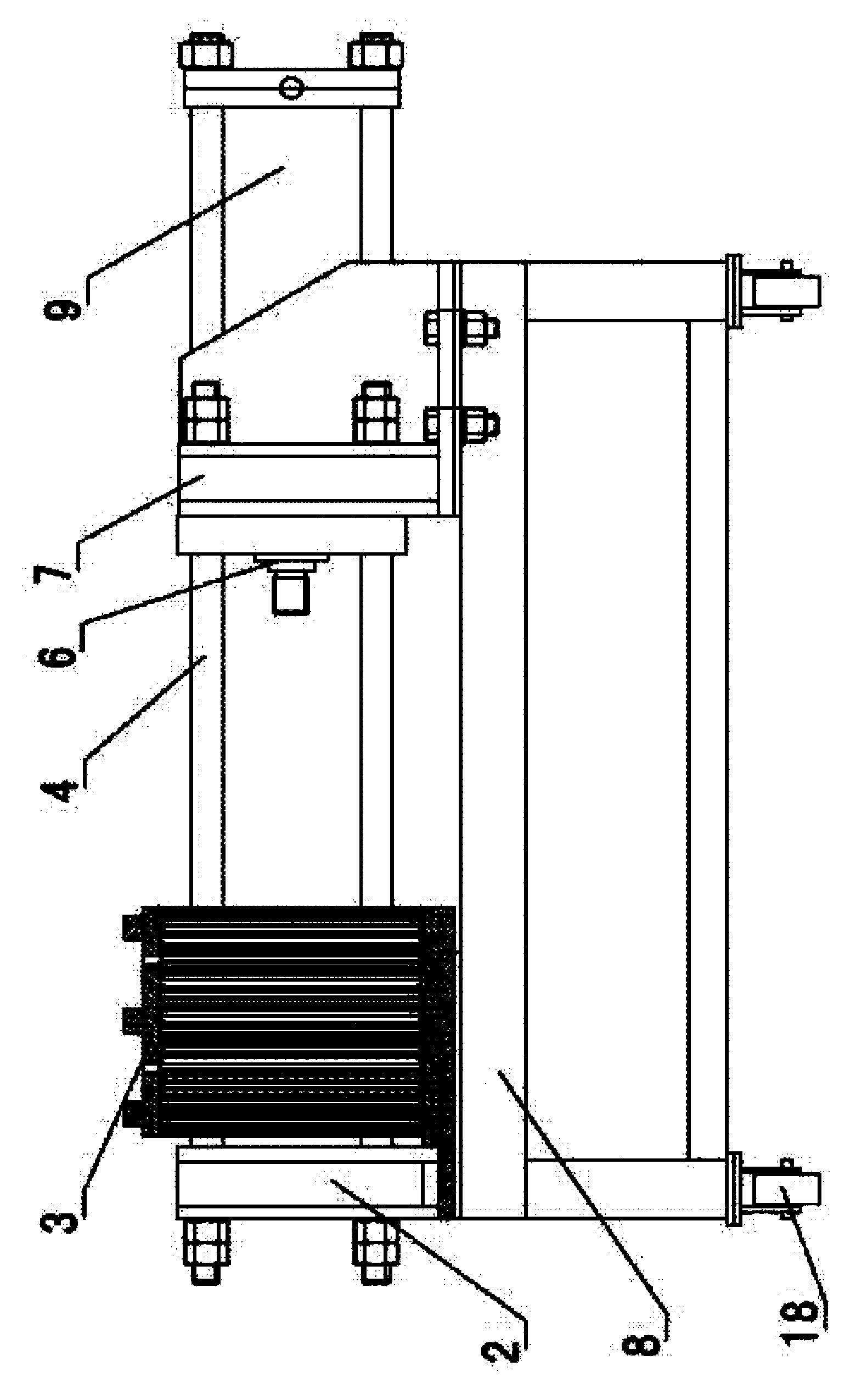

Flood drainage robot

PendingCN112344131AConvenient buoyancy structureSave materialAmphibious vehiclesPortable framesMechanical engineeringHydraulic pressure

The invention relates to a flood drainage robot. The robot comprises a main body of the flood drainage robot, a hydraulic execution element, a water suction pump, a hydraulic pipeline and a hydraulicpower station, and the hydraulic power station is arranged outside the main body and connected with the hydraulic pipeline on the main body through an oil inlet pipe and a first oil return pipe. Hydraulic power is provided for the hydraulic execution element on the main body through the hydraulic pipeline, the hydraulic pipeline comprises a second oil return pipe and an overflow system, the secondoil return pipe is communicated with the first oil return pipe, and the overflow system allows an overflow valve of the hydraulic execution element needing to overflow to be connected into the secondoil return pipe; and the main body comprises a buoyancy cabin, a base and a walking mechanism, the base is arranged at the bottom of the buoyancy cabin, the walking mechanism is arranged on the base,an accommodating notch for at least allowing the water suction pump to be contained is formed in the buoyancy cabin, and the water suction pump is driven by the hydraulic execution element to performflood drainage operation. The invention aims to provide a structure of the flood drainage robot adopting the external hydraulic power station.

Owner:广州源创智能装备有限公司

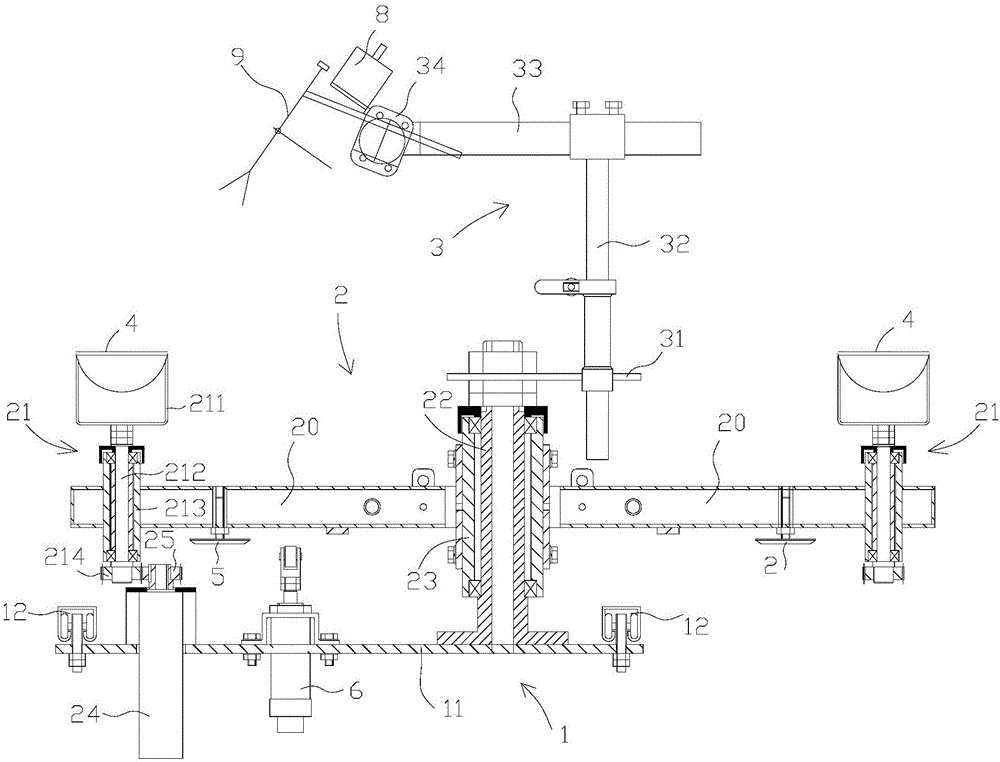

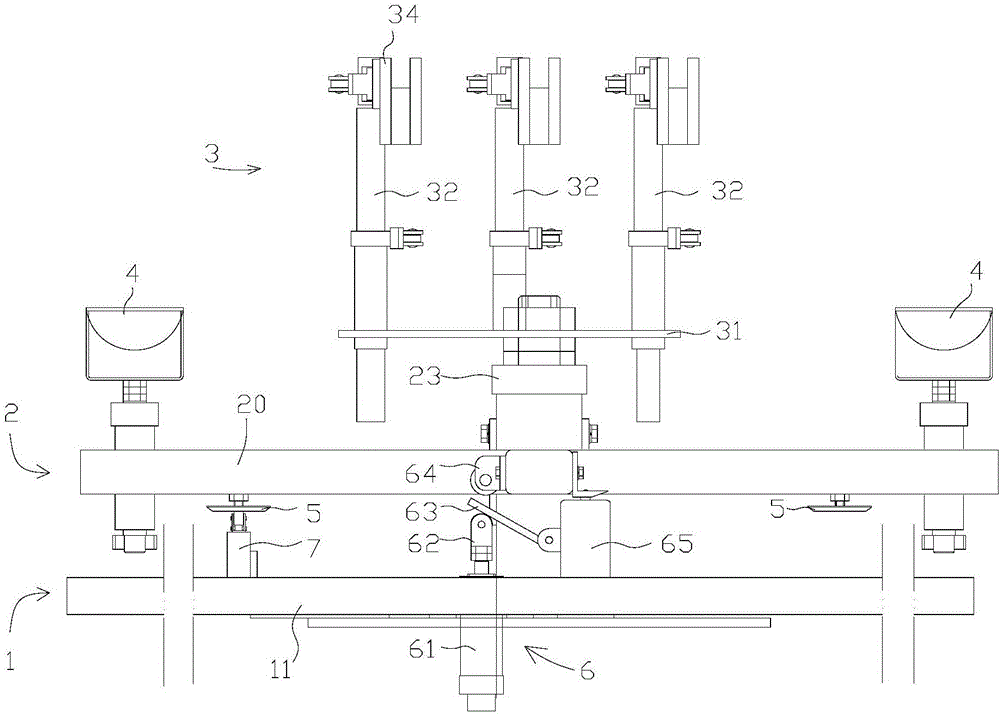

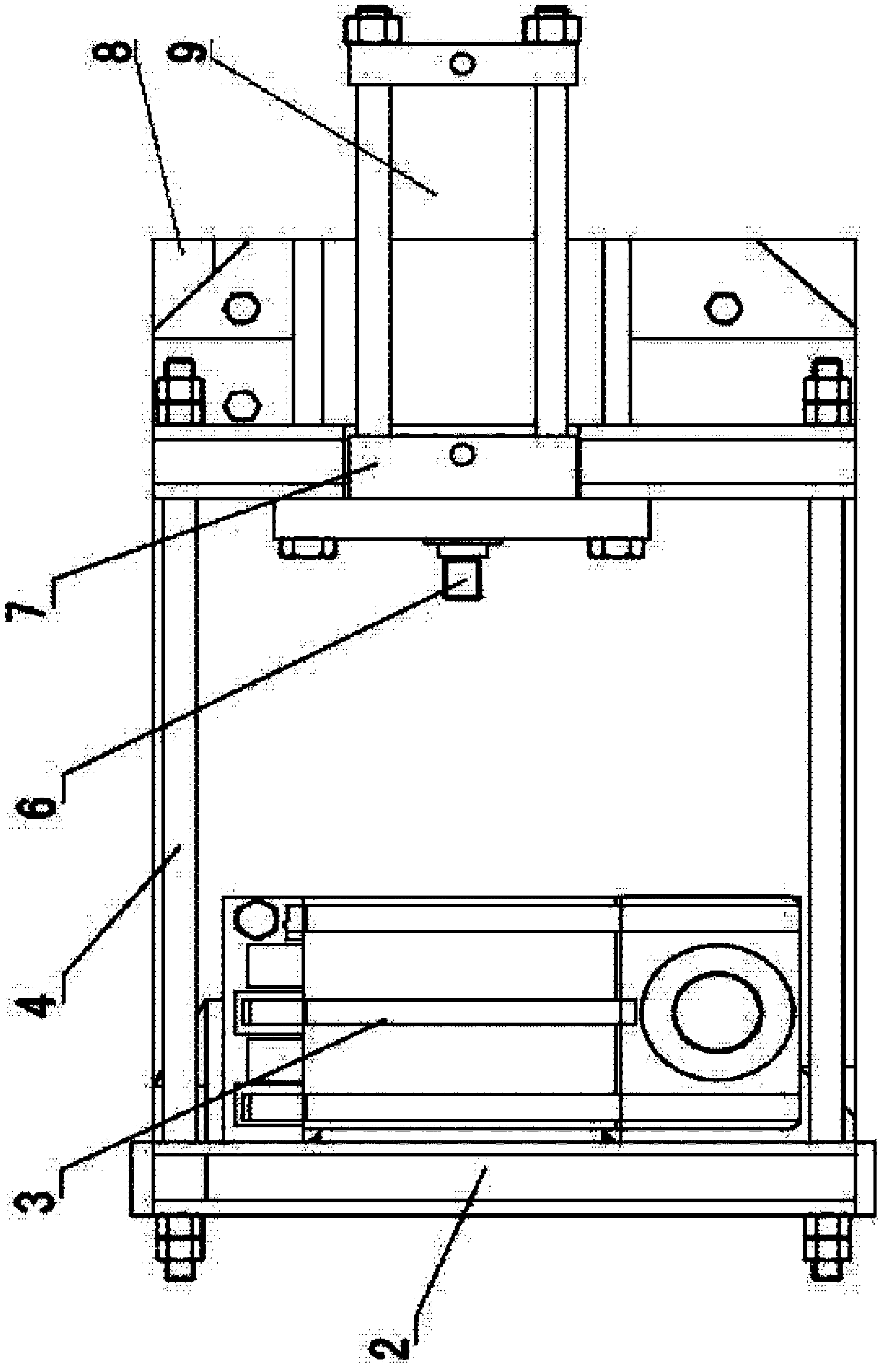

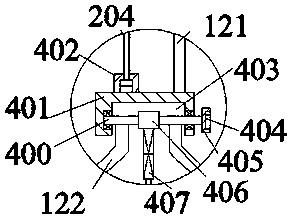

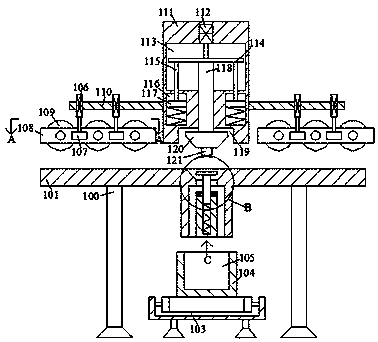

Flaring machine of plastic-steel-plastic composite pressure pipe

InactiveCN103568312AImprove installation and construction efficiencyReduce work intensityControl systemEngineering

The invention provides a flaring machine of a plastic-steel-plastic composite pressure pipe. The flaring machine of the plastic-steel-plastic composite pressure pipe comprises a rack, a flaring mechanism, a clamping mechanism and a control system, wherein the flaring mechanism is horizontally arranged above one end of the rack; the clamping mechanism is vertically arranged at the other end of the rack; the flaring mechanism comprises a flaring driving device and a profiling pressure head, wherein the flaring driving device is horizontally and fixedly arranged above the rack; the profiling pressure head is arranged on the output end of the flaring driving device; the clamping mechanism comprises a clamping and driving device and a separated-type annular fixture, wherein the clamping and driving device is vertically and fixedly arranged on one end of the rack; the separated-type annular fixture is fixedly arranged above the rack; the axis of the annular fixture is coincided with the axis of the profiling pressure head; the inner surface of the annular fixture is provided with annular inverted teeth which are distributed uniformly along the axis direction. The device is used for flaring the end opening of the plastic-steel-plastic composite pressure pipe by using a hydraulic device and the profiling pressure head, so that the working intensity of construction personnel is reduced; because the hydraulic device and the profiling pressure head are adopted for flaring, and consumable parts are not adopted for the device, the continuous operation capability of the device is improved, and the installation and construction efficiencies of the plastic-steel-plastic composite pressure pipe are improved.

Owner:NINGBO KANGRUN MACHINERY TECH

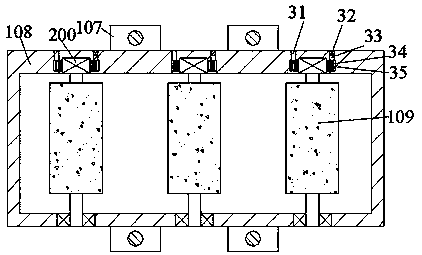

Municipal sewage advanced treatment system of 5G communication

InactiveCN108525380AImprove work coordinationImprove reliabilityMoving filtering element filtersDrive motorMunicipal sewage

The invention discloses a municipal sewage advanced treatment system of 5G communication. The municipal sewage advanced treatment system of the 5G communication comprises a connecting block. The rightside of the connecting block is provided with a side block. A upward and downward symmetrical connecting rod is fixedly installed between the connecting block and the side block. The outer surface ofthe connecting rod is slidably provided with a slider. The upper end face of the connecting block is fixedly provided with a driving motor. The outer surface of an output shaft of the driving motor is fixedly provided with a driving pulley. The upper end face of the side block is fixedly provided with a support block. The front end face of the support block is rotatably provided with a driven pulley. The driven pulley and the driving pulley are in power connection through a synchronous belt. The synchronous belt is fixed with the slider. The lower end face of the slider is fixedly provided with a rotation motor. The lower end face of an output shaft of the rotation motor is fixedly provided with a cross rod. A fixing rod is installed below the cross rod. The municipal sewage advanced treatment system of the 5G communication is simple in device structure, and convenient to use. The device uses a filter-type sewage treatment mode. A recovering problem of large-scale garbage is effectively solved, and the working efficiency of the device is effectively improved by using the simple treatment.

Owner:PUJIANG ZHIYIN TECH CO LTD

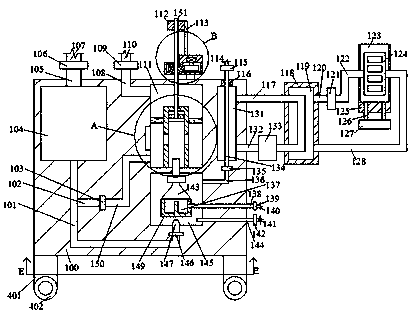

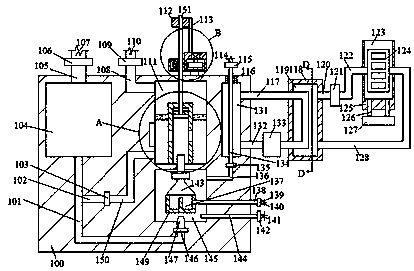

Metal manufacturing device for electronic components

The invention discloses a metal manufacturing device for electronic components. The metal manufacturing device for the electronic components comprises a machine body A, wherein support leg pillars arefixedly arranged on the periphery of the bottom surface of the machine body A; walking rollers are arranged on the support leg pillars; a generating chamber is arranged in the machine body A; a through pipe A outwards extending to the outer part is arranged in a left end wall of the generating chamber in a communicating way; a valve component A is arranged on the upper end surface of the throughpipe in a communicating way; a through pipe B is arranged on the upper end surface of the valve component A in a communicating way; a heating pipe is fixedly arranged in a left end wall of the generating chamber; a screen is fixedly arranged between the left end wall and a right end wall of the generating chamber; and a diffusion chamber is fixedly arranged in the screen and is fixed to a lower end wall of the generating chamber. The metal manufacturing device for the electronic components provided by the invention is simple in structure, convenient to use, beneficial to effectively reducing the manufacturing cost of metal parts for the electronic components, high in hydrogen preparation efficiency, adjustable in speed, capable of realizing heat recovery, low in energy consumption, simpleto operate, and time and labor saving.

Owner:广州常佰机械设计有限公司

Quick adjustment technology for gaps between grinding rollers of coal mill and liner plate of grinding bowl

ActiveCN105080664AAvoid repeated adjustmentsAvoid successive measurementsGrain treatmentsEconomic benefitsEngineering

The invention discloses a quick adjustment technology for gaps between grinding rollers of a coal mill and a liner plate of a grinding bowl, and belongs to the technical field of maintenance technologies of coal mills. The quick adjustment technology is used for quickly adjusting the gaps between the grinding rollers and the liner plate of the grinding bowl. According to the quick adjustment technology, the gaps between the grinding rollers of the bowl type coal mill and the liner plate of the grinding bowl are limited through asbestos boards, the grinding rollers go down slowly till the grinding rollers make contact with the asbestos boards and the asbestos boards slightly resist pulling, then, the gaps between the grinding rollers and the liner plate of the grinding bowl are limited within the needed gaps, and therefore, the gaps between the grinding rollers and the liner plate of the grinding bowl are quickly adjusted. The quick adjustment technology for the gaps between the grinding rollers of the coal mill and the liner plate of the grinding bowl is innovative in the industry; the process is simplified, and the adjustment process is completed in one step; the tedious measurement and adjustment process is avoided; maintenance time is shortened, and the labor efficiency of maintainers is improved; the continuous workability of a coal pulverizing system is improved, and it is guaranteed that the whole production process is smooth; and the quick adjustment technology provides guarantees for high-efficiency production of enterprises, has remarkable economic benefits and has great application and popularization value.

Owner:WUYANG IRON & STEEL

Construction hydraulic excavator grab

InactiveCN107326945AImprove continuous working abilityReduce unit energy consumptionMechanical machines/dredgersFuel tankControl engineering

The invention discloses a construction engineering hydraulic excavator bucket, which comprises an excavator body, a hydraulic oil tank is arranged on one side of the top of the excavator body, and the bottom end of the hydraulic oil tank is tightly welded to the top of the excavator body , the top of the hydraulic oil tank is provided with a hydraulic tank, the hydraulic tank and the hydraulic oil tank are fixedly connected by screws, one side of the body of the excavator is provided with an operating cabinet, and the outer surface of one side of the operating cabinet is provided with An operation panel, the operation panel is embedded in the interior of the operation case, and is connected with the signal of the operation case, the top of the operation panel is provided with an emergency stop button, and one side of the operation case is provided with an arm cylinder, The bucket arm oil cylinder is connected to the electric wire of the operation box. This kind of construction engineering hydraulic excavator bucket has a strong continuous operation ability for building excavation, transportation and unloading operations, and has lower energy consumption, and has broad market prospects. and application prospects.

Owner:TAICANG MIX MACHINERY EQUIP CO LTD

Low-energy-consumption sorghum stalk juicing device

ActiveCN108327334AImprove running stabilityImprove work coordinationJuice extractionPressesOuter spaceMechanical engineering

The invention discloses a low-energy-consumption sorghum stalk juicing device. The device comprises a cushion board, wherein supporting feet which are in contact with the ground are arranged on the lower end surface of the cushion board; an extruding chamber which is upwards opened is formed in the cushion board; a through chamber which is positioned in the cushion board is arranged below the extruding chamber in a communication chamber; a pipe chamber which is positioned in the cushion board and communicates with an outer space is arranged below the through chamber in a communication manner;a supporting block is fixedly arranged between the front end wall and the rear end wall of the pipe chamber; a compressing chamber in which a compressing spring is mounted is arranged in the supporting block; guide rods which are connected to the left end wall and the right end wall of the compressing chamber are elastically connected to the upper end surface of the compressing spring in a slidingfitting manner. The device is simple in structure, and convenient to use; and the production efficiency is effectively improved.

Owner:临沭县独沭一帜富华商贸有限公司

3D printer with cooling function

InactiveCN109353001AImprove air efficiencyEfficient heat dissipationAdditive manufacturing apparatus3D object support structuresWork performanceDrive motor

The invention discloses a 3D printer with a cooling function. By adoption of the 3D printer with the cooling function, the problem that a cooling component of an existing 3D printer is likely to be blocked by outside dust or impurities is solved. According to the scheme, the 3D printer with the cooling function comprises a printer shell, a vertically-arranged driving motor is welded to the inner wall of the bottom of the printer shell, and the output end of the driving motor is connected with a rotary shaft; a horizontally-arranged cooling fan is rotatably connected to the end, away from the driving motor, of the rotary shaft; a horizontally-arranged mounting plate is welded in the printer shell; a printer body is arranged at the top of the mounting plate, and cooling windows are arrangedon the two sides of the printer shell. The 3D printer with the cooling function is reasonable in structure, capable of being cooled rapidly and efficiently, high in working performance, high in cooling efficiency, long in service life, high in practicability and suitable for popularization, and cooling components of the 3D printer can be cleaned.

Owner:郑州智高电子科技有限公司

Coal gas hydrogen production equipment

InactiveCN108163808AIncrease flexibilitySimple equipment structureHydrogen productionElectric heatingHydrogen production

The invention discloses coal gas hydrogen production equipment which comprises a box body A, wherein the box body A is fixedly arranged on the ground, a reaction cavity is arranged in the box body A,a pipeline A which extends out of external space is arranged in a left end wall of the reaction cavity in a communication mode, a valve A is arranged on an upper end face of the pipeline A in a communication mode, a pipeline B is arranged on an upper end face of the valve A in a communication mode, an electric heating wire is fixedly arranged in the left end wall of the reaction cavity, a filter screen is fixedly arranged between the left end wall and a right end wall of the reaction cavity, an emitting box is fixedly arranged in the filter screen, and the emitting box is fixed with a lower end wall of the reaction cavity. The equipment disclosed by the invention has the advantages of simple structure and convenience in use; the equipment utilizes high-temperature steam generated by coal gas combustion to achieve the purpose of generating hydrogen from coal gas and the high-temperature steam; furthermore, a controllable reaction speed structure is utilized to achieve reaction speed adjustment; furthermore, liquid-state water and a heat transfer medium are utilized in a reaction process to achieve the purpose of recycling redundant heat; thus, equipment reliability is improved.

Owner:佛山腾谱工业设计有限公司

Wireless transmission module and manufacturing method thereof

ActiveCN108900216AHighly integratedSmall footprintSemiconductor/solid-state device detailsSolid-state devicesWireless transmissionEngineering

The application discloses a wireless transmission module and a manufacturing method thereof. The wireless transmission module has an integrated structure formed by a chip, a passive component and a coil, so that the integration degree of the wireless transmission module is improved. Moreover, on the basis of the integrated structure, the independence of the module can be realized effectively; flexible layout inside the electronic device is realized by using the independent module; and because only the input terminal of the wireless transmission module needs to be kept on the main board of theelectronic device instead of setting the independent module on the main board of the electronic device, the board occupation area by the wireless transmission module is reduced. Besides, on the basisof the wireless transmission module, the continuous normal working capability of the product in an extreme condition scene can be enhanced effectively and the product reliability is improved. In addition, the chip and the coil are integrated into one in the wireless transmission module and thus the signal transmission path between the chip and the coil is short, so that the generated parasitic impedance is small.

Owner:HUAWEI TECH CO LTD

Hybrid power transmission system of longitudinal flow cutting threshing device and harvesting machine

ActiveCN111226613AGuaranteed smoothnessAvoid problems such as winding or even failureMowersThreshersCapacitanceAgricultural engineering

The invention provides a hybrid power transmission system of a longitudinal flow cutting threshing device and a harvesting machine. The hybrid power transmission system comprises a driving device, a transmission device, a flow cutting cylinder, a sensing device, a longitudinal axial flow cylinder and a control unit, wherein the driving device comprises an engine, a power generator, a super capacitor and an electromotor; the engine is connected with the power generator; the electromotor is connected with the power generator; the super capacitor is connected with the electromotor and the power generator respectively; the power generator, the super capacitor and the electromotor are connected in parallel on the flow cutting cylinder through the transmission device; and the sensing device is used for measuring SOC (system on chip) values of the super capacitor and therotation speeds of the flow cutting cylinder and the longitudinal axial flow cylinder. By adopting the hybrid power transmission system, when a threshing cylinder is in shortage of operation power, motor driving can act up in time to supplement power; and when the threshing device has excessive energy of the transmission system, the energy can be recycled, so that the problem that the threshing cylinder is unstable caused by sudden change of cereal feeding amounts can be effectively solved, and the problems of blockingand straw tangling caused by sudden increase of cereal feeding amounts can be effectively prevented.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com